0% found this document useful (0 votes)

573 views19 pagesFacilities Planning: Presented By: Apple Jean Bonus Marielle Gerardo

This document discusses facility planning and provides information on:

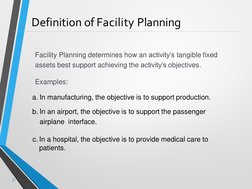

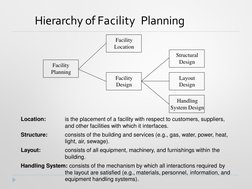

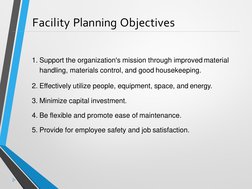

1) The definition and objectives of facility planning which is determining how assets support organizational objectives like production or service.

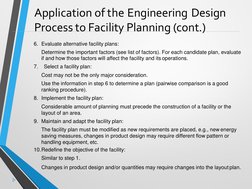

2) The engineering design process for facility planning which involves formulating the problem, analyzing it, generating alternatives, evaluating them, selecting a design, and implementing it.

3) Important factors to evaluate when comparing facility plan alternatives like layout, material handling, storage, and overall costs.

Uploaded by

Apple Jean BonusCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

573 views19 pagesFacilities Planning: Presented By: Apple Jean Bonus Marielle Gerardo

This document discusses facility planning and provides information on:

1) The definition and objectives of facility planning which is determining how assets support organizational objectives like production or service.

2) The engineering design process for facility planning which involves formulating the problem, analyzing it, generating alternatives, evaluating them, selecting a design, and implementing it.

3) Important factors to evaluate when comparing facility plan alternatives like layout, material handling, storage, and overall costs.

Uploaded by

Apple Jean BonusCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd