Professional Documents

Culture Documents

1679230

Uploaded by

prashant mishra0 ratings0% found this document useful (0 votes)

3 views27 pagesPump

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPump

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views27 pages1679230

Uploaded by

prashant mishraPump

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 27

Unit Seven

Unit Seven: Pumps and

Pumps andCompressors

Compressors

Pumps and compressors are primary sources

of flow in fluid power systems. Maximum

system horsepower is controlled by the size of

these components along with system flow.

The three basic types of pumps are the Gear,

Piston, and Vane designs.

The following hydraulic formula illustrates

a relationship between Horsepower,

Pressure, and Flow.

Hydraulic Horsepower = GPM x PSI x .000583

HYDRAULIC PUMPS AND POSITIVE

HYDRAULIC PUMPS AND POSITIVE

DISPLACEMENT

DISPLACEMENT

In its most basic sense, positive displacement means

what you take in you put out. In other words, for each

revolution of a hydraulic pump of this type, a specific

quantity of fluid is produced relating to the

displacement of the pump.

The Rule of 1500

The rule of 1500 is a engineering reference to a

predictable relationship between Horsepower, Flow,

and Pressure. This is used when sizing an electric

motor for a particular hydraulic system.

In any hydraulic system operating at a pressure of

1500psi, every gallon of flow produced by the pump

will require at least one horsepower to drive it.

In pneumatic systems there is a similar

relationship.

Pumps and Compressors

Before we go any further it should be pointed out that no

matter what design of pump or compressor is being

discussed they all produce flow the same way.

Pumps and compressors produce flow by creating a

“pressure differential.” An example would be a

person drinking water through a straw.

Pumps and Compressors

Hydraulic Pump Pneumatic

Symbol Compressor

Symbol

Its important to note that the above symbols do not

indicate a specific design type, just function. As you

can see, the only difference is the triangle.

Vane Pumps

In the above illustration, only the internal parts are shown.

Normally, one port would be connected to the “increasing” volume

side and another port would be connected to the “decreasing”

volume side. The outer piece does not move. The center piece rotates

and is off center. The dark lines are the vanes and they move in and

out.

Vane Pumps

To understand pump operation, first imagine that the

area in green is attached to a port and is under low

pressure. Fluid, as influenced by atmospheric

pressure, rushes in to fill the voids as the assembly

rotates.

Vane Pumps

As the fluid passes from left to right it becomes

“trapped” between the rotating group and the outlet

port. Fluids always take the path of least resistance as

does electricity so out to the system it goes. All pumps

operate in this manner regardless of design or

configuration.

Balanced Vane Design

In normal operation most pumps are “loaded” to one side because

of pressure at the outlet port. This has an effect on bearing life. A

balanced vane pump has its ports located in four distinct locations

around its shaft to offset this effect and extend service life.

Cartridge Assembly

A lot of vane pump manufacturers have incorporated the

rotating group into a removable assembly that can be

replaced independently of the housing.

Double Pump

Schematic symbol for a double pump

Although vane pumps are sometimes put

together in pairs to form a “double pump,” any

design could be made a double pump. All this

means is that you have two pumps driven by

one motor which may have their flows put

together or separated.

Variable Volume Vane Pump

“Variable volume” means that the “amount” of oil which is

displaced by a pump each revolution can change whereas in

other”fixed” displacement models it cannot. What controls the

“amount” of oil displaced by fixed displacement pumps?

Speed and Displacement

Variable Volume Vane Pump Operation

The key to understanding this illustration is knowing that

displacement depends on the amount of offset that exists between the

rotor and cam ring. The more the offset the more the displacement

and the less the offset the less the displacement. If the rotor becomes

centered, there is NO displacement. If the rotor travels from one

side to the next, flow reverses ports.

Volumetric Output of a Pump

Theoretical Pump Flow = Speed x Displacement

231

What this means is that other than an internal

mechanical mechanism that changes flow rate the only

two thins that control flow are the physical size of the

pump and how fast you run it.

Pressure Compensated Variable

Volume Vane Pump Operation

As pressure builds in the system it is felt everywhere including the

pump. The cam ring will push away from the pressure direction

toward the path of least resistance which is the spring. When the

pressure of the system is equal to the tension of the spring, the rotor

will be in the center of the cam ring and flow will stop while pressure

is maintained.

Pressure Compensated

Variable Volume Vane Case

Drain

All pumps experience internal leakage but it is worst in the

models illustrated here. To alleviate this pressure, and thus

prevent the front seal from blowing out, a case drain is

provided.

Gear Pumps

In a gear pump, an increasing volume is generated as teeth un-mesh

or move away from each other. The fluid drawn in is forced around

the teeth, not through the middle. As the teeth move toward each

other, fluid is forced from the outlet port.

Piston Pumps

There are two major categories of pumps: Axial and

Radial.

Axial(swash plate)piston pump

Piston Pumps

Radial piston pump

Piston Pumps

Piston pumps operate under the same controlling principles as all

other pumps. With this design, a piston moves back and forth in a

barrel. As the piston moves back, a larger volume is created that

provides a vacuum. As the piston moves forward, the volume is

decreased and fluid is forced out. Axial piston pumps have pistons

that move in parallel to the drive shaft axis. Radial piston pumps

have pistons that move at 90 degrees to the drive shaft axis. Either

type can be made variable volume by adjusting the amount of

stroke the piston travels in the cylinder bore.

Pressure Compensated Axial Piston

Pump

Low pressure-full stroke condition Compensator fires at pressure

setting- no flow

In the axial pump above, a pressure build up causes the

compensator rod to push against the swash plate which

in turn decreases the amount of flow to zero when the

tension of the spring has been reached.

Overcenter Axial Piston Pumps

As in the vane pump, reverse flow in the piston pump

is accomplished by moving the rotating group beyond

a “center” point. In the piston pump the swash plate

is the member that moves to + or – 0 degrees to

achieve this feature. These types of pumps are often

found in hydrostatic transmissions.

Compressors

Compressors operate by drawing in air at lower than

atmospheric conditions and then trapping, and

compressing it. Once compressed, the air is allowed

to escape to the path of least resistance, usually the

receiver tank. All compressors operate under the

same principles as pumps but the fluid is a gas.

Compressors

Compressors fall into one of two main categories; Dynamic and

Displacement.

Dynamic Compressors

Dynamic compressors are not positive displacement.

They move air by adding kinetic energy to it or in other

words they “throw” the air. Examples of dynamic

compressors would include a leaf blower, hair dryer, and

common fan. Dynamic compressors are known for low

pressures but high volumes of air. A jet engine is another

example of a dynamic compressor.

Displacement Compressors

Standard displacement compressors can be single stage

where the air is compressed once or multi-stage where

the air is compressed two or more times to achieve

higher efficiency. In operation, air is drawn in as the

piston moves down. When the piston moves up air is

compressed and then released to the receiver tank.

Multi-stage Compressors

In multi-stage compressors, air is compressed twice in

order to get it to the receiver tank at a higher pressure

but lower temperature. Single stage compression is less

efficient because so much heat is given up in the

receiver which translate into lost pressure.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Levers:: Pivoted About The FulcrumDocument14 pagesLevers:: Pivoted About The Fulcrumprashant mishraNo ratings yet

- Avi R. Chaudhary - Cover Letter (PWC)Document1 pageAvi R. Chaudhary - Cover Letter (PWC)prashant mishraNo ratings yet

- Principles and Use of Shafts and BearingsDocument115 pagesPrinciples and Use of Shafts and Bearingsprashant mishraNo ratings yet

- JP - BALANCING PROGRAM - Rev3Document114 pagesJP - BALANCING PROGRAM - Rev3prashant mishraNo ratings yet

- Design Spur Gear Study Material LectDocument6 pagesDesign Spur Gear Study Material Lectprashant mishraNo ratings yet

- Conveyor Frames MasonsDocument5 pagesConveyor Frames Masonsprashant mishraNo ratings yet

- Conveyor Pulley PDFDocument4 pagesConveyor Pulley PDFprashant mishraNo ratings yet

- Conveyor PulleyDocument4 pagesConveyor Pulleyprashant mishraNo ratings yet

- Chain Pulley Spare - Parts - Manual - Hoisting - SparDocument4 pagesChain Pulley Spare - Parts - Manual - Hoisting - Sparprashant mishraNo ratings yet

- Blast Furnace Tap Hole and Tapping of The FurnaceDocument11 pagesBlast Furnace Tap Hole and Tapping of The Furnaceprashant mishraNo ratings yet

- LLS S-220000S S 220000S S V VC CC C-220000S S: Industrial Air CompressorDocument148 pagesLLS S-220000S S 220000S S V VC CC C-220000S S: Industrial Air Compressormoh hardiusNo ratings yet

- Costing Sheet For PlantDocument84 pagesCosting Sheet For PlantmembranesNo ratings yet

- Daily Form BM Automotive Month: June 2016Document88 pagesDaily Form BM Automotive Month: June 2016Anonymous G08DSorFNo ratings yet

- 50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveDocument2 pages50B-4KG1 Globe 2050B-4KG1 Angle: Listed/Approved Fire Protection Pressure Relief ValveNazrul IslamNo ratings yet

- Carbon Steel: 3-Way High Pressure Ball ValvesDocument8 pagesCarbon Steel: 3-Way High Pressure Ball ValvesRolando Jara YoungNo ratings yet

- RE 25402 - 2021-08 Editado (Valvula Limitadora de Presion BOSCH)Document24 pagesRE 25402 - 2021-08 Editado (Valvula Limitadora de Presion BOSCH)nenuchoNo ratings yet

- Void Propulsion Drive FR., 24-34 Main Engine Room 2, Fr. 49-65Document1 pageVoid Propulsion Drive FR., 24-34 Main Engine Room 2, Fr. 49-65matteoNo ratings yet

- Fluid Flow MeterDocument25 pagesFluid Flow MeterFatinAmiraNo ratings yet

- Air Compressor Room Exhaust (8000CMH)Document1 pageAir Compressor Room Exhaust (8000CMH)Kumar sssssNo ratings yet

- Argohytoslr PDFDocument874 pagesArgohytoslr PDFdonnyNo ratings yet

- Hydraulic PressDocument73 pagesHydraulic PressAmar BhupaliNo ratings yet

- Split Inverter Fujitsu ASBA24JFC AOBR24JFCDocument19 pagesSplit Inverter Fujitsu ASBA24JFC AOBR24JFCWander PrexedeNo ratings yet

- Positive Displacement PumpsDocument13 pagesPositive Displacement PumpsahmadNo ratings yet

- PompaDocument71 pagesPompa3C10Iqbal Miftachul FalahNo ratings yet

- Ex450-5 Technical DrawingDocument12 pagesEx450-5 Technical DrawingTuan Pham AnhNo ratings yet

- Hydraulic Diagram, With Option Components: Service InformationDocument4 pagesHydraulic Diagram, With Option Components: Service InformationPetrus Kanisius WiratnoNo ratings yet

- Customer Part 2 Print OutDocument14 pagesCustomer Part 2 Print Outradient.freshNo ratings yet

- Pedrollo KatalogDocument76 pagesPedrollo KatalogDamir RaljevićNo ratings yet

- H1A2Document421 pagesH1A2Juan Pablo Sanchez MelgarejoNo ratings yet

- CT-2602 HE 2611 DEBUTANIZER COLUMN - Rev 0CxDocument1 pageCT-2602 HE 2611 DEBUTANIZER COLUMN - Rev 0CxMariaNo ratings yet

- PED ClassificationDocument5 pagesPED Classificationabdelkader benabdallahNo ratings yet

- Technical Data For The Bhel 500 MW Steam Turbine PDFDocument2 pagesTechnical Data For The Bhel 500 MW Steam Turbine PDFsai ramanaNo ratings yet

- Parts Manual-Cementing TrailerDocument146 pagesParts Manual-Cementing TrailerJose Rafael Urbina VelasquezNo ratings yet

- YUKEN Modular ValvesDocument136 pagesYUKEN Modular ValvestungNo ratings yet

- Lab # 2 Gear Pump: ObjectiveDocument7 pagesLab # 2 Gear Pump: ObjectiveNio100% (1)

- MGS Capacity CalculatorDocument13 pagesMGS Capacity CalculatorRodolfo MendezNo ratings yet

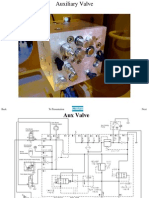

- Aux Valve Brakes ST710Document16 pagesAux Valve Brakes ST710Jose VegaNo ratings yet

- To Gas Turbines and ApplicationsDocument34 pagesTo Gas Turbines and Applicationstanojpatro1985100% (1)

- Equivalent Jenis MesinDocument1 pageEquivalent Jenis MesinJimmy ChangNo ratings yet