Professional Documents

Culture Documents

HL70

Uploaded by

Renato WatanabeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HL70

Uploaded by

Renato WatanabeCopyright:

Available Formats

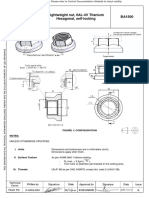

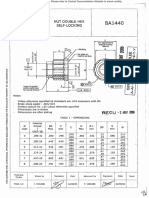

LISI AEROSPACE – Please refer to Central Documentation Website to check validity

HI-SHEAR Corporation, USA Design Holder CAGE No. 73197

S

AEROSPACE a LISI AEROSPACE Company

33 For the current list of licensed manufacturers, please visit the

LISI AEROSPACE website at:

hi-shear corporation

2600 SKYPARK DRIVE, TORRANCE, CALIFORNIA 90509 U.S.A. HTTP://WWW.LISI-AEROSPACE.COM/LICENSES

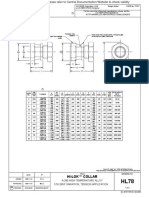

THREAD PER .020 WASHER THIS AREA PROVIDED WITH A PREVAILING

AS8879 THICKNESS (REF) TORQUE LOCKING FEATURE

A B A' P

33

DIA DIA A1 (REF)

DIA

(REF)

X X1

(REF) (REF)

W

L1 L2 HEX

(REF) (REF)

L L3

(REF)

33

DASH PIN A A' B L L1 L2 L3 P W X X1 UTS TORQUE-OFF

NO. NOM THREAD DIA A1 DIA (REF) (REF) (REF) (REF) HEX (REF) (REF) LBS. INCH-

DIA DIA MIN POUNDS

(REF)

.1640-32 .292 .173 .447 .314

5 5/32 UNJC-3B .337 .270 .300 .467 .344 .107 .137 1,400 15-25

.288 .166 .427 .302

.1900-32 .307 .200 .457 .314

6 3/16 UNJF-3B .360 .280 .310 .477 .344 .107 .137 1,600 25-35

.303 .192 .437 .302

.2500-28 .412 .261 .552 .346

8 1/4 UNJF-3B .462 .340 .370 .572 .380 .112 .142 3,000 60-80

.408 .252 .532 .332

.3125-24 .518 .325 .672 .440

10 5/16 UNJF-3B .575 .430 .460 .692 .484 .122 .152 5,000 130-160

.512 .314 .652 .425

.3750-24 .628 .388 .744 .503

12 3/8 UNJF-3B .690 .470 .500 .764 .557 .122 .152 7,000 200-240

.622 .376 .724 .488

.4375-20 .713 .450 .862 .565

14 7/16 UNJF-3B .770 .560 .590 .882 .624 .137 .167 9,500 270-330

.707 .442 .842 .550

.5000-20 .815 .513 .942 .690

16 1/2 UNJF-3B .872 .610 .640 .962 .763 .137 .167 12,500 370-430

.809 .501 .922 .675

.5625-18

18 9/16 UNJF-3B NOTE: USE HL79-18

.6250-18

20 5/8 UNJF-3B NOTE: USE HL79-20

.7500-16

24 3/4 UNJF-3B NOTE: USE HL79-24

28 7/8 .8750-14 NOTE: USE HL79-28

UNJF-3B

32 1 1.0000-12 NOTE: USE HL79-32

UNJF-3B

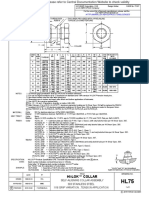

NOTES: 1. Go thread gage penetration shall be 3/4 of one revolution minimum.

33 2. Dimensions are in inches and apply after finish and before application of lubricants.

3. Use HL79 for oversize replacement.

33 4 Use TB286PY( )L for HL70K( ) thread lock inspection.

MATERIAL: 33 Collar 2024 aluminum alloy per AMS-QQ-A-225/6.

Washer NW - 300 series stainless steel.

TW - 5052 aluminum alloy per AMS-QQ-A-250/8, or 2024 aluminum alloy per AMS-QQ-A-250/4 or AMS-QQ-A-250/5.

HEAT TREAT: Collar Age to T6 condition per AMS2770.

Washer TW Age to T6 condition per AMS2770 (for 2024 only).

FINISH: 33 Collar HL70-( ) = Anodize per MIL-A-8625, dye color red, and cetyl alcohol lube per Hi-Shear Spec. 305.

HL70D( ) = Anodize per MIL-A-8625 and solid film lube per AS5272, Type I.

HL70K( ) = Anodize per MIL-A-8625 and solid film lube per "Lubeco" 905.

HL70TF( ) = Anodize per MIL-A-8625 and HI-KOTE™ 2 solid film lube per Hi-Shear Spec. 292.

HL70TT( ) = Anodize per MIL-A-8625, dye color red and translube.

Collar &

Washer HL70DTW( ) = Collar finish same as HL70D( ). Washer with anodize per MIL-A-8625, dye color grey, or blue (for 2024 only).

HL70NW( ) = Collar finish same as HL70-( ). Washer is passivated.

HL70TW( ) = Collar finish same as HL70-( ). Washer with anodize per MIL-A-8625, dye color grey, or blue (for 2024 only).

SPECIFICATION: HI-LOK™ Product Specification 345. Test bolt requirement exceptions per note 4 above. 33

CODE: Dash number indicates nominal thread size in 1/32nds.

See Finish note for explanation of code letters.

EXAMPLES: HL70-8 = .2500-28 HI-LOK™ collar.

HL70TW8 = .2500-28 HI-LOK™ collar with aluminum washer.

"HI-LOK" AND "HL" ARE INTERNATIONAL

REGISTERED TRADEMARKS OF HI-SHEAR CORPORATION

TITLE DRAWING NO.

DATE BY

HI-LOK™ COLLAR

HL70

DRAWN 1960-07-27 VAN

2024 - T6 ALUMINUM

APPROVED 1960-07-27 MEC

1/16 GRIP VARIATION, SHEAR APPLICATION

33 REVISION 2018-01-04 M.BEARD/S.WILEY 1 of 1

C 2018 Hi-Shear Corporation

You might also like

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrNo ratings yet

- Aircraft System 1 - Pneumatic SystemDocument14 pagesAircraft System 1 - Pneumatic SystemAndreas.G100% (1)

- CURVESDocument30 pagesCURVESPHULARAM PEGUNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Spring Support Data Sheet-Process AreaDocument1 pageSpring Support Data Sheet-Process AreaArash AghagolNo ratings yet

- NASM20426Document6 pagesNASM20426Konelek AeroNo ratings yet

- Isa 5 1 SymbolsDocument38 pagesIsa 5 1 SymbolsghadaNo ratings yet

- Mil PRF 87100a PDFDocument12 pagesMil PRF 87100a PDFNadia SalemNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- STS - Prelim Long QuizDocument1 pageSTS - Prelim Long QuizKent GallardoNo ratings yet

- Painting Procedure JotunDocument9 pagesPainting Procedure Jotunspazzbgt100% (2)

- Microservice PatternDocument1 pageMicroservice PatternHari Haran M100% (1)

- HL77Document1 pageHL77Renato WatanabeNo ratings yet

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: B DIA A DIA A1 DIA PDocument1 pageHi-Lok™ Collar: B DIA A DIA A1 DIA PRenato WatanabeNo ratings yet

- Hi-Lok™ Collar: B DIA A DIA A1 DIA PDocument1 pageHi-Lok™ Collar: B DIA A DIA A1 DIA PRenato WatanabeNo ratings yet

- HL379Document1 pageHL379Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- Pisco 2022Document11 pagesPisco 2022Gabriel RojasNo ratings yet

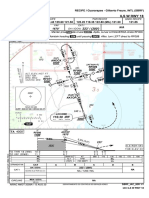

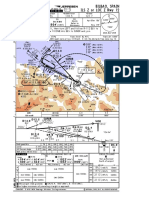

- SBRF Ils-W-Rwy-18 Iac 20200813Document1 pageSBRF Ils-W-Rwy-18 Iac 20200813Ricardo PalermoNo ratings yet

- SPSODocument9 pagesSPSOEO LozadiNo ratings yet

- TypeDocument1 pageTypeWaqas WaqasNo ratings yet

- Radiateur Cat 320c - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCDocument3 pagesRadiateur Cat 320c - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCMehdi ChakrouneNo ratings yet

- Scanning Area - Riso RZ3xx Series Technical Manual - Page 352 - ManualsLibDocument1 pageScanning Area - Riso RZ3xx Series Technical Manual - Page 352 - ManualsLiber nantoNo ratings yet

- Power Supply - Riso RZ3xx Series Technical Manual - Page 349 - ManualsLibDocument1 pagePower Supply - Riso RZ3xx Series Technical Manual - Page 349 - ManualsLiber nantoNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- SKSP PDFDocument1 pageSKSP PDFFabio BurgosNo ratings yet

- EB 06 LightingDocument45 pagesEB 06 LightingTamNo ratings yet

- Master Removal Area - Riso RZ3xx Series Technical Manual - Page 355 - ManualsLibDocument1 pageMaster Removal Area - Riso RZ3xx Series Technical Manual - Page 355 - ManualsLiber nantoNo ratings yet

- Print PDFDocument1 pagePrint PDFIvan Olmo ForniesNo ratings yet

- Saudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)Document1 pageSaudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)mmmNo ratings yet

- Main Components Area - Riso RZ3xx Series Technical Manual - Page 354 - ManualsLibDocument1 pageMain Components Area - Riso RZ3xx Series Technical Manual - Page 354 - ManualsLiber nantoNo ratings yet

- Fuji Frontier 355 375 Partslist PDFDocument185 pagesFuji Frontier 355 375 Partslist PDFЮрий ДмитриевNo ratings yet

- 2021-2022 Robonity eDocument35 pages2021-2022 Robonity eJ. S.No ratings yet

- Honda Beat Fi 2015Document66 pagesHonda Beat Fi 2015Adrian ZarateNo ratings yet

- Installation Testing ReportDocument1 pageInstallation Testing Reporteduardo rochaNo ratings yet

- Operation Panel Area - Riso RZ3xx Series Technical Manual - Page 356 - ManualsLibDocument1 pageOperation Panel Area - Riso RZ3xx Series Technical Manual - Page 356 - ManualsLiber nantoNo ratings yet

- Commscope RVVPX308.14R3Document1 pageCommscope RVVPX308.14R3blackcobrarockerulNo ratings yet

- Installation Testing ReportDocument1 pageInstallation Testing ReportKenneth PagalilawanNo ratings yet

- Installation Testing ReportDocument1 pageInstallation Testing ReportKenneth PagalilawanNo ratings yet

- Installation Testing ReportDocument1 pageInstallation Testing Reportyorktown gbaNo ratings yet

- Installation Testing ReportDocument1 pageInstallation Testing ReportmrsurantoNo ratings yet

- Installation Testing ReportDocument1 pageInstallation Testing ReportTee'Qae GeorgeNo ratings yet

- KM713018Document1 pageKM713018JavierRivasNeiraNo ratings yet

- ROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFDocument136 pagesROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFAob AprilNo ratings yet

- Ahw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Document6 pagesAhw 10 103500 Ea 3309 00053 0001 Noy0000y0812 CH 02Parag Lalit SoniNo ratings yet

- Airbus Aircraft Characteristics - A321 Ch.4Document33 pagesAirbus Aircraft Characteristics - A321 Ch.4andreijataNo ratings yet

- No Valido para Navegacion Real: AsemiDocument17 pagesNo Valido para Navegacion Real: AsemiNicolas OrtuosteNo ratings yet

- PP3 D714e4Document169 pagesPP3 D714e4Alvaro AlcaláNo ratings yet

- AtxDocument2 pagesAtxHatim AliNo ratings yet

- 2015 Catalog PreviewDocument31 pages2015 Catalog PreviewrandomNo ratings yet

- Irf540, Irf541, Irf542, Irf543, RF1S540, RF1S540SMDocument7 pagesIrf540, Irf541, Irf542, Irf543, RF1S540, RF1S540SMibnuNo ratings yet

