Tap Technical Data

Uploaded by

Chikondi KanamaTap Technical Data

Uploaded by

Chikondi KanamaTAP TECHNICAL DATA

TAP

TYPICAL PHYSICAL PROPERTIES RECOMMENDED ALTERNATIVE

TAP TYPE TAP TYPE * TAP

PERIPHERAL

TYPE GRADE LUBRICANTS

HARDNESS TONS PER SPEED

N/mm² THROUGH BLIND THROUGH BLIND

BRINELL SQ INCH m/min

HOLE HOLE HOLE HOLE

FREE CUTTING 150 33 500 10-15

0.3 to 0.4% Carbon 170 38 570

CARBON Gun Spiral Straight Straight 8-12 Sulphur

0.3 to 0.4% Carbon 248 54 800

STEEL Nose Flute Flute Flute based oil

T E C H N I CAL DATA ALLOY

STEEL

0.4 to 0.7% Carbon

0.4 to 0.7% Carbon

Tough

206

286

248

330

44

63

54

74

650

95

810

1100

Gun

Nose

Spiral

Flute

Straight

Flute

Straight

Flute

8-10

8-12

Sulphur

based oil

Hard 380 82 1250

CBA TAP TECHNICAL DATA Martensitic Free Cutting

248 54 810

Martensitic Std. Grade Heavy duty

SPEED M/MIN TAP TYPE STAINLESS Gun Spiral Straight Straight

TENSILE NORMAL 2-6 Sulphur

HARDNESS STEEL Nose Flute Flute Flute

STRENGTH Austenitic Free Cutting based oil

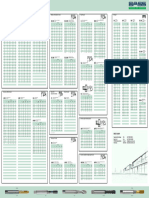

MATERIAL TYPES CHIP RED BLUE YELLOW WHITE GREEN As Supplied

HB (N/mm²) UNCOATED COATED

FORM BAND BAND BAND BAND BAND Austenitic Std. Grade

Free Cutting steels #120 #400 extra long 12 18 - 27

X NIMONIC

ALLOYS

Wrought 300 67 1000

See CBA Tap section 2-4

Chlorinated

oil

Structural steel. Case carburizing steel #200 #700 middle/long 12 18 - 27

X Cast 350 78 1170

STEEL

Plain Carbon steel #250 #850 long 10 18 - 24 X Titanium Comm: Pure

Titanium Comm: Pure

170

200

38

43

570

650

Alloy steel >250 #850 long 10 18 - 24

Titanium Comm: Pure 275 65 975 See CBA Tap section Chlorinated

TITANIUM 2-4

oil

Alloy steel. Hardened and tempered steel >250 >850 long 8 9 - 15 Titanium Alloyed 340 76 1140

#350 #1200

Titanium Alloyed 380 85 1275

Alloy steel. Hardened and tempered steel >350 >1200 long 5 9 -15

HSS Standard / Cobalt Grades 225 48 720

Free machining Stainless steel #250 #850 middle 9 18 - 24 X TOOL

STEEL

Gun

Nose

Spiral

Flute

Straight

Flute

Straight

Flute

8-10

Sulphur

based oil

STAINLESS Hot / Cold Working Steel 225 54 810

Austenitic #250 #850 long 6 9 - 15

STEEL

As Supplied Gun Straight Straight - Sulphur

Ferritic + Austenitic, Ferritic, Martensitic #300 #1000 long 5 8 - 15 MANGANESE STEEL Nose Flute Flute

15-20

based oil

Lamellar graphite #150 #500 extra short 11 18 - 27 X Grey

Ductile

240 52 780 5-10

Dry soluble

>150 >500 CAST Straight Straight Gun

CAST IRON

Lamellar graphite

#300 #1000

extra short 8 9 - 18

X IRONS

Maleable

Flute Flute Nose

- oil or

paraffin

330 74 1110 4-8

Nodular graphite, Malleable Cast Iron #200 #700 middle/short 11 18 - 27

X X Hardened & Tempered

Nodular graphite, Malleable Cast Iron >200 >700 Long Chip 20-25 Soluble oil

#300 #100

middle/short 8 9 - 18 ALUMINIUM As Supplied Gun Spiral

Fluteless Fluteless or light

ALLOYS Short Chip Nose Flute 10-15 material oil

Titanium, unalloyed # 200 #700 extra long 8 9 - 15

As Supplied Gun Spiral Straight Straight Sulphur

MANGANESE ALLOYS 15-20

TITANIUM Titanium, alloyed #270 #900 middle/short 9 12 - 18

X Nose Flute Flute

Straight

Flute

Straight

based oil

Soluble

>270 >900

Titanium, alloyed

#350 #1200

middle/short 6 6 - 12

X ZINC ALLOYS As Supplied Fluteless Fluteless

Flute Flute

15-20

oil

Nickel, unalloyed #150 #500 extra long 9 12 - 18

X Brass Free Cutting

Brass Low Lead Fluteless Fluteless

Straight Straight

15-20

25-30 Soluble oil

Flute Flute

NICKEL Nickel, alloyed #270 #900 long 5 6 - 12

X X Bronze Silicon 10-12 or light

mineral oil

>270 >900

Nickel, alloyed

#350 #1200

long 4 5 - 11

X Bronze Manganese

Gun

Nose

Straight

Flute

Straight

Flute

Straight

Flute

3-5

COPPER

Copper #100 #350 extra long 11 15 - 24 X ALLOYS

Copper Free Machining As Supplied

Fluteless Fluteless

Gun

Nose

Gun

Nose

15-20

Copper Electrolytic 8-12

COPPER

Beta Brass, Bronze #200 #700 middle/short 30 43 - 55 X X Chlorinated

oil or soluble

oil

Bronze Aluminium 10-12

Alpha Brass #200 #700 long 18 40 - 49

X Bronze Commercial Gun Straight Straight Straight 3-5

High strength Bronze #470 #1500 short 5 6 - 12 Nose Flute Flute Flute

Soluble oil or

Bronze Phosphor 3-5

light mineral oil

Al, Mg, unalloyed #100 #350 extra long 15 24 - 30 X Soft 4-7

ALUMINIUM Al alloyed Si < 0.5% #150 #500 middle 30 43 - 52 X PLASTICS Hard

As Supplied Straight

Flute

Straight

Flute

Gun

Nose

- Dry

MAGNESIUM

Al alloyed, Si > 0.5% < 10% #120 #400 middle/short 18 30 - 36 X X Reinforced

12-15

Al alloyed, Si > 10%, Al-alloys, Mg-alloys #120 #400 short 15 24 - 30 X X * Tapping speeds for fluteless taps are 2-3 times higher then the recommended speeds given

Thermoplastics - - extra long 27 -

X

SYNTHETIC

MATERIALS

Thermosetting plastics - - short 11 15 - 21

X

Reinforced plastic materials - - extra short 8 9 - 15

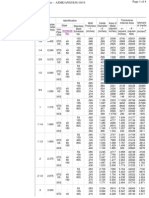

X TAP TERMINOLOGY THREAD FORMS TAP PERIPHERAL SPEED TO rpm CONVERSION CHART

Metres/Min 4 6 8 9 10 12 15 18 21 25 27 30 36

SIZE OF SQUARE 60°

ACROSS FLATS Tap Size

REVOLUTIONS PER MINUTE

mm inch

FLAT

LENGTH

RECOMMENDED DRILL SIZES FOR TAPPING TAPPING PROBLEMS: CAUSES AND SOLUTIONS B B

1.6 1/16 800 1194 1592 1791 1988 2386 2983 3579 4176 4971 5369 5965 7158

1.8 708 1065 1415 1598 1768 2121 2652 3182 3712 4419 4773 5303 6364

METRIC AND UNIFIED

SIZE | NOMINAL Pitch DRILL SIZE SIZE | NOMINAL Pitch DRILL SIZE SIZE | NOMINAL Pitch DRILL SIZE Damaged tap threads in the hole (e) Possible Cause 2 637 955 1274 1433 1591 1909 2386 2863 3341 3977 4295 4773 5727

SECTION B-B

DIAMETER TPI IN mm DIAMETER TPI IN mm DIAMETER TPI IN mm (a) Possible Cause The drilled hole is too small. 2.2 3/32 579 869 1158 1303 1446 1736 2169 2603 3037 3616 3905 4339 5207

Mis-alignment of the tap with the hole. Solution 55° 2.5 510 764 1019 1147 1274 1527 1909 2291 2673 3182 3436 3818 4582

LAND

Solution Use the recommended drill size. 3 1/8 425 637 849 955 1061 1273 1591 1909 2227 2651 2864 3182 3818

METRIC COARSE * Fluteless Tapping Drill Sizes

Care must be taken to align the tap with the hole 3.5 364 546 728 819 909 1091 1364 1636 1909 2273 2455 2727 3273

M1 0.25 0.75 (0.9*) M7 1 6 M27 3 24 (25.5*) before starting to tap. Over-Heating of tap SHANK FLUTE CUTTING 4 5/32 318 478 637 718 796 955 1193 1432 1671 1989 2148 2387 2864

M1.2 0.25 0.95 (1.1*) M8 1.25 6.8 (7.4*) M30 3.5 26.5 (28.2*) (b) Possible Cause (a) Possible Cause DIAMETER FACE 4.5 283 425 566 637 707 849 1061 1273 1485 1768 1909 2122 2546

OVERALL LENGTH

M1.4 0.3 1.1 (1.27*) M9 1.25 7.8 M32 3.5 28.5 The tap is too dull Lack of/or the wrong type of lubricant. BSW 5 3/16 255 382 510 573 637 764 955 1146 1337 1591 1719 1909 2292

M1.6 0.35 1.25 (1.45*) M10 1.5 8.5 (9.3*) M33 3.5 29.5 (31.2*) Solution Solution 6 1/4 212 319 425 477 530 636 795 954 1113 1326 1432 1592 1909

Use a tap which is in good condition. Apply an adequate supply and the correct type of WEB

M2 0.4 1.6 (1.85*) M11 1.5 9.5 M36 4 32 (33.9*) THICKNESS 7 9/32 182 273 364 409 455 546 682 818 955 1136 1227 1364 1636

M2.5 0.45 2.05 (2.3*) M12 1.75 10.2 (11.2*) M39 4 35 (36.9*) (c) Possible Cause lubricant to the cutting area. 47½°

SECTION A-A 8 5/16 159 239 319 358 398 477 597 716 835 994 1074 1193 1432

M3 0.5 2.5 (2.8*) M14 2 12 (13*) M42 4.5 37.5 (39.6*) Work hardened skin in the drilled hole. (b) Possible Cause

9 142 212 283 318 354 425 531 637 742 885 955 1061 1293

M3.5 0.6 2.9 (3.2*) M16 2 14 (15*) M45 4.5 40.5 (42.6*) Solution The tap is too dull.

Work hardening can be avoided when drilling by Solution 10 3/8 127 191 255 286 318 382 477 573 668 795 859 955 1146

M4 0.7 3.3 (3.7*) M18 2.5 15.5 (16.8*) M48 5 43 11 116 174 232 260 289 347 434 868 1041

using the correct speeds, and coolants. Use serial Use a tap which is in good condition. 521 608 723 781

M4.5 0.75 3.7 (4.2*) M20 2.5 17.5 (18.8*) M52 5 47

taps. (c) Possible Cause 12 1/2 106 159 212 238 265 318 398 477 557 663 716 796 955

M5 0.8 4.2 (4.65*) M22 2.5 19.5 (20.8*) M56 5.5 50.5 p BA 13 98 147 196 220 245 294 367 441 514 612 661 734 881

THREAD LENGTH

M6 1 5 (5.55*) M24 3 21 (22.5*) (d) Possible Cause Using the incorrect tap.

Incorrect rake angle Solution 14 9/16 91 136 182 205 277 273 341 409 477 568 614 682 818

A A 30°

METRIC FINE * Fluteless Tapping Drill Sizes Solution Use the recommended tap. 16 5/8 80 119 159 179 199 239 298 358 418 497 537 597 716

Use the recommended tap for the material. (d) Possible Cause 18 71 106 141 159 177 212 265 318 371 442 477 530 636

MF2 0.25 1.75 MF12 1.25 10.75 (11.45*) MF27 2

CHAMFER

25 Excessive tapping speed is applied. 20 3/4 64 96 127 143 159 191 239 286 334 398 430 477 573

MF2.5 0.35 2.15 MF12 1.5 10.5 (11.3*) MF30 1.5 28.5 Poor finish of the thread Solution n 22 7/8 58 87 116 130 145 174 217 260 304 362 391 434 521

LEAD

MF3 0.35 2.65 MF14 1.25 12.75 (13.4*) MF30 2 28 (a) Possible Cause Use the recommended tapping speed. 24 1" 53 80 106 119 133 159 199 239 275 331 353 398 477

MF3.5 0.35 3.15 MF14 1.5 12.5 (13.3*) MF32 1.5 30.5 Using the incorrect tap. TRAPEZOIDAL 27 47 71 94 106 118 141 177 212 245 295 318 354 424

MF4 0.5 3.5 MF16 1 15 MF33 1.5 31.5 Solution Over-size tapped hole 30 1.1/8 43 64 85 95 106 127 159 191 223 265 286 318 382

MF4.5 0.5 4 MF16 1.5 14.5 (15.3*) MF36 1.5 34.5 Use the recommended tap. (a) Possible Cause 29° 33 1.1/4 39 58 77 87 96 116 145 174 203 241 360 289 347

MF5 0.5 4.5 MF18 1.5 16.5 (17.3*) MF36 2 34 (b) Possible Cause Using the incorrect tap. NOMINAL 36 35 53 71 80 88 106 133 159 186 221 239 265 318

MF6 0.5 5.5 MF18 2 16 MF39 1.5 37.5 The drilled hole is too small. Solution DIAMETER LEAD 39 1.1/2 33 49 73 98 245 294

65 82 122 147 171 204 220

MF6 0.75 5.25 MF20 1.5 18.5 (19.3*) MF40 1.5 38.5 Solution Use the recommended tap. ANGLE

ROOT p = PITCH 42 30 46 61 68 76 91 114 186 159 189 205 227 273

MF7 0.75 6.25 MF20 2 18 MF42 1.5 40.5 Use the recommended drill size. (b) Possible Cause DIAMETER

(c) Possible Cause Mis-alignment of the tap with the hole. n = No. OF THREADS 45 1.3/4 28 42 57 64 71 85 106 127 149 177 191 212 255

MF8 0.75 7.25 MF22 1.5 20.5 (21.3*) MF45 1.5 43.5 ACME

The tap is too dull. Solution

PER INCH 48 27 40 53 60 66 80 99 119 139 166 179 199 239

MF8 1 7 (7.55*) MF22 2 20 MF48 1.5 46.5

Solution Care must be taken to align the tap with the hole 52 24 37 49 55 61 73 92 110 129 153 165 184 220

MF9 1 8 MF24 1.5 22.5 (23.3*) MF50 1.5 48.5

MF10 1 9 (9.55*) MF24 2 22 MF52 1.5 50.5 Use a tap which is in good condition. before starting to tap. Abbreviations for Standard Thread Forms 56 2" 23 34 46 51 57 68 85 102 119 142 153 170 205

MF10 1.25 8.75 (9.45*) MF25 1.5 23.5 (d) Possible Cause (c) Possible Cause BA - British Association BSF - British Standard Whitworth Fine NPS - National Pipe Straight

MF12 1 11 (11.55*) MF25 2 23 Insufficient number of threads on the lead. Lack of/or the wrong type of lubricant. BSB - British Standard Brass BSW - British Standard Whitworth NPT - National Pipe Taper FORMULA FOR CALCULATING rpm

Solution Solution BSP - British Standard Pipe (Fine) "G" Series M - Metric Coarse UNC - Unified National Coarse Dia (mm) x p

BSW Use a tap with the correct lead. Apply an adequate supply and the correct type of BSPT - British Standard Pipe Taper ("Rc" Series) MF - Metric Fine UNF - Unified National Fine rpm = Surface Speed (metres/min) ÷

1000

(e) Possible Cause lubricant to the cutting area.

3/32 48 1.9 3/8 16 8 1" 8 22 Mis-alignment of the tap with the hole. (d) Possible Cause

1/8 40 2.55 7/16 14 9.3 1.1/8 7 25 Solution Incorrect rake angle.

5/32 32 3.2 1/2 12 10.5 1.1/4 7 28 Care must be taken to align the tap with the hole Solution

3/16 24 3.7 9/16 12 12.2 1.1/2 6 34 before starting to tap. Use the recommended tap for the material.

7/32 24 4.5 5/8 11 13.5 1.3/4 5 39 (f) Possible Cause

1/4 20 5.1 3/4 10 16.5 2” 4.5 45 Incorrect rake angle Tap binding in the hole

5/16 18 6.5 7/8 9 19.5 Solution (a) Possible Cause MAIN TYPES OF TAPS AND THEIR USES

Use the recommended tap for the material. Using the incorrect tap.

BSF Solution Short Hand Taps Spiral Flute Tap such as aluminium and zinc alloys as the threads are cold formed, not cut like

3/16 32 4 7/16 18 9.8 7/8 11 19.5 Torn threads in the tapped hole Use the recommended tap. a conventional tap. For slightly tougher materials fluteless taps in the range of

7/32 28 4.7 1/2 16 11 1" 10 22.5 (a) Possible Cause (b) Possible Cause 5mm to 12mm can be supplied with a gash.

1/4 26 5.4 9/16 16 12.7 1.1/8 9 25.5 The flutes are clogged by chips. The drilled hole is too small.

5/16 22 6.8 5/8 14 14 1.1/4 9 29 Solution Solution These taps are designed for machine tapping in ductile materials, “Fluteless”

3/8 20 8.3 3/4 12 16.5 1.1/2 8 34.5 Use a spiral point or a spiral flute tap. Use the recommended drill size. taps have no flutes or cutting faces, but have special roll forming lobes with

(b) Possible Cause (c) Possible Cause This regular type is the basic tap designed as a general purpose tool for hand circular lands and have long or short taper leads for through or blind holes.

UNC Distortion of the walls in a thin walled workpiece. Lack of/or the wrong type of lubricant. and machine operation. As this basic tap will give acceptable performance in

Solution Solution most materials and for short production runs, it is usually the most Blue Band

No.3 2.51 48 2 5/16 18 6.6 1" 8 22 Use a multi-fluted tap. Apply an adequate supply and the correct type of

7 economical tap to use. However, it performs best in materials where the Mainly for work in blind holes and on ductile materials, such as aluminium and

No.4 2.84 40 2.25 3/8 16 8 1.1/8 25 (c) Possible Cause lubricant to the cutting area. cutting action results in chips which break up readily and do not present zinc alloys, which produce long stringy chips. The taps have a 15° or 35° right

No.5 3.18 40 2.6 7/16 14 9.4 1.1/4 7 28 The threads on the tap are broken. (d) Possible Cause problems of chip disposal. hand helix. The flute shape eliminates clogging and jamming, resulting in

No.6 3.51 32 2.75 1/2 13 10.8 1.3/8 6 31 Solution The flutes are clogged with chips. improved tap life.

No.8 4.17 32 3.4 9/16 12 12.2 1.1/2 6 34 Use a tap which is in good condition. Solution The regular hand tap has four flutes in sizes larger than 1/4 inch diameter.

No.10 4.83 24 3.8 5/8 11 13.5 1.3/4 5 39 (d) Possible Cause Use a spiral point or a spiral flute tap. These taps may not be suitable because of inadequate chip space when These taps are designed primarily for machine tapping of blind holes, are

No.12 5.49 24 4.4 3/4 10 16.5 2” 4.5 45 Lack of/or the wrong type of lubricant. (e) Possible Cause deep or blind holes have to be tapped in soft stringy materials. This applies used to the best advantage in materials which produce long stringy chips. The Designed for tough materials, such as Stainless Steel, Titanium Alloys, Cast

1/4 20 5.1 7/8 9 19.5 Solution Incorrect rake angle. particularly to the coarser pitch threads such as BSW and UNC. If a gun tap shearing action provided by the spiral flutes produces a better finish on Steel, Heat Resisting Steel and Work Hardening Steel. Used to tap materials

Apply an adequate supply and the correct type of Solution or spiral fluted tap cannot be used, a three fluted tap which permits extra chip difficult to machine metals and causes the chips to be drawn back, eliminating with hardness up to 350HB, tensile strength up to 1250N/mm².

UNF lubricant to the cutting area. Use the recommended tap for the material. space, is recommended. clogging at the cutting chamfer.

(e) Possible Cause Truncated thread after lead reduces frictional contact with the threaded hole

No.3 2.51 56 2.1 1/4 28 5.5 7/8 14 20.5

Using the incorrect or unsuitable tap for the Flutes clogged with chips and allows easier penetration of coolant. Spiral flute taps have 40° right hand

No.4 2.84 48 2.35 5/16 24 6.9 1" 12 23.5 material. (a) Possible Cause

No.5 3.18 44 2.65 3/8 24 8.5 1.1/8 12 26.5 Serial Hand Taps Pipe Taps helix allowing tough material swarf to be efficiently removed from the hole.

Solution Using the incorrect tap. Supplied as standard with TiAIN coating.

No.6 3.51 40 2.9 7/16 20 9.8 1.1/4 12 29.5 Use the recommended tap for the material. Solution

No.8 4.17 36 3.5 1/2 20 11.5 1.3/8 12 32.5 (f) Possible Cause Use a spiral point or spiral flute tap.

No.10 4.83 32 4.1 9/16 18 12.8 1.1/2 12 36 Rougher Green Band

Tap hitting the bottom of the hole. (b) Possible Cause

No.12 5.49 28 4.6 5/8 18 14.5 Solution Lack of/or the wrong type of lubricant.

3/16 32 4 3/4 16 17.5 Allow sufficient clearance at the bottom of the Solution For machine use on pipe work for parallel threads.

hole. Apply an adequate supply and the correct type of

BSP (g) Possible Cause lubricant to the cutting area.

Intermediate

1/8 28 8.8 5/8 14 21 1.1/4 11 40 Incorrect rake angle.

1/4 19 11.8 3/4 14 24.5 1.1/2 11 45.5 Solution Tap Breakage

3/8 19 15.5 7/8 14 28.5 1.3/4 11 51.5 Use the recommended tap for the material. (a) Possible Cause

1/2 14 19 1” 11 31 2” 11 57 Using the incorrect tap. For machine use on pipe work for tapered threads. The machinebility of different steels is just as varied as their properties. Soft-

Excessive Tap Wear Solution Finisher tough construction steels place completely different demands on the tools,

BSPT (a) Possible Cause Use the recommended tap. Pipe taps are supplied with PARALLEL threads or with TAPER threads. These and the green band combination of taps has been perfected for this range of

Mis-alignment of the tap with the hole. (b) Possible Cause taps are shorter than a similar size of regular hand tap, but the design steels.

1/8 28 8.6 1/2 14 18.5 1.1/4 11 39 Solution The tap is too dull.

1/4 19 11.5 3/4 14 24 1.1/2 11 45 Serial taps comprise of one or more undersized roughing taps which remove features are the same. They are suitable for hand or machine use.

Care must be taken to align the tap with the hole Solution most of the material before final sizing with a finishing tap. Green Band characteristics include ability to machine materials with hardness

3/8 19 15 1” 11 30.25 2” 11 56.5 before starting to tap. Use a tap which is in good condition. up to 250HB, tensile strength up to 900N/mm². Surface finish - TiN Coating

(b) Possible Cause (c) Possible Cause

NPS Lack of/or the wrong type of lubricant. The drilled hole is too small.

Some reasons for using serial taps are: Colour Band Application (CBA) Taps (standard) increases surface hardness of the tool to around 85RC, with

(a) The toughness of the material being tapped. The primary benefit of the CBA range is enhanced threading performance due excellent resistance to abrasion and cold welding. Thread and flute

1/8 27 9.1 1/2 14 19 1.1/4 11.5 39.4 Solution Solution (b) The amount of material to be removed could cause swarf choking with a to geometry designed for specific material application groups. The result is an configuration design for free cutting and structural steels in the general

1/4 18 12 3/4 14 24.5 1.1/2 11.5 45.5 Apply an adequate supply and the correct type of Use the recommended drill size. single tap. improved quality of finish and an increased number of holes per tap, giving purpose range of medium tensile strengths.

3/8 18 15.5 1" 11.5 30.5 2” 11.5 57.5 lubricant to the cutting area. (d) Possible Cause (c) The very small tolerance on pitch diameter. extended tap life and reduced cost per hole. Manufactured from HSSE-V3

(c) Possible Cause The drilled hole is too shallow. (d) An extremely good finish required. steel (High Vanadium) for greater wear resistance. Red Band

NPT The material is abrasive. Solution

Solution Allow clearance at the bottom of the hole when Yellow Band

1/8 27 8.4 1/2 14 17.5 1.1/4 11.5 37.5 (i) Use the correct type of tap. drilling.

1/4 18 11 3/4 14 23 1.1/2 11.5 43.5 Short MachineTaps

(ii) Use a surface treated tap. (e) Possible Cause

3/8 18 14.25 1” 11.5 29 2” 11.5 55.5 (d) Possible Cause Mis-alignment of the tap with the hole. Gun Nose (Spiral Point) Tap

Using the incorrect tap. Solution

BA Solution Care must be taken to align the tap with the hole Designed for high tensile materials such as Tool Steels, Heat Treatable

12 1.3 90.1 1.05 7 2.5 52.9 2.05 3 4.1 34.8 3.4 (i) Use a tap with the correct lead. before starting to tap. Steels, Spring Steel, Case Hardening Steel, Unalloyed Titanium, Nitriding

10 1.7 72.6 1.4 6 2.8 47.9 2.3 2 4.7 31.3 3.9 (ii) Use a surface treated tap. (f) Possible Cause For machine use on through holes. Suitable for a wide range of materials. Designed for more ductile materials such as Aluminium, Magnesium Alloys, Steel, Cold Drawn Constructional Steel and High Tensile Steel.

