Professional Documents

Culture Documents

HL77

Uploaded by

Renato WatanabeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HL77

Uploaded by

Renato WatanabeCopyright:

Available Formats

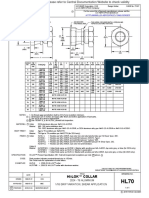

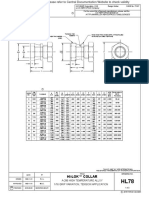

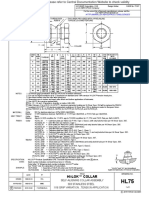

LISI AEROSPACE – Please refer to Central Documentation Website to check validity

HI-SHEAR Corporation, USA Design Holder CAGE No. 73197

S

AEROSPACE a LISI AEROSPACE Company

For the current list of licensed manufacturers, please visit the

LISI AEROSPACE website at:

hi-shear corporation

2600 SKYPARK DRIVE, TORRANCE, CALIFORNIA 90509 U.S.A.

HTTP://WWW.LISI-AEROSPACE.COM/LICENSES

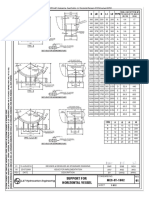

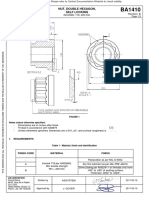

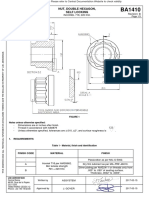

THREAD PER .020 WASHER THIS AREA PROVIDED WITH A PREVAILING

AS8879 THICKNESS (REF) TORQUE LOCKING FEATURE

A B P

A1

DIA DIA (REF)

DIA

(REF)

X X1

(REF) (REF)

W

L1 L3 HEX

(REF) (REF)

L L2

(REF)

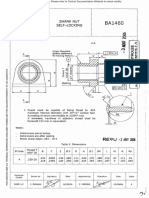

PIN A1 TENSION UTS TORQUE-OFF

DASH NOM A B L1 L2 L3 P W X X1 PRELOAD LBS. INCH-

THREAD DIA DIA DIA L (REF) (REF) (REF) (REF) HEX (REF) (REF) LBS.

NO. DIA (REF) MIN POUNDS

MIN.

.1640-32 .292 .173 .447 .314

5 5/32 UNJC-3B .340 .270 .467 .300 .344 .107 .137 350 1,400 10-20

.288 .166 .427 .302

.1900-32 .307 .200 .457 .314

6 3/16 UNJF-3B .360 .280 .477 .310 .344 .107 .137 500 1,600 20-30

.303 .192 .437 .302

.2500-28 .412 .261 .552 .346

8 1/4 UNJF-3B .465 .340 .572 .370 .380 .112 .142 1,000 3,000 55-70

.408 .252 .532 .332

.3125-24 .518 .325 .672 .440

10 5/16 UNJF-3B .575 .430 .692 .460 .484 .122 .152 1,650 5,000 100-125

.512 .314 .652 .425

.3750-24 .628 .388 .744 .503

12 3/8 UNJF-3B .690 .470 .764 .500 .557 .122 .152 2,300 7,000 170-200

.622 .376 .724 .488

.4375-20 .713 .450 .862 .565

14 7/16 UNJF-3B .770 .560 .882 .590 .624 .137 .167 3,100 9,500 220-270

.707 .442 .842 .550

.5000-20 .815 .513 .942 .690

16 1/2 UNJF-3B .875 .610 .962 .640 .763 .137 .167 4,100 12,500 310-370

.809 .501 .922 .675

GENERAL NOTES: 1. Go thread gage penetration shall be 3/4 of one revolution minimum.

30 2. Dimensions are in inches and apply after finish and before application of lubricants.

3. Use HL377 for oversize replacement.

4 Cetyl alcohol per Hi-Shear Spec. 305 maybe applied at manufacturer's option.

30 5 Use the following test bolts for thread lock inspection:

TB7075AA( )L for HL77-( ), HL77CM( ), HL77-( )D or HL77-( )DA, HL77FK-( ), HL77TF-( ),

HL77-( )DDW or HL77-( )DADW, HL77TF( )NW, and HL77-( )TW.

TB64VF( )L for HL77-( )TY.

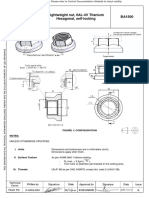

MATERIAL: Collar 2024 aluminum alloy per QQ-A-430 or AMS-QQ-A-225/6.

30 Washer "DW" & "TW" = 2024 aluminum alloy per AMS-QQ-A-250/4 or AMS-QQ-A-250/5.

"NW" & "TY" = 300 series stainless steel per ASTM A240/A240M.

HEAT TREAT: Collar Age to T6 condition per AMS2770.

30 Washer "DW" & "TW" = Age to T6 condition per AMS2770 (for 2024 only).

"NW" & "TY" = Anneal in vacuum furnace per AMS2759/4.

VOI-SHAN

FINISH: 30 Collar HL77-( ) = Collar only anodized per MIL-A-8625, dye color brown, and cetyl alcohol 1 raised bead indicates

lube per Hi-Shear Spec. 305.

HL77CM( ) = Collar only with chemical conversion coat per MIL-DTL-5541 class 1A and VOI-SHAN identification

cetyl alcohol lube per Hi-Shear Spec. 305.

HL77-( )D or

HL77-( )DA = Collar only anodized per MIL-A-8625 and solid film lube per AS5272, Type I.

HL77TF-( ) = Collar only anodized per MIL-A-8625 and HI-KOTE™ 2 solid film lube per Hi-

Shear Spec. 292.

Collar & HL77-( )DDW or

30

Washer HL77( ) DADW = Collar finish same as HL77-D( ) or DA. Washer is anodized per

MIL-A-8625 and solid film lube per AS5272, Type I.

HL77TF-( )NW = Collar finish same as HL77TF-( ). Washer is passivated per AMS2700,

Type 8, Method 1. STANDARD PRESSED STEEL

HL77-( )TW = Collar finish same as HL77-( ). Washer is anodized per Spec. 2 raised beads indicate STANDARD

MIL-A-8625, dye color blue. PRESSED STEEL identification.

HL77-( )TY = Collar finish same as HL77-( ). Washer is passivated per AMS2700,

Type 8, Method 1 with "Kalgard" FC-2 teflon.

SPECIFICATION: HI-LOK™ Product Specification 345. except tension preload as tabulated and test bolt requirement exceptions per note 5 above. 30

CODE: Dash number indicates nominal thread size in 1/32nds.

See "Finish" note for explanation of code letters.

EXAMPLES: HL77-8 = .2500-28 collar only, anodize and cetyl alcohol lube.

HL77-8DADW = Assembly of HL77-8DA collar and HL77-8DW washer with solid film lube.

"HI-LOK" AND "HL" ARE INTERNATIONAL

REGISTERED TRADEMARKS OF HI-SHEAR CORPORATION

TITLE DRAWING NO.

DATE BY

HI-LOK™ COLLAR

HL77

DRAWN 1961-12-19 R.K.C.

2024 - T6 ALUMINUM ALLOY

APPROVED 1961-12-19 M.M.S.

1/16 GRIP VARIATION, SHEAR APPLICATION

30 REVISION 2018-09-04 S. WILEY FOR USE ON STANDARD SIZE ALUMINUM ALLOY HI-LOK™ PINS 1 of 1

C 2018 Hi-Shear Corporation

You might also like

- HL70Document1 pageHL70Renato WatanabeNo ratings yet

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- Hi-Lok™ Collar: B DIA A DIA A1 DIA PDocument1 pageHi-Lok™ Collar: B DIA A DIA A1 DIA PRenato WatanabeNo ratings yet

- Hi-Lok™ Collar: B DIA A DIA A1 DIA PDocument1 pageHi-Lok™ Collar: B DIA A DIA A1 DIA PRenato WatanabeNo ratings yet

- HL379Document1 pageHL379Renato WatanabeNo ratings yet

- Pisco 2022Document11 pagesPisco 2022Gabriel RojasNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrNo ratings yet

- Print PDFDocument1 pagePrint PDFIvan Olmo ForniesNo ratings yet

- ROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFDocument136 pagesROC-MSE-SPC-00157 - 01-Standard Pipe Support PDFAob AprilNo ratings yet

- SPSODocument9 pagesSPSOEO LozadiNo ratings yet

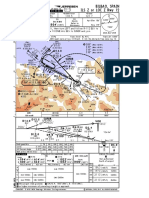

- Sie Ban Rbo CNR Iml: Madrid, Spain Lemd/Mad Ilszorlocrwy18LDocument1 pageSie Ban Rbo CNR Iml: Madrid, Spain Lemd/Mad Ilszorlocrwy18LLuther Suerte III50% (2)

- No Valido para Navegacion Real: AsemiDocument17 pagesNo Valido para Navegacion Real: AsemiNicolas OrtuosteNo ratings yet

- Nozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)Document17 pagesNozzle and Flange Check Calculation at OWT For CN-3-02 (Heavy Duty Pump)SingoNo ratings yet

- KRNODocument58 pagesKRNOzacklawsNo ratings yet

- NASM20426Document6 pagesNASM20426Konelek AeroNo ratings yet

- Spur Vor Rwy 19 Cat A, BDocument1 pageSpur Vor Rwy 19 Cat A, BEduardo CruzadoNo ratings yet

- Pso Loc Rwy 20 PDFDocument1 pagePso Loc Rwy 20 PDFAlexandra DiazNo ratings yet

- Spring Support Data Sheet-Process AreaDocument1 pageSpring Support Data Sheet-Process AreaArash AghagolNo ratings yet

- Buenos Aires, Argentina Sabe/Aep Ilszrwy13: Muper D5.1 OmDocument1 pageBuenos Aires, Argentina Sabe/Aep Ilszrwy13: Muper D5.1 Omfrancisco buschiazzoNo ratings yet

- Nas 1714Document2 pagesNas 1714YossiNo ratings yet

- MES ST 1002 - SaddleDocument2 pagesMES ST 1002 - SaddleDarshan PanchalNo ratings yet

- Nas464 PDFDocument4 pagesNas464 PDFGlenn CHOU100% (1)

- WMKIDocument26 pagesWMKIandrewchong31No ratings yet

- Wamm (MDC) - Sam RatulangiDocument18 pagesWamm (MDC) - Sam RatulangiRafly AndrianzaNo ratings yet

- SBRJ - RNP X Rwy 20l Ar - Iac - 20211230Document1 pageSBRJ - RNP X Rwy 20l Ar - Iac - 20211230gameplayPSNo ratings yet

- Layout AED, SID, STAR & Map RNAV 2Document8 pagesLayout AED, SID, STAR & Map RNAV 2oka nNo ratings yet

- 1267-STR ModelDocument1 page1267-STR ModelJenna Mortel-DoligolNo ratings yet

- SBRF Ils-W-Rwy-18 Iac 20200813Document1 pageSBRF Ils-W-Rwy-18 Iac 20200813Ricardo PalermoNo ratings yet

- Hesh 2Document23 pagesHesh 2Ali 35No ratings yet

- SKSP PDFDocument1 pageSKSP PDFFabio BurgosNo ratings yet

- Fall Arrester DrawingDocument1 pageFall Arrester DrawingthomsonNo ratings yet

- Spyl Charts Vor Rwy 17 Cat A, BDocument1 pageSpyl Charts Vor Rwy 17 Cat A, BEduardo CruzadoNo ratings yet