- M-16.1 Control Air Dryer (Nihon Seiki) Finished PlanDocument6 pagesM-16.1 Control Air Dryer (Nihon Seiki) Finished Planpas87554No ratings yet

- RX & TX Field Valreg Preocedure V1: Arm TypeDocument5 pagesRX & TX Field Valreg Preocedure V1: Arm TypeJulio LiranzoNo ratings yet

- K81 PCDocument61 pagesK81 PCAhmad FirdausNo ratings yet

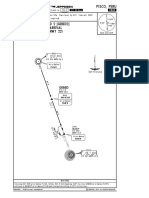

- Buenos Aires, Argentina Sabe/Aep Ilszrwy13: Muper D5.1 OmDocument1 pageBuenos Aires, Argentina Sabe/Aep Ilszrwy13: Muper D5.1 Omfrancisco buschiazzoNo ratings yet

- 1267-STR ModelDocument1 page1267-STR ModelJenna Mortel-DoligolNo ratings yet

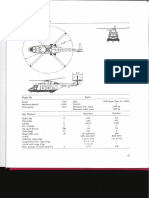

- Westland Model 30Document1 pageWestland Model 30Jurriën PltNo ratings yet

- Print Drum Area - Riso RZ3xx Series Technical Manual - Page 357 - ManualsLibDocument1 pagePrint Drum Area - Riso RZ3xx Series Technical Manual - Page 357 - ManualsLiber nantoNo ratings yet

- Master Making Area - Riso RZ3xx Series Technical Manual - Page 350 - ManualsLibDocument1 pageMaster Making Area - Riso RZ3xx Series Technical Manual - Page 350 - ManualsLiber nantoNo ratings yet

- Saudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)Document2 pagesSaudi Aramco Test Report: Radiography Interpretation (To Be Filled in by The Responsible RTFI)mmmNo ratings yet

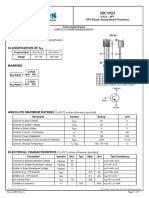

- 2SC1923Document1 page2SC1923Rey TiburonNo ratings yet

- List Part 550Document282 pagesList Part 550Marcos peralta peraltaNo ratings yet

- MES ST 1002 - SaddleDocument2 pagesMES ST 1002 - SaddleDarshan PanchalNo ratings yet

- Fuji Frontier 350 370 Parts List Fourth Edition PDFDocument173 pagesFuji Frontier 350 370 Parts List Fourth Edition PDFOMPRAKASH100% (2)

- 2018 Catalog E PDFDocument627 pages2018 Catalog E PDFpaulina rifaiNo ratings yet

- 40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesDocument1 page40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesRenato WatanabeNo ratings yet

- City of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyDocument1 pageCity of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyRenato WatanabeNo ratings yet

- Faa-Tso Authorized Part - .... - C........ : Afl (RDocument1 pageFaa-Tso Authorized Part - .... - C........ : Afl (RRenato WatanabeNo ratings yet

- Only Superior Casters Are Durable!Document2 pagesOnly Superior Casters Are Durable!Renato WatanabeNo ratings yet

- Faa-Tso Authorized 1s1 : 11unu, JLLJDocument3 pagesFaa-Tso Authorized 1s1 : 11unu, JLLJRenato WatanabeNo ratings yet

- Ms 16624Document11 pagesMs 16624Renato WatanabeNo ratings yet

- Hi-Loktm Collar: LISI AEROSPACE Website atDocument1 pageHi-Loktm Collar: LISI AEROSPACE Website atRenato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Nut, Double Hex, Self-Locking, Alloy Steel, Cadmium Plated and Dry Film Lubricant, Iso M, 1100 Mpa, 235°C Max. Page 1/3Document3 pagesNut, Double Hex, Self-Locking, Alloy Steel, Cadmium Plated and Dry Film Lubricant, Iso M, 1100 Mpa, 235°C Max. Page 1/3Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- MS14182B - Parafuso Cabeça EstriadaDocument3 pagesMS14182B - Parafuso Cabeça EstriadaRenato WatanabeNo ratings yet

- Lightweight Nut, 6AL-4V Titanium Hexagonal, Self-Locking BA1500Document6 pagesLightweight Nut, 6AL-4V Titanium Hexagonal, Self-Locking BA1500Renato WatanabeNo ratings yet

- Nut Double Hex Self-Locking: REPU-2AOUT2006Document3 pagesNut Double Hex Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Shank Nut Self-Locking: REPU-2AOUT2006Document3 pagesShank Nut Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Mathematics SSC-I SolutionDocument14 pagesMathematics SSC-I SolutionFaisal SamiNo ratings yet

- Mini Shear ManualDocument39 pagesMini Shear Manualhenry vegaNo ratings yet

- Skill Trees 1-6-23 (40594786)Document21 pagesSkill Trees 1-6-23 (40594786)Scribble StixNo ratings yet

- Simulation of Formaldehyde Production ProcessDocument10 pagesSimulation of Formaldehyde Production ProcessDoctorObermanNo ratings yet

- The Old Shop Houses As Part of Malaysian Urban Heritage The Current DilemmaDocument18 pagesThe Old Shop Houses As Part of Malaysian Urban Heritage The Current DilemmaBoon Kean100% (1)

- Brown Field TNO 0019 RevDocument2 pagesBrown Field TNO 0019 RevDaniele GouveiaNo ratings yet

- Main Duties and ResponsibilitiesDocument3 pagesMain Duties and ResponsibilitiessafiullahNo ratings yet

- QP - PDF Class XIth MathsDocument7 pagesQP - PDF Class XIth MathsSivakumar NairNo ratings yet

- 0607 s09 QP 2 PDFDocument8 pages0607 s09 QP 2 PDFJoseph ThanaNo ratings yet

- FUYP+RZP CieloDocument19 pagesFUYP+RZP CieloCarlos ManriquezNo ratings yet

- Code PtitDocument27 pagesCode Ptitđinh trungNo ratings yet

- Tutorial 06 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Document5 pagesTutorial 06 Questions With Possible Solutions: IS333: Project Management - Semester I 2021Chand DivneshNo ratings yet

- 12MMD24 - Dec 2013-Jan 2014 - Advanced Theory of VibrationsDocument2 pages12MMD24 - Dec 2013-Jan 2014 - Advanced Theory of VibrationsrajuNo ratings yet

- ART in AsiaDocument3 pagesART in AsiaMark Joseph Corum EsmenioNo ratings yet

- Stats 2022-2Document6 pagesStats 2022-2vinayakkNo ratings yet

- Lesson Plan - JobsDocument2 pagesLesson Plan - JobsMiska KubaščíkováNo ratings yet

- Rok 3lt enDocument2 pagesRok 3lt enJesus SanchezNo ratings yet

- 440 V AC Class: CapacitorsDocument2 pages440 V AC Class: CapacitorsIgor PNo ratings yet

- Assignment 2 Sem 1Document6 pagesAssignment 2 Sem 1d_systemsugandaNo ratings yet

- CV Career DubaiDocument5 pagesCV Career Dubairasik fareed Jafarulla khanNo ratings yet

- Dual-Phase PWM Controller With PWM-VID Reference: General Description FeaturesDocument21 pagesDual-Phase PWM Controller With PWM-VID Reference: General Description FeaturesДмитрий НичипоровичNo ratings yet

- A Survey On The Effects of Aggressive Marketing PRDocument4 pagesA Survey On The Effects of Aggressive Marketing PRROMEET PANIGRAHINo ratings yet

- An Introduction To Mathematical ReasoninDocument3 pagesAn Introduction To Mathematical ReasoninGero Nimo100% (1)

- Dbrac1120315 Ovm TMPLT Test Config 2751661Document42 pagesDbrac1120315 Ovm TMPLT Test Config 2751661ganesh_24No ratings yet