0% found this document useful (0 votes)

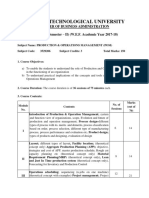

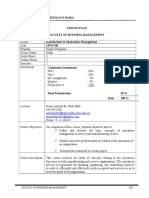

105 views2 pagesProduction and Operations Management

The document outlines the course structure for 'Production and Operations Management' in an MBA program, detailing objectives, outcomes, and unit topics. Key areas of focus include product design, operational planning, scheduling, materials management, and quality management. It also includes references to textbooks and digital resources for further study.

Uploaded by

siddamreddylakshmiahalyaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

105 views2 pagesProduction and Operations Management

The document outlines the course structure for 'Production and Operations Management' in an MBA program, detailing objectives, outcomes, and unit topics. Key areas of focus include product design, operational planning, scheduling, materials management, and quality management. It also includes references to textbooks and digital resources for further study.

Uploaded by

siddamreddylakshmiahalyaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd