Professional Documents

Culture Documents

HL379

Uploaded by

Renato WatanabeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HL379

Uploaded by

Renato WatanabeCopyright:

Available Formats

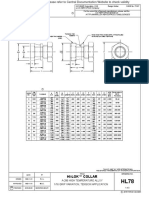

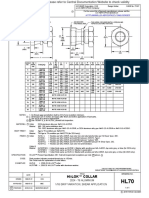

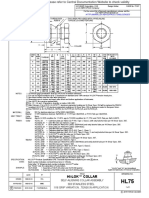

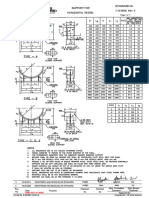

LISI AEROSPACE – Please refer to Central Documentation Website to check validity

HI-SHEAR Corporation, USA Design Holder CAGE No. 73197

S

AEROSPACE a LISI AEROSPACE Company

For the current list of licensed manufacturers, please visit the

LISI AEROSPACE website at:

hi-shear corporation

2600 SKYPARK DRIVE, TORRANCE, CALIFORNIA 90509 U.S.A.

HTTP://WWW.LISI-AEROSPACE.COM/LICENSES

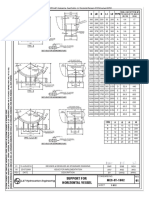

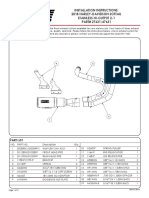

INDENTED IDENTIFICATION THREAD PER AS8879 THIS AREA PROVIDED WITH A

.010 MAXIMUM DEPTH PREVAILING TORQUE

.005 LOCKING FEATURE

.015 .010 THICK

RAD WASHER

379

A B A1

DIA DIA P

DIA

X X1

L1 W

L2

HEX

L

L3

FIRST PIN

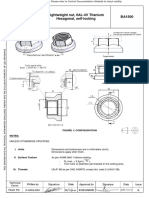

A A1 B L1 L2 L3 P W X X1 UTS TORQUE-

DASH NOM THREAD DIA DIA DIA

L MAX REF REF REF HEX REF REF

LBS. OFF

NO. DIA REF MIN IN-LBS

.1640-32 .287 .173 .447 .314

5 5/32 .325 .272 .290 .460 .344 .107 .125 2,300 15-25

UNJC-3B .283 .166 .427 .302

.1900-32 .307 .212 .457 .314

6 3/16 .345 .292 .295 .470 .344 .107 .125 2,750 22-32

UNJF-3B .303 .208 .437 .302

.2500-28 .412 .272 .552 .440

8 1/4 .450 .347 .360 .565 .484 .112 .130 5,000 50-70

UNJF-3B .408 .268 .532 .425

.3125-24 .518 .336 .672 .565

10 5/16 .560 .437 .460 .685 .624 .122 .145 8,300 80-110

UNJF-3B .512 .330 .652 .550

.3750-24 .620 .398 .744 .628

12 3/8 .670 .479 .500 .760 .700 .122 .150 12,700 140-180

UNJF-3B .614 .392 .724 .613

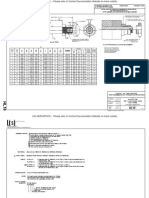

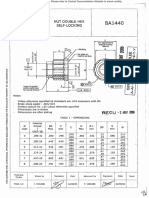

GENERAL NOTES: 1. Go thread gage penetration shall be 3/4 of one revolution minimum after thread lock.

2. Dimensions are in inches and to be met after finish and before application of lubricants.

3. Use the following test bolts for thread lock inspection:

TB64VF( )L for HL379-( ), HL379DL( ), HL379TA( ), and HL379V( ).

TB64EG( )L for HL379EG( ).

MATERIAL: Collar - 6Al-4V titanium alloy per AMS4928, AMS4930 or AMS4967 or

3Al-2.5V titanium alloy per AMS6940. 28

Washer - 300 series stainless steel.

FINISH: Collar HL379-( ) = Surface coating per Hi-Shear Spec. 306, Type II, and HI-KOTE™ 2 solid film

lube per Hi-Shear Spec. 292.

HL379DL( ) = Solid film lube per AS5272, Type I and cetyl alcohol lube per Hi-Shear Spec. 305.

HL379EG( ) = Solid film lubricant per Everlube 620C.

HL379TA( ) = Pretreat per Hi-Shear Ti-Shield III, HI-KOTE™ 2 solid film lube per Hi-Shear

Spec. 292, and cetyl alcohol lube per Hi-Shear Spec. 305.

HL379V( ) = Pretreat Ticermet B and solid film lubricant per Lubeco 2123, Type II.

HL379HK( ) = HI-KOTE™ 4 NC aluminum coating per Hi-Shear Spec. 397.

Collar &

Washer: HL379VW( ) = Both collar and washer with solid film lube per Lubeco 2123, Type II.

HL379DLW( ) = Collar finish is same as HL379DL( ) and washer is passivate.

HL379W( ) = Collar finish is same as HL379-( ) and washer is passivate.

SPECIFICATION: HI-LOK™ Product Specification 345. Use shear collar tension preload requirements. Test bolt requirement exceptions per

note 3 above.

CODE: Dash number indicates nominal diameter in 1/32nds.

See Finish note for explanation of code letters.

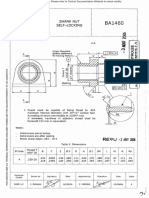

"HI-LOK" AND "HL" ARE INTERNATIONAL

REGISTERED TRADEMARKS OF HI-SHEAR CORPORATION

TITLE DRAWING NO.

DATE BY

HI-LOK™ COLLAR

HL379

DRAWN 1967-01-20 SHRODE

TITANIUM ALLOY

APPROVED 2018-12-03 J.SOCKETT

1/16 GRIP VARIATION, SPECIAL APPLICATION

FOR USE ON STANDARD AND 1/64 OVERSIZE

28 REVISION 2018-12-03 D. OZCELIK

HI-LOK™ PINS 1 OF 1

C 2018 Hi-Shear Corporation

You might also like

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: B DIA A DIA A1 DIA PDocument1 pageHi-Lok™ Collar: B DIA A DIA A1 DIA PRenato WatanabeNo ratings yet

- Hi-Lok™ Collar: B DIA A DIA A1 DIA PDocument1 pageHi-Lok™ Collar: B DIA A DIA A1 DIA PRenato WatanabeNo ratings yet

- HL77Document1 pageHL77Renato WatanabeNo ratings yet

- HL70Document1 pageHL70Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- HL18 1Document2 pagesHL18 1FlorinNo ratings yet

- MES ST 1002 - SaddleDocument2 pagesMES ST 1002 - SaddleDarshan PanchalNo ratings yet

- HL19Document2 pagesHL19Bogdan RusuNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- Pisco 2022Document11 pagesPisco 2022Gabriel RojasNo ratings yet

- ROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFDocument136 pagesROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFAob AprilNo ratings yet

- MRLMDocument2 pagesMRLMByron BolañosNo ratings yet

- Fall Arrester DrawingDocument1 pageFall Arrester DrawingthomsonNo ratings yet

- Print PDFDocument1 pagePrint PDFIvan Olmo ForniesNo ratings yet

- Beam SchedDocument1 pageBeam Schedristration2No ratings yet

- HL21Document2 pagesHL21Bogdan RusuNo ratings yet

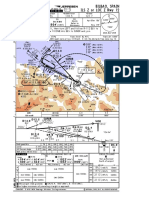

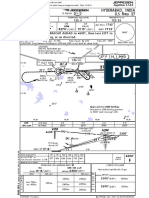

- Pso Loc Rwy 20 PDFDocument1 pagePso Loc Rwy 20 PDFAlexandra DiazNo ratings yet

- RC 45 - RC 55 Rim Clamp Tire Changer ManualDocument28 pagesRC 45 - RC 55 Rim Clamp Tire Changer ManualmechanicsNo ratings yet

- HL23Document1 pageHL23Bogdan RusuNo ratings yet

- Toshiba/Houston: Totally-Enclosed Fan-CooledDocument4 pagesToshiba/Houston: Totally-Enclosed Fan-CooledmarceloNo ratings yet

- Pipe Culvert DrawingDocument1 pagePipe Culvert DrawingPramesh Kori100% (2)

- Pipe Culvert Drawing PDFDocument1 pagePipe Culvert Drawing PDFPramesh Kori100% (3)

- 1267-STR ModelDocument1 page1267-STR ModelJenna Mortel-DoligolNo ratings yet

- 70088-R-BJ101-XD-1333021 DDM - Ibop Mechanism Sleeve & Crank Assembly - 012922Document1 page70088-R-BJ101-XD-1333021 DDM - Ibop Mechanism Sleeve & Crank Assembly - 012922abdi rachmanNo ratings yet

- WMKIDocument26 pagesWMKIandrewchong31No ratings yet

- NAS1713Document2 pagesNAS1713Bogdan RusuNo ratings yet

- Ga 2400 Kva, 11-0.800 KV Octc R5Document10 pagesGa 2400 Kva, 11-0.800 KV Octc R5Chaturbhai HadiyalNo ratings yet

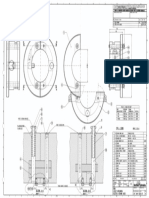

- Nidec Motor Corporation: Assembled View V01 ADocument1 pageNidec Motor Corporation: Assembled View V01 AEDUARDOMTZNo ratings yet

- 03 01 05 PDFDocument1 page03 01 05 PDFKR123No ratings yet

- Watlow FLUENT HeaterDocument1 pageWatlow FLUENT HeaterchipulinoNo ratings yet

- StairsDocument1 pageStairsALANA PACHECONo ratings yet

- Rfg70N06, Rfp70N06, Rf1S70N06, Rf1S70N06Sm: 70A, 60V, Avalanche Rated, N-Channel Enhancement-Mode Power MosfetsDocument6 pagesRfg70N06, Rfp70N06, Rf1S70N06, Rf1S70N06Sm: 70A, 60V, Avalanche Rated, N-Channel Enhancement-Mode Power MosfetsRomário CaribéNo ratings yet

- SKSP PDFDocument1 pageSKSP PDFFabio BurgosNo ratings yet

- 3-1/16" 10K (Typ. in 3 Sides and Top) : 1 19-03-2024 MOH SRS MED For Approval REV Date Drawn Chekd Aprvd DescriptionDocument1 page3-1/16" 10K (Typ. in 3 Sides and Top) : 1 19-03-2024 MOH SRS MED For Approval REV Date Drawn Chekd Aprvd DescriptionAbdul Rafiq SoudagarNo ratings yet

- Nas464 PDFDocument4 pagesNas464 PDFGlenn CHOU100% (1)

- A8vo RDE93010-26 LAOXSDocument7 pagesA8vo RDE93010-26 LAOXSjose manuel barroso pantoja100% (1)

- 7-12-0002 Rev5 - Support For Horizontal VesselDocument1 page7-12-0002 Rev5 - Support For Horizontal VesselSachinNo ratings yet

- SF1521 60070 2S - PDDDocument1 pageSF1521 60070 2S - PDDpayoseNo ratings yet

- Catalog C v5 PDFDocument80 pagesCatalog C v5 PDFAshokNo ratings yet

- Catalog C v5Document80 pagesCatalog C v5Sivi NallamothuNo ratings yet

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrNo ratings yet

- 03 01 02 PDFDocument1 page03 01 02 PDFAnonymous lswzqloNo ratings yet

- 2h Hvac-102 Roof Floor Hvac Layout-Rf HvacDocument1 page2h Hvac-102 Roof Floor Hvac Layout-Rf HvacWaqar KhanNo ratings yet

- Vohy Ils 27-PlainDocument1 pageVohy Ils 27-PlainRajeshNo ratings yet

- Features SOT-23: 60V, 0.15A, 200mW NPN Plastic Encapsulate Transistor Elektronische BauelementeDocument2 pagesFeatures SOT-23: 60V, 0.15A, 200mW NPN Plastic Encapsulate Transistor Elektronische Bauelementezenal abidNo ratings yet

- Installation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Document11 pagesInstallation Instructions: 2018 Harley-Davidson Softail Stainless Hi-Output 2-1 PART# 27631/47631Kurt LeadbeaterNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument41 pagesJeppview For Windows: List of Pages in This Trip KitDiosnel RodriguezNo ratings yet

- wi-STLS-06.750-036-10001 Rev 0Document1 pagewi-STLS-06.750-036-10001 Rev 0Dinesh YkatilNo ratings yet

- 7200 Shoulder 27200 7200 1500 Shoulder: Pembangunan Jalan Tol Trans Sumatera Ruas Terbanggi Besar - Pematang PanggangDocument1 page7200 Shoulder 27200 7200 1500 Shoulder: Pembangunan Jalan Tol Trans Sumatera Ruas Terbanggi Besar - Pematang PanggangTya Anggelinaputri DattebaneNo ratings yet

- Pot PDFDocument1 pagePot PDFTya Anggelinaputri DattebaneNo ratings yet

- 2638D - Snap Ring Gasket CompositeDocument2 pages2638D - Snap Ring Gasket CompositeRocio AriasNo ratings yet

- Sie Ban Rbo CNR Iml: Madrid, Spain Lemd/Mad Ilszorlocrwy18LDocument1 pageSie Ban Rbo CNR Iml: Madrid, Spain Lemd/Mad Ilszorlocrwy18LLuther Suerte III50% (2)

- Drawing 2000 MM - PT Trans Power Shaft 6.5 InchiDocument1 pageDrawing 2000 MM - PT Trans Power Shaft 6.5 InchimadpethalNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument7 pagesJeppview For Windows: List of Pages in This Trip KitisaacvoxNo ratings yet

- Texas Flange CatalogDocument80 pagesTexas Flange CatalogAlvin KimNo ratings yet

- Spur Vor Rwy 19 Cat A, BDocument1 pageSpur Vor Rwy 19 Cat A, BEduardo CruzadoNo ratings yet

- A B C D E F G H: Pt. Asphalt Bangun SaranaDocument1 pageA B C D E F G H: Pt. Asphalt Bangun SaranaNugroho ArifNo ratings yet

- 40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesDocument1 page40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesRenato WatanabeNo ratings yet

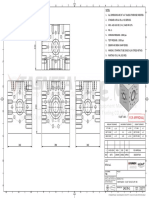

- City of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyDocument1 pageCity of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyRenato WatanabeNo ratings yet

- Faa-Tso Authorized Part - .... - C........ : Afl (RDocument1 pageFaa-Tso Authorized Part - .... - C........ : Afl (RRenato WatanabeNo ratings yet

- Faa-Tso Authorized 1s1 : 11unu, JLLJDocument3 pagesFaa-Tso Authorized 1s1 : 11unu, JLLJRenato WatanabeNo ratings yet

- Only Superior Casters Are Durable!Document2 pagesOnly Superior Casters Are Durable!Renato WatanabeNo ratings yet

- MS14182B - Parafuso Cabeça EstriadaDocument3 pagesMS14182B - Parafuso Cabeça EstriadaRenato WatanabeNo ratings yet

- Hi-Loktm Collar: LISI AEROSPACE Website atDocument1 pageHi-Loktm Collar: LISI AEROSPACE Website atRenato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Lightweight Nut, 6AL-4V Titanium Hexagonal, Self-Locking BA1500Document6 pagesLightweight Nut, 6AL-4V Titanium Hexagonal, Self-Locking BA1500Renato WatanabeNo ratings yet

- Nut, Double Hex, Self-Locking, Alloy Steel, Cadmium Plated and Dry Film Lubricant, Iso M, 1100 Mpa, 235°C Max. Page 1/3Document3 pagesNut, Double Hex, Self-Locking, Alloy Steel, Cadmium Plated and Dry Film Lubricant, Iso M, 1100 Mpa, 235°C Max. Page 1/3Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- Ms 16624Document11 pagesMs 16624Renato WatanabeNo ratings yet

- Nut Double Hex Self-Locking: REPU-2AOUT2006Document3 pagesNut Double Hex Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Shank Nut Self-Locking: REPU-2AOUT2006Document3 pagesShank Nut Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Schunk Carbon Technology Carbon Brush enDocument4 pagesSchunk Carbon Technology Carbon Brush enanm bNo ratings yet

- JIS 5K, 10K Flanges (Carbon Steel, Mild Steel, Stainles Steel (304, 304L, 316, 316L)Document3 pagesJIS 5K, 10K Flanges (Carbon Steel, Mild Steel, Stainles Steel (304, 304L, 316, 316L)niginpNo ratings yet

- " Work Experience in Ishan Equipments Pvt. LTD.": Internship Presentation OnDocument20 pages" Work Experience in Ishan Equipments Pvt. LTD.": Internship Presentation OnrajivNo ratings yet

- 068 - ME8351, ME6302 Manufacturing Technology I - 2 Mark Important QuestionsDocument5 pages068 - ME8351, ME6302 Manufacturing Technology I - 2 Mark Important QuestionsMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- ASTM - D6386-99 (Reapproved 2005)Document4 pagesASTM - D6386-99 (Reapproved 2005)tkNo ratings yet

- 02 Forms of CorrosionDocument41 pages02 Forms of CorrosionNino AngobNo ratings yet

- Packing of ValvesDocument4 pagesPacking of ValvesNaved HavaNo ratings yet

- Product Data Sheet Insulated Roof & Wall PanelsDocument6 pagesProduct Data Sheet Insulated Roof & Wall PanelsmuathNo ratings yet

- Tle Q3 Las 1Document6 pagesTle Q3 Las 1Glenda GestiadaNo ratings yet

- Standards: Working Together To Raise Industry StandardsDocument28 pagesStandards: Working Together To Raise Industry StandardssamanNo ratings yet

- 04-Industrial FittingsDocument120 pages04-Industrial FittingsJoe RuddyNo ratings yet

- Global Industry Classification StandardDocument54 pagesGlobal Industry Classification StandardGeorge GeorgeNo ratings yet

- Is 1865 - 2Document1 pageIs 1865 - 2Svapnesh ParikhNo ratings yet

- API Inspection GuideDocument14 pagesAPI Inspection Guidesouilah100% (1)

- DIVERSEY NAME Chemical Usgae ManualDocument5 pagesDIVERSEY NAME Chemical Usgae ManualArokiaraj AmalrajNo ratings yet

- Chunky GraphiteDocument16 pagesChunky GraphitesachinguptachdNo ratings yet

- Solid Fundamentals For Success: TSX: Bki Otc: Bkirf FWB: BinDocument2 pagesSolid Fundamentals For Success: TSX: Bki Otc: Bkirf FWB: BinSergey KNo ratings yet

- Material Safety Data Sheet: Tianjin New Century Refractories Co., LTDDocument3 pagesMaterial Safety Data Sheet: Tianjin New Century Refractories Co., LTDRosibel YgNo ratings yet

- Cast Iron Basic Training and ApplicatonsDocument34 pagesCast Iron Basic Training and ApplicatonsKeerthivasan NNo ratings yet

- Uv 421 TT (Sa FB 1 65 DC h5)Document4 pagesUv 421 TT (Sa FB 1 65 DC h5)brunizzaNo ratings yet

- Internship Report: by Rakhi A. Toshniwal PRN NO.20213220181137210089Document26 pagesInternship Report: by Rakhi A. Toshniwal PRN NO.20213220181137210089Rakhi ToshniwalNo ratings yet

- Difference Between Pipes and TubesDocument2 pagesDifference Between Pipes and TubesDiego GaunaNo ratings yet

- Reinforcing Bar: Hardening Mechanisms and Performance in UseDocument6 pagesReinforcing Bar: Hardening Mechanisms and Performance in UseJ HungNo ratings yet

- Kanepox UnifastDocument3 pagesKanepox UnifastFatih AydoğanNo ratings yet

- First Summative TestDocument5 pagesFirst Summative TestDy IsottoNo ratings yet

- Forging: Forging Machinery, Dies, and ProcessesDocument12 pagesForging: Forging Machinery, Dies, and ProcessesKasia MazurNo ratings yet

- Owner'S Manual For Hoist: CXT40410050P35FCD0SDocument92 pagesOwner'S Manual For Hoist: CXT40410050P35FCD0SmanafNo ratings yet

- Carbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothDocument13 pagesCarbon Steel, Alloy Steel, and Stainless Steel Nuts For Bolts For High Pressure or High Temperature Service, or BothRoberto Gutierrez SaldañaNo ratings yet

- Blow Moulding1Document54 pagesBlow Moulding1M PraveenNo ratings yet