Professional Documents

Culture Documents

Controllogix Controllers, Revision 18: Release Notes

Uploaded by

Sohaib AdilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Controllogix Controllers, Revision 18: Release Notes

Uploaded by

Sohaib AdilCopyright:

Available Formats

Release Notes

ControlLogix Controllers, Revision 18

ControlLogix Controllers Catalog Numbers 1756-L73, 1756-L75

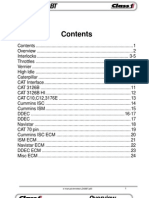

Topic Before You Begin Corrected Anomalies Known Anomalies Restrictions Install the Controller Revision Additional Memory Requirements Additional Resources

Page 2 3 4 8 9 10 16

IMPORTANT

After upgrading the firmware on your module, we strongly recommend that you retest your application offline before going online.

About This Publication

This publication describes anomalies (corrected and known), and restrictions for ControlLogix controllers, revision 18.

Cat. No. 1756-L73 1756-L75 Major and Minor Firmware Revision No. 18.12

Compatible Versions of Software

To use firmware revision 18.12, these minimum software versions are required.

Software RSLinx Classic RSLinx Enterprise RSLogix 5000 RSNetWorx for ControlNet RSNetWorx for DeviceNet RSNetWorx for EtherNet/IP Required Version 2.56 (CPR 9, SR2)(1) 5.21(CPR 9, SR2) 18.00 (CPR 9, SR2) 10.00 (CPR 9, SR2)

ControlLogix Controllers, Revision 18

(1) RSLinx Classic communication software, version 2.56, is the minimum required version. However, we recommend that you use version 2.57, when available, for optimal performance.

Before You Begin

Before you upgrade your firmware, consider the following.

IMPORTANT Loss of communication or power during a controller firmware flash upgrade may result in the controller rejecting the new firmware. If the controller firmware upgrade fails due to the conditions described, these corrective actions may be required:

Cycle controller power and successfully complete the flash

upgrade. If a nonrecoverable fault occurs, then return the controller for factory repair.

Before Updating 1756-L7x Controllers

Before you begin updating your 1756-L7x controller, check the status of your Secure Digital (SD) card.

If your SD card is Unlocked Locked and the Load Image option is set to On Power Up Then You can successfully update the firmware to the intended revision. You should unlock the SD card before beginning the update. If the card is locked when you attempt to update the firmware, the update fails and the controller reverts to the firmware revision already stored on the SD card.

Figure 1 - SD Card - Unlocked and Locked

Unlocked

Locked

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Corrected Anomalies

Corrected Anomaly Displacement between Actual Positions on Produced and Consumed Axes Description

This table describes anomalies corrected with firmware revision 18.12.

Table 1 - Corrected Anomalies with Firmware Revision 18.12

When a 1756-L7x controller is configured for rotary operation and produces axes that other controllers consume, the consumed actual position was not tracking the consumed commanded position and manifested itself via two anomalous behaviors. The actual position appeared to have a small constant displacement in comparison to commanded position and would also exceed the expected unwind value.

IMPORTANT

This anomaly occurs only when the 1756-L7x producing the axes is configured for rotary operation.

You could work around this anomaly in one of the following ways:

If the produced axes were commanded axes, and it was acceptable in your application, you could reference the

consumed axes Commanded Position.

If the produced axes were virtual axes, you could reference the consumed axes Commanded Position. This option

would work for all applications.

Lgx00111591, Lgx00111473

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Known Anomalies

This table describes known anomalies that have been identified with firmware revision 18.12.

