100% found this document useful (6 votes)

15K views29 pagesProgressive Die Strip Layout Design

This document discusses strip layout, which is an important step in designing progressive stamping dies. Strip layout directly impacts die size, cost, press selection, and part quality. It serves as a master plan that determines decisions made during die design. Different types of strip layouts are discussed, including single row one pass, narrow vs wide run, angular pass, and single row two pass layouts. Key terms like scrap bridge, front scrap, back scrap, and economy factor are also defined. Examples are provided on calculating blanks per strip and waste end strip for a given strip layout.

Uploaded by

AnishMendisCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (6 votes)

15K views29 pagesProgressive Die Strip Layout Design

This document discusses strip layout, which is an important step in designing progressive stamping dies. Strip layout directly impacts die size, cost, press selection, and part quality. It serves as a master plan that determines decisions made during die design. Different types of strip layouts are discussed, including single row one pass, narrow vs wide run, angular pass, and single row two pass layouts. Key terms like scrap bridge, front scrap, back scrap, and economy factor are also defined. Examples are provided on calculating blanks per strip and waste end strip for a given strip layout.

Uploaded by

AnishMendisCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Cover Page: The cover page for the document, displaying the title 'STRIP LAYOUT'.

- Introduction: An overview of strip layout and its importance in the design of sheet metal operations, including utilization and cost considerations.

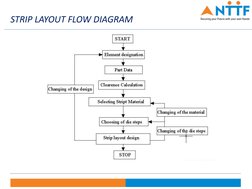

- Strip Layout Flow Diagram: Describes a flow diagram outlining the steps involved in creating a strip layout from element designation to design changes.

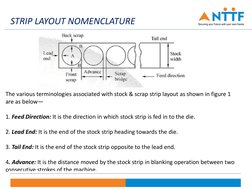

- Strip Layout Nomenclature: Explains the terms associated with stock and scrap strip layout, including directions and essential parts of the layout.

- Choice of Strip Layout Method: Discusses different methods for strip layout considering efficiency, tool profiles, accuracy, and edge constraints.

- What is Strip Layout?: Defines strip layout in terms of logical sequencing of operations for progressive stamping dies, highlighting design factors.

- Economy Factor: Introduces the concept of economy factor in strip design to optimize material usage without compromising accuracy.

- Terms Used in Strip Layout: Listing and explaining essential terms such as scrap bridge, front scrap, and back scrap used in strip layout.

- Example Problems: Provides example calculations related to the economy factor in single row and double row feeding methods.

- Strip Layout Types: Illustrates and describes different types of strip layouts like narrow run, wide run, and gang dies, visualizing their configurations.