- TibongDocument1 pageTibongcastrorexelNo ratings yet

- Buenos Aires, Argentina Saez/Eze RNP Rwy 17: EZ177 ArsotDocument1 pageBuenos Aires, Argentina Saez/Eze RNP Rwy 17: EZ177 Arsotfrancisco buschiazzoNo ratings yet

- BUTUAN ChartsDocument8 pagesBUTUAN ChartsDavid van TeeselingNo ratings yet

- 2SC1923Document1 page2SC1923Rey TiburonNo ratings yet

- Rfg70N06, Rfp70N06, Rf1S70N06, Rf1S70N06Sm: 70A, 60V, Avalanche Rated, N-Channel Enhancement-Mode Power MosfetsDocument6 pagesRfg70N06, Rfp70N06, Rf1S70N06, Rf1S70N06Sm: 70A, 60V, Avalanche Rated, N-Channel Enhancement-Mode Power MosfetsRomário CaribéNo ratings yet

- LFBD 6 20 Star Stars 1708865 BDocument1 pageLFBD 6 20 Star Stars 1708865 Bjames.gimenezNo ratings yet

- EDDF ILS Y Rwy 25RDocument1 pageEDDF ILS Y Rwy 25RItsIlaiNo ratings yet

- Attachment - Line SizingDocument25 pagesAttachment - Line Sizingfebriyan.saputraNo ratings yet

- Function Diagram DCS500Document1 pageFunction Diagram DCS500Charoon SuriyawichitwongNo ratings yet

- Jeppesen Trip KitDocument19 pagesJeppesen Trip KitKyle BrandonNo ratings yet

- RX & TX Field Valreg Preocedure V1: Arm TypeDocument5 pagesRX & TX Field Valreg Preocedure V1: Arm TypeJulio LiranzoNo ratings yet

- LUKK Airport Information - JeppesenDocument28 pagesLUKK Airport Information - JeppesenCristian Mihai AldeaNo ratings yet

- SLM SLM: Mexico City, Mexico Mmmx/Mex Ils Dme 1 or Loc Rwy 23LDocument1 pageSLM SLM: Mexico City, Mexico Mmmx/Mex Ils Dme 1 or Loc Rwy 23LLucas KnightNo ratings yet

- LIBP (Pescara)Document26 pagesLIBP (Pescara)Alessio BellucciNo ratings yet

- Features SOT-23: 60V, 0.15A, 200mW NPN Plastic Encapsulate Transistor Elektronische BauelementeDocument2 pagesFeatures SOT-23: 60V, 0.15A, 200mW NPN Plastic Encapsulate Transistor Elektronische Bauelementezenal abidNo ratings yet

- Skps/Pso Pasto, Colombia ILS Rwy 20: 116.3 MER PS588Document1 pageSkps/Pso Pasto, Colombia ILS Rwy 20: 116.3 MER PS588Alexandra DiazNo ratings yet

- 10-T-101 10-P-101A/B: Revision HistoryDocument7 pages10-T-101 10-P-101A/B: Revision HistoryAlfonNo ratings yet

- Sco Isan: Spso/Pio Pisco, Peru Ilsyrwy22Document5 pagesSco Isan: Spso/Pio Pisco, Peru Ilsyrwy22Harold DongoNo ratings yet

- Iesa Planeamiento Sem33 2021Document28 pagesIesa Planeamiento Sem33 2021Jefferson Carlos RomeroNo ratings yet

- Drawing 2000 MM - PT Trans Power Shaft 6.5 InchiDocument1 pageDrawing 2000 MM - PT Trans Power Shaft 6.5 InchimadpethalNo ratings yet

- SAE Flywheel & Bell Housing ChartDocument3 pagesSAE Flywheel & Bell Housing ChartRogelio Reyes Romero100% (1)

- StairsDocument1 pageStairsALANA PACHECONo ratings yet

- General Spec Sheets of All InstrumentsDocument32 pagesGeneral Spec Sheets of All InstrumentsArslan NisarNo ratings yet

- Mark. No. QTY. DN Rating Flange Type SCH Description Remark Table NozzleDocument1 pageMark. No. QTY. DN Rating Flange Type SCH Description Remark Table NozzleEdi KurniawanNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument23 pagesJeppview For Windows: List of Pages in This Trip KitAmirAli MohebbiNo ratings yet

- HKJKDocument50 pagesHKJKEmmanuel Kalisti Maenda IINo ratings yet

- City of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyDocument1 pageCity of Industry, California Title,: Dimenss Decimal c4WNYD Oft OnlyRenato WatanabeNo ratings yet

- Faa-Tso Authorized 1s1 : 11unu, JLLJDocument3 pagesFaa-Tso Authorized 1s1 : 11unu, JLLJRenato WatanabeNo ratings yet

- Faa-Tso Authorized Part - .... - C........ : Afl (RDocument1 pageFaa-Tso Authorized Part - .... - C........ : Afl (RRenato WatanabeNo ratings yet

- 40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesDocument1 page40 32UNJF 3B: 18O1 Dimensions Are in Inches. Toleranc AnglesRenato WatanabeNo ratings yet

- Only Superior Casters Are Durable!Document2 pagesOnly Superior Casters Are Durable!Renato WatanabeNo ratings yet

- Hi-Loktm Collar: LISI AEROSPACE Website atDocument1 pageHi-Loktm Collar: LISI AEROSPACE Website atRenato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- HL77Document1 pageHL77Renato WatanabeNo ratings yet

- HL78Document2 pagesHL78Renato WatanabeNo ratings yet

- Hi-Loktm Collar: LISI AEROSPACE Website atDocument1 pageHi-Loktm Collar: LISI AEROSPACE Website atRenato WatanabeNo ratings yet

- Nut, Double Hex, Self-Locking, Alloy Steel, Cadmium Plated and Dry Film Lubricant, Iso M, 1100 Mpa, 235°C Max. Page 1/3Document3 pagesNut, Double Hex, Self-Locking, Alloy Steel, Cadmium Plated and Dry Film Lubricant, Iso M, 1100 Mpa, 235°C Max. Page 1/3Renato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- MS14182B - Parafuso Cabeça EstriadaDocument3 pagesMS14182B - Parafuso Cabeça EstriadaRenato WatanabeNo ratings yet

- Shank Nut Self-Locking: REPU-2AOUT2006Document3 pagesShank Nut Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Ms 16624Document11 pagesMs 16624Renato WatanabeNo ratings yet

- Nut Double Hex Self-Locking: REPU-2AOUT2006Document3 pagesNut Double Hex Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Ms 16624Document11 pagesMs 16624Renato WatanabeNo ratings yet

- Lightweight Nut, 6AL-4V Titanium Hexagonal, Self-Locking BA1500Document6 pagesLightweight Nut, 6AL-4V Titanium Hexagonal, Self-Locking BA1500Renato WatanabeNo ratings yet

- MS14145C Porca CasteloDocument2 pagesMS14145C Porca CasteloRenato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- Hi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyDocument1 pageHi-Lok™ Collar: 303 Stainless Steel 1/16 Grip Variation, Tension Application Self-Aligning Collar AssemblyRenato WatanabeNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- APIU CARMT Syllabus Version 1.0 - Confidential For Review CommitteeDocument49 pagesAPIU CARMT Syllabus Version 1.0 - Confidential For Review CommitteeFuad HassanNo ratings yet

- Keyop Functions 9F3715Document114 pagesKeyop Functions 9F3715Art MessickNo ratings yet

- Quantum Optical Memory For Entanglement DistributionDocument22 pagesQuantum Optical Memory For Entanglement DistributionJay-R Notorio PallegaNo ratings yet

- Fluid and Electrolytes Lecture NotesDocument85 pagesFluid and Electrolytes Lecture NotesVince Peliño De MesaNo ratings yet

- Ohm's Law (Lab Report)Document7 pagesOhm's Law (Lab Report)yuta titeNo ratings yet

- ORM. Lucene. Elasticsearch. Integrated. - Hibernate SearchDocument6 pagesORM. Lucene. Elasticsearch. Integrated. - Hibernate SearchChandu ChandrakanthNo ratings yet

- SM2059 (Apr-67)Document310 pagesSM2059 (Apr-67)EdU RECTIFICANo ratings yet

- Study of RGB Color Classification Using Fuzzy LogicDocument6 pagesStudy of RGB Color Classification Using Fuzzy LogicBhavin GajjarNo ratings yet

- CTR Manufacturing Develops 2 Tap Changer Transformers With FR3 Fluid 1Document5 pagesCTR Manufacturing Develops 2 Tap Changer Transformers With FR3 Fluid 1SM KNo ratings yet

- C Atomic StructureDocument34 pagesC Atomic StructureMarshmalloowNo ratings yet

- Excel - 1G - Regional - Sales: Project DescriptionDocument3 pagesExcel - 1G - Regional - Sales: Project Descriptioncurtis brownNo ratings yet

- Web Technology QuantumDocument335 pagesWeb Technology QuantumabhishekgsNo ratings yet

- Department of Civil Engineering Lakshmi Narain College of Technology BHOPAL-462021 (INDIA)Document48 pagesDepartment of Civil Engineering Lakshmi Narain College of Technology BHOPAL-462021 (INDIA)Vikash SinghNo ratings yet

- BS 7941-1-2006Document20 pagesBS 7941-1-2006Willy AryansahNo ratings yet

- Bazaar Tent StructureDocument5 pagesBazaar Tent StructurephilipyapNo ratings yet

- SMM200 Derivatives and Risk Management 2021 QuestionsDocument5 pagesSMM200 Derivatives and Risk Management 2021 Questionsminh daoNo ratings yet

- Electrical UnitsDocument2 pagesElectrical Unitsevtoma100% (1)

- RPI Form PDFDocument1 pageRPI Form PDFJoko WiwiNo ratings yet

- WIND LOADS (Computation of QH For MWFRS, Low Rise BuildingDocument2 pagesWIND LOADS (Computation of QH For MWFRS, Low Rise BuildingRomeo QuerubinNo ratings yet

- Metrel Mi 3290 Earth AnalyserDocument4 pagesMetrel Mi 3290 Earth AnalyserMarijan MustačNo ratings yet

- C ProgramsDocument16 pagesC Programsvaishuraji2001No ratings yet

- WL 80250 4 EA 0510 MainCat Equipment and ServicesDocument116 pagesWL 80250 4 EA 0510 MainCat Equipment and ServicesApetrei Ioan CristianNo ratings yet

- Direct and Indirect SpeechDocument30 pagesDirect and Indirect SpeechGiridhar Suresh KitturNo ratings yet

- MANUAL For IONIZING AIR BARDocument11 pagesMANUAL For IONIZING AIR BARGerardo BoisNo ratings yet

- GroupTheory SERC2015 PDFDocument43 pagesGroupTheory SERC2015 PDFsayan100% (1)

- LP2 Lubrication Pinion For Lubrication of Open Girth Gears, Tooth Wheels and Gear RodsDocument44 pagesLP2 Lubrication Pinion For Lubrication of Open Girth Gears, Tooth Wheels and Gear RodsThanhluan NguyenNo ratings yet

- MP Module 2 - Modified - CorrectDocument24 pagesMP Module 2 - Modified - Correctakhil krishnanNo ratings yet

- Applsci 1985066 Peer Review v1Document19 pagesApplsci 1985066 Peer Review v1mlupoae2003No ratings yet

- Ca 3241Document1 pageCa 3241Tien LamNo ratings yet

- 6242 01 Rms 20060616Document10 pages6242 01 Rms 20060616UncleBulgariaNo ratings yet