Professional Documents

Culture Documents

Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)

Uploaded by

Panisa BanimaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)

Uploaded by

Panisa BanimaCopyright:

Available Formats

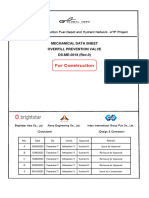

Engineering and Construction Fuel Depot and Hydrant Network -UTP Project

MECHANICAL DATA SHEET

EXPANSION JOINTS

DS-PP-0015 (Rev. 0)

Brightstar Asia Co., Ltd. Alana Engineering Co., Ltd. Index International Group Pub Co., Ltd.

(Consultant) (Design & Contractor)

Rev. Date By Check Approved Remark

A 09/10/2023 Teerachai T. Atthaphan Y. Suchart K. Issue for Approval

0 19/10/2023 Teerachai T. Atthaphan Y. Suchart K. Issue for construction

MECHANICAL DATASHEET

EXPANSION JOINTS

PROJECT NAME U-TAPAO AIRPORT PROJECT DOC NO. DS-PP-0015

CLIENT GLOBAL AERO ASSOCIATES CO., LTD. DATE OF ISSUED 19/10/2023 REVISION 0

LOCATION U-TAPAO AIRPORT, BANCHANG, RAYONG CONTRACTOR INDEX

PLANT AREA / UNIT GAA PHASE 1 PREPARED BY JVCM

1 SPECIALTY TAG NO. SP-1101, SP-1201, SP-1301 SP-1102, SP-1202, SP-1302

2 QUANTITY 3 3

3 LOCATION P&ID DWG. NO. PC-01-10-0001, PC-01-10-0002, PC-01-10-0003 PC-01-10-0001, PC-01-10-0002, PC-01-10-0003

4 FLUID Jet A-1

5 INSTALLATION LOCATION Tank Inlet and Outlet Nozzles

DESIGN CONDITION

6 DESIGN PRESS. barg 16

7 OPERATING PRESS. barg 10

8 DESIGN TEMP. °C 70

9 OPERATING TEMP. °C 40

10 DENSITY : kg/m³ 840 at 15 °C

11 VISCOSITY cSt 2.2

12 EQUIPMENT TYPE (DETAIL) Universal Expansion Joint

13 DESIGN As per EJMA Standard

14 FUNCTION SERVICE Abosrb soil differential settlement and thermal expansion from piping system

15 SIZE 16" 24"

16 OVERALL LENGTH mm. 600 (VTA) 700 (VTA)

17 CONNECTION ANSI 150# RF Flange

18 TYPE OF FLANGE Fixed Flange x Loose Flange

19 BELLOW TYPE Double

20 MAX. AXIAL MOVEMENT mm. 25 (TBC, Note 4)

21 MAX. LATERAL MOVEMENT mm. 25 (TBC, Note 4)

2 1452 (VTA) 3230 (VTA)

22 EFFECTIVE AREA cm

SPECIFICATION

23 AXIAL SPRING RATE N/mm 138 (VTA) 221 (VTA)

24 LATERAL SPRING RATE N/mm 137 (VTA) 316 (VTA)

25 BELLOWS MATERIAL SS316L

26 FLANGE MATERIAL SS400

27 SHORT PIPE MATERIAL Carbon Steel (Note 6)

28 MIDDLE MATERIAL Carbon Steel (Note 6)

29 MIDDLE HOLDER MATERIAL SS400

30 LIMIT RODS MATERIAL SS400

31 THICK HOLDER MATERIAL SS400

32 CONICAL SEAT MATERIAL SS400

33 LIMIT / CONTROL ROD GAP VTA (Note 5)

34 EXTERNAL PAINTING As per Specification for Field Painting; SP-ME-0101

35 MATERIAL CERTIFICATE Required

DOC.

36 TEST CERTIFICATE Required

37 Warranty 1 Year after installation

38 REMARK : SKETCH :

39

40 1. REQUIRED INSTALLATIN & MAINTENACE MAUAL

41 2. REQUIRED GA DRAWING INCLUDED FULL PARTS LIST

42 3. VTA=VENDOR TO ADVISE, VTC=VENDOR TO CONFIRM,

43 TBC = TO BE CONFIRMED BY EPC CONTRACTOR

44 4. TO BE CONFIRMED BY EPC CONTRACTOR PER FINAL PIPE STRESS

45 ANALYSIS.

46 5. GAP FOR EACH NUT ON LIMIT ROD SHALL BE ADVISED BY VENDOR

47 TO SUIT WITH APPLICATION.

48 6. VENDOR TO CONFIRM THAT THESE PIPES CAN BE SUPPLIED WITH

49 CS EPOXY LINED OR SS MATEIRAL.

MECHANICAL DATASHEET

EXPANSION JOINTS

PROJECT NAME U-TAPAO AIRPORT PROJECT DOC NO. DS-PP-0015

CLIENT GLOBAL AERO ASSOCIATES CO., LTD. DATE OF ISSUED 18/10/2023 REVISION B

LOCATION U-TAPAO AIRPORT, BANCHANG, RAYONG CONTRACTOR INDEX

PLANT AREA / UNIT GAA PHASE 1 PREPARED BY JVCM

1 SPECIALTY TAG NO. SP-1101 SP-1501 SP-1102 to SP-1105

2 QUANTITY 1 1 4

3 LOCATION P&ID DWG. NO. PC-01-07-0006 PC-01-07-0005 PC-01-07-0007, PC-01-07-0008

4 FLUID Jet A-1

Tank-to-Tank Transfer

5 INSTALLATION POSITION Jockey Pump Suction Hydrant Pumps Suction

Pump Suction

DESIGN CONDITION

6 DESIGN PRESS. barg 16

7 OPERATING PRESS. barg 10

8 DESIGN TEMP. °C 70

9 OPERATING TEMP. °C 40

10 DENSITY : kg/m³ 840 at 15 °C

11 VISCOSITY cSt 2.2

12 EQUIPMENT TYPE (DETAIL) Pump Expansion Joint

13 DESIGN As per EJMA Standard

14 FUNCTION SERVICE Vibration Isolation, Absorb Misalignment & Thermal expansion from piping

15 SIZE 4" (TBC) 6" (TBC) 8" (TBC)

16 OVERALL LENGTH mm. 200 (VTA) 200 (VTA) 200 (VTA)

17 CONNECTION ANSI 150# RF Flange

18 TYPE OF FLANGE Fixed Flange x Loose Flange

19 BELLOW TYPE Single

20 MAX. AXIAL MOVEMENT mm. 25 (TBC, Note 4)

SPECIFICATION

21 EFFECTIVE AREA cm2 131 (VTA) 440 (VTA)

22 AXIAL SPRING RATE N/mm 105 (VTA) 166 (VTA)

23 BELLOWS MATERIAL SS316L

24 FLANGE MATERIAL SS400

25 SHORT PIPE MATERIAL Carbon Steel

26 INTERNAL SLEEVE MATERIAL SS316L

27 TIED RODS MATERIAL SS400

28 THICK HOLDER MATERIAL SS400

29 CONICAL SEAT MATERIAL SS400

30 LIMIT / CONTROL ROD GAP VTA (Note 5)

31 EXTERNAL PAINTING As per Specification for Field Painting; SP-ME-0101

32 MATERIAL CERTIFICATE Required

DOC.

33 TEST CERTIFICATE Required

34 Warranty 1 Year after installation

35 REMARK : SKETCH :

36

37 1. REQUIRED INSTALLATIN & MAINTENACE MAUAL

38 2. REQUIRED GA DRAWING INCLUDED FULL PARTS LIST

39 3. VTA=VENDOR TO ADVISE, VTC=VENDOR TO CONFIRM,

40 TBC = TO BE CONFIRMED BY EPC CONTRACTOR

41 4. TO BE CONFIRMED BY EPC CONTRACTOR PER FINAL PIPE STRESS

42 ANALYSIS.

43 5. GAP FOR EACH NUT ON LIMIT ROD SHALL BE ADVISED BY VENDOR

44 TO SUIT WITH APPLICATION.

You might also like

- Ds-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Document2 pagesDs-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Panisa BanimaNo ratings yet

- Ds-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Document2 pagesDs-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Panisa BanimaNo ratings yet

- Ds-pp-0014 - Mechanical Data Sheet Y-Strainers (Rev. B)Document2 pagesDs-pp-0014 - Mechanical Data Sheet Y-Strainers (Rev. B)Panisa BanimaNo ratings yet

- Ds-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Document5 pagesDs-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Panisa BanimaNo ratings yet

- Ds-pp-0010 - Mechanical Data Sheet Basket Strainers (Rev. 1)Document2 pagesDs-pp-0010 - Mechanical Data Sheet Basket Strainers (Rev. 1)Panisa BanimaNo ratings yet

- Ds-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Document3 pagesDs-pp-0006 - Data Sheet For Sampling Jars (Rev.0) - 24!10!2023Panisa BanimaNo ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- DSH in 621 3Document13 pagesDSH in 621 3Procurement PardisanNo ratings yet

- SA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02Document2 pagesSA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02altipatlarNo ratings yet

- Mechanical Data Sheet For Nitrogen ReceiverDocument8 pagesMechanical Data Sheet For Nitrogen ReceiversudjonoNo ratings yet

- Data Sheet For Temperature Gauges and ThermowellsDocument29 pagesData Sheet For Temperature Gauges and ThermowellsSardar PerdawoodNo ratings yet

- Dwg./Doc. Approval: Wha Water Co., LTDDocument47 pagesDwg./Doc. Approval: Wha Water Co., LTDธนาชัย เต็งจิรธนาภาNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- GeneralDocument1 pageGeneralamirNo ratings yet

- A3080 6040 Dat MC 142 eDocument11 pagesA3080 6040 Dat MC 142 erameshqcNo ratings yet

- 10J01762 Ict DS 000 012 D0Document14 pages10J01762 Ict DS 000 012 D0Sardar PerdawoodNo ratings yet

- Ds-El-0105 - Data Sheet For Ground Verification Monitor (Rev.b)Document4 pagesDs-El-0105 - Data Sheet For Ground Verification Monitor (Rev.b)Panisa BanimaNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Flare Scrubber DSDocument8 pagesFlare Scrubber DSsudjonoNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray NozzlebecpavanNo ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- RT Request 008Document4 pagesRT Request 008Anonymous AdofXEYAgENo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Basf Mechanical Euipmen: 08-01-20 R3.1 d0 IFB ST PV AL HS RMDocument9 pagesBasf Mechanical Euipmen: 08-01-20 R3.1 d0 IFB ST PV AL HS RMbecpavanNo ratings yet

- Datasheet For Cyclone Hopper (D-3116)Document1 pageDatasheet For Cyclone Hopper (D-3116)Joe GrosirNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Skh3-Ds-60-022-A4 Rev-4 11des2015Document15 pagesSkh3-Ds-60-022-A4 Rev-4 11des2015sugeng wahyudiNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- Data Sheet For Spray NozzleDocument3 pagesData Sheet For Spray Nozzlebecpavan100% (1)

- Planta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEDocument1 pagePlanta de Relleno Hidraulico Cementado DATA SHEET N°: W51-2019-7102-3000-IC-DSH-020 PINCH VALVEAnthony InostrozaNo ratings yet

- BLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFDocument6 pagesBLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFEdy AlamNo ratings yet

- Data SheetDocument3 pagesData SheetMaribeth AgubaNo ratings yet

- Hoja de Datos de Recipiente BechtelDocument3 pagesHoja de Datos de Recipiente BechtelPedro Luis Choque MamaniNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- Data sheetCExlsDocument1 pageData sheetCExlsElias Elias100% (1)

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument7 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument4 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Low SupportDocument1 pageLow SupportMDhana SekarNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Tank Design APIDocument63 pagesTank Design APIBSK entertainmentNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Anexo Fire PumpsDocument37 pagesAnexo Fire PumpsTommy salimNo ratings yet

- (6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FDocument15 pages(6648-0200-5-PS-DS-0026) 200-C-51 - Rev.FMohamed OuichaouiNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- Reporte Completamiento PCP: Informacion GeneralDocument1 pageReporte Completamiento PCP: Informacion GeneralEsteban santamaria ovalleNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityDocument5 pagesKu-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityAbdur RehmanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Token Ring Technology ReportFrom EverandToken Ring Technology ReportNo ratings yet

- ชุดเอกสารวางบิล Downpayment30 - TAX.IV.24-04-045 BASF Intech - T24.048 - ฉบับแก้Document9 pagesชุดเอกสารวางบิล Downpayment30 - TAX.IV.24-04-045 BASF Intech - T24.048 - ฉบับแก้Panisa BanimaNo ratings yet

- TemplateDocument3 pagesTemplatePanisa BanimaNo ratings yet

- Q3074 - Pump Data Sheet R0-240215Document8 pagesQ3074 - Pump Data Sheet R0-240215Panisa BanimaNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Ds-pp-0013 - Data Sheet For Gammon Sampling Kit No.7 (Rev.b)Document3 pagesDs-pp-0013 - Data Sheet For Gammon Sampling Kit No.7 (Rev.b)Panisa BanimaNo ratings yet

- Specification For Fuel Hydrant Pumps (Rev.0) - (p1102 To P-1105)Document9 pagesSpecification For Fuel Hydrant Pumps (Rev.0) - (p1102 To P-1105)Panisa Banima100% (1)

- Ds-Me-0017 - Mechanical Data Sheet For Air Elimnator Vessels (Rev.b)Document2 pagesDs-Me-0017 - Mechanical Data Sheet For Air Elimnator Vessels (Rev.b)Panisa BanimaNo ratings yet

- Ds-Me-0022 - Mechanical Data Sheet For Hand Pump (Rev.0)Document2 pagesDs-Me-0022 - Mechanical Data Sheet For Hand Pump (Rev.0)Panisa BanimaNo ratings yet

- Auditorium Acoustics 101: by Arthur NoxonDocument4 pagesAuditorium Acoustics 101: by Arthur NoxonMani MuruganNo ratings yet

- Heavy Duty Process Pumps According To API 610, 11 Ed. Type NCRDocument11 pagesHeavy Duty Process Pumps According To API 610, 11 Ed. Type NCRJaldhi PatelNo ratings yet

- Orifice and Free Jet Flow - F1-17Document1 pageOrifice and Free Jet Flow - F1-17MohammadNo ratings yet

- Pump Selection ExampleDocument3 pagesPump Selection ExampleKrishnaprasad Nair100% (2)

- Ecs MatlabDocument14 pagesEcs MatlabVinay ShekarNo ratings yet

- Tunnel Modelling Features in PLAXIS 3DDocument44 pagesTunnel Modelling Features in PLAXIS 3DMiguel SanchezNo ratings yet

- Lecture 6 Heat TransactionsDocument8 pagesLecture 6 Heat TransactionsScrappy WellNo ratings yet

- Chemical Equilibrium WorksheetDocument2 pagesChemical Equilibrium WorksheetThaarvena RetinaNo ratings yet

- 200319-Final Exam - Machine DesignDocument2 pages200319-Final Exam - Machine DesignJoseph RefuerzoNo ratings yet

- Analysis and Simulation of Residual Stresses of Thermal Barrier CoatingDocument18 pagesAnalysis and Simulation of Residual Stresses of Thermal Barrier Coatingfares99No ratings yet

- CL60157G PDFDocument3 pagesCL60157G PDFRisal RNo ratings yet

- Lateral Earth Pressure I PDFDocument71 pagesLateral Earth Pressure I PDFazharNo ratings yet

- Physics 05-05 Flow Rate and Bernoullis Equation PDFDocument2 pagesPhysics 05-05 Flow Rate and Bernoullis Equation PDFtonisupriadi100% (2)

- 4 1 Fluid KinematicsDocument20 pages4 1 Fluid KinematicsShoaib TariqNo ratings yet

- Italian FeedbackDocument2,856 pagesItalian FeedbackAnkith NaiduNo ratings yet

- Course Title: Laser Physics: Lecture # 3Document17 pagesCourse Title: Laser Physics: Lecture # 3FAKIHA GULZAR BS PhysicsNo ratings yet

- 2.3 Diesel CycleDocument15 pages2.3 Diesel CycleSan Jose, Kyla Mae M.No ratings yet

- 2 Pure Substance PDFDocument17 pages2 Pure Substance PDFalamzaibkhanNo ratings yet

- Platform Design GuidelinesDocument89 pagesPlatform Design Guidelinespandi muthuppandiNo ratings yet

- Experiment - 6: Cascade ControlDocument13 pagesExperiment - 6: Cascade ControlMilan PoudelNo ratings yet

- HysteresisModels OTANIDocument57 pagesHysteresisModels OTANImancas50No ratings yet

- Netzsch-ARC en Web PDFDocument20 pagesNetzsch-ARC en Web PDFdarksideministryNo ratings yet

- (Phd124) Uitm Pp/Fakulti Farmasi Questions On Chapter 8 - Phase EquilibriumDocument3 pages(Phd124) Uitm Pp/Fakulti Farmasi Questions On Chapter 8 - Phase EquilibriumIZZAN IZALIA MAHZANNo ratings yet

- Simulating Coastal Morphodynamics With Delft3D: Case Study Egmond Aan ZeeDocument78 pagesSimulating Coastal Morphodynamics With Delft3D: Case Study Egmond Aan ZeeAli MezaalNo ratings yet

- Finals Quiz 1 Soil MechanicsDocument2 pagesFinals Quiz 1 Soil MechanicsJefrey DeleonNo ratings yet

- HVAC Handbook New Edition Part 4 Refrigerant Brines OilsDocument71 pagesHVAC Handbook New Edition Part 4 Refrigerant Brines OilsShakir Ahmed Kalkundri100% (3)

- ME 401 Applied Thermodynamics-Problems PDFDocument5 pagesME 401 Applied Thermodynamics-Problems PDFVikasKumarSharmaNo ratings yet

- International Journal of Heat and Mass Transfer: B.S. Bhadauria, Atul K. SrivastavaDocument9 pagesInternational Journal of Heat and Mass Transfer: B.S. Bhadauria, Atul K. SrivastavaNabihah HusnaNo ratings yet

- EXPT 4 HEAT of COMBUSTIONDocument3 pagesEXPT 4 HEAT of COMBUSTIONBeatrice BenoliraoNo ratings yet

- WRC 297 Vs WRC 107Document2 pagesWRC 297 Vs WRC 107Rakesh100% (2)