0% found this document useful (0 votes)

110 views4 pagesJSA 018 Cable Testing

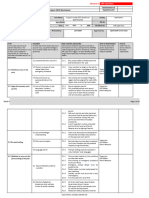

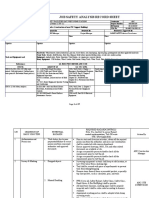

The document is a Job Safety Analysis (JSA) worksheet for cable testing at the VCP-Phase III Housing site, prepared by Almeer Saudi Technical Services. It outlines potential hazards, hazard controls, and emergency procedures related to the task, emphasizing the importance of safety protocols and proper communication among workers. Additional precautions include adherence to COVID-19 safety protocols and maintaining clear access ways on site.

Uploaded by

Asad AwanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

110 views4 pagesJSA 018 Cable Testing

The document is a Job Safety Analysis (JSA) worksheet for cable testing at the VCP-Phase III Housing site, prepared by Almeer Saudi Technical Services. It outlines potential hazards, hazard controls, and emergency procedures related to the task, emphasizing the importance of safety protocols and proper communication among workers. Additional precautions include adherence to COVID-19 safety protocols and maintaining clear access ways on site.

Uploaded by

Asad AwanCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd