A SEMINAR ON MATERIAL SELECTION PRESENTED BY MD SHAHID & MD FASI UR RAHMAN

OVERVIEW

Materials Selection Why Materials Selection ??? Product Analysis

Product function and interdependent

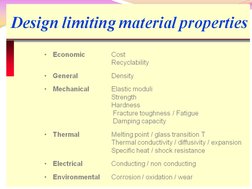

Design limiting material properties Stress strain diagram for material

Fundamental properties

Classification of materials Flow chart of material selection

Ashby chart

Examples LEAF SPRINGS, HELMET,

VACCUM CLEANER, DRINKS CONTAINER

�Materials Selection

Material selection is a step in the process of designing any physical object. In the context of Product Design, the main goal of material selection is to minimize cost while meeting product performance goals

The designer of any product must get involved with

material selection.

Only occasionally will the exact grade of material be

specified by the customer.

Even then the designer must understand the material

to be able to design the product.

��IN ORDER TO STAY COMPETITIVE IN TODAYS MARKETPLACE, A COMPANY MUST UNDERSTAND ITS CUSTOMERS' WANTS AND NEEDS AND DESIGN PROCESSES TO MEET THEIR EXPECTATIONS AND REQUIREMENTS.

�Decisions, decisions!

So many materials, so much information.

How do we decide? How do we begin to choose?

First we need to look at the function of the product product analysis

�Product Analysis

Just what it says analyse the product!

What does it do? How does it do it? Where does it do it? Who uses it? What should it cost?

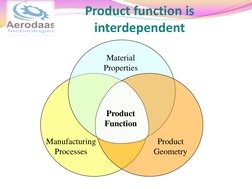

�Product function is interdependent

Material Properties

Product Function

Manufacturing Processes

Product Geometry

�Material properties

Mechanical properties quantities that characterize the behavior of a material in response to external, or applied forces

Physical properties quantities that characterize the behavior of a material in response to physical phenomena other than mechanical forces (e.g. such as heat, electricity, radiation)

��Mechanical properties

stress

F/A

A

ductile ?

S ut

Sy

L L

brittle

elastic plastic

strain

L L L

stiffness ?

Strength = stress at failure = (failure)

�Mechanical properties

�Fundamental properties

Characteristic Strength Elastic strength Stiffness Ductility Hardness Corrosion resistance Behavior strong, weak elastic then plastic flexible, rigid draws, forms easily resists surface indentation resists chemicals, oxidation Property ultimate strength yield strength modulus of elasticity % elongation, % area reduction Brinell No. galvanic series Units MPa (ksi) MPa (ksi) MPa (Mpsi) dimensionless MPa (ksi) activity number

�Fundamental properties

Characteristic Fatigue resistance Conductivity (heat, electric) Creep resistance Impact resistance Density (mass) Density (weight) Temperature tolerance Behavior endures many load cycles Property endurance limit thermal conductivity electrical conductivity creep strength Charpy energy mass density weight density melting point Units MPa (Mpsi) (Btu/hr) / (F-ft), Mhos MPa (ksi) N-m, (ft-lbs) kg/m3, (slugs/ft3) N/m3, (lbs/ft3) degrees C, F

conducts, insulates

time dependent stretching shock, impact loads heavy, light softens, or melts easily

�Property profiles by family

�Material families / subfamilies

Materials

Metals Ferrous

Plastics Thermoplastics Thermosets Elastomers

Ceramics

Composites

Family (Ashby)

Non-ferrous

Sub-family

�Material sub-families / classes

Materials

Metals Ferrous Cast iron Carbon steel Alloy steel Stainless steel

Family Sub-family

Classes

�Metals

Metals

Ferrous cast iron carbon steel alloy steel stainless steel

Non-ferrous aluminum brass bronze copper lead magnesium nickel tin titanium tungsten zinc

�Polymers

Polymers

Natural and synthetic rubbers

Thermoplastics

ABS acetal acrylic nylon polycarbonate polyethylene polypropylene polystyrene vinyl

Thermosets alkyd epoxy melamine phenolic polyester urethane

Elastomers butyl fluorocarbon neoprene nitrile polysulfide rubber silicone

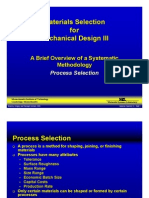

�Materials selection

prospective materials and processes

functional? manufacturable?

screening

rejected materials and processes

feasible materials and processes

relative performance?

rating

best material(s) and processes

�Screening: How do we choose a material?

Product function depends upon

material, manufacturing process, geometry

We have to consider all three

Do we select a few feasible materials first then select the specific mfg process?

or

Do we select a few feasible mfg processes then select the specific material?

�Screening: Materials first approach

Application Information

1. Applied loads magnitude cyclic nature (steady, fatigue) rate (slow, impact) duration (creep) 2. Ambient conditions temperature moisture sunlight chemical liquids/vapors 3. Safety 4. Cost

�Screening: Manufacturing process first approach

Part Information

1. 2. 3.

Production volume Part size (overall) Shape capability (features) boss holes undercuts (internal/external) uniform walls cross sections (uniform /regular) rotational symmetry captured cavities

�ASHBY CHART

How can we use it?

��EXAMPLE 1

�Given conditions

�Result

�EXAMPLE 2

�����EXAMPLE 3

��Drink Container