0% found this document useful (0 votes)

61 views2 pagesHD Uk

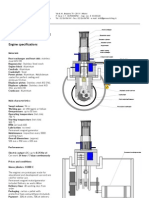

The ROTAN® HD heavy-duty pumps are designed for high viscosity, non-corrosive liquids and feature flexible sealing options, a true back pull-out design, and self-priming capabilities. They can handle capacities up to 250 m3/h, differential pressures up to 16 bar, and temperatures up to 250°C. These pumps are essential for industries where production stops are costly, providing reliable performance for various applications including oil, asphalt, and chocolate.

Uploaded by

PanisaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

61 views2 pagesHD Uk

The ROTAN® HD heavy-duty pumps are designed for high viscosity, non-corrosive liquids and feature flexible sealing options, a true back pull-out design, and self-priming capabilities. They can handle capacities up to 250 m3/h, differential pressures up to 16 bar, and temperatures up to 250°C. These pumps are essential for industries where production stops are costly, providing reliable performance for various applications including oil, asphalt, and chocolate.

Uploaded by

PanisaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd