Professional Documents

Culture Documents

Technical Data Sheet: Features

Uploaded by

eddy ortegaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet: Features

Uploaded by

eddy ortegaCopyright:

Available Formats

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 228

FEATURES

Definition of pressures

The pumps can be subjected to the pressures P1, P2 or P3

indicated in the performance tables. The following diagram

illustrates the definitions and applicability of these, compared

to the rotation speed limits included.

P

[bar-PSI]

Max. peak pressure

P3

Max. intermittent pressure P2

Continuous max. pressure P1

t

[sec]

Max 20 sec Max 5 sec

Hydraulic measures Useful formulas Conversion factors

Q = V [cm3/rev] x ηv x n 10-3 l/min 1 l/min = 0.2641 US Gal/min

Q Flow [l/min - Gal/min]

1 Nm = 8.851 in.lbs

Δp [bar] xV [cm3rev] 1 Nm = 0.7375 ft.lbs

M Torque [Nm - lbf.in] M= Nm

62.83 x ηm 1 N = 0.2248 lbs

P Power [kW - HP] 1kW = 1.34 HP

Δp [bar] x V [cm3rev] x n 1cm3/giro = 0.061 in3/rev

P= kW

600 x 1000 x ηt 1 bar = 14.5 PSI

V Displacement [cm /rev - in /rev]

3 3

1 mm = 0.0394 in

N Speed [min-1 - rpm] 1 kg = 2.205 lbs

Δp Pressure [bar - PSI]

ηv Volumetric efficiency

ηm Mechanical efficiency

228 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 229

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 229

TECHNICAL INFORMATION

TECHNICAL INFORMATION

Hydraulic fluids Pressure drops

Hydraulic

It is advisable fluids

to use hydraulic oils of mineral origin with anti- Pressure drops

The following nomogram allows you to calculate the pressure

foaming, anti-oxidant

It is advisable to useand anti-corrosion

hydraulic characteristics

oils of mineral origin withand

anti-a drops

The for each

following 100 m of allows

nomogram piping when

you tothe viscosity

calculate theofpressure

the oil, the

high viscosity

foaming, index;

anti-oxidant and anti-corrosion characteristics and a delivery

drops capacity

for each 100 of the

m of pump

piping whenandthetheviscosity

diameter of the

of the piping

oil, the

- Recommended viscosity 15 ÷ 92 mm² /s (cSt)

high viscosity index; are known.

delivery capacity of the pump and the diameter of the piping

- Start-up viscosity viscosity

- Recommended limit 300015mm²÷ 92/smm²

(cSt)

/s (cSt) Theknown.

are viscosity (V), flow capacity (Q) and diameter (D) values are

During normal

- Start-up operation,

viscosity the mm²

limit 3000 temperature

/s (cSt) of the oil must be fixedviscosity

The on the respective scales;(Q)

(V), flow capacity a line

and is drawn joining

diameter (D) valuesthe are

points

between

During 20°C

normal and 65°C and

operation, thelimit values between

temperature of the oil-15°C

mustand

be

V and

fixed onQ;the the point where

respective this aintersects

scales; the index

line is drawn joiningline

the is defined

points

80°C.

between 20°C and 65°C and limit values between -15°C and

Vasand

point

Q; theI. Ifpoint

the line

wherejoining point I tothe

this intersects point D line

index is extended,

is defined the

80°C.

load

as pressure

point I. If thedrops value point

line joining can then be read

I to point D isatextended,

the intersection

the

Suction pressure with pressure

load the last scale.

drops value can then be read at the intersection

Suction pressure with the last scale.

The allowed working pressure supplied must be in the range

0.7The allowed

- 3 bar working pressure supplied must be in the range

(absolute).

For0.7 - 3 barvalues

higher (absolute).

(up to 30 bar), versions with a K seal must 500 4000

3000

beFor higher values (up to 30 bar), versions with a K seal must 400

used. 400

500 4000

400

3000

2000

0.03

be used. 400

300 2400

300 2000

0.03

0.04

300 0.04 0.05

300 2400

Suction and delivery pipes 200 1500 900

1000 0.05 0.06

Suction and delivery pipes 200 1500 200

200 1000

800

900 700

0.06 0.07

0.07 0.08

Particular attention must be given to the sizing of pipes (rigid or

800

700 600 0.08 0.09

0.1

Particular attention must be given to the sizing of pipes (rigid or 600 500 0.09

0.1

flexible), avoiding disproportionate lengths, sudden variations 100 800 500 400

flexible), avoiding disproportionate lengths, sudden variations 100 90 800 400

in cross section or small curvature radius, in any case selecting 9080 100 300

in cross section or small curvature radius, in any case selecting 8070 550 90

100 300

Q 0.2

pipe cross-sections that guarantee an oil speed between 0.6 7060 550 90 80

Q 200 0.2

pipe cross-sections that guarantee an oil speed between 0.6 60

50

80 70

200

andand1212

m/s.

m/s.

50

40 300 I

70

60

60

0.3

0.3

40 300 I 50 100 0.4

30 50 10090 0.4

30 90 80 0.5

40

Filtration

80 70 0.5

VV D D

40

Filtration 70 60 0.6

20 150 60

0.6

20 150 30 50 0.7

30 50 0.7

0.8

In In

order

orderto toeliminate

eliminateany anyimpurities

impurities present

present in in the

the oil

oil and to

and to 40

40 0.8

0.9

0.9

1

P P 1

guarantee a longer

a longerduration

durationofofthe thepump,

pump, thethe system

system must be

30

guarantee must be 20 30

10

10 7575 20

99

equipped

equippedwith witheffective

effectivefiltration

filtration which

which must

must be be periodically

periodically 88

77

6060 20 20

2

checked

checked to to

ensure

ensurethat

thatit itisisoperating

operatingcorrectly.

correctly. 66 4545

2

55

TheThefollowing

following are

arethe

therecommended

recommendedfiltration filtration levels:

levels: 44 2929 9

10 10

9

9

10

9

10

3 3

8 8

- 26/23

- 26/23ISOISO DIS 4406

DIS 4406upuptoto150 150barbar 33 2121

8

7

8 7

6

7

6

4 4

7

- 23/20

- 23/20 ISOISO DISDIS 4406for

4406 forhigher

higherpressures.

pressures. 6 6

5 5 5 5

1212 4 4 6 6

22

5 5 7 7

3 3 8 8

4 9

Installation

Installation notes

notes

4

1 1

10

9

10

1 3

1

0.9 3

- Make

- Make sure

sure that

that thecoupling

the couplingused

usedfor

forpulling

pulling compensates

compensates for for

0.9

0.8

0.8

0.7

any axial misalignmentsthat thatcould

couldcompromise

compromise the the integrity

integrity 0.7 1 20

any axial misalignments 0.6 2 1 20

0.6 2

0.5

of the

of the pump. pump. 0.5

0.4 30

30

- If- there

If there are radialand/or

and/oraxial/

axial/loads

loadsonon the

the pump

pump shaft

shaft (as 0.4

are radial (as 0.3 40

40

is isthethe case, for example, when pulling is carried out using 0.3

case, for example, when pulling is carried out using 1 50

1 50

pulleys and belts) the versions available with a support must 0.2 60

pulleys and belts) the versions available with a support must 0.2 60

be chosen.

be chosen. Viscosity Inner pipe diameter Flow Load loss every 100 m

- The connection coupling between spline shafts must be ap- Viscosity

[cSt]

Index

Inner pipe diameter [l/mm]Flow

[mm] Load loss

[kg/cm 2 every 100 m

]

- The connection coupling between spline shafts must be ap-

propriately lubricated, free to move axially and of an adequate

[cSt]

Index

[mm] [l/mm] [kg/cm2]

propriately

length to lubricated, free toextension

cover the entire move axially

of theand

twoofshafts

an adequate

(motor

length to cover the entire extension of the two shafts (motor

and pump).

and pump).

- If the pump is painted, protect the shaft seal and also make

- If the

surepump is painted,

that the contact protect the shaft

zone between theseal and

shaft also

seal andmake

the

sure shaftthat the contact

is free of dust orzone between

abrasive the shaft seal and the

sediments.

shaft is free of dust or abrasive sediments.

Rotation direction

Rotation direction

The rotation direction is defined as S (left/anticlockwise) or D

The (right/clockwise) by observing

rotation direction is definedtheasshaft from the front.

S (left/anticlockwise) or D

The pumps arebymonodirectional

(right/clockwise) and therefore

observing the shaft from the when

front. ordering

The thepumps

required

arerotation direction must

monodirectional and be specified;

therefore alternatively

when ordering

theit required

is possible to modify

rotation the internal

direction set-up

must be as illustrated

specified; below

alternatively

it is(inversion

possibleoftothe rotation

modify thedirection).

internal set-up as illustrated below

The pages

(inversion regarding

of the rotationthe pump characteristics highlight the di-

direction).

The rections

pagesofregarding

the delivery

the and

pumpsuction flows for each

characteristics version

highlight theand

di-

rotation

rections ofdirection.

the delivery and suction flows for each version and

rotation direction.

50% OFF ALL PRICES GEAR PUMPS • 229

50% OFF ALL PRICES GEAR PUMPS • 229

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 230

TECHNICAL INFORMATION

How to reverse pump rotation

F

E

Fig. 1

D

B

n

a tio * Suction

rot A

se

wi

ck

ti clo

An

Fig. 2

* Suction

n

a tio

rot

w ise

ck

Clo

The technical data pages specify the

* connections depending on the preconfigured

rotation direction (L or R).

The gear pumps direction of rotation is indicated

by an arrow on the label.

How to reverse the pumps rotation:

● Disassemble pump as shown in figure 1.

● Pull off gears C - D and reassemble according to figure 2.

● Reassemble bushing B as before.

● Reverse the flange A and reassemble the pump tightening

the screws by using a torque wrench.

● For the pumps GR3 - GR4, disassemble only front flange.

Type of pump GR1 GR2 GR3 GR4

Numbers of screws 4 4 16 16

Type of threads M8 M10 M10 M14

sin ento

30 Nm 50 Nm 60 Nm 140 Nm

ut

Tightening torque of screws (266 in-lbs) (443 in-lbs) (531 in-lbs) (1239 in-lbs)

Pha urim

g-o

2IS 14M

Type of coupling 1IS 12M 3IS 18M 4IS 23M

2IS 15M

22 ÷ 25 Nm

esa

Tightening torque at nut coupling 9 ÷ 10 Nm (195 ÷ 221 in-lbs) 50 ÷ 55 Nm 100 ÷ 120 Nm

(80 ÷ 89 in-lbs) 32 ÷ 35 Nm (443 ÷ 487 in-lbs) (885 ÷ 1062 in-lbs)

Ad

(283 ÷ 310 in-lbs)

230 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 235

PUMPS GROUP 3 • PERFORMANCE

Flow - Speed chart

160 42

52

3P

62

3P

140

35

44

3P

36

120 3P

Flow [Gal/min]

33

3P 28

100 29

Flow [Lit./min-1]

3P

80 22 21

3P

9

3P 1

60

14

40

7

20

0 0

0 500 1000 1500 2000 2500 3000 3500 4000

Speed [rpm]

Pumps Group 3 Power and Speed Diagrams

3P 19 η=0.95÷1 3P 22 η=0.95÷1 3P 29 η=0.95÷1

40 40 50

50 50

*

ar

45 60

0b

rr*

35 35

*

26

a

r

0b

ba

40

I)

ar

24

PS

70

ar

30 30

0b

40 40

0b

50

2

I)

77

PS

I)

24

22

35

Power [HP]

Power [HP]

Power [HP]

PS

r

(3

ba

r a

0

I)

I)

48

ba 0b

5

PS

PS

50

91

(3

25 25 0 20

90

(3

20 30

48

40

1

I)

r I)

(3

PS

(3

a 30 I) 30 PS

0b PS

5

ar

0

62

20 20 20 00 ar 25 90 b

(3

9 (2

PS

I) (2 0b 50

0 0 ar 15 I )1 30

0b

) 20

15 29 15 SI PS

(

1 5 20 P 20 75

Power [kW]

Power [kW]

Power [kW]

5 1

SI) 17 (2 r

P (2 ar ba

00b

75 15 00 20

10 (21

ba r 10 I) 1 I) 1

100

S S

) 5 0P 5 0P

PSI (14 10 (14

50 10 10

(14 r r 10

5 5 50ba 50ba

5 PSI)

50bar (7 25 P

SI) 5 (725

PSI)

(72

0 0 0 0 0 0

500 1000 1500 2000 2500 3000 3500 500 1000 1500 2000 2500 3000 3500 500 1000 1500 2000 2500 3000 3500

Speed [rpm] Speed [rpm] Speed [rpm]

* Only for cast iron pumps

50% OFF ALL PRICES GEAR PUMPS • 235

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 236

PUMPS GROUP 3 • PERFORMANCE

Pumps Group 3 Power and Speed Diagrams

3P 33 η=0.95÷1 3P 36 η=0.95÷1 3P 44 η=0.95÷1

55 55 55

70 70 70

10 *

r

2 ar

ba

50 50 50

r*

ar

PS 0b

0b

ba

23

20

0

45 45 45

I)

24

60

ar

60 60

I)

I)

ar

Power [HP]

Power [HP]

Power [HP]

PS

ba 20b

PS

I)

0b

04

PS

35

40 40 40

0

(3

00 ) 2

90

20

3

0

ar

r

(3

48

(2

I

PS

50

I)

50 50

0b

(3

PS

PS 190

35 35 35

15

0

2

(3

90

r )

SI

I)

ba

(2

30 30 30 P

r 40 0 40 5 40

00

15 17

ba

9

(2

(2

0 I)

25 15 25 PS 25 b ar

Power [kW]

Power [kW]

Power [kW]

SI

) 75 00

I) 1

P 30 1 30 30

5 (2 r

20 17 20 ba 20 PS

(2 a r 0 50

0 0b I) 10 (14

15 I) 1 20 15

50

PS 20 15 20

50

PS

(14

SI) 5

0bar

10 (14 P

10 r 10 (725

50ba

r 10 PSI)

50ba 10 10

5 PSI) 5 (725 5

(725

0 0 0 0 0 0

500

0 1000 1500 2000 2500 3000 3500 500

0 1000 1500 2000 2500 3000 3500 500

0 1000 1500 2000 2500 3000

Speed [rpm] Speed [rpm] Speed [rpm]

3P 52 η=0.95÷1 3P 62 η=0.95÷1

65 60 80

60 80 55

ar

0b

ar

55 70

0b

50

20

70

18

I)

PS

50

ar

I)

45

PS

60

0

Power [HP]

Power [HP]

0b

90

r

0

45 a

(2

15

61

60

0b 40

(2

I)

40

I)

15 5

PS 50

PS 50 35 17

35 5 (2

17

(2 30 r

r ba 40

30

0 ba 40 1 00

10 25 SI)

SI) 0P

Power [kW]

Power [kW]

25 5

50

P

(14 30

(14 30 20

20

ar

15 50ba

r 20

15

PSI)

50b 20

PSI) (725

10 (725 10

10 10

5 5

0 0 0 0

500 1000 1500 2000 2500 3000 500 1000 1500 2000 2500

Speed [rpm] Speed [rpm]

236 • GEAR PUMPS

* Solo pom pe in ghisa / Only for cast iron pumps 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:02 Page 273

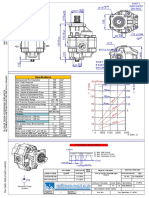

PUMPS GROUP 3 • STANDARD

PUMPS GROUP

Flange and cover in Aluminium

Technical data

Displacement Max. working pressure Max. speed Max. flow . Min. speed Min. flow Dimensions Mass Min. volumetric

efficiency

Size P1 P2 P3 A B

[cm3/rev] [bar] [bar] [bar] [g/min] [lt/min] [g/min] [lt/min] [mm] [mm] [Kg]

(in3/rev) (PSI) (PSI) (PSI) (rpm) (Gal/min) (rpm) (Gal/min) (inch) (inch) (lbs) %

19 250 270 300 66.5 12.64 62.4 128.3 5.23

3SP A19 (1.16) (3625) (3915) (4350)

3500 (17.57)

700 (3.34) (2.457) (5.051) (11.53)

22.3 240 260 290 78 14.83 63.9 131.3 5.36

3SP A22 (1.36) (3480) (3770) (4205)

3500 (20.61)

700 (3.92) (2.516) (5.169) (11.82)

29.3 220 240 260 96.7 19.48 66.9 137.3 5.64

3SP A29 (1.79) (3190) (3480) (3770)

3300 (25.55)

700 (5.15) (2.634) (5.406) (12.44)

32.9 220 230 260 108.6 21.88 68.4 140.3 5.78

3SP A33 (2.01) (3190) (3335) (3770)

3300 (28.69)

700 (5.78) (2.693) (5.524) (12.75)

95*

36.4 210 230 250 120.1 24.21 69.9 143.3 5.91

3SP A36 (2.22) (3045) (3335) (3625)

3300 (31.73)

700 (6.40) (2.752) (5.642) (13.03)

43.5 200 220 240 130.5 28.93 72.9 149.3 6.19

3SP A44 (2.65) (2900) (3190) (3480)

3000 (34.48)

700 (7.64) (2.870) (5.878) (13.65)

51.7 200 210 240 155.1 34.38 76.4 156.3 6.50

3SP A52 (3.15) (2900) (3045) (3480)

3000 (40.98)

700 (9.08) (3.008) (6.154) (14.33)

61.1 180 190 200 152.7 40.63 80.4 164.3 6.87

3SP A62 (3.73) (2610) (2755) (2900)

2500 (40.34)

700 (10.73) (3.165) (6.469) (15.15)

* Value collected during the testing at 1500 rpm)

Example of ordering code

3SP A 22 D (H) - 10 G (VT)

3SP Pump type see table

A Flange and cover A = Aluminium

22 Displacement see table

D = Clockwise rotation

D Clockwise rotation

S = Anticlockwise rotation

(H) Stiffening seal for low suction pressure (optional)

—

10 Shaft type 10 - 13 - 14

G Connections type G-N- W-F-T

(VT) Viton seals (optional)

(VT) Optional

VLP-I (N) Pressure relief valve (page A-63)

Conn Port Connections

G N W F T

OU

T

IN

The sign on the body identifies the suction side for the pumps.

IN

OU

T

Rotation

D S

SEE PAGE 285 FOR PRICES

50% OFF ALL PRICES GEAR PUMPS • 273

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 274

PUMPS GROUP 3 • STANDARD

Flange and cover in Aluminium 3

B 120 (4.724)

A 12

Shaft (0.472)

(1.99988)

50.8 f8 -0.076 (1.97008)

42.62

(1.678)

150 (5.906)

-0.003

128 (5.039)

2 1 . 3 7 (0.841)

5 22.4 98 (3.858)

(0.197) (0.882) Conn

110 (4.331)

Shaft Available shafts

Type 10 Type 13 Type 14

0 (0.15748) 47.2 38 38.2

- 0.013 (0.24949 )

M14x1.5

4 - 0.02 (0.15669)

(1.858) 6.35 f8 - 0.035 (0.24862 )

(1.496) (1.504)

Splined profile 7/8"

ø 18.91 (0.744)

(0.87480)

ø 22 22 -0.03 (0.87362)

SAE 16/32 DP

13.79 (0.543)

11.7 (0.461)

nr of teeth = 13

1/4"-28 UNF

0

1:8

14.4 32.8 33

(1.299) 34

(0.567) (1.291) (1.339)

Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177s ft.lbs

SEE PAGE 283 FOR PORT SIZES AVAILABLE

SEE PAGE 285 FOR PRICES

274 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 275

PUMPS GROUP 3 • STANDARD

PUMPSand

Flange GROUP

cover in Cast iron

Technical data

Max. working pressure . Dimensions

Displacement Max. speed Max. flow Min. speed Min. flow Mass Min. volumetric

efficiency

Size P1 P2 P3 A B

[cm3/rev] [bar] [bar] [bar] [g/min] [lt/min] [g/min] [lt/min] [mm] [mm] [Kg]

(in3/rev) (PSI) (PSI) (PSI) (rpm) (Gal/min) (rpm) (Gal/min) (inch) (inch) (lbs) %

19 270 290 320 66.5 12.64 62.4 128.3 7.53

3SP G19 (1.16) (3915) (4205) (4640)

3500 (17.57)

700 (3.34) (2.457) (5.051) (16.60)

22.3 260 280 300 78 14.83 63.9 131.3 7.66

3SP G22 (1.36) (3770) (4060) (4350)

3500 (20.61)

700 (3.92) (2.516) (5.169) (16.89)

29.3 240 260 280 96.7 19.48 66.9 137.3 7.94

3SP G29 (1.79) (3480) (3770) (4060)

3300 (25.55)

700 (5.15) (2.634) (5.406) (17.51)

32.9 240 260 280 108.6 21.88 68.4 140.3 8.08

3SP G33 (2.01) (3480) (3770) (4060)

3300 (28.69)

700 (5.78) (2.693) (5.524) (17.82)

95*

36.4 230 250 270 120.1 24.21 69.9 143.3 8.21

3SP G36 (2.22) (3335) (3625) (3915)

3300 (31.73)

700 (6.40) (2.752) (5.642) (18.10)

43.5 200 220 240 130.5 28.93 72.9 149.3 8.49

3SP G44 (2.65) (2900) (3190) (3480)

3000 (34.48)

700 (7.64) (2.870) (5.878) (18.72)

51.7 200 220 240 155.1 34.38 76.4 156.3 8.80

3SP G52 (3.15) (2900) (3190) (3480)

3000 (40.98)

700 (9.08) (3.008) (6.154) (19.40)

61.1 180 190 200 152.7 40.63 80.4 164.3 9.17

3SP G62 (3.73) (2610) (2755) (2900)

2500 (40.34)

700 (10.73) (3.165) (6.469) (20.22)

* Value collected during the testing at 1500 rpm)

Example of ordering code

3SP G 22 D (H) - 10 G (VT)

3SP Pump type see table

G Flange and cover G = Ghisa / Cast iron

22 Displacement see table

D = Clockwise rotation

D Clockwise rotation

S = Anticlockwise rotation

(H) Stiffening seal for low suction pressure (optional)

—

10 Shaft type 10 - 13 - 14

G Connections type G-N- W-F-T

(VT) Viton seals (optional)

(VT) Optional

VLP-I (N) Pressure relief valve (page A-63)

Conn Port Connections

G N W F T

OU

T

IN

The sign on the body identifies the suction side for the pumps.

IN

OU

T

Rotation

D S

SEE PAGE 285 FOR PRICES

50% OFF ALL PRICES GEAR PUMPS • 275

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 276

PUMPS GROUP 3 • STANDARD

Flange and cover in Cast iron

B 120 (4.724)

A 12

Shaft (0.472)

(1.99988)

50.8 f8 -0.076 (1.97008)

42.62

(1.678)

-0.003

150 (5.906)

128 (5.039)

2 1 . 3 7 (0.841)

5 22.4 98 (3.858)

(0.197) (0.882) Conn

110 (4.331)

Shaft Available shafts

Type 10 Type 13 Type 14

0 (0.15748) 47.2 38 38.2

- 0.013 (0.24949 )

M14x1.5

4 - 0.02 (0.15669)

(1.858) 6.35 f8 - 0.035 (0.24862 )

(1.496) (1.504)

Splined profile 7/8"

ø 18.91 (0.744)

(0.87480)

ø 22 22 -0.03 (0.87362)

SAE 16/32 DP

13.79 (0.543)

11.7 (0.461)

nr of teeth = 13

1/4"-28 UNF

0

1:8

14.4 32.8 33

(1.299) 34

(0.567) (1.291) (1.339)

Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177s ft.lbs

SEE PAGE 283 FOR PORT SIZES AVAILABLE

SEE PAGE 285 FOR PRICES

276 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 277

P

PUMPS GROUP 3 • SAE B, SAE B-OR

Flange and cover in Aluminium

Technical data

Max. working pressure . Dimensions

Displacement Max. speed Max. flow Min. speed Min. flow Mass Min. volumetric

efficiency

Size P1 P2 P3 A B

[cm3/rev] [bar] [bar] [bar] [g/min] [lt/min] [g/min] [lt/min] [mm] [mm] [Kg]

(in3/rev) (PSI) (PSI) (PSI) (rpm) (Gal/min) (rpm) (Gal/min) (inch) (inch) (lbs) %

19 250 270 300 66.5 12.64 59.4 125.3 5.23

3SP A19 (1.16) (3625) (3915) (4350)

3500 (17.57)

700 (3.34) (2.339) (4.933) (11.53)

22.3 240 260 290 78 14.83 60.9 128.3 5.36

3SP A22 (1.36) (3480) (3770) (4205)

3500 (20.61)

700 (3.92) (2.398) (5.051) (11.82)

29.3 220 240 260 96.7 19.48 63.9 134.3 5.64

3SP A29 (1.79) (3190) (3480) (3770)

3300 (25.55)

700 (5.15) (2.516) (5.287) (12.44)

32.9 220 230 260 108.6 21.88 65.4 137.3 5.78

3SP A33 (2.01) (3190) (3335) (3770)

3300 (28.69)

700 (5.78) (2.575) (5.406) (12.75)

95*

36.4 210 230 250 120.1 24.21 66.9 140.3 5.91

3SP A36 (2.22) (3045) (3335) (3625)

3300 (31.73)

700 (6.40) (2.634) (5.124) (13.03)

43.5 200 220 240 130.5 28.93 69.9 146.3 6.19

3SP A44 (2.65) (2900) (3190) (3480)

3000 (34.48)

700 (7.64) (2.752) (5.760) (13.65)

51.7 200 210 240 155.1 34.38 73.4 153.3 6.50

3SP A52 (3.15) (2900) (3045) (3480)

3000 (40.98)

700 (9.08) (2.890) (6.035) (14.33)

61.1 180 190 200 152.7 40.63 77.4 161.3 6.87

3SP A62 (3.73) (2610) (2755) (2900)

2500 (40.34)

700 (10.73) (3.047) (6.350) (15.15)

* Value collected during the testing at 1500 rpm)

Example of ordering code

3SP A 22 D (H) SAEB - 14 G (VT)

3SP Pump type see table

A Flange and cover A = Aluminium

22 Displacement see table

D = Clockwise rotation

D Clockwise rotation

S = Anticlockwise rotation

(H) Stiffening seal for low suction pressure (optional)

SAEB Flange type SAE B - SAE B - OR

—

14 Shaft type 10 - 13 - 14

G Connections type G-N- W-F-T

(VT) Viton seals (optional)

(VT) Optional

VLP-I (N) Pressure relief valve (page A-63)

Conn Port Connections

G N W F T

OU

T

IN

IN

OU

OU T The sign on the body identifies the suction side for the pumps.

T

IN

Rotation

D S

IN

OU

T

SEE PAGE 285 FOR PRICES

50% OFF ALL PRICES GEAR PUMPS • 277

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 278

PUMPS GROUP 3 • SAE B, SAE B-OR

Flange and cover in Aluminium

SAE B-OR SAE B

B

A

15

Shaft (0.591)

(0.571)

(4.00000)

101.6 -0.05 (3.99803)

14.5

2 1 . 3 7 (0.841)

0

OR 2.62x75.87 9.5 28.9 108 (4.252)

(0.374) (1.138)

Conn 146 (5.748)

174 (6.850)

Shaft Available shafts

Type 10 Type 13 Type 14

0

(0.15748) 50.2 (0.24949) 41 41.2

- 0.013

M14x1.5

4 - 0.02 (0.15669) (1.976) 6.35 f8 - 0.035 (0.24862) (1.614) (1.622)

Splined profile 7/8"

(0.87480)

-0.03 (0.87362)

ø 18.91 (0.744)

SAE 16/32 DP

11.7 (0.461)

13.79 (0.543)

1/4"-28 UNF

nr of teeth = 13

0

ø 22 22

1:8

14.4 35.8

34

(0.567) (1.409) 33(1.299) (1.339)

Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177 ft.lbs

SEE PAGE 283 FOR PORT SIZES AVAILABLE

SEE PAGE 285 FOR PRICES

278 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 279

PUMPS GROUP 3 • SAE B, SAE B-OR

Flange and cover in Cast iron

Technical data

Max. working pressure . Dimensions

Displacement Max. speed Max. flow Min. speed Min. flow Mass Min. volumetric

efficiency

Size P1 P2 P3 A B

[cm3/rev] [bar] [bar] [bar] [g/min] [lt/min] [g/min] [lt/min] [mm] [mm] [Kg]

(in3/rev) (PSI) (PSI) (PSI) (rpm) (Gal/min) (rpm) (Gal/min) (inch) (inch) (lbs) %

19 270 290 320 66.5 12.64 59.4 125.3 7.59

3SP G19 (1.16) (3915) (4205) (4640)

3500 (17.57)

700 (3.34) (2.339) (4.933) (16.74)

22.3 260 280 300 78 14.83 60.9 128.3 7.72

3SP G22 (1.36) (3770) (4060) (4350)

3500 (20.61)

700 (3.92) (2.398) (5.051) (17.02)

29.3 240 260 280 96.7 19.48 63.9 134.3 8.00

3SP G29 (1.79) (3480) (3770) (4060)

3300 (25.55)

700 (5.15) (2.516) (5.287) (17.64)

32.9 240 260 280 108.6 21.88 65.4 137.3 8.14

3SP G33 (2.01) (3480) (3770) (4060)

3300 (28.69)

700 (5.78) (2.575) (5.406) (17.95)

95*

36.4 230 250 270 120.1 24.21 66.9 140.3 8.27

3SP G36 (2.22) (3335) (3625) (3915)

3300 (31.73)

700 (6.40) (2.634) (5.524) (18.24)

43.5 200 220 240 130.5 28.93 69.9 146.3 8.55

3SP G44 (2.65) (2900) (3190) (3480)

3000 (34.48)

700 (7.64) (2.752) (5.760) (18.85)

51.7 200 220 240 155.1 34.38 73.4 153.3 8.86

3SP G52 (3.15) (2900) (3190) (3480)

3000 (40.98)

700 (9.08) (2.890) (6.035) (19.54)

61.1 180 190 200 152.7 40.63 77.4 161.3 9.23

3SP G62 (3.73) (2610) (2755) (2900)

2500 (40.34)

700 (10.73) (3.047) (6.350) (20.35)

* Value collected during the testing at 1500 rpm)

Example of ordering code

3SP G 22 D (H) SAEB - 14 G (VT)

3SP Pump type see table

G Flange and cover G = Cast iron

22 Displacement see table

D = Clockwise rotation

D Clockwise rotation

S = Anticlockwise rotation

(H) Stiffening seal for low suction pressure (optional)

SAEB Flange type SAE B - SAE B - OR

—

14 Shaft type 10 - 13 - 14

G Connections type G-N- W-F-T

(VT) Viton seals (optional)

(VT) Optional

VLP-I (N) Pressure relief valve (page A-63)

Conn Port Connections

G N W F T

OU

T

IN

The sign on the body identifies the suction side for the pumps.

IN

OU OU

T T

IN

Rotation

D S

IN

OU

T

8

SEE PAGE 285 FOR PRICES

50% OFF ALL PRICES GEAR PUMPS • 279

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 280

PUMPS GROUP 3 • SAE B, SAE B-OR

Flange and cover in Cast iron

SAE B-OR SAE B

B

A

15

Shaft (0.591)

(0.571)

(4.00000)

101.6 -0.05 (3.99803)

14.5

2 1 . 3 7 (0.841)

0

OR 2.62x75.87 9.5 28.9 108 (4.252)

(0.374) (1.138)

Conn 146 (5.748)

174 (6.850)

Shaft Available shafts

Type 13 Type 14

0

(0.15748) 50.2 (0.24949) 41 41.2

- 0.013

M14x1.5

4 - 0.02 (0.15669) (1.976) 6.35 f8 - 0.035 (0.24862) (1.614) (1.622)

Splined profile 7/8"

(0.87480)

-0.03 (0.87362)

ø 18.91 (0.744)

SAE 16/32 DP

11.7 (0.461)

13.79 (0.543)

nr of teeth = 13

1/4"-28 UNF

0

ø 22 22

1:8

14.4 35.8

34

(0.567) (1.409) 33(1.299) (1.339)

Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177 ft.lbs Torque 240 Nm / 177 ft.lbs

SEE PAGE 283 FOR PORT SIZES AVAILABLE

SEE PAGE 285 FOR PRICES

280 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 281

PUMPS GROUP 3 • ZFC

Technical data

Max. working pressure . Dimensions

Displacement Max. speed Max. flow Min. speed Min. flow Mass Min. volumetric

efficiency

Size P1 P2 P3 A B

[cm3/rev] [bar] [bar] [bar] [g/min] [lt/min] [g/min] [lt/min] [mm] [mm] [Kg]

(in3/rev) (PSI) (PSI) (PSI) (rpm) (Gal/min) (rpm) (Gal/min) (inch) (inch) (lbs) %

19 270 290 320 66.5 12.64 110.5 176.4 7.58

3SP G19 (1.16) (3915) (4205) (4640)

3500 (17.57)

700 (3.34) (4.350) (6.945) (16.71)

22.3 260 280 300 78 14.83 112.0 179.4 7.72

3SP G22 (1.36) (3770) (4060) (4350)

3500 (20.61)

700 (3.92) (4.409) (7.063) (17.02)

29.3 240 260 280 96.7 19.48 115.0 185.4 8.0

3SP G29 (1.79) (3480) (3770) (4060)

3300 (25.55)

700 (5.15) (4.528) (7.299) (17.64)

32.9 240 260 280 108.6 21.88 116.5 188.4 8.14

3SP G33 (2.01) (3480) (3770) (4060)

3300 (28.69)

700 (5.78) (4.587) (7.417) (17.95)

95*

36.4 230 250 270 120.1 24.21 118.0 191.4 8.28

3SP G36 (2.22) (3335) (3625) (3915)