Table 2 - Known Anomalies with Firmware Revision 18.12

Known Anomaly Shutdown Fault Overrides Drive State Change Executing a Motion Axis Home (MAH) Instruction Results in Unexpected Movement Description A Shutdown fault action issued by the controller overrides the drive state change only when the drive state change is reported as Disable. Lgx00109658, Lgx00106420 In an application where the Homing Sequence attribute of the Homing Configuration is set to 'Active Unidirectional Home with Switch' and the Home Switch bit is active (that is, the Home Switch is closed if normally open, or open if normally closed), then executing a Motion Axis Home (MAH) instruction results in a move that is inversely-proportional to the commanded position value. For example, if the commanded position was specified as -2 before the MAH instruction was executed, then the motor moves to +2. This anomaly may occur when the Home Direction attribute is set to forward or reverse. In addition, it may also occur when the Home Switch bit is set to be normally open or normally closed. To keep this anomaly from occurring, program to test for the state of the home input before initiating a home command. If the state is active and true or inactive and true, use a Motion Access Jog (MAJ) instruction to move the axis off the switch or wait to initiate the home command until the switch is no longer active. Once the home input is no longer active, the MAH instruction can be executed successfully. Lgx00109660, Lgx00108517 A Certain Homing Configuration and Execution of a Motion Axis Home (MAH) Instruction Causes Unexpected Motor Movement With the home switch active and the homing configuration set to 'Active Reverse Bidirectional Home', either with or without the marker, then executing a Motion Axis Home (MAH) instruction causes the motor to move in the opposite direction at the return speed you defined. The move continues until the switch is deactivated and the marker is found. Once the switch is deactivated and the marker is found, the MAH instruction is identified as complete. To keep this anomaly from occurring, program to test for the state of the home input before initiating a home command. If the state is active and true or inactive and true, use a Motion Access Jog (MAJ) instruction to move the axis off the switch or wait to initiate the home command until the switch is no longer active. Once the home input is no longer active, the MAH instruction can be executed successfully. Lgx00109661, Lgx00108519 Executing a Motion Axis Move (MAM) or Motion Coordinated Linear Move (MCLM) Instruction Can Cause a Major Nonrecoverable Fault Break in Connection between Controller and CIP-enabled Device Causes Invalid Data If a Motion Axis Move (MAM) or Motion Coordinated Linear Move (MCLM) instruction is executed on a Coordinate System that contains the source axes configured in a Motion Coordinated Transform (MCT) instruction that is also being executed (that is, while the target axes are moving and the transformations are active), then a Major Nonrecoverable Fault (MNRF) occurs. To work around this anomaly, set the Transform Dimension of the Coordinate System that contains the source axes to a value >0. This keeps the MNRF from occurring. Lgx00109662, Lgx00108920 In an application that uses CIP motion, you can enable certain tags to monitor the performance of a connection between a ControlLogix controller and a CIP-enabled device, such as a Kinetix 6500 Single Axis Ethernet Drive. For example, the following tag is one through which you can monitor connection status: [Device Name]:S.LostControllerToDriveTransmissions If the physical connection between the controller and the device breaks, for example, because a 1756-EN2T module is disconnected from the network, the data in tags that are enabled to monitor connection status is no longer updated. When you physically reconnect the controller to the device, the data resumes updating in the enabled tags. However, the data in those tags is invalid. Follow these steps to work around this anomaly. 1. Physically reconnect the controller to the device. 2. Cycle power to the controllers chassis or redownload the program from RSLogix 5000 programming software to the controller. Lgx00111385, Lgx00110902

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Table 2 - Known Anomalies with Firmware Revision 18.12

Known Anomaly CIP Axes Continue Moving after Losing CST Master Description CIP axes do not stop, as expected, after losing the CST master in an application with these conditions: A ControlLogix SynchLink module, that is, 1756-SYNCH module, is the CST master in the chassis that contains the controller that is commanding CIP motion. CIP axes are running. Precision Time Protocol (PTP) remains synchronized despite the loss of the CST master. IMPORTANT: If the CST master is the same module as the PTP master, CIP axes stop as expected. Also, regardless of conditions, any time the CST master is lost, SERCOS and analog axes stop as expected. Lgx00110467, Lgx00109725 Add-On Instruction Stops a Master Control Reset (MCR) Zone from Working A Master Control Reset (MCR) zone does not work properly after an Add-On Instruction is added. You can work around this anomaly so that the MCR zone works properly. Remove the Add-On Instruction from the MCR zone by repositioning it before or after the MCR zone and by adding to its own conditional logic. For more information about this anomaly, see the Technical Note titled MCR Zones Containing AOI's May Not Scan Rungs as False in Certain Firmware Revisions #68915, in the Technical Support Knowledgebase (available at http://www.rockwellautomation.com/knowledgebase/). Lgx00111328, Lgx00110876 PI Function Block Stops Executing PI function block appears to stop executing as the output does not change and no instruction faults are logged. If the PI instruction is being used in Linear mode, this floating-point equation is used to calculate the ITerm. WldInput + WldInput n 1 Kp Wld ---------------------------------------------------------------- DeltaT + ITerm n 1 2 Due to the use of the single-precision floating point values, it may be possible, depending on the values of WLD and KP, for the ITerm value to be small enough, less than 0.0000001, to be lost when adding to the ITermn-1. For more information regarding the PI instruction, see the Logix5000 Controllers Process Control and Drives Instructions User Manual, publication 1756-RM006. Lgx00070832 Buffer Timeout Changes Do Not Take Effect as Expected Changes made to the Buffer Timeout value for FactoryTalk Alarms and Events subscribers do not take effect until the existing buffer has been deleted. The FactoryTalk Alarms and Events alarm buffer (stored in Logix controller memory) is designed to persist through power cycles. If you change the Buffer Timeout value (via the Communication Setup dialog box in FactoryTalk View SE software), the controller does not use the new timeout value until the existing buffer is deleted and then recreated. To force recreation of this buffer, you can do one of the following:

Re-download the project to the controller. Disconnect the FactoryTalk Alarms and Events subscriber and leave it disconnected until the existing timeout

expires.

Lgx00069461 Unsuccessful MSG Execution Causes Issues

Unsuccessful MSG execution results in subsequent unsuccessful messages in master/slave controller configurations.

When a DF-1 serial connection is used between a master and slave controller, a MSG instruction is not successfully executed and an in-polling sequence error occurs if the master station address is not listed in the poll node list. However, with this anomaly, after the in-polling sequence error, subsequent MSG instructions are also unsuccessful. To workaround this anomaly, change the master controller's station address to a different value or re-execute the unsuccessful MSG instruction in Master Transmit mode and use the Between Station Polls parameter. Lgx00083882, Lgx00082610

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Table 2 - Known Anomalies with Firmware Revision 18.12

Known Anomaly Absolute Feedback Offset Results in Feedback Fault Description If you issue an Absolute Feedback Offset it results in a Feedback Fault. If you issue an Absolute Feedback Offset via an SSV instruction on the 1756-M02AS module, the result is a feedback fault. The feedback fault occurs regardless of whether feedback is on or off. Lgx00076298 Motion Axis Move Under some rare occurrences, if a Motion Axis Move (MAM) instruction with Merge Enabled is activated during the deceleration (MAM) May segment of an active MAM instruction then the new MAM instruction may overshoot its programmed endpoint. The occurrence of Overshoot Endpoint the overshoot depends on these factors:

The original MAM instructions remaining travel distance at the time of the merge and the new MAM instructions

remaining travel distance.

The relationship of the decel jerk of the new MAM instruction to the decel jerk of the original MAM instruction. If the original MAM instruction is decelerating.

Typically, the overshoot does not occur. If either of these conditions exist, you will avoid the overshoot.

The new MAM instruction is programmed with Merge Disabled. If there is no other motion active at the time of the

merge, then the Merge Disable results in the same operation as the Merge Enable.

The new MAM instruction has a slightly higher jerk (in Units/sec3) than the original MAM instruction. You should

note, though, lower value of jerk in% of time results in higher value of jerk (in Units/sec3).

Lgx00078822 Execution of Motion Group Shutdown Reset (MGSR) and Motion Group Shutdown (MGSD) Result in Error If a Motion Group Shutdown Reset (MGSR) instruction is executed while a Motion Group Shutdown (MGSD) is still executing, motion error #7, that is, Shutdown State Error, results. The purpose of an MGSR instruction is to bring an axis group out of the shutdown state. However, when the scenario described in the previous paragraph exists, the MGSR instruction is not executed because the shutdown procedure, initiated by the MGSD instruction, has precedence. Thus, the MGSR instruction generates motion error #7 because the shutdown procedure has not completed. The shutdown procedure must complete before any attempt to reset the shutdown. Lgx00095484 Disabling One CIP Axis in a Multi-axis System Causes Error With any coordinated move in a system that uses two or more CIP axes, if one axis is disabled by using a Motion Servo Off (MSF) instruction, any remaining CIP axes will generate an Excessive Velocity Error, that is, Drive Error S55. Important: This anomaly affects only CIP axes. Lgx00105360 DriveEnableStatus Bit Set Incorrectly Only in a program that is configured with Stop mode set to Fast Disable, the axis status bit 'DriveEnableStatus' is set to true for one coarse update after a Motion Group Stop (MGS) instruction transitions to the Process Complete (.PC) state. The axis status bit should be false when the MGS instruction transitions to the .PC state but remains true. You may need to delay initiation of other motion instructions until the enable status has cleared. Lgx00106782 Command Update Delay Offset Does Not Affect CIP Axis The Command Update Delay Offset feature is typically used with generic SERCOS drives that have different dynamic responses. The feature aligns the command position for each drive to compensate for the different dynamic responses. The Command Delay Compensation Offset parameter for each drive is adjusted as needed. However, the Command Update Delay Offset feature does not affect a CIP axis. An SSV instruction of CommandUpdateDelayOffset on a CIP axis is accepted but has no effect on the Command Delay Compensation Offset feature. Even though the axis attributes can be modified, the instruction execution does not alter the command position of a CIP axis. Lgx00107320

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Table 2 - Known Anomalies with Firmware Revision 18.12

Known Anomaly .ACCEL and .DECEL Motion Status Bits Operate Differently Description In RSLogix 5000 programming software, version 18.00 and Logix controller, firmware revision 18.11, the .ACCEL and .DECEL Motion status bits operate differently than in RSLogix 5000 programming software, version 17.x because the axis status bits of the consumed axis are recalculated instead of reusing the axis status bits of the producer axis. Lgx00107454 Real Time Axis Attribute VelocityFeedback Can Contain Incorrect Value

IMPORTANT

This anomaly occurs only in SERCOS applications that use Kinetix SERCOS drives and linear motors.

Under certain conditions, it is possible that the Real Time Axis attribute VelocityFeedback contains an incorrect value. The inaccuracy is the result of incorrect scaling of that attribute. Your program will have an incorrect value for the VelocityFeedback attribute if you follow these steps.

1. While offline, you write your RSLogix 5000 program and, as part of that program, the VelocityFeedback attribute is selected. 2. You save the program and download it to the controller. 3. You go online.

The VelocityFeedback attribute value is incorrect because that attribute was enabled before the program was saved, downloaded and put online. Workaround - To avoid this anomaly, do not enable the VelocityFeedback attribute until the RSLogix 5000 program is online. Lgx00107793

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Restrictions

Restrictions with Firmware Revision 18.12

Restriction Firmware Upgrade to Multiple Modules Optimal External Access Tag Attributes Use Description

This table describes restrictions that have been identified with firmware revisions 18.12.

Do not upgrade the firmware for more than one module at a time through the USB port of the controller. Lgx00105374 Use RSLinx Classic communication software, version 2.56 or later(1), and RSLinx Enterprise communication software, version 5.21 or later, for best results with the new External Access tag attributes provided with RSLogix 5000 programming software, version 18, and controller firmware revision 18.11. Using earlier versions of RSLinx Classic and RSLinx Enterprise software may result in anomalous behavior from the data servers with the External Access options Read Only and None. For more information about tag data access attributes, see the Logix5000 Controllers I/O and Tag Data Programming Manual, publication 1756-PM004. Lgx00103263

Update EtherNet/IP Modules Firmware Revision

With the use of the CIP Sync time synchronization feature, made available with controller firmware revision 18.x, if one of the ControlLogix EtherNet/IP modules listed below is used in the controllers chassis, we recommend that you update the firmware of all your EtherNet/IP modules in the chassis to major revision 3.x. This restriction applies to these ControlLogix EtherNet/IP modules:

1756-EN2T 1756-EN2TF 1756-EN2TR 1756-EN3TR

If the ControlLogix EtherNet/IP modules in the chassis with the controller are not all at major revision 3.x, then system may change the time master and/or reductions in synchronization accuracy and system performance may result.

(1) RSLinx Classic communication software, version 2.56, is the minimum required version. However, we recommend that you use version 2.57, when available, for optimal performance.

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

Install the Controller Revision

To download the latest ControlLogix controllers firmware revision, go to http://www.rockwellautomation.com/support/downloads and click your desired revision. Then, use the ControlFlash utility to upgrade your controller. Alternatively, if you have installed RSLogix 5000 programming software, version 16, and related firmware, you may not need to complete the tasks described. The AutoFlash feature of RSLogix 5000 programming software detects if your controller firmware needs upgraded upon a program download to the controller. If a firmware upgrade is necessary, AutoFlash will initiate an update. After you have completed your firmware upgrade, you should complete these steps to verify that the upgrade was successful. 1. Cycle power to the controller. 2. Go online with the controller and view controller properties. 3. Verify that the firmware revision listed matches the firmware to which you intended to upgrade. 4. If the controllers firmware is not correct, initiate another firmware upgrade. For more information about errors when completing a ControlFlash upgrade, see the ControlFlash Firmware Upgrade Kit Quick Start, publication 1756-QS105.

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

10

ControlLogix Controllers, Revision 18

Additional Memory Requirements

This firmware revision may require more memory than previous revisions (for example, 10.x, 11.x). To estimate additional memory requirements for your application, you can either use the memory estimation tool provided with RSLogix 5000 programming software or the tables provided in these release notes.

Use the Estimate Tool

To estimate the amount of memory required by your application, convert the project to the controller revision desired and use the Estimate tool available in the Memory tab of the Controller Properties.

IMPORTANT

When used with a 1756-L7x controller, the RSLogix 5000 programming software Estimate Memory tool does not provide exact memory requirement values. You must add 1.3 KBper user task in your program to the Max Used: values that the Estimate Tool provides, to get an exact value. Keep in mind, your program can contain a maximum of 32 user tasks.

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

11

Estimate Based on Application Components

If you do not have the desired version of RSLogix 5000 programming software, use this table to estimate the additional memory that your project may require. If you are upgrading your system through multiple firmware revisions, add all components your application uses for each of the revisions you upgrade through. For example, if you are upgrading from revision 15.x to revision 18.x, total your application components for revisions 15.x to 16.x, 16.x to 17.x, and 17.x to 18.x.

Table 3 - Additional Memory Requirements per Application Component

If you upgrade from revision (add all that apply) 17.x to 18.x Then add the following memory requirements to your project Component Program Equipment Phase Add-On Instruction Each tag In addition, if you use a tag of the types listed below, increase the memory as indicated for each instance: Produced tag Consumed tag Data Access Control Tag that uses ALARM_ANALOG data type Tag that uses ALARM_DIGITAL data type Tag that uses MOTION_GROUP data type Tag that uses AXIS_SERVO_DRIVE or AXIS_GENERIC_DRIVE data type Tag that uses AXIS data type other than AXIS_SERVO_DRIVE or AXIS_GENERIC_DRIVE Tag that uses COORDINATE_SYSTEM data type with no transform dimensions Tag that uses COORDINATE_SYSTEM data type with transform dimensions Module input connection Module output connection Safety controller Safety partner Increase/Decrease Per Instance + 8 bytes + 20 bytes + 12 bytes + 4 bytes Which comes from this type of memory I/O Data and Logic

+ 36 bytes + (24 bytes number of consumers) + 24 bytes + 4 bytes per symbol - 20 bytes + 28 bytes + 76 + 786 bytes + 818 bytes + 40 bytes + 100 bytes + 20 bytes + 24 bytes - 8 bytes - 8 bytes

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

12

ControlLogix Controllers, Revision 18

Table 3 - Additional Memory Requirements per Application Component

If you upgrade from revision (add all that apply) 17.x to 18.x Then add the following memory requirements to your project Component For each controller (> 1K bytes change): 1756-L6x, 1756-L6xS, 1756-L63XT 1768-L4x, 1768-L4xS 1769-L2x 1769-L31 1769-L32C, 1756-L35CR 1769-L32E, 1756-L35E 1789-L10, 1789-L30, 1789-L60 PowerFlex 700S 2 16.x to 17.x Task Program Equipment Phase LD Routine FBD Routine SFC Routine ST Routine Add-On Instruction If you use a tag of the types listed below, increase the memory as indicated for each instance: Produced Tag Consumed Tag Tag that uses MESSAGE data type Tag that uses ALARM_ANALOG data type Tag that uses ALARM_DIGITAL data type Tag that uses AXIS_SERVO_DRIVE or AXIS_GENERIC_DRIVE data type + 16728 bytes + 14448 bytes + 35084 bytes + 14740 bytes + 35400 bytes + 35036 bytes + 4992 + 55340 bytes + 4 bytes + 4 bytes + 8 bytes + 12 bytes - 8 bytes + 28 bytes + 4 bytes - 12 bytes Increase/Decrease Per Instance Which comes from this type of memory I/O Data and Logic

+ [4 bytes + (4 bytes number of consumers)] + 8 bytes + 4 bytes - 64 bytes - 28 bytes - 34 bytes (2 bytes x number of output cam execution targets) - 52 bytes (2 bytes x number of output cam execution targets) + 20 bytes + 108 bytes

Tag that uses AXIS data type other than AXIS_SERVO_DRIVE or AXIS_GENERIC_DRIVE

Tag that uses COORDINATE_SYSTEM data type of 2 dimensions with 2 transform dimensions Tag that uses COORDINATE_SYSTEM data type of 3 dimensions with 3 transform dimensions

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

13

Table 3 - Additional Memory Requirements per Application Component

If you upgrade from revision (add all that apply) 15.x to 16.x Then add the following memory requirements to your project Component If you use a tag of the types listed below, increase the memory as indicated for each instance: Tag that uses ALARM_ANALOG data type (with no associated tag references) Tag that uses ALARM_DIGITAL data type (with no associated tag references) Tag that uses ALARM_ANALOG data type (if associated tags are configured for the ALARM_ANALOG tag) Increase/Decrease Per Instance Which comes from this type of memory I/O Data and Logic

+ 16 bytes + 4 bytes + 22 bytes + (9 x the number of configured, associated tags) + (3 x the sum of the bytes used by the data type of each of the configured associated tags) For example, an analog alarm moved to V16.03 with two Associated Tags one DINT (4 bytes) and one STRING (88 bytes) would need to add: 22 + 9(2) + 3(92) = 316 bytes + 132 bytes + 4 bytes

Tag that uses the COORDINATE_SYSTEM data type 14.x to 15.x Input module If you use a tag of the types listed below, increase the memory as indicated for each instance: Produced tag Consumed tag Tag that uses COORDINATE_SYSTEM data type Tag the uses any AXIS data type Task Program or equipment phase Routine Serial port Project

+ 12 bytes + 4 bytes + 748 bytes + 800 bytes + 20 bytes + 24 bytes + 4 bytes + 1120 bytes + 4012 bytes

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

14

ControlLogix Controllers, Revision 18

Table 3 - Additional Memory Requirements per Application Component

If you upgrade from revision (add all that apply) 13.x to 14.x Then add the following memory requirements to your project Component If you use a tag of the types listed below, increase the memory as indicated for each instance: Tag that uses the COORDINATE SYSTEM data type Tag that uses any AXIS data type 12.x to 13.x Program Task User-defined data type I/O module Increase/Decrease Per Instance Which comes from this type of memory I/O Data and Logic

+ 60 bytes + 4 bytes + 12 bytes + 4 bytes + 4 bytes + 16 bytes (8 bytes) (8 bytes)

If you use a tag of the types listed below, increase the memory as indicated for each instance: Produced tag Consumed tag 11.x to 12.x I/O module with a comm format = Rack Optimization I/O module with a comm format = something other than Rack Optimization (such as a direct connection) CompactLogix 1769 I/O module Bridge module with a comm format = None Bridge module with a comm format = Rack Optimization 10.x to 11.x User-defined data type

+ 8 bytes + 8 bytes + 90 bytes + 144 bytes + 170 bytes + 160 bytes + 220 bytes + 128 bytes

Number of user-defined data types in the controller

organizer > Data Types folder > User-Defined folder

Not the use of that data type in tags

Indirect address (using a tag as the subscript for an array in an instruction, such as an Array_A[Tag_B]). This memory change applies only if the array does the following: - 60 bytes

Uses a structure as its data type Does not use one of these data types: CONTROL,

COUNTER, PID, or TIMER

Has only one dimension (such as UDT_1[5])

9.x to 10.x Program Routine + 12 bytes + 16 bytes

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

ControlLogix Controllers, Revision 18

15

Table 3 - Additional Memory Requirements per Application Component

If you upgrade from revision (add all that apply) 8.x to 9.x Then add the following memory requirements to your project Component If you use a tag of the types listed below, increase the memory as indicated for each instance: Tag that uses the MESSAGE data type Project Tag Message that transfers more than 500 bytes of data and targets a controller in the same chassis This memory is allocated only when the MSG instruction is enabled. To estimate, count the number of these messages that are enabled and/or cached at one time If you use a tag of the types listed below, increase the memory as indicated for each instance: Base tag Alias tag Produced tag DINT REAL Consumed tag DINT REAL Routine 5.x to 6.x Routine 4 4 4 4 Increase/Decrease Per Instance Which comes from this type of memory I/O Data and Logic

+ 376 bytes + 1050 bytes + 0.55 bytes + 2000 bytes

7.x to 8.x

6.x to 7.x

+ 24 bytes + 16 bytes + 12 bytes + 12 bytes + 12 bytes + 12 bytes + 68 bytes + 116 bytes

Rockwell Automation Publication 1756-RN677A-EN-P - July 2010

Additional Resources

These documents contain additional information.

Resource Logix5000 Controllers Common Procedures Reference Manual, publication 1756-PM001 ControlLogix Controllers Revision 16 Release Notes, publication 1756-RN016 ControlLogix Controllers, Revision 17 Release Notes, publication 1756-RN017 Add-On Instruction Programming Manual, publication 1756-PM010 GuardLogix Controller Systems User Manual, publication 1756-RM093 Description Contains information specific to procedures related to programming your controller. Describes anomalies and enhancements related to controller revision 16. Describes anomalies and enhancements related to controller revision 17. Explains Add-On Instructions and related features. Provides information specific to the use of GuardLogix controllers and safety program elements.

Logix5000 Controllers I/O and Tag Data Explains I/O and tag data. It also includes Programming Manual, publication 1756-PM004 information about using the Data Access Control and External Access features. Produced and Consumed Tags Programming Manual, publication 1756-PM011 Logix5000 Controllers Execution Time and Memory Use Reference Manual, publication 1756-RM087 Logix5000 Controllers Process Control and Drives Instructions Reference Manual, publication 1756-RM006 ControlFlash Firmware Upgrade Kit Quick Start, publication 1756-QS105 Explains produced and consumed tags and includes information about RPI Limitations and Negotiated Default features. Provides calculations of execution times and memory use for Logix5000 controllers. Contains information specific to the PI instruction.

Contains informations about upgrading firmware and related error messages.

You can view or download Rockwell Automation publications at http://www.rockwellautomation.com/literature. To order paper copies of technical documentation, contact your local Rockwell Automation distributor or sales representative. Tech Notes and other resources are available at the Technical Support Knowledgebase, http://www.rockwellautomation.com/knowledgebase.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc. Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.., Kar Plaza Merkezi E Blok Kat:6 34752 erenky, stanbul, Tel: +90 (216) 5698400

Publication 1756-RN677A-EN-P - July 2010

PN-64932

Copyright 2010 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

You might also like

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Throttle Information Reference Guide PDFDocument24 pagesThrottle Information Reference Guide PDFJohn Rivera100% (1)

- CAT ParalelingDocument68 pagesCAT ParalelingGabriel Paco LunaNo ratings yet

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Componetes Electronicos Cat (056-109)Document54 pagesComponetes Electronicos Cat (056-109)Edgar MaldonadoNo ratings yet

- Projects With Microcontrollers And PICCFrom EverandProjects With Microcontrollers And PICCRating: 5 out of 5 stars5/5 (1)

- Chapter 9 - Program Control InstructionsDocument60 pagesChapter 9 - Program Control Instructionsmmorsy1981100% (4)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Trans. de 140hDocument4 pagesTrans. de 140hvictor franco gallegos100% (1)

- Workshopman 03Document33 pagesWorkshopman 03Mohand Oubélaid Ait HammouNo ratings yet

- Huawei Tecal RH2288 V2 Server Compatibility List PDFDocument30 pagesHuawei Tecal RH2288 V2 Server Compatibility List PDFMenganoFulanoNo ratings yet

- Trouble Shooting Guide For Loco Pilots On Microprocessor MEP 660 Ver 2 0 WDM3A WDG3A Locomotives EnglishDocument58 pagesTrouble Shooting Guide For Loco Pilots On Microprocessor MEP 660 Ver 2 0 WDM3A WDG3A Locomotives Englishajay_kairi100% (1)

- PLC Ans Scada ProjectDocument36 pagesPLC Ans Scada ProjectshinyNo ratings yet

- For Loco Pilots On Microprocessor Based Control System MEP660 (Version 3.0) Fitted On Diesel LocomotivesDocument104 pagesFor Loco Pilots On Microprocessor Based Control System MEP660 (Version 3.0) Fitted On Diesel Locomotivespunctuality scr100% (1)

- Cyber Security Lab ManualDocument73 pagesCyber Security Lab ManualANNANAHMED SHAIKH50% (2)

- 03 Hoisting GearDocument89 pages03 Hoisting GearpablodcabreraNo ratings yet

- DeltaV Controller RedundancyDocument5 pagesDeltaV Controller RedundancyturboedNo ratings yet

- Atv31 Mapa ModbusDocument56 pagesAtv31 Mapa ModbusOsoHonguitoMurteNo ratings yet

- 1995 ManualDocument33 pages1995 ManualAntonis BafatakisNo ratings yet

- IGS NT 3 9 0 New FeaturesDocument21 pagesIGS NT 3 9 0 New Featuresandrea8031No ratings yet

- Monitorizar Estado de Red ControlnetDocument7 pagesMonitorizar Estado de Red ControlnetkillnueveNo ratings yet

- CiA402 CANopenDrivesAndMotionControlProfileDocument50 pagesCiA402 CANopenDrivesAndMotionControlProfilechialiNo ratings yet

- MSA2000 Controller ReplacementDocument4 pagesMSA2000 Controller ReplacementGeorge_TNTNo ratings yet

- Logix5550 Controller: Firmware Release NotesDocument2 pagesLogix5550 Controller: Firmware Release NotesTerry XuNo ratings yet

- Rockwell Automation Medium Voltage Drives: El BrocalDocument18 pagesRockwell Automation Medium Voltage Drives: El BrocalRaul quispe quispeNo ratings yet

- TSB Nitro 2100207aDocument6 pagesTSB Nitro 2100207aJoaquin TorreroNo ratings yet

- Ecm Gain SettingDocument2 pagesEcm Gain SettingMuomen FarooqNo ratings yet

- PLC Controlled Motion Release NotesDocument5 pagesPLC Controlled Motion Release NotesEduardo Antonio MateusNo ratings yet

- Robot Error 20143 - Start at Main RejectedDocument3 pagesRobot Error 20143 - Start at Main Rejectedsupendra phuyalNo ratings yet

- DGPMANDocument168 pagesDGPMANnabil160874No ratings yet

- Assessment of Various Unit Control Architecture FoxDocument5 pagesAssessment of Various Unit Control Architecture FoxDavid DelgadoNo ratings yet

- Variador de Frecuencia AbbDocument308 pagesVariador de Frecuencia AbbMoises Malagon100% (1)

- BLX PLC LogicDocument8 pagesBLX PLC LogicbrenbraNo ratings yet

- Manual AbbDocument290 pagesManual Abbgabrielxareu100% (1)

- Software 78Document12 pagesSoftware 78Brayan Sánchez ParedesNo ratings yet

- PowerFlex UDC AOPs Release Notes v15.00.01Document15 pagesPowerFlex UDC AOPs Release Notes v15.00.01Allen BradleyNo ratings yet

- Ic 693 Cpu 313Document5 pagesIc 693 Cpu 313mubashersaeedNo ratings yet

- MORE PLC APPLICATIONS in TRAFFIC SIGNAL OPERATIONSDocument9 pagesMORE PLC APPLICATIONS in TRAFFIC SIGNAL OPERATIONSapi-3770306100% (3)

- Controllogix Controllers, Revision 21: Release NotesDocument22 pagesControllogix Controllers, Revision 21: Release NotesDanilo MalanchinoNo ratings yet

- Logix SERCOS Tuning Tips v1.02 1Document6 pagesLogix SERCOS Tuning Tips v1.02 1José AlanizNo ratings yet

- 2092-At001 - En-P Ab Simple Motion Control PLC BasedDocument5 pages2092-At001 - En-P Ab Simple Motion Control PLC BasedCristopher EntenaNo ratings yet

- BHEL Turbine Start-UpDocument17 pagesBHEL Turbine Start-UpSelvakumar SubramanianNo ratings yet

- ACH580 Override Functionality Appl Guide 3AUA0000206522 RevD ENDocument16 pagesACH580 Override Functionality Appl Guide 3AUA0000206522 RevD ENAmilcar CastilloNo ratings yet

- 1756 RN611CDocument16 pages1756 RN611CPaul Ramos CarcaustoNo ratings yet

- Erhardt + Leimer DC5500 Digital ControllerDocument64 pagesErhardt + Leimer DC5500 Digital ControllerUlises PCNo ratings yet

- Soft-Start Controller For Switching Power Supplies: ImplementationDocument6 pagesSoft-Start Controller For Switching Power Supplies: ImplementationMuhammad Umair JavedNo ratings yet

- Crio-9012 9014 Operating InstructionsDocument20 pagesCrio-9012 9014 Operating InstructionskalovireNo ratings yet

- FSK-628D Gobernador Electronico de MotorDocument35 pagesFSK-628D Gobernador Electronico de Motorsoldadores motoresNo ratings yet

- Testing and Adjusting (SENR9167-02)Document19 pagesTesting and Adjusting (SENR9167-02)Anderson Oliveira Silva100% (1)

- 32.051 - Kit1 RNDocument6 pages32.051 - Kit1 RNyoquins22No ratings yet

- Com01 Manual EnglishDocument89 pagesCom01 Manual EnglishMauricio Rodríguez QuirogaNo ratings yet

