Professional Documents

Culture Documents

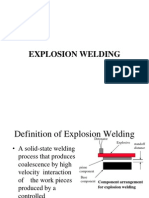

Explosion Welding

Uploaded by

JohnLesterD.BoyoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Explosion Welding

Uploaded by

JohnLesterD.BoyoCopyright:

Available Formats

Explosion Welding

Keith Powell

Michael Fernandez

Staton Burrell

Basics

Explosion welding is a solid-state process

that produces a high velocity interaction of

dissimilar metals by a controlled

detonation

Oxides found on material surfaces must

be removed by effacement or dispersion

Surface atoms of two joining metals must

come into intimate contact to achieve

metallic bond

Advantages

No heat-affected zone (HAZ)

Only minor melting

Material melting temperatures and

coefficients of thermal expansion

differences do not affect the final product

The shock front compresses and heats the

explosive material which exceeds the

sonic velocity of undetonated explosives

Component Terminology

Base component

Joined to cladder

Remains stationary

Supported by anvil

Cladding metal

Thin plate in direct contact with explosives

Can be shielded by flyer plate

Flyer plate

Sacrificial plate placed between explosive

material and cladder plate

Used to protect cladder metal

Interlayer

Thin metal layer

Enhances joining of cladder to base plate

Anvil

Surface of which the backer rests during

explosion

Standoff

Distance between cladder and base plate

before explosion

Bond Window

A range of variable in process such as

velocity, dynamic bend, and standoff distance

that result in successful weld

Bonding Operation

Detonation of explosives that result in a weld

Principle of Explosion

Cladder metal can be placed parallel or

inclined to the base plate

Explosive material is distributed over top

of cladder metal

Upon detonation, cladder plate collides

with base plate to form weld

Placement of Cladder metal-parallel

Standoff distance predetermined

and unique to material combination

Achieved by placing shims

between plates

Shims designed to be

consumed by explosion wave

and do not affect weld

Usually ranges between 0.5-2 times

the thickness of cladder plate

Cladder must reach critical velocity

before impact

Cladder placement-Angled

Where:

Vc = collision velocity

VD = detonation velocity

Vp = plate Collision velocity

= preset angle

= dynamic bend angle

= collision angle

Vc

VD

Vp

Explosive material

High velocity (14750-25000 ft/s)

Trinitrotoluene (TNT)

Cyclotrimethylenetrinitramine (RDX)

Pentaerythritol Tetranitrate (PETN)

Mid-low velocity (4900-47500 ft/s)

Ammonium nitrate

Ammonium perchlorate

Amatol

Assuring a good weld

Three types of detonation wave welds

Shock wave develops if sonic velocity is

greater than 120% of material sonic velocity

(type 1)

Detached shock wave results when

detonation velocity is between 100% and

120% of material sonic velocity (type 2)

No shock wave is produced if detonation

velocity is less than material sonic velocity

(type 3)

Assuring a good weld

Type 1

Material behind shock wave is compressed to

peak pressure and density

Creates significant plastic deformation locally

and results in considerable shock hardening

Type 2 & 3

Pressure is generated ahead of collision point

of metals

When subject to large pressures, metal

ahead of collision point flows into spaces

between plates and takes form of high-

velocity jet

Effaces material and removes unwanted

oxides and other unwanted surface films

No bulk diffusion and only localized melting

Assuring a good weld

Detonation velocity is a function of

Explosive type

Composition of explosive

Thickness of explosive layer

Can be found in tables

Assuring a good weld

Sonic velocity of cladding material can

calculated using:

Where:

K = adiabatic bulk modulus

= cladding material density

E = Youngs Modulus of cladding material

= Poissons ratio of cladding material

Applications

Any metal with sufficient strength and

ductility can be joined

Applications

Can weld large areas of metal

Can weld inside and outside surfaces of

pipes

Transition joints can be made

History

Arnold Holtzman and a team at DuPont in Delaware put

a lot of research into developing the process.

Holtzman filed for a US patent in 1962 for explosion

welding, received the patent in 1964 and began

commercial production of bi-metallic explosion welded

clad in 1965.

Detaclad licensed the process and was bought by

Dynamic Materials Corporation (DMC).

Other companies have merged with DMC and acquired

the current name DMC Groupe SNPE making them a

worldwide company.

Common industries that use explosion welding

Chemical Processing

Petroleum Refining

Hydrometallurgy

Aluminum Smelting

Shipbuilding

Electrochemical

Oil & Gas

Power Generation

Cryogenic Processing

Pulp & Paper

Air conditioning & Chillers

Metal Production

Examples

Examples

3 Diameter AI/SS Ring Copper/Stainless 12 UHV Assembly

Examples

United States dimes and quarters are

presently a clad sandwich of copper

inner-core and a silver-colored nickel-

copper alloy

Works Cited

http://www.annualreviews.org/doi/pdf/10.1146/annurev.ms.05.08017

5.001141

http://www.authorstream.com/Presentation/rock354-421051-

explosive-welding-final-unconventional-machining-mp-iii-education-

ppt-powerpoint/

Young, G (2004). "Explosion Welding, Technical Growth and

Commercial History" (PDF). Dynamic Materials Corporation.

http://www.dynamicmaterials.com/data/brochures/1-

%20Young%20Paper%20on%20EXW%20History.pdf. Retrieved

2010-11-29

You might also like

- Explosion WeldingDocument22 pagesExplosion WeldingezzataNo ratings yet

- Explosion Welding: A Guide to the Solid-State Joining ProcessDocument22 pagesExplosion Welding: A Guide to the Solid-State Joining ProcessdnatarajanNo ratings yet

- Explosion WeldingDocument22 pagesExplosion WeldingLesther Alexander CorreaNo ratings yet

- Explosion Welding: A Solid-State Process for Joining Dissimilar MetalsDocument23 pagesExplosion Welding: A Solid-State Process for Joining Dissimilar MetalsAnurag SinghNo ratings yet

- Explosion WeldingDocument25 pagesExplosion WeldingKameswara ReddyNo ratings yet

- Explosion Welding ProcessDocument12 pagesExplosion Welding ProcessManash DeyNo ratings yet

- Explosion Welding SeminarDocument22 pagesExplosion Welding Seminarvaibhavsawal100% (1)

- Explosive FormingDocument16 pagesExplosive FormingAshutoshSingh100% (1)

- SMT BrochureDocument8 pagesSMT BrochureLucas LobãoNo ratings yet

- Explosive Welding TechniquesDocument13 pagesExplosive Welding TechniquesBimurta DasNo ratings yet

- Explosive WeldingDocument54 pagesExplosive WeldingNallappan Rajj ANo ratings yet

- MANUFACTURING TECHNOLOGY GUIDEDocument46 pagesMANUFACTURING TECHNOLOGY GUIDEMuthu BaskaranNo ratings yet

- Explosion Bonding Process: Nobelclad Technical Bulletin NT 200Document9 pagesExplosion Bonding Process: Nobelclad Technical Bulletin NT 200MilindMotghareNo ratings yet

- HERFDocument9 pagesHERFDhiraj RauniyarNo ratings yet

- ENS 205 Failure Analysis and PreventionDocument76 pagesENS 205 Failure Analysis and PreventionBolaji Suberu100% (1)

- Welding Processes ExplainedDocument20 pagesWelding Processes ExplainedNawaz RafiqueNo ratings yet

- SOLID STATE WELDING TECHNIQUESDocument77 pagesSOLID STATE WELDING TECHNIQUESparthibankNo ratings yet

- Sravan WeldingDocument16 pagesSravan WeldingSravan Kumar50No ratings yet

- Explosion Bonding: An SEO-Optimized TitleDocument6 pagesExplosion Bonding: An SEO-Optimized TitleJason SmithNo ratings yet

- Explosive Welding 1 WeldingDocument4 pagesExplosive Welding 1 WeldingRabindra DashNo ratings yet

- Diffusion Bonded Welding (DBW) Process OverviewDocument23 pagesDiffusion Bonded Welding (DBW) Process OverviewKameswara ReddyNo ratings yet

- Joining ProcessesDocument10 pagesJoining ProcessesSachin KhotNo ratings yet

- Surface TreatmentDocument34 pagesSurface TreatmentnagarajNo ratings yet

- Material ScienceDocument46 pagesMaterial Sciencealfa89pNo ratings yet

- Explosive WeldingDocument33 pagesExplosive WeldingNivedh VijayakrishnanNo ratings yet

- Chapter 8 Failure Analysis and PreventionDocument76 pagesChapter 8 Failure Analysis and Preventionminh_bk0101100% (1)

- Fundamentals of Welding Joints and ProcessesDocument32 pagesFundamentals of Welding Joints and ProcessescrheidrNo ratings yet

- Arc Welding and Gas Welding Processes ExplainedDocument23 pagesArc Welding and Gas Welding Processes ExplainedRaghu ChowdaryNo ratings yet

- Manufacturing Processes (Welding (BENG) HandoutDocument67 pagesManufacturing Processes (Welding (BENG) HandoutbananaNo ratings yet

- WeldingDocument48 pagesWeldingOkti GiffariNo ratings yet

- Mechanisms of Wear in HSS Cutting ToolsDocument31 pagesMechanisms of Wear in HSS Cutting Toolsjyoti ranjan nayak100% (2)

- Unit 5 Welding ProcessDocument57 pagesUnit 5 Welding Processmahammad kamaluddeenNo ratings yet

- Effect of Temperature and Strain RateDocument4 pagesEffect of Temperature and Strain RateRavichandran GNo ratings yet

- Cte U1l4Document20 pagesCte U1l4Nikhil VishavkramaNo ratings yet

- Temp. Effects Metal FormingDocument14 pagesTemp. Effects Metal FormingSatyamKumarNo ratings yet

- Friction Welding, Explosive WeldingDocument7 pagesFriction Welding, Explosive WeldingASHUTOSH KUMAR SHRIVASTWANo ratings yet

- Solid State WeldingDocument14 pagesSolid State WeldingRaju_pancal100% (1)

- 2 Tool Wear & Tool Life 2Document40 pages2 Tool Wear & Tool Life 2haile mehariNo ratings yet

- Welding Processes: EN358 - Ship StructuresDocument27 pagesWelding Processes: EN358 - Ship StructuresMayur PatelNo ratings yet

- Welding Processes and Principles for Ship StructuresDocument27 pagesWelding Processes and Principles for Ship StructuresRavindra ReddyNo ratings yet

- Joining Part2Document27 pagesJoining Part2Dune StarlightNo ratings yet

- Impact TestingDocument27 pagesImpact Testingravi00098No ratings yet

- Impact TestingDocument27 pagesImpact Testingapi-3764139100% (2)

- Non-Arc Welding Processes: Laser, Electron Beam, Brazing & MoreDocument41 pagesNon-Arc Welding Processes: Laser, Electron Beam, Brazing & Moresushil sandhuNo ratings yet

- Unit 302: Engineering Principles: Characteristics of Engineering MaterialsDocument22 pagesUnit 302: Engineering Principles: Characteristics of Engineering MaterialsKeron BretalNo ratings yet

- 6,7-Forge Welding, Resistance WeldingDocument13 pages6,7-Forge Welding, Resistance WeldingRamu AmaraNo ratings yet

- ME: 121 Engineering Practices: Types of WeldingDocument21 pagesME: 121 Engineering Practices: Types of WeldingHammad AhmedNo ratings yet

- Lecture 1Document17 pagesLecture 1Gökhan ÇiçekNo ratings yet

- Wear and Repair in Vechicle 1Document69 pagesWear and Repair in Vechicle 12B Dai Ko DUPLICATENo ratings yet

- Unit-V: Metal Joining ProcessesDocument110 pagesUnit-V: Metal Joining ProcessesSubbu AynavillyNo ratings yet

- AMP (MIN572) Lecture 3 FormingDocument46 pagesAMP (MIN572) Lecture 3 FormingNAMAN AGARWALLANo ratings yet

- Welding ProcessDocument27 pagesWelding ProcessMultiverseIit0% (1)

- 2-3 Diffusion WeldingDocument40 pages2-3 Diffusion WeldingDanny Vargas HuamanNo ratings yet

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforFrom EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforNo ratings yet

- Structural Performance of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)Document7 pagesStructural Performance of Concrete by Partial Replacement of Cement With Hypo Sludge (Paper Waste)ijeteeditorNo ratings yet

- Thermoset Powder Coatings: Lawrence R. WaeldeDocument12 pagesThermoset Powder Coatings: Lawrence R. WaeldeMihaela LetNo ratings yet

- DSMTS-0093.2 NiCoCrAlYDocument5 pagesDSMTS-0093.2 NiCoCrAlYjpereiraucNo ratings yet

- Sandeep ChemistryDocument21 pagesSandeep ChemistrySandeep Nandan MishraNo ratings yet

- Paint and Surface CoatingsDocument7 pagesPaint and Surface Coatingssami_sakrNo ratings yet

- Slab-on-Grade Reinforcing Design Course OutlineDocument9 pagesSlab-on-Grade Reinforcing Design Course OutlineAdam GreenlawNo ratings yet

- Katalog Intek Bara PaltrosionDocument32 pagesKatalog Intek Bara PaltrosionsandbadbahriNo ratings yet

- Joints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint SealantsDocument4 pagesJoints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint SealantsRenish Regi100% (1)

- Fire Fighting EquipmentDocument2 pagesFire Fighting EquipmentuniversalfireprotectionNo ratings yet

- Roller Compacted Concrete For DamsDocument16 pagesRoller Compacted Concrete For Damsabhineet srivastavaNo ratings yet

- Specmca Ons " "'H" Sections of The Technical IDocument7 pagesSpecmca Ons " "'H" Sections of The Technical Idcdecastrojr100% (1)

- DuctboardDocument25 pagesDuctboardpal_stephenNo ratings yet

- Flowserver Duriron Price ListDocument12 pagesFlowserver Duriron Price ListOgochukwuNo ratings yet

- 56 Windows Dornier 328Document9 pages56 Windows Dornier 328miguel ayala100% (2)

- Stone Masonry TechniquesDocument9 pagesStone Masonry TechniquesprashmceNo ratings yet

- Guide To Jewelry TechniquesDocument22 pagesGuide To Jewelry TechniquesJill Krahling80% (5)

- TPE Vs EPDM Vs SBR and QualityDocument10 pagesTPE Vs EPDM Vs SBR and QualityManas Mondal100% (1)

- Electrosteel UK BrochureDocument40 pagesElectrosteel UK Brochureroco_3213No ratings yet

- FibranCatalog PDFDocument16 pagesFibranCatalog PDFIonut JilNo ratings yet

- Casamilano 2009Document28 pagesCasamilano 2009branajasenNo ratings yet

- Din 914Document6 pagesDin 914Mark802No ratings yet

- FMDS0112 Ceiling and Concealed SpacesDocument8 pagesFMDS0112 Ceiling and Concealed Spacesshazan45No ratings yet

- IAPD Plastics Intro1Document4 pagesIAPD Plastics Intro1eduardo_umNo ratings yet

- IKEA Catalogue 2012Document189 pagesIKEA Catalogue 2012jaysonx29100% (1)

- Al Tahadi UnivesityDocument19 pagesAl Tahadi UnivesityPadma SundarNo ratings yet

- Air Fiter - Regulator SB10Document3 pagesAir Fiter - Regulator SB10Abhishek SinghNo ratings yet

- Stone LithochromeColorHardener 1110 21Document5 pagesStone LithochromeColorHardener 1110 21tigre_fielNo ratings yet

- Perimeter Joints Fire Protection System Design and TestingDocument56 pagesPerimeter Joints Fire Protection System Design and Testingromeojr sibullasNo ratings yet

- Metal Clay Jewelry EbookDocument21 pagesMetal Clay Jewelry Ebook110802100% (2)

- Ferrocement Structural ApplicationsDocument19 pagesFerrocement Structural ApplicationsSivaramakrishnaNalluriNo ratings yet