3300 (31.73)

700 (6.40) (4.646) (7.535) (18.26)

43.5 200 220 240 130.5 28.93 121.0 197.4 8.55

3SP G44 (2.65) (2900) (3190) (3480)

3000 (34.48)

700 (7.64) (4.764) (7.772) (18.85)

51.7 200 220 240 155.1 34.38 124.5 204.4 8.88

3SP G52 (3.15) (2900) (3190) (3480)

3000 (40.98)

700 (9.08) (4.902) (8.047) (19.58)

61.1 180 190 200 152.7 40.63 128.5 212.4 9.25

3SP G62 (3.73) (2610) (2755) (2900)

2500 (40.34)

700 (10.73) (5.059) (8.362) (20.40)

* Value collected during the testing at 1500 rpm)

Example of ordering code

3SP G 22 D ZFC - 24 G (VT)

3SP Pump type see table

G Flange and cover G = Cast iron

22 Displacement see table

D = Clockwise rotation

D Clockwise rotation

S = Anticlockwise rotation

ZFC Flange type SAE B - SAE B - OR

—

14 Shaft type 10 - 13 - 14

G Connections type G-N- W-F-T

(VT) Optional (VT) Viton seals (optional)

Conn Port Connections

G N W F T

OU

T

IN

The sign on the body identifies the suction side for the pumps.

IN

OU

T

Rotation

D S

SEE PAGE 285 FOR PRICES

50% OFF ALL PRICES GEAR PUMPS • 281

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 282

PUMPS GROUP 3 • ZFC

108 (4.252)

13 n°4 fori

Shaft (0.512) Nr. 4 holes 80 (3.150)

(3.14843)

80 f7 -0.06 (3.14724)

80 (3.150)

108 (4.252)

-0.03

142.8 (5.622)

21.4 (0.828)

9 14.5 110 (4.331)

(0.354) (0.571) Conn

A

B

Shaft Available shafts

Type 24 SEE PAGE 283 FOR PORT SIZES AVAILABLE

37.6

(1.480)

36.4

(1.433)

1.85 H13 26

(0.073 H13) (1.024)

(1.299)

33

8.1

(0.319)

(45.6)

Profilo scanalato (1.795 )

Splined profile

8x32x36 UNI 8953 54.6

(2.150)

Torque 240 Nm / 177 ft.lbs

SEE PAGE 285 FOR PRICES

282 • GEAR PUMPS 50% OFF ALL PRICES

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 283

PUMPS GROUP 3 • PORT CONNECTIONS

G N

Suction Delivery Suction Delivery

51(2.008) 40 (1.575)

G 1” G 3/4” 27 (1.063) 19 (0.748)

d M10 M8

W F

Suction Delivery Suction Delivery Size

19 ÷ 36

E 26.2 C D E

1" 5/16 12UN 1" 1/16 12UN

(1.031)

27 52.4 26.2

(1.063) (2.063) (1.031)

Size

52.4

(2.063)

(0.945)

D

24

C

44 ÷ 62

C D E

42 35.6 69.8

(1.654) (1.402) (2.748)

M8 M8

Suction Delivery

90° 90°

M8

M8

26 (1.024) 18 (0.709)

55 (2.165) 55 (2.165)

The sign on the body identifies the suction side for the

pumps.

Port Connection positions

OU

T

IN

Rotation

D S

IN

OU

T

SEE PAGE 285 FOR PRICES

50% OFF ALL PRICES GEAR PUMPS • 283

TECHNICAL DATA SHEET

227-317 Harrier Catalogue 14 [5A].qxd:Layout 1 14/11/14 17:03 Page 284

PUMPS GROUP 3 • OPTIONAL

VLP- I (N) Pressure relief valve with internal exhaust

A

E32 BX

Standard SAE AA

E32 CX

127.3 129.3 124.6

78 max A 3SP A19

(5.012) (5.091) (4.906)

(3.071)

111 (4.370) 17 130.3 132.3 127.6

(0.669) 3SP A22

(5.130) (5.209) (5.024)

P 136.3 138.3 133.6

3SP A29

(5.366) (5.445) (5.260)

139.3 141.3 136.6

3SP A33

142.75

(5.620)

(5.484) (5.563) (5.378)

142.3 144.3 139.6

3SP A36

(5.602) (5.681) (5.496)

Suction 148.3 150.3 145.6

T 3SP A44

(5.839) (5.917) (5.732)

155.3 157.3 152.6

3SP A52

(6.114) (6.193) (6.008)

163.3 165.3 160.6

3SP A62

(6.429) (6.508) (6.323)

Warning.

The pressure relief valve can be applied by substituting the rear

cover.

It is supplied only with aluminium flange and cover.

The showed pump is anticlockwise rotation.

The opening of the pressure relief valve should be carry out for

times not over 7" each minute to avoid the overheating of the

pump.

Example of ordering code

3SP A 22 D SAE B - 10 G (VT) VLP-I (N)

VLP-I VPL-I

Cover with VLP (at internal exhaust)

(N) Spring type B - N - R (See table)

Spring type

B N R

white spring black spring red spring

[bar] 10 ÷ 100 30 ÷ 280 80 ÷ 380

Calibration fields*

(psi) (145 ÷ 1450) (435 ÷ 4060) (1160 ÷ 5510)

* Without setting request, it will be considered standard (black spring: 2175 psi).

SEE PAGE 283 FOR PORT SIZES AVAILABLE

SEE PAGE 285 FOR PRICES

284 • GEAR PUMPS 50% OFF ALL PRICES

You might also like

- K3 V280 SpecsDocument1 pageK3 V280 SpecsJuan AcostaNo ratings yet

- Calculation of Cyl SizeDocument1 pageCalculation of Cyl SizePRAVEEN ENo ratings yet

- Agitator Calculation. - SPLDocument2 pagesAgitator Calculation. - SPLAbarajithan RajendranNo ratings yet

- Manhole ScheduleDocument7 pagesManhole SchedulejibinNo ratings yet

- Variable Displacement Axial Piston Pump Type V30D: 1. General DescriptionDocument12 pagesVariable Displacement Axial Piston Pump Type V30D: 1. General DescriptionMHS teamNo ratings yet

- Technical Specifications: HC 95 LMDocument1 pageTechnical Specifications: HC 95 LMJuan Enrique Perez VillanuevaNo ratings yet

- Series: K5V 200 DT H 100 R 9N 01Document1 pageSeries: K5V 200 DT H 100 R 9N 01Stelian Crisan100% (1)

- Focs Plus Ldw1003 - GBDocument4 pagesFocs Plus Ldw1003 - GBRafael LopezNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- Gearbox-Mounted Power Take Off: General InstructionsDocument4 pagesGearbox-Mounted Power Take Off: General InstructionsChimuonechi NyirendaNo ratings yet

- Beginner's Guide To Centrifugal Compressor Design and SimulationDocument17 pagesBeginner's Guide To Centrifugal Compressor Design and Simulationvijay_jvNo ratings yet

- Air Only Pressure Drop: Do Not Use This Method For Detail Design - Always Consult A Reputable Supplier For Detail DesignDocument6 pagesAir Only Pressure Drop: Do Not Use This Method For Detail Design - Always Consult A Reputable Supplier For Detail DesignRahul ChandrawarNo ratings yet

- DataSheet LOMBARDINI (CHD SERIES)Document4 pagesDataSheet LOMBARDINI (CHD SERIES)CristianTeodorescuNo ratings yet

- Product Technical Details RXTM RDocument2 pagesProduct Technical Details RXTM Rviki mikiNo ratings yet

- Rotary Screw Compressor Discussion and Calculations: NotesDocument9 pagesRotary Screw Compressor Discussion and Calculations: Notesfarshad100% (2)

- PV 21 PumpDocument13 pagesPV 21 PumpJayath Bogahawatte100% (1)

- Guidelines On Compressor Sizing and SelectionDocument35 pagesGuidelines On Compressor Sizing and SelectionIan LuyaoNo ratings yet

- Beginner's Guide To Centrifugal Compressor System Design & SimulationDocument17 pagesBeginner's Guide To Centrifugal Compressor System Design & Simulationkavinmech1No ratings yet

- Calculation Dilute Phase Air Only Pressure DropDocument6 pagesCalculation Dilute Phase Air Only Pressure DropGeorgi Mitkov SavovNo ratings yet

- MONTABERT HC112 Tech Spec 1 PDFDocument1 pageMONTABERT HC112 Tech Spec 1 PDFSaid TouhamiNo ratings yet

- Serie Focs: HomologationDocument4 pagesSerie Focs: HomologationValeriyNo ratings yet

- BN52 6L PDFDocument1 pageBN52 6L PDFeduinNo ratings yet

- Valvole Solenoidi Per-Impieghi-IndustrialiDocument8 pagesValvole Solenoidi Per-Impieghi-IndustrialiAdrián Fernández AnduezaNo ratings yet

- Op Uc 101Document1 pageOp Uc 101Fabian SNo ratings yet

- 096000-352# Pump Test Specification (Plano de Teste Denso)Document4 pages096000-352# Pump Test Specification (Plano de Teste Denso)Junior IungNo ratings yet

- R-Pump Cal Sheet1Document12 pagesR-Pump Cal Sheet1santosh kumarNo ratings yet

- Technical Data D1-30: GeneralDocument2 pagesTechnical Data D1-30: Generaldgrivas9333No ratings yet

- Technical Data D1-30: GeneralDocument2 pagesTechnical Data D1-30: Generaldgrivas9333No ratings yet

- d1 30 SP PDFDocument2 pagesd1 30 SP PDFdgrivas9333No ratings yet

- d1 30 SP Te PDFDocument2 pagesd1 30 SP Te PDFdgrivas9333No ratings yet

- Series 90 Pumps BLN-10029 e 11Document1 pageSeries 90 Pumps BLN-10029 e 11Vipin GuptaNo ratings yet

- Data Sheet EUROSTAR 20 DigitalDocument1 pageData Sheet EUROSTAR 20 DigitalLeandro Francisco da SilvaNo ratings yet

- Design of Agitator 8 Batch Volume PDFDocument3 pagesDesign of Agitator 8 Batch Volume PDFakash kumarNo ratings yet

- TD 302 Cemp EEx-d Technische Catalogus ATEX 63-315Document87 pagesTD 302 Cemp EEx-d Technische Catalogus ATEX 63-315TrePcaNo ratings yet

- Compressors, An Introduction: © Siemens AG 2008. All Rights ReservedDocument63 pagesCompressors, An Introduction: © Siemens AG 2008. All Rights ReservedMuhammad Saad KhanNo ratings yet

- The Engine For Construction Equipment.: 63 - 190 KW at 1500 - 2300 MinDocument6 pagesThe Engine For Construction Equipment.: 63 - 190 KW at 1500 - 2300 MinSiding Barro100% (1)

- Variable Displacement Axial Piston Pumps For Truck ApplicationsDocument8 pagesVariable Displacement Axial Piston Pumps For Truck ApplicationsRNo ratings yet

- 22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpDocument3 pages22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpChike NwachukwuNo ratings yet

- Tech Spec50e PDFDocument1 pageTech Spec50e PDFJorge godoy inostrozaNo ratings yet

- Test Specifications Test Injector: Opening Pressure: For Field Service OnlyDocument2 pagesTest Specifications Test Injector: Opening Pressure: For Field Service OnlyAadil KhanNo ratings yet

- 2.basics of HydraulicsDocument110 pages2.basics of Hydraulicssurianto100% (1)

- Refrigerant Charge Volume For R410A Heat Recovery Model Correction of Service Manual Si39-306Document12 pagesRefrigerant Charge Volume For R410A Heat Recovery Model Correction of Service Manual Si39-306Nyandoro E-max MaxmoreNo ratings yet

- Img 001Document1 pageImg 001alfredo lopez regaladoNo ratings yet

- Process SizingDocument41 pagesProcess SizingBóng Đá- Quán bia tổng hợp100% (1)

- Hydroulik Roll Crusher PDF FreeDocument15 pagesHydroulik Roll Crusher PDF Freemu.loa91No ratings yet

- Sizing of Gas Pressure Regulating and Metering Stations (GRMS)Document12 pagesSizing of Gas Pressure Regulating and Metering Stations (GRMS)Ben MusimaneNo ratings yet

- SMIT Axial Piston Pumps SHPVDocument10 pagesSMIT Axial Piston Pumps SHPVvyacheslav belovNo ratings yet

- Francis Turbine LabDocument2 pagesFrancis Turbine LabLurking RogueNo ratings yet

- Voith Gear Pump RecommendationDocument28 pagesVoith Gear Pump RecommendationcotteNo ratings yet

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDocument2 pagesExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineM RoyNo ratings yet

- Experiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineDocument2 pagesExperiment No. 6 Combustion Parameter Study of A Single Cylinder Four Stroke Diesel EngineMuket AgmasNo ratings yet

- Compressor Power Calculator 28-05-20Document2 pagesCompressor Power Calculator 28-05-20Khánh ĐặngNo ratings yet

- ANNEXURE For HVW SPRAY SYSTEM - StandardDocument1 pageANNEXURE For HVW SPRAY SYSTEM - StandardVaibhav SawantNo ratings yet

- Rexnord Falk SteelflexDocument2 pagesRexnord Falk SteelflexTIOCA01No ratings yet

- CompressorsDocument63 pagesCompressorsKarim KarimNo ratings yet

- ZENNER Single Jet ETKD-N, 2-Page BROCHUREDocument2 pagesZENNER Single Jet ETKD-N, 2-Page BROCHUREVikram S GadreNo ratings yet

- Experiment 7: To Demonstrate The Reaction Turbine Power As A Function of TorqueDocument5 pagesExperiment 7: To Demonstrate The Reaction Turbine Power As A Function of TorqueKamil Rasheed SiddiquiNo ratings yet

- Blue Ascend Hydraulics Orbital Motors (Web)Document9 pagesBlue Ascend Hydraulics Orbital Motors (Web)eddy ortegaNo ratings yet

- Aluminium Hydraulic Gear Pumps T03Document116 pagesAluminium Hydraulic Gear Pumps T03eddy ortegaNo ratings yet

- CAT Hydraulic Piston Pump PartsDocument16 pagesCAT Hydraulic Piston Pump Partseddy ortega50% (2)

- Yuken Gear PumpDocument4 pagesYuken Gear Pumpeddy ortegaNo ratings yet

- Commercial Generator Set Hydraulic Series HG 15000: Features and Benefits Weight, Size and Sound LevelDocument4 pagesCommercial Generator Set Hydraulic Series HG 15000: Features and Benefits Weight, Size and Sound Leveleddy ortegaNo ratings yet

- PDTDT401330011Document1 pagePDTDT401330011eddy ortegaNo ratings yet

- PDTDT401330012 1Document1 pagePDTDT401330012 1eddy ortegaNo ratings yet

- PDTDT401330132Document1 pagePDTDT401330132eddy ortegaNo ratings yet

- PDTDT401330131Document1 pagePDTDT401330131eddy ortegaNo ratings yet

- 1 SGPKZP4-1Document6 pages1 SGPKZP4-1eddy ortegaNo ratings yet

- Bombas de Aluminio Segun CodigoDocument44 pagesBombas de Aluminio Segun Codigoeddy ortegaNo ratings yet

- Hydraulic Pumps SiteDocument133 pagesHydraulic Pumps Siteeddy ortega100% (1)

- Bent Axis Piston Pump: 2PBA Pumps Have The Following AdvantagesDocument23 pagesBent Axis Piston Pump: 2PBA Pumps Have The Following Advantageseddy ortegaNo ratings yet

- List of Companies: Hy-Pro Manufactures Performance UpgradeDocument4 pagesList of Companies: Hy-Pro Manufactures Performance Upgradeeddy ortegaNo ratings yet

- BW177-179DH4 Service Training PDFDocument201 pagesBW177-179DH4 Service Training PDFeddy ortega33% (3)

- Pump SciDocument78 pagesPump Scieddy ortegaNo ratings yet

- KJ PumpDocument5 pagesKJ Pumpeddy ortegaNo ratings yet

- Oil en It 12 14Document12 pagesOil en It 12 14eddy ortegaNo ratings yet

- The Perfect Line: ConfidentialDocument10 pagesThe Perfect Line: Confidentialeddy ortegaNo ratings yet

- Screw Conveyor Engineering GuideDocument44 pagesScrew Conveyor Engineering Guideaxl1100% (2)

- LTX 1040 Service ManualDocument91 pagesLTX 1040 Service Manuallarry50179% (14)

- Dokumen - Tips - HVP 90 ManualDocument10 pagesDokumen - Tips - HVP 90 Manualalfa AlfianNo ratings yet

- ROULUNDS RUBBER - Korea - JapanDocument60 pagesROULUNDS RUBBER - Korea - JapanВладимир АнаймановичNo ratings yet

- Roll Crusher 1 SingleDocument3 pagesRoll Crusher 1 SingleBobby A. Palem100% (1)

- Junior Instructor in Draftsman Mechanic in Industrial TDocument6 pagesJunior Instructor in Draftsman Mechanic in Industrial ThariNo ratings yet

- User 'S Manual Parts Book: SSU UN Nssttaarr M Maac CH Hiin Neerryy C CO O..,, LLTTD D.Document72 pagesUser 'S Manual Parts Book: SSU UN Nssttaarr M Maac CH Hiin Neerryy C CO O..,, LLTTD D.Luis Caba RamirezNo ratings yet

- V-Belt DrivesDocument12 pagesV-Belt DrivesSufiyan MohammedNo ratings yet

- AdmDocument6 pagesAdmLenin Jhair Valderrama SeguraNo ratings yet

- Belt DriveDocument14 pagesBelt DriveSumit VakhariaNo ratings yet

- Models HRSB & HRSD: Model FeaturesDocument4 pagesModels HRSB & HRSD: Model FeaturesAlejandro DuranNo ratings yet

- YK系列振动筛 XZUM 0700 0202Document15 pagesYK系列振动筛 XZUM 0700 0202Carlos Eugenio LoveraNo ratings yet

- Marine PurifierDocument30 pagesMarine PurifierJayDelosSantos100% (1)

- Otto Group 2Document23 pagesOtto Group 2otto groupNo ratings yet

- Mbs 45 ManualDocument15 pagesMbs 45 ManualJohn StrohlNo ratings yet

- Datasheet - Uni QNB CDocument4 pagesDatasheet - Uni QNB CYeisonNo ratings yet

- Nagel PLC Upgradtion ProjectDocument35 pagesNagel PLC Upgradtion Projectnarendramaharana39No ratings yet

- 頁面擷取自 ED3051G442Document2 pages頁面擷取自 ED3051G442QooNo ratings yet

- Wirtgen Parts CatalogueDocument462 pagesWirtgen Parts CatalogueMgc Elektronik86% (14)

- (TIPTOP) Hot-Splicing-of-Rubber-Conveyor-Belts-with-Fabric-PliesDocument28 pages(TIPTOP) Hot-Splicing-of-Rubber-Conveyor-Belts-with-Fabric-PliesasdasdNo ratings yet

- Final ThesisDocument59 pagesFinal ThesisBALRAM37710% (1)

- Guideline For Writing A Lab Report: Title PageDocument66 pagesGuideline For Writing A Lab Report: Title PageAshiqur RahmanNo ratings yet

- Despiece MP2000 PDFDocument83 pagesDespiece MP2000 PDFAnonymous UHcbrUNo ratings yet

- Tension Gauges: OptikrikDocument2 pagesTension Gauges: Optikrik02031989No ratings yet

- Autocad Mechanical 2007 Product DetailDocument9 pagesAutocad Mechanical 2007 Product DetailpetereidNo ratings yet

- 303-08 P1396 RepairDocument6 pages303-08 P1396 Repairmarcelo ustarezNo ratings yet

- Aston Martin DB7 Workshop ManualDocument421 pagesAston Martin DB7 Workshop Manualjorge Angel LopeNo ratings yet

- Belts For The Airport Industry: Helping AchieveDocument6 pagesBelts For The Airport Industry: Helping AchieveIrina AtudoreiNo ratings yet

- Vdocuments - MX - Catalogo de Partes Finisher sr860 sr850 rfg005432 2 PDFDocument58 pagesVdocuments - MX - Catalogo de Partes Finisher sr860 sr850 rfg005432 2 PDFRomeo Ivan Velazquez PaniaguaNo ratings yet