0% found this document useful (0 votes)

20 views19 pagesUnit I PPT - RHA

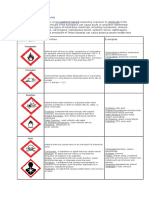

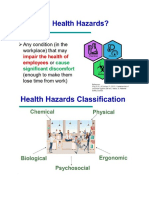

The document outlines various concepts and types of industrial safety hazards, including chemical, physical, mechanical, ergonomic, biological, and noise hazards. It emphasizes the importance of safety programs in protecting workers by identifying and mitigating risks associated with these hazards. Additionally, it discusses specific hazards related to utilities such as air, water, and steam, along with their potential health impacts and preventive measures.

Uploaded by

MirdhulaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

20 views19 pagesUnit I PPT - RHA

The document outlines various concepts and types of industrial safety hazards, including chemical, physical, mechanical, ergonomic, biological, and noise hazards. It emphasizes the importance of safety programs in protecting workers by identifying and mitigating risks associated with these hazards. Additionally, it discusses specific hazards related to utilities such as air, water, and steam, along with their potential health impacts and preventive measures.

Uploaded by

MirdhulaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd