100% found this document useful (2 votes)

1K views29 pagesSteel Connections

1) Connections are structural elements used for joining steel members like beams and columns.

2) Common steel connection types include riveted, bolted, welded, and bolted-welded connections.

3) Connections can fail due to shearing of bolts, bearing failure of bolts or plates, tearing of bolts or plates, and block shear of plates. Exposure to fire further weakens connections through loss of member strength and stiffness from high temperatures.

Uploaded by

SHRADDHA KADAMCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (2 votes)

1K views29 pagesSteel Connections

1) Connections are structural elements used for joining steel members like beams and columns.

2) Common steel connection types include riveted, bolted, welded, and bolted-welded connections.

3) Connections can fail due to shearing of bolts, bearing failure of bolts or plates, tearing of bolts or plates, and block shear of plates. Exposure to fire further weakens connections through loss of member strength and stiffness from high temperatures.

Uploaded by

SHRADDHA KADAMCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Steel Connections: Cover page introducing the topic of steel connections, listing student identification information.

- Introduction: Defines structural elements and their purpose in joining various members of a steel framework, emphasizing design strength considerations.

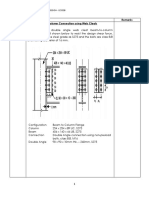

- Components of a Connection: Illustrates and describes key components such as bolts, welds, plates, and angles used in steel connections.

- Classification of Connections: Explains different classifications of steel connections based on materials, forces, structural elements, and member types.

- Riveted Connections: Describes the materials, installation methods, and phasing out of riveting in engineering structures.

- Bolted Connections: This section explains the types, advantages, and disadvantages of bolted connections used in steel structures.

- Welded Connections: Overview of welded connections, including types of welds and joints, advantages, and disadvantages.

- Types of Failures in Bolted Connections: Examines different failure modes for bolted connections, including shearing and bearing failure types.

- Effect of Elevated Temperature on Steel Connections: Analyzes the impact of high temperatures on the strength and behavior of steel connections, using empirical data and stress-strain curves.

- Conclusion: Summarizes the essential aspects of steel connection design for safety and economy by considering different failure modes.

- References: Lists the references and literature considered in the study of steel connections and failures.

- Summary of Relevant Technical Papers: Summarizes conclusions from various technical papers on steel connections, exploring different failure modes and design methodologies.