Professional Documents

Culture Documents

NTPC Training Report

Uploaded by

pankajpnd1100%(1)100% found this document useful (1 vote)

255 views83 pagesSUMMER VOCATIONAL TRAINING PEPORT

Original Title

NTPC TRAINING REPORT

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSUMMER VOCATIONAL TRAINING PEPORT

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

255 views83 pagesNTPC Training Report

Uploaded by

pankajpnd1SUMMER VOCATIONAL TRAINING PEPORT

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 83

SUMMER TRAINING

NTPC Ltd. ,BARH(PATNA)

IIMT INSTITUTE OF ENGINEERING

& TECHNOLOGY

ELECTRICITY GENRATION FROM COAL

Presented by: MUNNA KUMAR

B.Tech(E.C.-G1)

4th yr.

Roll no.- 1037131040

Electricity Generation From Coal

Electricity Generation From

Coal

Lets start at the beginning.

Almost everything in our homes and

businesses today run on electricity.

That electricity has to come from somewhere.

Some sources of electricity are nuclear power,

solar power, wind power, and most important

for us Coal Power.

The Process

Coal was used to heat water in boiler room pipes to

produce steam

The steam was used in a reciprocating (piston)

steam engine to produce mechanical energy

The mechanical energy was converted into

electricity by a dynamo (generator)

Inside the dynamo room

www.nps.gov

Boiler plant can be divided in to three parts.

i) water circuit

ii) steam circuit

iii) The air and fuel gas circuit.

1) Water circuit

In the water circuit, water is fed from the boiler feed pumps into the boiler

through economiser. In the economiser, it receives some heat from the

departing flue gas before it goes to the boiler drum. The drum acts as a

reservoir for the various water walls of the boiler and also acts as a

separation chamber where water is removed from the steam before the

steam goes to the superheaters.

From the boiler drum the water passes down through pipes called down

comers to headers at the bottom of the boiler water walls.

The tubes which makeup the walls contain a mixture of

steam bubbles and water. This mixture being low dense

than water in the down comers, rises rapidly and reaches

back to the drum and its place is taken by the water

flowing through down comers. This produces what we call

is natural circulation.

The steam and water mixture which is returned to the

drum is separated so that water only (with no steam

bubbles) is returned to the down comers, and steam

only(with no water droplets) passed to the super heaters.

2) Steam circuit

Dry steam from the boiler drum goes to the various

superheater sections. Steam from the boiler drum passes

through the superheater connecting tubes to the primary

superheater, which is positioned in the convection pass.

The steam then flows from the primary superheater outlet

header to the secondary superheater located in the

combustion chamber.

Steam then goes to the final superheater which is located in

the combustion chamber in the outlet section, it then leaves

the final super heater outlet header and passes to the main

stem pipe which has a boiler stop valve.

3)Air/gas circuit

To burn the fuel in the combustion chamber air is required. After

combustion, the hot gases are to be evacuated from furnace through the

heat absorbing surfaces. This air and gas flow is created by the boiler

draught system, which may be either natural or mechanised.

The air drawn from the atmosphere is first routed through an air heater

where air is heated by the outgoing flue gases. The hot air is then admitted

to the furnace through wind box. In coal fired boilers part of this hot air is

used for drying the coal in the pulvariser and transporting the pulvarised

coal to furnace.

The gases pass through the radiant heat release zone and then through

various superheaters and reheaters (in reheat boilers). Normally there will

be a primary superheater and secondary superheater.

After passing through the air heater the flue gas goes to the chimney. In

between the air heater and chimney it is customary to provide

precipitator to remove the flyash from the flue gas (especially in coal

fired boilers) and induced draught fans to suck out the flue gases from

the furnace (in balanced draught/induced draught boilers).

water is the working medium which transfers the heat energy available in

the fuel to the turbine in the form of steam.

22 C reduction in flue gas temperature increases boiler efficiency by 1%

Water is chosen as the medium because of the

following reasons.

a) its easy availability

b) its low viscous property

c) it has high specific heat

d) Its non-reactivity with surfaces with which it comes in

to contact.

The following can be termed as boiler

pressure parts.

1. Boiler drum

2. Water walls

3. Superheaters

4. Reheaters and

5. Economisers

BOTTOM RNG HDR & Z-PANEL 1

ST

PASS W.W

1

ST

PASS W.W O/L HDRS ROOF I/L HEADER

2

ND

PASS UPPER C-HDR 2

nd

PASS LOWER C-HDRS

LTSH I/L HEADER LTSH O/L HEADER

D.P.I/L HEADER D.P.O/L HEADER

S.H. HEADER R.H.HEADER

2

ND

PASS ROOF O/L HDR(REAR ECONOMISER

M.S

H.

R.

H C.R.H

FROM F.R.S

Steam Generator

Bottom

Ash Hopper

Bottom

Ring Header

Economiser

LTSH

Eco Hopper

Drum

Final SH

Furnace

Reheater Platen SH

Front Pass

Rear Pass

Goose Neck

Water Walls

Pent House

Steam cooled

Walls

Air Pre Heater

Wind Box

Burners

Platen SH.

375C-425C

Final SH.

500-540C

Economizer

240-310C

LTSH

330-375C

Water Wall

310C

210 MW Boiler: Water and Steam Circuit

BOILER DRUM

The drum acts as reservoir for water &

saturated steam and also provides

separation and purification of steam.

The feed water to the drum reaches

the drum from the boiler feed pump via

the economizer.

A stronger material for use in boiler

drums is Ducal W30.

Methods of Steam Separation:

1. By Gravity separation

This is employed for boilers having low generation rates.

2. By use of Baffles

These are in the form of obstacles in the direct path of steam towards outlet.

WATER WALL SYSTEM:

In the boiler the walls of the combustion chamber are

formed by tubular wall sections which not only form the

enclosure for the furnace but also provides the

evaporating surface for the feed water.

The water from the boiler drum is admitted in to the

water wall tubes through the downcomers and bottom

ring headers.

As the water circulates through the waterwall tubes,

which receive heat from the furnace radiation, water

partially evaporates into steam.

Water-steam mixture then return back to the boiler

drum.

SUPER HEATERS:

Super heaters (SH) are meant for raising the steam temperature above the

saturation temperature.

The superheated and reheated steam temperature around 540C and pressure

165 bar.

i) SH (Reheater also) can classified into convection and radiation type

as per heat transfer process.

The super heaters and reheaters which are placed above the furnace and can view

the flame are called radiant type.

ii) Super heater may be classified also according to the shape of the tube banks

and the position of the headers, such as pendant SH, platen SH, horizontal SH,

Ceiling SH, wall SH etc.

iii) They may be classified according to their stages of superheating they perform,

like primary SH, Secondary SH, Final SH etc.

Reheaters:

Reheaters (RH) are provided to raise the temperature of the steam

from which part of energy has already been extracted by HP turbine.

De-superheaters:

Though super heaters are designed in such a way that heat

absorbed by radiant and convection super heaters always try

to maintain the steam temperature constant in practice the

necessary control is achieved by using de-super heater.

All modern boiler contact type de-super heaters by which feed water are sprayed

directly into the steam for required cooling.

Amount of feed water to be sprayed is controlled by automatic control system

which is designed to maintain a set final steam temperature. Provision of manual

control is also there for emergency.

ECONOMISERS:

The economiser absorbs heat from the flue

gas and adds it mainly as sensible heat to the

feed water.

The material used in the manufacture of

furnace wall tubes for coal fired boiler is

ordinary carbon steel but in the 500 MW oil

fired units the major proportion of the furnace

is constructed from the 1% Cr. % Mo Alloy.

In 660 MW units also this material is used for

whole of the furnace.

The Boiler Auxiliaries :

Draft system

Air heaters

Milling systems

Electrostatic precipitators,

etc.

DRAFT SYSTEM:

The combustion process in a furnace can take place only when it

receives a steady flow of Air and has the combustion gases

continuously removed.

The Boiler draft system includes Air and Flue gas flow.

All modern large utility boilers are fired under "balanced draft"

condition, i.e. where draft is zero. This condition is created by the

combination of "forced draft" and "Induced draft".

SOOT BLOWERS

deposits resulting from the combustion of coal will be deposited on

the boiler tubes at various zones will be cleaned by soot blowing for

effective heat transfer while on-load.

AIR HEATERS:

The air heater is required for efficient combustion in the furnace and

also for drying wet coal in the milling plant. to recover "waste" heat

from the flue gas to increase boiler efficiency

AIR PREHEATER

MILLING PLANT :

raw coal from the bunker is fed at a regulated rate to the mills through

a feeder.

Air required for drying and transporting the pulverized coal from the

mill is obtained from the FD fan.

Hot air is drawn through air heaters and cold air directly from FD fan

discharge.

The drying and grinding takes place inside the mills. The pulverized

particles are being carried from the mill to the classifier, which is

directly mounted on the mill.

The medium is directed into the burners through various fuel

pipelines.

Type of Pulverizers:

Drum/Tube mills:

Ball mills:

Bowl mills:

ELECTROSTATIC PRECIPITATORS:

Working Principle:

The principles upon which an electrostatic precipitator

operates are that the dust laden gases pass into a

chamber where the individual particles of dust are given

an electric charge by absorption of free ions from a high

voltage D.C. ionising field.

They are removed by an intermittent blow usually

referred to as rapping. This causes the dust particles to

drop into dust hoppers situated below the collecting

electrodes.

The following fans are used in the boiler houses:

1. Forced Draft fan (F.D. Fan):

To take air from atmosphere to supply all the Combustion air. Speeds vary between

600 to 1500 r.p.m.

2. Induced Draft Fan (I.D. Fan):

Used only in balanced draft units to suck the gases out of the furnace and throw them

into the stack.

Handles flue gases at temperatures of 125 to 200

o

C.

Speed generally does not exceed 1000 rpm.

3. Primary Air Fans (P.A. Fans) or Exhauster Fan:

Used for pulverized system

Primary air has got two functions viz. Drying the coal and transportation into the

furnace.

Usually 1500 r.p.m.

Stator Casing

Ece.umr.edu

Steam Turbine

As mentioned before,

something has to turn the

rotor in order to generate

electricity.

In our case the prime mover

happens to be a steam

turbine.

Steam comes out of the tubes

in the boiler and into a

manifold then into the turbine.

As the steam passes over the

turbine blades, torque is

produced as a result of the

blade shape.

Steam Turbine

Wikipedia

Turbine Generator and Condenser

Steam Turbine

The rate of steam flow controls how fast the turbine

rotates and therefore the frequency of the electricity

produced.

As the steam moves through the turbine energy is

extracted which results in a pressure drop.

Therefore the LP turbine is located at the exit of the

HP turbine to extract the maximum amount of

energy from the steam before it is sent to the

condenser.

As electricity is generated it leaves the building

though a very large circuit breaker and a series of

transformers before it enters the power grid.

Path of Electricity

Control Room

Condenser

After the steam leaves the LP turbine it travels to the

condenser, where it is condensed back to liquid

water.

The condenser is a heat exchanger that cools the

steam while is passes over tubes that have cold

water running through them.

The cold water removes energy from the heated

steam causing it to condense which is necessary for

the water to be re-used as feed.

There is another reason why the condenser is

necessary which we will discuss shortly.

Cooling Towers

The water that runs through the tubes in the

condenser must be cooled down in order to

condense the steam.

This is accomplished using very large cooling

towers, in which the water is atomized by

sprayers and cooled down by atmospheric

conditions and fans.

The substance leaving cooling towers is

sometimes mistaken for smoke, but it is in fact

just water vapor.

Cooling Towers

Cooling Tower

Main Condenser

Holte International

Feed System

After the condensate is collected in the

hotwell of the condenser it is pumped through

the feed system.

The feed pump increases the pressure of the

feed water in order for it to flow back into the

boiler to be turned back into steam to start

the cycle over again.

This stage turns out to be the 4

th

and final

stage of something called a heat engine.

Basic Heat Engine

Laws of Thermodynamics

1

st

: The increase in internal energy of a

system is equal to the amount of heat energy

added to the system minus the work done by

the system on the surroundings.

Laws of Thermodynamics

2

nd

: The temperature differences between systems in

contact with each other tend to even out and that work

can be obtained from these non-equilibrium differences,

but that loss of heat occurs, in the form of entropy, when

work is done.

2

nd

: It is impossible to produce work in the surroundings

using a cyclic process connected to a single heat reservoir

(Kelvin, 1851).

Laws of Thermodynamics

The second law also states that the maximum

efficiency of a heat engine can be determined by:

= 1-(T

h

/T

c

)

Efficiency is also equal to the work output over the

heat input.

= W/ Q

H

Efficiency

An ordinary power plant operates between the

temperatures of 565C and 25C which leads to

maximum efficiency of around 64%.

However, due to the losses mentioned earlier

the usual observed efficiency is about 35%.

This shows how much of the energy stored in

the coal is just wasted instead of being

converted to electricity.

Steam Cycle

The previous part of the presentation was to

explain the process behind electricity

generation that occurs after the coal portion.

I will now go through some of the components

dealing with the coal aspect of the power

plant ending at the boiler which is where the

steam cycle began.

Most of what I will discuss is particular to the

Co-gen plant that I visited.

Coal Delivery

After the coal is mined and loaded into trucks

it is delivered into chutes that lead to the

Bradford Breaker.

The breaker is a drum with hammers in it that

rotates and breaks the coal down into pieces

about 4 diameter, which fall through the

screen and onto the conveyor belt which leads

to the storage facility.

Bradford Breaker

www.penncrusher.com

Bradford Breaker

Coal Storage

After the coal has been sufficiently reduced in

size, it enters a storage facility, in this case, a

large dome.

The coal is then stacked using a machine you

will see in the next slide, which rotates and

places the coal around the perimeter of the

dome.

This same machine also takes coal from the

pile and delivers it to the crusher building.

Coal Storage

Crusher

The coal is delivered from the storage facility to a

device conveniently called a coal crusher.

This machine takes the 4 pieces of coal and through

a series of rollers converts the fuel into a fine

powder.

This powder is necessary for proper combustion in

the boilers.

All newer state of the art power plants are set up to

work with pulverized coal, but older plants may

operate with lumped coal.

Crusher

Crusher

Fuel Feed System

The conveyor belt

delivers the crushed

coal to a series of fuel

feeders, which inject

coal into the boilers

along with a mixture of

high pressure air for

combustion.

Boiler Base

Boiler Building

Boilers

The final stage for the coal coincides with the

first stage of the steam plant.

The boiler is usually the largest component of

the coal power plant climbing as high as 200 ft.

Inside the boilers the pulverized coal is burned

while it more or less floats with the aid of HP

air.

Lining the entire inside of the boiler are tubes

which carry the feed water to be turned into

steam.

Boilers

www.boatnerd.com

Boiler

Wikipedia

Inside the Boiler

news.minnesota.publicradio.org

After the Boiler

As the coal is burned a large amount of ash is

produced.

Some falls to the bottom and is collected, then

mixed with water and sent to the ash pile.

Very light ash particles also escape with the

exhaust gasses which are captured by a bag

filter system.

This fly ash is collected in a silo until a certain

level is reached when it is pumped to the ash

pile via HP air.

Fly Ash

www.concretethinker.com

Ash Pile

Ash

This ash has a basic pH and has

some beneficial uses.

After a truck delivers coal to the

plant it is filled with ash to return to

the reclamation site.

The high pH helps treat acid mine

drainage.

Ash

The fly ash is used as a substitute to

make Portland cement.

Another use of fly ash is structural

fill for highway embankments and

the fill under new highways.

Exhaust Gasses and the Stack

One of the most controversial aspects of a coal

power plant is what comes out of the stack.

During the combustion process dangerous

gasses and particulates are released, such as

NO

x

, SO

x

, and CO

2

.

Controls are in effect for each of these in new

plants, however older plants spew thousands of

pounds of each of these into the atmosphere

every year.

Intermittent Blowdown

The intermittent blown down is given by manually

operating a valve fitted to discharge pipe at the lowest

point of boiler shell to reduce parameters (TDS or

conductivity, pH, Silica etc) within prescribed limits so

that steam quality is not likely to be affected

TDS level keeps varying

fluctuations of the water level in the boiler.

substantial amount of heat energy is lost with

intermittent blow down.

Continuous Blowdown

A steady and constant dispatch of small

stream of concentrated boiler water, and

replacement by steady and constant inflow

of feed water.

This ensures constant TDS and steam

purity.

This type of blow down is common in high-

pressure boilers.

Boiler Water Treatment

Internal Water Treatment: It is carried out by adding

chemicals to boiler to prevent the formation of scale by

converting the scale-forming compounds to free-flowing

sludges, which can be removed by blowdown.

Limitation: Applicable to boilers, where feed water is low

in hardness salts, to low pressures- high TDS content in

boiler water is tolerated, and when only small quantity

of water is required to be treated.

Internal treatment alone is not recommended.

External Water Treatment

Propose: External treatment is used to remove suspended

solids, dissolved solids (particularly the calcium and

magnesium ions which are a major cause of scale formation)

and dissolved gases (oxygen and carbon dioxide).

Different treatment Process :

ion exchange;

demineralization;

reverse osmosis and

de-aeration.

Demineralization

Demineralization is the complete removal of all salts.

This is achieved by using a cation resin, which exchanges the cations

in the raw water with hydrogen ions, producing hydrochloric, sulphuric

and carbonic acid.

Carbonic acid is removed in degassing tower in which air is blown

through the acid water.

Following this, the water passes through an anion resin which

exchanges anions with the mineral acid (e.g. sulphuric acid) and forms

water.

Regeneration of cations and anions is necessary at intervals using,

typically, mineral acid and caustic soda respectively. The complete

removal of silica can be achieved by correct choice of anion resin.

De-aeration

When heated in boiler systems, carbon dioxide

(CO

2

) and oxygen (O

2

) are released as gases and

combine with water (H

2

O) to form carbonic acid,

(H

2

CO

3

).

Deaerator

In de-aeration,

dissolved gases, such

as oxygen and carbon

dioxide, are expelled

by preheating the feed

water before it enters

the boiler.

Exhaust Gasses and the Stack

The Stack

www.industcards.com/as-pontes.jpg

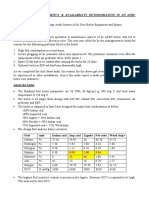

Reduce Stack Temperature

Stack temperatures greater than 200C

indicates potential for recovery of waste heat.

It also indicate the scaling of heat

transfer/recovery equipment and hence the

urgency of taking an early shut down for water

/ flue side cleaning.

22

o

C reduction in flue gas temperature

increases boiler efficiency by 1%

THANK YOU

Questions?

You might also like

- How To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineDocument5 pagesHow To Adjust Rough Idle and Camshaft Timing On VW and Audi TDI Pumpe Duse EngineALP1981100% (2)

- Mushrooms, Electricity, and Neural Networks! - Herbal Visionz.Document22 pagesMushrooms, Electricity, and Neural Networks! - Herbal Visionz.nicungNo ratings yet

- Boiler TrainingDocument40 pagesBoiler TrainingHarry Ansari100% (1)

- Supercritical PlantDocument71 pagesSupercritical PlantNitish KumarNo ratings yet

- Green Building - Thesis Report (Administrative Block of NIT Raipur, New Campus)Document86 pagesGreen Building - Thesis Report (Administrative Block of NIT Raipur, New Campus)Pranav Mishra89% (47)

- Heat Rate of Thermal Power PlantDocument15 pagesHeat Rate of Thermal Power Plantsameer betal100% (1)

- Extraction Condensing Steam TurbineDocument3 pagesExtraction Condensing Steam TurbineNaeemSiddiquiNo ratings yet

- Bhatia Gummidipoondi WHRSG O&m Manual FinalDocument224 pagesBhatia Gummidipoondi WHRSG O&m Manual Finalt_syamprasadNo ratings yet

- Boiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsDocument56 pagesBoiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsPranav Sai100% (1)

- NPTI Publications PDFDocument3 pagesNPTI Publications PDFBalraj SinghNo ratings yet

- A. Indira National Power Training InstituteDocument80 pagesA. Indira National Power Training InstituteAyan MajiNo ratings yet

- Boiler Efficiency CalculationDocument44 pagesBoiler Efficiency CalculationgARRYNo ratings yet

- BOE Viva Exam PreparationDocument43 pagesBOE Viva Exam PreparationMV AmohanAKarthicKNo ratings yet

- Doc-2 Training Material On Coal Fired Thermal Power PlantsDocument21 pagesDoc-2 Training Material On Coal Fired Thermal Power PlantsSharan100% (2)

- Design and Thermal Analysis of A Supercritical CFB BoilerDocument89 pagesDesign and Thermal Analysis of A Supercritical CFB Boilerbharathkumar0310No ratings yet

- Pump BasicsDocument118 pagesPump BasicsVinod GuptaNo ratings yet

- A Case Study On-Shutdown Audit of AFBC BoilerDocument12 pagesA Case Study On-Shutdown Audit of AFBC BoilerSelvakumar Palaniandavar100% (1)

- ET 2008 Steam Circulation SystemDocument49 pagesET 2008 Steam Circulation SystemSam100% (1)

- Draught System Gyanendra Sharma NPTI DelhiDocument24 pagesDraught System Gyanendra Sharma NPTI DelhiNPTINo ratings yet

- Boiler Mounting and AccessoriesDocument20 pagesBoiler Mounting and AccessoriesAshok Joshi92% (12)

- Discussion & Conclusion Dry Fractionation MuzDocument4 pagesDiscussion & Conclusion Dry Fractionation MuzAhmad MuzammilNo ratings yet

- Supercritical Boiler Cleanup Cycle: Ranjan KumarDocument23 pagesSupercritical Boiler Cleanup Cycle: Ranjan Kumarscentpcbarauni BARAUNINo ratings yet

- Condensate Extraction Pump: GeneralDocument5 pagesCondensate Extraction Pump: GeneralAnonymous DKv8vpNo ratings yet

- Supercritical Benson BoilerDocument18 pagesSupercritical Benson BoilerJerry Mateo100% (2)

- 500 MW BoilerDocument5 pages500 MW BoilerJimsNo ratings yet

- Title: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectDocument24 pagesTitle: Boiler No.:-PH0351 Page No. 1 of 22 Project: M/s Jacobs Netherlands BV A/c Schoonebeek Oil Field Redevelopment ProjectRamalingam PrabhakaranNo ratings yet

- Scope of Work ContractDocument6 pagesScope of Work ContractTiu TonNo ratings yet

- 3 Benefites of CFB Boiler Over Pc-Fired BoilerDocument9 pages3 Benefites of CFB Boiler Over Pc-Fired BoilersunitbhaumikNo ratings yet

- Heat Required in Kcal For Unit Generation of ElectricityDocument18 pagesHeat Required in Kcal For Unit Generation of ElectricityAyan ChattarajNo ratings yet

- SNJB's Late Sau. Kantabai Bhavarlalji Jain College of Engineering, ChandwadDocument10 pagesSNJB's Late Sau. Kantabai Bhavarlalji Jain College of Engineering, ChandwadAkash JadhavNo ratings yet

- 500MWDocument18 pages500MWAlok Ranjan TripathiNo ratings yet

- BT Reach Truck PARTS Manual - RRE200CCDocument337 pagesBT Reach Truck PARTS Manual - RRE200CCAl FajarNo ratings yet

- Smart Soot Blower SystemDocument8 pagesSmart Soot Blower SystemidigitiNo ratings yet

- This Bhel ProjectDocument51 pagesThis Bhel ProjectRaj_005No ratings yet

- Boilers of Thermal Power PlantsDocument150 pagesBoilers of Thermal Power PlantsanasawaisNo ratings yet

- Calculation of PHRDocument13 pagesCalculation of PHRSiddhant SatpathyNo ratings yet

- Operation of Reheat Steam Temperature Control Concept in Sub Critical Boiler: Operational Review Practices and MethodologyDocument6 pagesOperation of Reheat Steam Temperature Control Concept in Sub Critical Boiler: Operational Review Practices and MethodologyNuraini Abdul AzizNo ratings yet

- Catalog Steam Turbines 2013 Engl PDFDocument36 pagesCatalog Steam Turbines 2013 Engl PDFvamsiklNo ratings yet

- Pulverizers PDFDocument6 pagesPulverizers PDFOscar DorantesNo ratings yet

- Once Through BoilerDocument16 pagesOnce Through BoilerYousuf Ali100% (1)

- Once Through and Drum Type Boiler Designs ComparedDocument3 pagesOnce Through and Drum Type Boiler Designs ComparedagusfaizinNo ratings yet

- Super Critical Power PlantDocument27 pagesSuper Critical Power PlantPrabir Kumar PatiNo ratings yet

- Boilers For Plant Waste-RajavelDocument21 pagesBoilers For Plant Waste-RajavelSathish PaulNo ratings yet

- History of Thermal Power PlantsDocument9 pagesHistory of Thermal Power PlantsAnonymous gr5Pr9AVNo ratings yet

- Ultra Supercritical BoilerDocument10 pagesUltra Supercritical Boilerzsuzsapogats04100% (2)

- TPP Steel PlantDocument25 pagesTPP Steel PlantPRASANTHNo ratings yet

- Training ReportPDF PDFDocument42 pagesTraining ReportPDF PDFAman RajNo ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- TP CFB 12 03Document16 pagesTP CFB 12 03Harish MechNo ratings yet

- Boiler and Its Efficiency-1Document38 pagesBoiler and Its Efficiency-1Madhu KamshettyNo ratings yet

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocument10 pagesEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaNo ratings yet

- Overview of NTPC PDFDocument40 pagesOverview of NTPC PDFRahul KediaNo ratings yet

- Nrs 1-50 GestraDocument28 pagesNrs 1-50 Gestramike tsakirisNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- Heat Balance DiagramDocument10 pagesHeat Balance DiagramKartheek RamishettiNo ratings yet

- Mechanical Engg.: Report On Industrial TrainingDocument44 pagesMechanical Engg.: Report On Industrial TrainingSakshi SanghiNo ratings yet

- 1.1 Background of Project 1.2 Assignment & Objectives 1.3 Instruction To Reader 1.4 Limitation 1.5 Organisational ProfileDocument87 pages1.1 Background of Project 1.2 Assignment & Objectives 1.3 Instruction To Reader 1.4 Limitation 1.5 Organisational Profilezerocool86100% (1)

- CH-14 Design Fundamentals of BoilerDocument15 pagesCH-14 Design Fundamentals of BoilerRavi ShankarNo ratings yet

- Ennore Thermal Power StationDocument14 pagesEnnore Thermal Power StationRajesh Kumar100% (2)

- Pump Manual - Single Plunger AmbicaDocument24 pagesPump Manual - Single Plunger AmbicaHimTex /JaswinderNo ratings yet

- Comparison Between EN12952-15, BS 2885, ASME PTC4 Effy CodesDocument3 pagesComparison Between EN12952-15, BS 2885, ASME PTC4 Effy CodesRamalingam PrabhakaranNo ratings yet

- Xviii. Soot Blowers and Furnace Temperature ProbeDocument18 pagesXviii. Soot Blowers and Furnace Temperature Probeupt vadodaraNo ratings yet

- Chandrapur CTPS 15 Days Training ReportDocument21 pagesChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- Unit - I Steam Power PlantsDocument32 pagesUnit - I Steam Power Plantsrsankarganesh MECH-HICET100% (1)

- Thermal Power StationDocument6 pagesThermal Power StationAnkit RajNo ratings yet

- CoalDocument41 pagesCoalKarthi KeyanNo ratings yet

- Heat Engines Steam Generators: ObjectivesDocument7 pagesHeat Engines Steam Generators: ObjectivesSergiu DragulinNo ratings yet

- Car Door Opening Geometry For Enhanced Entry/ExitDocument70 pagesCar Door Opening Geometry For Enhanced Entry/Exitpankajpnd1No ratings yet

- Lab 8: Polarization of Light: Figure 1: (A) Oscillation of E Vector, (B) An Electromagnetic FieldDocument10 pagesLab 8: Polarization of Light: Figure 1: (A) Oscillation of E Vector, (B) An Electromagnetic Fieldpankajpnd1No ratings yet

- Conservation of Energy: Principle. One Way To State This Principle Is "Energy Can Neither Be Created NorDocument7 pagesConservation of Energy: Principle. One Way To State This Principle Is "Energy Can Neither Be Created Norpankajpnd1No ratings yet

- Uttar Pradesh Technical University (UPTU)Document1 pageUttar Pradesh Technical University (UPTU)pankajpnd1No ratings yet

- SK PDFDocument12 pagesSK PDFpankajpnd1No ratings yet

- Lab 3 - SeepageTankDocument6 pagesLab 3 - SeepageTankPrantik MaityNo ratings yet

- Current Transformer: Engineering DepartmentDocument8 pagesCurrent Transformer: Engineering DepartmentbinodeNo ratings yet

- Solution of The Graetz-Brinkman Problem With The Laplace Transform Galerkin MethodDocument9 pagesSolution of The Graetz-Brinkman Problem With The Laplace Transform Galerkin MethodDeny Arief RusamsiNo ratings yet

- Establish A New Commercial BankDocument60 pagesEstablish A New Commercial Bankmamun322No ratings yet

- Bagi 'LKPD 2 Teks News ItemDocument8 pagesBagi 'LKPD 2 Teks News ItemMuhammad IhsanNo ratings yet

- Epocoat 111 PDFDocument3 pagesEpocoat 111 PDFjunaid112No ratings yet

- E1 2 Example String NotesDocument1 pageE1 2 Example String NotesSAEL SOLARNo ratings yet

- Applied Aerodynamics (2-0) : Text Book "Introduction To Flight" by John D. Anderson, Mcgraw-Hill Ref Books/MaterialDocument19 pagesApplied Aerodynamics (2-0) : Text Book "Introduction To Flight" by John D. Anderson, Mcgraw-Hill Ref Books/MaterialAhmed Faraz GujjarNo ratings yet

- Chemical Engineering World - June 2016Document60 pagesChemical Engineering World - June 2016ioanaandra5690No ratings yet

- PORAM Standard SpecificationDocument3 pagesPORAM Standard SpecificationAristonNo ratings yet

- Ahu Transfer RoomDocument7 pagesAhu Transfer RoomCITACOM UTAMANo ratings yet

- Analysis of Mechanical SystemDocument16 pagesAnalysis of Mechanical SystembigbangNo ratings yet

- 33KV GTP WbsebDocument13 pages33KV GTP Wbsebmaniking1No ratings yet

- Ria LeptinDocument37 pagesRia Leptin1alfredo12100% (1)

- ISO-50001-JK-WhiteDocument24 pagesISO-50001-JK-WhiteAgustinusDwiSusantoNo ratings yet

- Ques - 14 55 PDFDocument15 pagesQues - 14 55 PDFVosuMittalNo ratings yet

- Jindal India Thermal Power Limited Integrated Management SystemDocument8 pagesJindal India Thermal Power Limited Integrated Management SystemSantoshkumar GuptaNo ratings yet

- Design and Application of A Spreadsheet-Based ModelDocument7 pagesDesign and Application of A Spreadsheet-Based ModelPassmore DubeNo ratings yet

- Attenuation ProjectDocument12 pagesAttenuation Projectapi-352698073No ratings yet

- HSC Physics Paper 2 Target PDFDocument17 pagesHSC Physics Paper 2 Target PDFAnonymous QvdxO5XTR63% (8)

- PS Phy chp.1 5Document6 pagesPS Phy chp.1 5Shivang GuptaNo ratings yet

- HW ProblemsDocument34 pagesHW ProblemsMarkk ClainNo ratings yet