9 1.9 65.1 1.55 5 3.2 43.1 2.65 1 5.3 28.2 4.5 (e) Possible Cause The flutes are clogged with chips. The gun nose creates chip disposal ahead of the tap while the flute geometry Soft Brass (MS58), Plastics, Zinc Alloys and Copper. Used to tap materials

8 2.2 59.1 1.8 4 3.6 38.3 3 0 6 25.4 5.1 Incorrect rake angle Solution allows an adequate supply of lubricant to the cutting area, making higher with hardness up to 200HB, tensile strength up to 700N/mm². Used to tap materials with hardness up to 470HB, tensile strength up to

Solution Use a spiral point or spiral flute tap. tapping speed possible. 1500N/mm². Spiral flute taps have 15° right hand helix which efficiently forces

Use the recommended tap for the material. (g) Possible Cause Wide flutes allow more efficient swarf removal which prevents clogging and high tensile material swarf up out of the hole, while still maintaining correct

Excessive tapping speed is applied. Gun nose taps have straight flutes supplemented by angular cutting faces at excessive torque. High rake angle improves shear characteristic and reduces cutting geometry. The red band tap is supplied as standard with TiAlN coating.

Bell-Mouthed Tapped Hole Solution the point. These faces cut with a shearing action which propels the chips build-up on the cutting edge, allowing tap to cut more freely for longer periods.

(a) Possible Cause Use the recommended tapping speed. ahead of the tap leaving the flutes clear for the free flow of coolant to the Spiral flute taps have 40° right hand helix, allowing ductile material swarf to be White Band

Mis-alignment of the tap with the hole. (h) Possible Cause point. efficiently forced out of the hole. The yellow band tap is supplied as standard

Solution The tap holding device is not suitable. in bright condition.

Care must be taken to align the tap with the hole Solution Primarily designed for use in through holes, these taps can be used in blind

before starting to tap. Use the appropriate tapping attachment. holes providing that there is ample clearance beyond the threaded section to Yellow Band Fluteless Taps Designed for highly abrasive materials such as Cast Iron and reinforced

(b) Possible Cause (i) Possible Cause accommodate the chips. The advantages of a gun nose tap are, the shearing plastics. Used to tap materials with hardness up to 300HB, tensile strength up

The workpiece is not rigidly held. The work material is work hardened. action of the angular cutting faces which produce a fine finish on the threads to 1000N/mm². Increased number of flutes reduces torque and increases tap

Solution Solution and, shallower flutes which permit a stronger cross section throughout the life. Taps have 15° right hand helix. The white band tap is TiAlN coated as

Secure the workpiece Use serial taps. tap. For machine use on through or blind holes. Best suited for ductile materials, standard.

(c) Possible Cause (j) Possible Cause

Excessive pressure is applied when starting to tap. Lack of/or the wrong type of lubricant.

Solution Solution

Only sufficient pressure to initiate self-feeding Apply an adequate supply and the correct type of

should be applied. lubricant to the chamfer lead of the tap.

(d) Possible Cause (k) Possible Cause

Insufficient number of threads on the lead. Incorrect rake angle.

Solution Solution

Use a tap with the correct lead. Use the recommended tap for the material.

Manufacturers & Suppliers of Drills, Reamers, End

Mills, Bore Cutters, Taps & Dies, Toolbits, Solid Carbide

Tooling, Carbide Insert Tooling, Custom Tools & Surface Coatings

Tel: Sales: +27 11 390 8700 (Local) • Fax: Sales: +27 11 397 6720/1 (Local) • Email: jhbsales@somta.co.za

Tel: Sales: +27 33 355 6600 (Export) • Fax: Sales: +27 33 394 7509 (Export) • Email: exports@somta.co.za

http://app.somta.co.za Technical information E-mail: tech@somta.co.za • Toll Free Number: 0800 331 399

You might also like

- 3408C & 3412C Electrical System Marine Auxillary Generator Set100% (1)3408C & 3412C Electrical System Marine Auxillary Generator Set2 pages

- TS 01878 - 0.00 - Precast Reinforced Concrete Pile - Hard Driving ConditionsNo ratings yetTS 01878 - 0.00 - Precast Reinforced Concrete Pile - Hard Driving Conditions1 page

- CFW500 Frequency Inverter Installation GuideNo ratings yetCFW500 Frequency Inverter Installation Guide12 pages

- 127-CIV-BRT-TD-202-REV01 (TRAFFIC SIGNAL PLANS) - SHT 2 - SgndABNo ratings yet127-CIV-BRT-TD-202-REV01 (TRAFFIC SIGNAL PLANS) - SHT 2 - SgndAB1 page

- NCAB Design Guidelines FlexRigid 1 2 231221No ratings yetNCAB Design Guidelines FlexRigid 1 2 2312211 page

- Aluminum Coping and Waterproofing DetailsNo ratings yetAluminum Coping and Waterproofing Details1 page

- Aal00 C37369 100 y Dyt 0001 02 - 1 - Ifp - 2024 02 01 - 01No ratings yetAal00 C37369 100 y Dyt 0001 02 - 1 - Ifp - 2024 02 01 - 011 page

- A B C D E F B' B'' C' C'' D' D'' E' A'' A': Reflected Ceiling PlanNo ratings yetA B C D E F B' B'' C' C'' D' D'' E' A'' A': Reflected Ceiling Plan13 pages

- QCNA Tech Scope Drawings - 02.27.2025-39No ratings yetQCNA Tech Scope Drawings - 02.27.2025-391 page

- 07 152502 4800000647 RTC STR DRG 040012 - BNo ratings yet07 152502 4800000647 RTC STR DRG 040012 - B1 page

- TS 01880 - 0.00 - Precast Prestressed Reinforced Concrete Pile - Normal Driving ConditionNo ratings yetTS 01880 - 0.00 - Precast Prestressed Reinforced Concrete Pile - Normal Driving Condition1 page

- C15 and C18 Electrical System Industrial and Petroleum Engine0% (1)C15 and C18 Electrical System Industrial and Petroleum Engine4 pages

- STR - 670 GB - Rev-3-Rvt (Edicion para Rev 3) - MariaNo ratings yetSTR - 670 GB - Rev-3-Rvt (Edicion para Rev 3) - Maria17 pages

- Electrical System With EMCP 3 C9 Generator Set: Engine Top ViewNo ratings yetElectrical System With EMCP 3 C9 Generator Set: Engine Top View2 pages

- Graphic Design Rates Master Sheet - DataNo ratings yetGraphic Design Rates Master Sheet - Data12 pages

- 13 The Specific Heat Capacities of GasesNo ratings yet13 The Specific Heat Capacities of Gases2 pages

- E D BS Cable-Size-Chart REBRAND-2024 V1.1No ratings yetE D BS Cable-Size-Chart REBRAND-2024 V1.11 page

- Application of Charts, Graphs and BS en - Pin and Cable SizeNo ratings yetApplication of Charts, Graphs and BS en - Pin and Cable Size3 pages

- Biomass Dominates in The Energy Mix For MalawiNo ratings yetBiomass Dominates in The Energy Mix For Malawi5 pages

- Emmie Mvalo - Swot Analysis For Organisational CompetitivenessNo ratings yetEmmie Mvalo - Swot Analysis For Organisational Competitiveness6 pages

- E. Mvalo - Jack Welch - Five Applicable PrinciplesNo ratings yetE. Mvalo - Jack Welch - Five Applicable Principles4 pages

- A Semantic Analysis of Wedding Messages in Malawian SocietiesNo ratings yetA Semantic Analysis of Wedding Messages in Malawian Societies5 pages

- Chichewa - Dongosolo Loyenera Kutsata Musanalembe Chimangirizo100% (1)Chichewa - Dongosolo Loyenera Kutsata Musanalembe Chimangirizo4 pages

- Quality Assurance Plan for Steel ProjectNo ratings yetQuality Assurance Plan for Steel Project1 page

- Welding AISI 8630 to API X80: Cracking IssuesNo ratings yetWelding AISI 8630 to API X80: Cracking Issues18 pages

- Rencana Kerja Konstruksi Gudang PLTP PatuhaNo ratings yetRencana Kerja Konstruksi Gudang PLTP Patuha1 page

- Ni-based Barriers in Ferritic Steel JointsNo ratings yetNi-based Barriers in Ferritic Steel Joints9 pages

- Communicative English 2 DUE 3012 Assignment: Introduction of AluminiumNo ratings yetCommunicative English 2 DUE 3012 Assignment: Introduction of Aluminium5 pages

- Understanding Tool Life and Taylor's EquationNo ratings yetUnderstanding Tool Life and Taylor's Equation9 pages

- Array Metal Catalogue - Cable Ladder-ACD-0118 (AL)No ratings yetArray Metal Catalogue - Cable Ladder-ACD-0118 (AL)53 pages

- Laser Welding Impact on Duplex Steel FatigueNo ratings yetLaser Welding Impact on Duplex Steel Fatigue10 pages