Professional Documents

Culture Documents

Mine Signaling Methods Bare Wire Pull Wire Keys

Uploaded by

NJ Ranveer Choudhary0 ratings0% found this document useful (0 votes)

153 views15 pagesOriginal Title

Signaling System in Mines.pptx

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

153 views15 pagesMine Signaling Methods Bare Wire Pull Wire Keys

Uploaded by

NJ Ranveer ChoudharyCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 15

Signaling System in Mines

• three main methods of signalling system in

mines. The methods are:

• 1. Bare Wire System

• 2. Pull Wire System

• 3. Signaling Keys and Receivers.

Signaling System in Mines: Method

# 1. Bare Wire System:

• In this system there are two parallel bare

wires, usually of galvanized iron, which are

suspended at a convenient height just above

head level along the entire length of the

haulage road or conveyor. A signal can be sent

from any point along the run by making

connection between the two wires. This can

be done either by squeezing them together

with the hand, or by bridging them with a

signaling device.

Signaling System in Mines: Method

# 2. Pull Wire System

• Along the haulage road or conveyor in the

colliery, pull switches are placed at regular

intervals. These are connected together into

the signalling circuit by insulated cable. A

signal can be sent from any position along the

haulage road or conveyor by pulling a flexible

steel wire running between the switches.

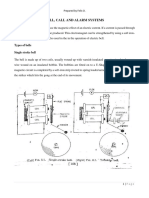

• The signalling cable itself is sometimes used as

the pull wire. It is then lashed to the pull key

and looped into the cable entry as shown in

Fig 10.8(a).

• Some types of pull switch are designed so that the

operating cable enters the switch through a gland

and is connected to a spring loaded contact. The

contact is operated directly by pulling on the cable.

Fig. 10.8(b) shows diagrammatically such a pull

switch. Generally this type of switch is used in a

break-to-operate signal-stop circuit.

•

Signaling System in Mines: Method

# 3. Signaling Keys and Receivers

• Signalling keys are make-and-break switches

operated by a pull lever or button. The operating

device is usually shrouded, or otherwise protected,

to prevent accidental operation. A common type of

signalling key consists of a robust metal box as shown

in Fig. 10.9(a) with an operating bar spanning two

levers underneath.

• The operating bar is protected by a fixed bar

in front of it, and the key is operated by

squeezing the-two bars together. The signal

receiver is usually an electric bell as shown in

Fig. 10.9(b), but hooters as in Fig 10.9(c) are

used if a distinctive signal is required.

Signal Bells:

The signal receiver is usually an electric bell, but

hooters are also used particularly if a distinctive signal

is required. Bells can be designed for use either on a.c.

systems, or d.c. systems. Alternatively they can be

designed for use on D.C. bells which are obviously for

use on d.c. systems only, as shown in Fig. 10.10

schematically.

However these can be designed for use on both a.c.

or d.c system by supplying the bell through a bridge

rectifier. Whatever supply is connected to the

terminals, d.c. current is supplied to the bell coils. Fig.

10.11 explains how a bell operates.

• A bell for use with a.c. systems only consists of

a simple solenoid polarized by a permanent

magnet as shown in Fig. 10.12. During one

half of each cycle of supply, the solenoid has

the same polarity as the permanent magnet

and these two magnetic fields augment one

another attracting the striker arm of the bell.

• During the other half of each cycle the polarity of the solenoid

field opposes that of the permanent magnet so that the field

is neutralized and the striker arm is returned to its normal

position by its return spring. The striker arm, therefore, moves

rapidly backwards and forwards striking the gong once for

each cycle of supply.

• A single stroke bell as explained in Fig. 10.10(a) consists of a

coil, or solenoid wound on to a soft iron core, a soft iron

armature with a striker arm fixed to it, a return spring and a

gong. A single stroke bell sounds the gong once only with a

single stroke when the solenoid is energised.

• The bell does not sound again until the solenoid has been

de-energised and is then energised again. This type of bell

can be used in a circuit with a make and break operating

device to deliver number code signals.

• The main disadvantage of a single stroke bell is that due to

the short duration of its sound, in a noisy surrounding a

signal could easily be lost. But more pronounced signaling

is possible with a continuously ringing bell.

• A continuously ringing bell, as shown in Fig. 10.10(b), is

similar to a single stroke bell, except that the solenoid

circuit is completed through a switch operated by the

striker arm. The arm moves continuously and rapidly

backwards and forwards, as long as the supply is connected

to the bell terminals.

• The principal requirements for a rope haulage signalling

system are that it must be possible to ring signals from any

point along the haulage roads and that any signal which is

rung can be heard at all the main stations. The second of

these requirements may mean that two or more bells must

ring simultaneously whenever a signal is given.

You might also like

- Electric Gas Lighting How to Install Electric Gas Ignition ApparatusFrom EverandElectric Gas Lighting How to Install Electric Gas Ignition ApparatusRating: 3 out of 5 stars3/5 (1)

- Sge Block InstrumentDocument20 pagesSge Block InstrumentVikas Srivastav90% (10)

- IUBAT-International University of Business Agriculture and TechnologyDocument19 pagesIUBAT-International University of Business Agriculture and TechnologyMd Hasibur RahmanNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Unit-2 ANS KEYDocument13 pagesUnit-2 ANS KEYRajaNo ratings yet

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Twin LoopDocument5 pagesTwin LoopBalbalaManiuk100% (1)

- Name: Kaushal Oswal Roll No:39: Class: P18Document17 pagesName: Kaushal Oswal Roll No:39: Class: P18Kaushal OswalNo ratings yet

- Lighting Circuits and Power Circuits Socket OutletsDocument13 pagesLighting Circuits and Power Circuits Socket OutletsLawrence Wahome ngariNo ratings yet

- Domestic and Lighting CircuitDocument16 pagesDomestic and Lighting CircuitCOLLINS KIPRUTO100% (1)

- PSG 2Document146 pagesPSG 2Shiva PavanNo ratings yet

- Topic 2-1f37518Document31 pagesTopic 2-1f37518norzamiraNo ratings yet

- Bells and AlarmsDocument17 pagesBells and Alarmsmedassan7100% (1)

- 1 Supply of Power at High Voltage: 1.2 Different HV Service ConnectionsDocument3 pages1 Supply of Power at High Voltage: 1.2 Different HV Service Connectionstucurici5740No ratings yet

- Twin Loop Treasure Seeker: Robert and David CroneDocument5 pagesTwin Loop Treasure Seeker: Robert and David CronesafdsfdNo ratings yet

- DC GeneratorsDocument47 pagesDC GeneratorsIshmael KibetNo ratings yet

- Types of Relays ExplainedDocument19 pagesTypes of Relays ExplainedbhavikNo ratings yet

- Topic 2a DC and Ac Meter - Templete Jke PPDDocument30 pagesTopic 2a DC and Ac Meter - Templete Jke PPDmunNo ratings yet

- Axle CounterDocument24 pagesAxle CounterVikas Srivastav100% (9)

- Lighting Circuits DiagramDocument25 pagesLighting Circuits DiagramCrizel N. Potante100% (1)

- Unit 2 Single Line Diagram of SubstationsDocument14 pagesUnit 2 Single Line Diagram of SubstationsHimanshu RanjanNo ratings yet

- Electric BellsDocument36 pagesElectric Bellsmedassan7No ratings yet

- Strowger Switch - PPSXDocument22 pagesStrowger Switch - PPSXCharles Kenn MantillaNo ratings yet

- Electrical Measuring Devices and MeasurementDocument62 pagesElectrical Measuring Devices and MeasurementDanelNo ratings yet

- Substation Visit ReportDocument10 pagesSubstation Visit ReportRyan JacobNo ratings yet

- Unit - 4Document8 pagesUnit - 4Angamuthu AnanthNo ratings yet

- The Silicon-Controlled Switch (SCS)Document7 pagesThe Silicon-Controlled Switch (SCS)Joshua Roberto GrutaNo ratings yet

- Position SensorsDocument24 pagesPosition SensorsTadese AtomssaNo ratings yet

- Electromagnetic, Thermal, Static and Microprocessor RelaysDocument11 pagesElectromagnetic, Thermal, Static and Microprocessor RelaysSoumajit PoddarNo ratings yet

- Komatsu Hydraulic Excavator Pc25!30!40 45 Operator Manual Seam020s0703Document22 pagesKomatsu Hydraulic Excavator Pc25!30!40 45 Operator Manual Seam020s0703margaretjefferson060403pxf100% (25)

- 220/110 KV SUB-STATION EQUIPMENT AND OPERATIONDocument16 pages220/110 KV SUB-STATION EQUIPMENT AND OPERATIONarshidtaNo ratings yet

- Boonton 59 - Grid Dip MeterDocument27 pagesBoonton 59 - Grid Dip MeterRaffaele Zignale100% (2)

- Electrical Type Flow MetersDocument22 pagesElectrical Type Flow MetersAnuNarayan R0% (1)

- DC Armature WindingDocument2 pagesDC Armature Windinglvb123No ratings yet

- AssignmentDocument39 pagesAssignmentMaharnab Paul MugdhaNo ratings yet

- V An Innovative Magnetic Field Sweep Unit: of of of ofDocument20 pagesV An Innovative Magnetic Field Sweep Unit: of of of ofBerthaFloresNo ratings yet

- Lightening Arrestar: The Most Common Device Used For Protection The Power System Against High VoltageDocument28 pagesLightening Arrestar: The Most Common Device Used For Protection The Power System Against High VoltagePallavi JainNo ratings yet

- Electromagnetic-Attraction-RelaysDocument15 pagesElectromagnetic-Attraction-RelaysbarmavathnikhilnayakNo ratings yet

- DC Machines: Principles and PartsDocument10 pagesDC Machines: Principles and PartsFrances GalangNo ratings yet

- Protective RelaysDocument60 pagesProtective RelaysAnkit JoshiNo ratings yet

- Starting Up The Power Station SimulatorDocument7 pagesStarting Up The Power Station SimulatoraajilNo ratings yet

- Switchgear ComponentsDocument17 pagesSwitchgear ComponentsNAIMUR RAHAMAN ANIK 1802104No ratings yet

- EE312L Research WorkDocument20 pagesEE312L Research WorkJohn Carl TiburcioNo ratings yet

- PAKISTAN ORDNANCE FACTORY WAH CANTTDocument11 pagesPAKISTAN ORDNANCE FACTORY WAH CANTTNusrat Abbas AwanNo ratings yet

- MultivibratorsDocument14 pagesMultivibratorsMuhammadSajidNo ratings yet

- Assignment 01 Aircraft Lighting Systems Task 01 Landing Gear Light CircuitDocument14 pagesAssignment 01 Aircraft Lighting Systems Task 01 Landing Gear Light CircuitShahriar Ali SifatNo ratings yet

- CB CVT Capacitor Voltage Transformer CT Current Transformer PT Potential Transformer HV High Voltage LV Low Voltage LA Lightning ArrestorDocument45 pagesCB CVT Capacitor Voltage Transformer CT Current Transformer PT Potential Transformer HV High Voltage LV Low Voltage LA Lightning ArrestorVeera Venkata SurendraNo ratings yet

- Neals Token InstrumentDocument39 pagesNeals Token InstrumentVikas Srivastav100% (2)

- Maintenence of Double Line Block Instrument Used in Indian RailwaysDocument7 pagesMaintenence of Double Line Block Instrument Used in Indian RailwaysVikas Srivastav100% (1)

- Oscillators Module 02Document20 pagesOscillators Module 02ervaishu5342100% (1)

- Swyd PDFDocument82 pagesSwyd PDFRajeevAgrawal100% (2)

- LVDT and Capacitance Strain GuagesDocument13 pagesLVDT and Capacitance Strain GuagesJignesh P Korat100% (1)

- Manitou Telehandler BT 420 Series 3 Operators Manual enDocument24 pagesManitou Telehandler BT 420 Series 3 Operators Manual enhovy1876100% (4)

- III DECE Advanced Communications LabDocument23 pagesIII DECE Advanced Communications LabKethavath Sakrunaik K100% (1)

- Module 2Document40 pagesModule 2syedabdulla442No ratings yet

- Protection of Induction Motors and Bus Bars from Ground FaultsDocument33 pagesProtection of Induction Motors and Bus Bars from Ground FaultsViswanathanBalaji100% (1)

- SwitchgearDocument6 pagesSwitchgearChayon KarmakarNo ratings yet

- Assignment 2Document9 pagesAssignment 2Noor HassanNo ratings yet

- Computer Organization Unit-1Document147 pagesComputer Organization Unit-1Akula Lakshmi SreenivasuluNo ratings yet

- Elcometer 101: 101 - TMA - 0465 - 00 - 03 (Part Number 2185) .FM Page - 1 Tuesday, August 20, 2013 11:03 AMDocument7 pagesElcometer 101: 101 - TMA - 0465 - 00 - 03 (Part Number 2185) .FM Page - 1 Tuesday, August 20, 2013 11:03 AMDania GomezNo ratings yet

- ProductSpecialLights EngDocument32 pagesProductSpecialLights EngPT. Andara Prima UtamaNo ratings yet

- Chicago Pneumatic CP7255 Random Orbital Sander Repair PartsDocument3 pagesChicago Pneumatic CP7255 Random Orbital Sander Repair PartsChaouki Ben jemaaNo ratings yet

- Mechatronics PDFDocument18 pagesMechatronics PDFnirajNo ratings yet

- Amphenol A SeriesDocument36 pagesAmphenol A SeriesAMNo ratings yet

- Hand Tools and Materials for CarpentryDocument24 pagesHand Tools and Materials for CarpentryMer'at LoulNo ratings yet

- Coduri MandqwdqwDocument59 pagesCoduri MandqwdqwRazvanSandolacheNo ratings yet

- FM Transmitter DesignDocument5 pagesFM Transmitter DesignLaty Bayb100% (1)

- Liye - Info Manual Motro Cat 3406 Volumen 01pdf PRDocument634 pagesLiye - Info Manual Motro Cat 3406 Volumen 01pdf PRM/V C-Ambassador100% (1)

- H Series Natural Gas and Biogas Genset PricelistDocument3 pagesH Series Natural Gas and Biogas Genset Pricelist2326839No ratings yet

- Delta6rc FinalDocument2 pagesDelta6rc FinalsarvottamNo ratings yet

- Industrial Solid State RelaysDocument5 pagesIndustrial Solid State Relaysjromero_rpgNo ratings yet

- Scada SpecsDocument3 pagesScada SpecsPinoy DawahNo ratings yet

- Multiple choice questions on servomechanisms, relays, PLCs and control systemsDocument2 pagesMultiple choice questions on servomechanisms, relays, PLCs and control systemsHamza MustafaNo ratings yet

- API-U ELrng OilGas Cat 10.12.12 (Online) OptDocument44 pagesAPI-U ELrng OilGas Cat 10.12.12 (Online) OptMaría BossaNo ratings yet

- Turkred Globoid WormgearingDocument3 pagesTurkred Globoid Wormgearingnagaraj.ss@quest-global.comNo ratings yet

- Airframe Control Ball Bearings - DSRP, GDSRP Series Self-Aligning RollerDocument1 pageAirframe Control Ball Bearings - DSRP, GDSRP Series Self-Aligning RollerSeba PaceNo ratings yet

- 75 Ton Terex-T750 PDFDocument9 pages75 Ton Terex-T750 PDFheriberto vazquez sosaNo ratings yet

- Pulsar Evolution 500 To 1500 - Installation and User Manual - Multi LangDocument196 pagesPulsar Evolution 500 To 1500 - Installation and User Manual - Multi LangAlhan SimonNo ratings yet

- Cuponal Bolted JointsDocument8 pagesCuponal Bolted JointsAhmedNo ratings yet

- Architecture of RFID Systems in 40 CharactersDocument4 pagesArchitecture of RFID Systems in 40 CharactersJay MehtaNo ratings yet

- OM 532-06435-En-Collahuasi Rev000Document112 pagesOM 532-06435-En-Collahuasi Rev000Marcos Matias MedinaNo ratings yet

- Data Sheet - Series 7000 Meter DSDocument6 pagesData Sheet - Series 7000 Meter DSJesus DavalosNo ratings yet

- Samsung k15d Chassis Cl15k5mnfx TV SMDocument38 pagesSamsung k15d Chassis Cl15k5mnfx TV SMJosé Roberto Paat BarahonaNo ratings yet

- A8 3D Printer Installation Instructions-161230Document46 pagesA8 3D Printer Installation Instructions-161230Сергей ЖаркихNo ratings yet

- Asrock 970 Extreme3Document64 pagesAsrock 970 Extreme3acchacalNo ratings yet

- LIT1117 RingLug Datasheet v9Document6 pagesLIT1117 RingLug Datasheet v9alltheloveintheworldNo ratings yet

- CANON ImageRUNNER Ir7086, Ir7095, Ir7105 Series Portable ManualDocument170 pagesCANON ImageRUNNER Ir7086, Ir7095, Ir7105 Series Portable ManualAlexanderChacon67% (3)

- Wiring Ac Doorstrike ButterflymxDocument1 pageWiring Ac Doorstrike ButterflymxadenijisegunNo ratings yet