- 3 Sept 2018 Lester Controls Almega 3 Power Relay CardDocument2 pages3 Sept 2018 Lester Controls Almega 3 Power Relay CardrajaduraibtechNo ratings yet

- ATV 11 Technical Manual - EN - Mais AtualDocument61 pagesATV 11 Technical Manual - EN - Mais AtualJéferson de LimaNo ratings yet

- RPR and SSODocument16 pagesRPR and SSOBiplab RoyNo ratings yet

- Openloop Motor ModelingDocument16 pagesOpenloop Motor ModelingUmair RazaNo ratings yet

- Single Axis Stepper ControlDocument23 pagesSingle Axis Stepper Controlpaik12No ratings yet

- Rockwell Automation Medium Voltage Drives: Sociedad Minera El BrocalDocument17 pagesRockwell Automation Medium Voltage Drives: Sociedad Minera El BrocalRaul quispe quispeNo ratings yet

- WAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksFrom EverandWAN TECHNOLOGY FRAME-RELAY: An Expert's Handbook of Navigating Frame Relay NetworksNo ratings yet

- Chap05gtp03kh 130222002052 Phpapp01Document26 pagesChap05gtp03kh 130222002052 Phpapp01thanhbcvt_1989No ratings yet

- Basic OpenLdap TutorialDocument5 pagesBasic OpenLdap TutorialHaldar RajarshiNo ratings yet

- Mplabx Pickit3Document1 pageMplabx Pickit3Anthony SahuanayNo ratings yet

- Unix QBDocument17 pagesUnix QBstudy materialNo ratings yet

- EximDocument11 pagesEximapi-3764104No ratings yet

- This Study Resource Was: Chapter 16-Network SecurityDocument6 pagesThis Study Resource Was: Chapter 16-Network SecurityErickson Alex Vargas RoqueNo ratings yet

- Linux CommandsDocument10 pagesLinux CommandsrajduttNo ratings yet

- Web Services Repeating Groups DataStageDocument32 pagesWeb Services Repeating Groups DataStageCarlosO0% (1)

- S S D M: Srinivas BondadaDocument3 pagesS S D M: Srinivas BondadaJason CNo ratings yet

- Hitesh Prajapati - Appointment LetterDocument1 pageHitesh Prajapati - Appointment LetterHitesh PrajapatiNo ratings yet

- Cluster Admin GuideDocument41 pagesCluster Admin GuideVikash BoraNo ratings yet

- Fortinet Nse 2 - Lesson 6Document2 pagesFortinet Nse 2 - Lesson 6Tony CelliNo ratings yet

- ACS Express 5 0 1 User GuideDocument142 pagesACS Express 5 0 1 User Guidejalo1797No ratings yet

- Dynamic Adaptive Streaming Over HTTP (DASH) Ravi 062Document9 pagesDynamic Adaptive Streaming Over HTTP (DASH) Ravi 062Rusteze ChaRanNo ratings yet

- 2014 CEPSI - On-Line PD and Fault Location With SCGDocument8 pages2014 CEPSI - On-Line PD and Fault Location With SCGdes1982No ratings yet

- Hipath 4000Document51 pagesHipath 4000rulogeNo ratings yet

- TTL55-A Large System ConfigDocument2 pagesTTL55-A Large System ConfigDaniel FernandezNo ratings yet

- LetterDocument1 pageLetterYogeshSharmaNo ratings yet

- ADSL RouterDocument2 pagesADSL RouterHichem RkoNo ratings yet

- MP801E Install Manual enDocument44 pagesMP801E Install Manual enmalik006No ratings yet

- Math Project: Karnataka Law Society's Gogte Institute of Technology, BelgaumDocument13 pagesMath Project: Karnataka Law Society's Gogte Institute of Technology, BelgaumVaishnavi B HNo ratings yet

- Action Plan How To Crack CCIE RS V5Document12 pagesAction Plan How To Crack CCIE RS V5NguyễnThanhAnNo ratings yet

- VIZIO VBR120 Blu-Ray User ManualDocument51 pagesVIZIO VBR120 Blu-Ray User ManualKevin Fillips100% (1)

- IDC PlanScape-The Essentials of IoT Investment For Smart CitiesDocument12 pagesIDC PlanScape-The Essentials of IoT Investment For Smart CitiesWilfresh KhafadhiNo ratings yet

- Harga DistributorDocument16 pagesHarga DistributorAta NurdinNo ratings yet

- SaaS Strategic BackgrounderDocument18 pagesSaaS Strategic BackgrounderAnkit KhuranaNo ratings yet

- Iphone Trimline User Guide: For Models At1101, At1102, At1201, At1202Document3 pagesIphone Trimline User Guide: For Models At1101, At1102, At1201, At1202Armando RamirezNo ratings yet

- Configuring+Tomcat-Connector+for+IIS+8 0+ (Windows+Server+2012+or+Windows+8)Document8 pagesConfiguring+Tomcat-Connector+for+IIS+8 0+ (Windows+Server+2012+or+Windows+8)osvserNo ratings yet