0% found this document useful (0 votes)

149 views2 pagesHL13

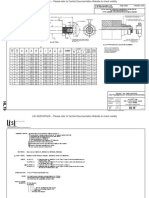

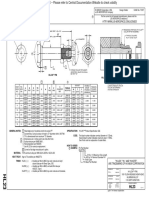

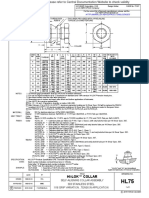

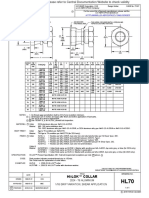

The document provides specifications and details for HI-LOK™ pins manufactured by Hi-Shear Corporation, including dimensions, materials, and coatings. It outlines general notes, ordering information, and various finish codes for the pins. For further details and validity, users are directed to the LISI AEROSPACE website.

Uploaded by

vracicotCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

149 views2 pagesHL13

The document provides specifications and details for HI-LOK™ pins manufactured by Hi-Shear Corporation, including dimensions, materials, and coatings. It outlines general notes, ordering information, and various finish codes for the pins. For further details and validity, users are directed to the LISI AEROSPACE website.

Uploaded by

vracicotCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd