Professional Documents

Culture Documents

Boiler Operation

Boiler Operation

Uploaded by

Salwan ShubhamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boiler Operation

Boiler Operation

Uploaded by

Salwan ShubhamCopyright:

Available Formats

BOILER PLANT OPERATION

Presented By Mr. Sivanand Ray

Fleet Management Training

Institute

ID IDC Technologies - Technical Training That Works

INSTRUMENTATION USED ON A SHELL

BOILER

Fire-tube type boiler reviewed for simplicity

Instrumentation:

» Items that provide operator with indication of

condition within the boiler

» Ensure indications are within SAFETY limits and

design OPERATIONAL PARAMETERS

Operating pressures, temperatures, flows, water

level

M4-2

ID IDC Technologies - Technical Training That Works

INSTRUMENTATION

PRESSURE GAUGE

» Normally Bourdon type of gauge

» Large with large numbers

» Graduated approximately double the pressure

of safety valve setting, not < than 1,5

» Located on top of shell/drum on an

independent nozzle

» Supplied with a siphon (“pigtail”) to develop a

water seal

» Must be calibrated at least once a year

M4-3

ID IDC Technologies - Technical Training That Works

INSTRUMENTATION

PRESSURE TRANSMITTER

» Where a remote pressure indicator required,

an electrical signal used

» Separate transducer

» Mounted on same branch as pressure

indicator

M4-4

ID IDC Technologies - Technical Training That Works

INSTRUMENTATION

LEVEL COLUMNS

» Provides VISIBLE water level indication

» Minimum 25NB pipe line connecting column to boiler

» TWO water gauge glasses for boiler pressure >28

bar

» Normally simple gauge glass type

Installed such that with lowest reading on gauge glass, 75

mm water over highest point of tubes

Visible range of water level approx. 125mm from NWL

» Daily routine blow down to remove debris, scale,

sludge

M4-5

ID IDC Technologies - Technical Training That Works

Typical Water Level

Gauge for Low Pressure Boiler

M4-6

ID IDC Technologies - Technical Training That Works

Electronic and digital water level indicators

M4-7

ID IDC Technologies - Technical Training That Works

INSTRUMENTATION

LEVEL SWITCHES

» Float type (Mobrey)

» Single-element control (on-off or modulating)

» Normally located in an external chamber

» TWO chambers mandatory

Low level alarm

Low-low-level shut down

» Weekly routine test to check correct

operation of switches

M4-8

ID IDC Technologies - Technical Training That Works

INSTRUMENTATION

TEMPERATURE MEASUREMENT

» Flue gas exit temperature

» An increase indicates fouling problems

» Thermocouples, insulated from gas sampling

tube

M4-9

ID IDC Technologies - Technical Training That Works

TYPICAL PROCESS AND

INSTRUMENTATION DIAGRAM (P&ID)

COAL FIRED LP BOILER

» Instrumentation

» Control loops

OIL OR GAS FIRED LP BOILER

» Instrumentation

» Control loops

M4-10

ID IDC Technologies - Technical Training That Works

CONTROL AND SYSTEM

OPERATING PHILOSOPHY

CONTROLS :

» Regulate the various quantities indicated by

the instruments

» Shut down (with interlocks) the plant if

parameters exceeded

» Manual operation to sophisticated automatic

computer operation (DCS)

M4-11

ID IDC Technologies - Technical Training That Works

CONTROL AND SYSTEM

OPERATING PHILOSOPHY

To control a boiler, following quantities

require to be regulated :

» Fuel/air ratio to maintain optimum

combustion conditions

» Water flow to match steam flow from boiler

» Steam flow and pressure to regulate heat

input

» Combustion chamber pressure (balanced

draught boilers)

» Combustion safety M4-12

ID IDC Technologies - Technical Training That Works

COMBUSTION CONTROL

Manual control cannot continuously control

combustion in a reliable and efficient manner

Automatic control systems used :

» maintains fuel-air ratio to furnace at an optimum

» maintains a relatively constant steam pressure

Combustion control mechanisms vary slightly

depending on fuel fired

No matter what fuel, four aspects that are

regulated:

Air supply; Fuel supply; Ratio of fuel to air; Flame safety

M4-13

ID IDC Technologies - Technical Training That Works

COMBUSTION CONTROL

Two basic types of combustion control

systems:

» Positioning

» Metering

Pneumatic or Electrical control drives

M4-14

ID IDC Technologies - Technical Training That Works

COMBUSTION CONTROL

Positioning Type Control:

» Designed to control based on a change in

steam pressure

» Components :

Master steam pressure controller

Fuel control valve with cam for oil / gas or feed

control drive for coal

Combustion air fan inlet vanes / outlet damper

operator

» Simplistic

cannot maintain fuel – air ratio at optimum over

full load range

M4-15

ID IDC Technologies - Technical Training That Works

COMBUSTION CONTROL

Metering Type controller :

» Components as per Positioning type with :

Fuel flow measuring device

Air flow signal

» Fuel-air ratio is controlled by a relay

» Capable of adjusting fuel-air ratio and where

fuel pressure may vary

M4-16

ID IDC Technologies - Technical Training That Works

General Selection Chart for

Combustion Control Systems

Type of Fuel Type of Control Steam Generation

System Capacity Ranges

(kg/hr)

Coal Modulating positioning to 27 500

Full metering (Steam

/air flow) 18 000 – 36 000

Full metering with

Oxygen compensation above 36 000

Fuel Oil & Gas Modulating positioning to 11 500

Full metering (Steam

/ air flow) 11 500 – 45 000

Full metering with

Oxygen compensation above 45 000 M4-17

ID IDC Technologies - Technical Training That Works

STEAM PRESSURE CONTROL

Main purpose of a steam boiler is to

produce steam within a definite pressure

range

Steam pressure dictated by :

» process plant steam demand

» heat input to the boiler furnace

Pressure fluctuates between minimum

and maximum settings

M4-18

ID IDC Technologies - Technical Training That Works

STEAM PRESSURE CONTROL

Modulating control linked to upper and

lower pressure limits

» On-off pressure switch – low or high fire

burner

» Definite limitation exists on burner minimum

firing rate

turndown ration varies : 4:1 gas; 2:1 oil

M4-19

ID IDC Technologies - Technical Training That Works

FEED WATER SUPPLY CONTROL

Purpose is to provide sufficient feed water flow

to ensure all heat transfer surfaces are cooled

with water

Visible water level provided by :

» Two simple gauge glasses

» More sophisticated devices (electrodes, capacitance

or conductivity type)

Water sensor controls :

» Normally two independent

» Float operated

» Thermostatic

M4-20

ID IDC Technologies - Technical Training That Works

FEED WATER SUPPLY CONTROL

Typical arrangements of feed water plant

:

» Two or more pumps (standby) from hot well

tank (10-15 min. storage)

Either on-off operation or a feed valve station

» Feed valve station :

Check valve

Stop valve

Feed control valve c/w isolation and bypass valves

M4-21

ID IDC Technologies - Technical Training That Works

FEED WATER CONTROL SYSTEMS

ON AND OFF FEED WATER PUMP

» Small boilers with relatively large water

storage, slow load changes

» Typical float operated water level controller,

mounted at water line

» Also serves either as low-water level alarm or

low water cut off

M4-22

ID IDC Technologies - Technical Training That Works

FEED WATER CONTROL SYSTEMS

MODULATING LEVEL CONTROLLERS

» Boilers with relatively small water volume

relative to steam demand

» Thermostatic type regulator feeds water

continuously to the boiler, stabilising the

water level

» THREE types of modulating controllers :

SingleElement Level Controller

Two Element Level Controller

Three Element Level Controller

M4-23

ID IDC Technologies - Technical Training That Works

Schematic of Three

Element Level Controller

M4-24

ID IDC Technologies - Technical Training That Works

SOME CONSIDERATIONS REGARDING

WATER LEVEL CONTROL

Rapid changes in steam flow rate can cause

SURGING of the water level and carry-over

VERY IMPORTANT that the :

» steam qualities

» characteristics of boiler (size, firing system)

MUST be properly matched to the OPERATING

characteristics of water level controlling system

Highest water level, NWL, lowest level for safe

operation should be MARKED on boiler outer

shell

M4-25

ID IDC Technologies - Technical Training That Works

FURNACE PRESSURE CONTROL

Only really required on coal fired boilers

with FD and ID fan

Required to :

» prevent excessive negative pressure and

uncontrolled air entering furnace

» products of combustion to percolate back to

coal supply

Controller transmitter range not too

narrow

» typically +250 to –1250 Pa

» ideal control point –100 Pa M4-26

ID IDC Technologies - Technical Training That Works

AUTOMATIC CONTROLS

Instrumentation employed same as that

for manual operation

Rapid and continuous development of

electronic control systems means systems

for boilers are now DIVERSE

Selection shall depend on owner /

purchaser present complexity of control

systems

M4-27

ID IDC Technologies - Technical Training That Works

AUTOMATIC CONTROLS

ASPECTS that do not vary whether

auto/manual :

» Principles of operation

» Areas of control (control loops)

» Direct reading of instruments

» Safety devices and interlocks

» Selector for “manual” or “automatic”

M4-28

ID IDC Technologies - Technical Training That Works

You might also like

- Bms System-Basic PDFDocument59 pagesBms System-Basic PDFWaelBou95% (22)

- Cummins 4BT3.3-G5 Parts ManualDocument130 pagesCummins 4BT3.3-G5 Parts Manualthaihung thep100% (1)

- Vega IiDocument6 pagesVega Iiganeshram2305No ratings yet

- Lochinvar Water HeatersDocument52 pagesLochinvar Water HeatersJohn MoreNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Partes IngersollDocument56 pagesPartes IngersollDaniel Arbeláez100% (7)

- Boiler OperationDocument28 pagesBoiler OperationMacho ManNo ratings yet

- Boiler Plant OperationDocument28 pagesBoiler Plant OperationShaami Atm100% (1)

- 5.0 IBMS SlideDocument40 pages5.0 IBMS Slidedhevashini narayananNo ratings yet

- 970 Series Hydraulic Test Stand: With Computer Monitoring and Data Acquisition (Apd )Document5 pages970 Series Hydraulic Test Stand: With Computer Monitoring and Data Acquisition (Apd )Sajad KarimiNo ratings yet

- FICHA TECNICA CONTROLADOR MetronMP15 PDFDocument2 pagesFICHA TECNICA CONTROLADOR MetronMP15 PDFAndres CortesNo ratings yet

- Copeland Digital Compressor Controller en Us 160802Document12 pagesCopeland Digital Compressor Controller en Us 160802clkent2022No ratings yet

- 002 - Gas ChromatographDocument52 pages002 - Gas Chromatographtubagus syariefNo ratings yet

- Cat 30xqDocument40 pagesCat 30xqNabil AliNo ratings yet

- ICM User GuideDocument84 pagesICM User Guidewords2zhigang_612545No ratings yet

- Carrier CatalogDocument35 pagesCarrier CatalogPradeep Kumar Sharma100% (1)

- Controlador SiemensDocument20 pagesControlador SiemensManuel Navarro SorianoNo ratings yet

- 241CE II Hydrocarbon Dew Point Analyzer1Document2 pages241CE II Hydrocarbon Dew Point Analyzer1Bryan TungNo ratings yet

- Transform - 2004 - Flyer - MTeC Ept202Document3 pagesTransform - 2004 - Flyer - MTeC Ept202gixer985No ratings yet

- وحدات التحكم للطلمباتDocument8 pagesوحدات التحكم للطلمباتRheoserve Industrial SolutionsNo ratings yet

- Media Temperature Controller: User GuideDocument16 pagesMedia Temperature Controller: User GuideClaudio CostaNo ratings yet

- CMC Presentation March - 2004Document43 pagesCMC Presentation March - 2004SegeyNo ratings yet

- SITRAM Multisense 9: Customer Services For TransformersDocument2 pagesSITRAM Multisense 9: Customer Services For Transformersxiaomi0% (1)

- Fachprogramm: Exhibition Hall 7Document34 pagesFachprogramm: Exhibition Hall 7vvukmirovic_2No ratings yet

- 30 1 13 D Series Brochure Air Cooled EnglishDocument8 pages30 1 13 D Series Brochure Air Cooled Englishjennlin.changNo ratings yet

- High-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic ModuleDocument16 pagesHigh-Temperature Monobloc Air-to-Water Heat Pumps With Integrated Hydronic Modulekathy_es16No ratings yet

- Bmssystem Basic 141229052438 Conversion Gate02 PDFDocument59 pagesBmssystem Basic 141229052438 Conversion Gate02 PDFMahmoudMohsenNo ratings yet

- PSD 61af 022 105 - enDocument23 pagesPSD 61af 022 105 - enDavid BlagojevicNo ratings yet

- 61af - 022 - 105 - P DataDocument16 pages61af - 022 - 105 - P DatasarcitoNo ratings yet

- FT3 - Fox ThermalDocument6 pagesFT3 - Fox ThermalRoLopNo ratings yet

- Catálogo de Productos MurphyDocument28 pagesCatálogo de Productos MurphyRené GPNo ratings yet

- Gallus Net - Residential Smart Gas MeterDocument2 pagesGallus Net - Residential Smart Gas MeterFilip SerafimovNo ratings yet

- Chicago Automation and Energy Efficiency of Industrial Refrigeration Systems en 1583972Document24 pagesChicago Automation and Energy Efficiency of Industrial Refrigeration Systems en 1583972kkmarus9837No ratings yet

- Monitor de Transformador-Ap-M09-08l-01en - 506 - VTM - 507 - ItmDocument4 pagesMonitor de Transformador-Ap-M09-08l-01en - 506 - VTM - 507 - ItmFernando RodriguezNo ratings yet

- Product Data: Axis Single-Duct Terminal Units For Variable Air Volume Systems Nominal 23 To 7100 CFMDocument28 pagesProduct Data: Axis Single-Duct Terminal Units For Variable Air Volume Systems Nominal 23 To 7100 CFMJorge VillanuevaNo ratings yet

- Easidew Transmitters 97554 UK DatasheetDocument4 pagesEasidew Transmitters 97554 UK Datasheetrafik1995No ratings yet

- Ad00879m Nuflo Scanner 2200 Efm Data SheetDocument4 pagesAd00879m Nuflo Scanner 2200 Efm Data SheetCarlos Alberto MoviNo ratings yet

- 81381C Plastic Machinery Eng PDFDocument76 pages81381C Plastic Machinery Eng PDFEvandro Amaral RodriguesNo ratings yet

- Data Sheet For Mag Bearing Centrifugal ChillersDocument4 pagesData Sheet For Mag Bearing Centrifugal ChillersHemanti SharmaNo ratings yet

- Ewaq140g SsDocument5 pagesEwaq140g SsTofan VasileNo ratings yet

- Turbocore ChillersDocument4 pagesTurbocore Chillerss341232No ratings yet

- Burner Management and Combustion Control PrimerDocument25 pagesBurner Management and Combustion Control PrimerJerry WenzelNo ratings yet

- Gas Turbine Pump Drive Integrated Control System: Petrotech Home PageDocument4 pagesGas Turbine Pump Drive Integrated Control System: Petrotech Home Pagescribdkhatn100% (1)

- Controlador para Calderetea de Motores Lmo44.255 - 38ld0015Document10 pagesControlador para Calderetea de Motores Lmo44.255 - 38ld0015Pablo AllosiaNo ratings yet

- 42BJ ICM LEC 1.9 - 2.9 - 4.9: Individual Comfort Module For Variable Air Volume SystemsDocument20 pages42BJ ICM LEC 1.9 - 2.9 - 4.9: Individual Comfort Module For Variable Air Volume SystemsBulat IııNo ratings yet

- Air-Cooled Liquid Chillers: Models CGA and CGAF 10 To 60 TonsDocument52 pagesAir-Cooled Liquid Chillers: Models CGA and CGAF 10 To 60 TonsFrancisco RenteriaNo ratings yet

- Chillgard® LE Photoacoustic Infrared Refrigerant MonitorDocument2 pagesChillgard® LE Photoacoustic Infrared Refrigerant MonitortodocatsolucionesNo ratings yet

- 5B. - Steam Turbine Control - Petrotech PDFDocument4 pages5B. - Steam Turbine Control - Petrotech PDFJaviStg1100% (1)

- Measurement and Safety Devices For Distribution and Power Transformers - ABB - Comem-EN - catalogue-REV-B-24-06-2019Document34 pagesMeasurement and Safety Devices For Distribution and Power Transformers - ABB - Comem-EN - catalogue-REV-B-24-06-2019snooty.eli.gamedogsNo ratings yet

- Catalogue C M Máy Nén Emeson ZX 2021Document48 pagesCatalogue C M Máy Nén Emeson ZX 2021Nguyễn Hữu HiệpNo ratings yet

- Diesel Engine Fire Pump Controllers (Firetrol)Document4 pagesDiesel Engine Fire Pump Controllers (Firetrol)Shibu ThomasNo ratings yet

- EMCP 3 Controller: Electric PowerDocument29 pagesEMCP 3 Controller: Electric Powerabailey12100% (2)

- Copeland Scroll. ZX Condensing Unit For Refrigeration Applications. Product CatalogueDocument47 pagesCopeland Scroll. ZX Condensing Unit For Refrigeration Applications. Product CatalogueConstantinos EconomidesNo ratings yet

- PSD 01 2022 61af B 030 105Document22 pagesPSD 01 2022 61af B 030 105PedroNo ratings yet

- Oil-Less Scroll Air Compressor System With Desiccant Air TreatmentDocument2 pagesOil-Less Scroll Air Compressor System With Desiccant Air TreatmentroyvindasNo ratings yet

- RC Ecu 1Document2 pagesRC Ecu 1Vincent DetroyatNo ratings yet

- Chillers TraneDocument52 pagesChillers TranesnakelostNo ratings yet

- DCS Control SystemDocument24 pagesDCS Control Systemhonchoabhi50% (2)

- The PIC Microcontroller: Your Personal Introductory CourseFrom EverandThe PIC Microcontroller: Your Personal Introductory CourseRating: 1 out of 5 stars1/5 (2)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Aston Fittings BrochureDocument34 pagesAston Fittings BrochurefahedNo ratings yet

- Created by - Vimal Fire Controls Pvt. LTDDocument18 pagesCreated by - Vimal Fire Controls Pvt. LTDdebu1985No ratings yet

- CS533E Hydraulic Schematic KENR3668Document2 pagesCS533E Hydraulic Schematic KENR3668Luis Florentino Grajeda100% (5)

- Fireproofing From ChevronDocument25 pagesFireproofing From ChevronAnonymous pH3jHscX983% (6)

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Forwarder 564Document70 pagesForwarder 564Anderson Salzano100% (2)

- Tu-Flo 501 (SD-01-337)Document13 pagesTu-Flo 501 (SD-01-337)emmanuelNo ratings yet

- Portable Screw Compressor: Instruction Book and Part ListDocument33 pagesPortable Screw Compressor: Instruction Book and Part ListAbhishek GauravNo ratings yet

- Common Rail ReportDocument4 pagesCommon Rail Reportnuwan_nishaNo ratings yet

- Power Steering: Models FA and FBDocument32 pagesPower Steering: Models FA and FBKomatsu Perkins HitachiNo ratings yet

- CBM Digital SystemDocument238 pagesCBM Digital Systemadm comex bibNo ratings yet

- 5001 Fa User ManualDocument27 pages5001 Fa User ManualAnoj pahathkumburaNo ratings yet

- Catalog - 2016 (Shinwoo Valve) 1.7MDocument20 pagesCatalog - 2016 (Shinwoo Valve) 1.7Mensi116No ratings yet

- Lada 1600 Maintenance ManualDocument28 pagesLada 1600 Maintenance ManualMike BacklerNo ratings yet

- API - Valve StandardsDocument1 pageAPI - Valve StandardszzapiecheNo ratings yet

- Subsea Manifold HandbookDocument97 pagesSubsea Manifold HandbookLarry Ubu100% (1)

- Mud ValvesDocument4 pagesMud ValvesFabio Peres de LimaNo ratings yet

- HD Series: Butterfly ValvesDocument16 pagesHD Series: Butterfly ValvesGourav SharmaNo ratings yet

- HT64-132 OWS Final Drawings150525Document24 pagesHT64-132 OWS Final Drawings150525jamukanak padNo ratings yet

- Sprinkler DesignDocument10 pagesSprinkler Designsk lukoNo ratings yet

- ValvesDocument3 pagesValveshummingbird4uNo ratings yet

- 47 Series Service & Parts ManualDocument87 pages47 Series Service & Parts ManualibrahimNo ratings yet

- ValvesDocument14 pagesValvesRojan PradhanNo ratings yet

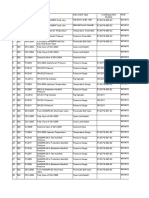

- NGP-000-INS-15.02-0001-00-00-Instrument IndexDocument267 pagesNGP-000-INS-15.02-0001-00-00-Instrument Indexwqs_19No ratings yet

- ZF6 Webinar-FINALDocument72 pagesZF6 Webinar-FINALженя евчин100% (4)

- Burocco S3000 ManualDocument4 pagesBurocco S3000 ManualJose David Leon BetancourtNo ratings yet

- The Need For Balancing Valves in A Chilled Water SystemDocument50 pagesThe Need For Balancing Valves in A Chilled Water SystemNoushad P Hamsa100% (1)

- Amerex KP System Kitchen Supressor BrochureDocument4 pagesAmerex KP System Kitchen Supressor BrochureEstevan huertasNo ratings yet