Professional Documents

Culture Documents

Foundations On Sand and Nonplastic Silt: Dave Khyl J. Bosque

Uploaded by

Dave KhylOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foundations On Sand and Nonplastic Silt: Dave Khyl J. Bosque

Uploaded by

Dave KhylCopyright:

Available Formats

Foundations on Sand

and Nonplastic Silt

Dave Khyl J. Bosque

Reporter

DP 19.1

Significant Characteristics of

Sand and Silt Deposits

If the site is underlain by sand, the foundation may consist of footings, rafts,

piers or piles. The choice depends primarily on the relative density of the

sand and on the position of the water table.

RELATIVE DENSITY – determines the bearing capacity and settlement of

footings, rafts or piers, and it also establishes the resistance of piles.

WATER TABLE POSITION – is important mainly because excavation below

the water table requires drainage and increases the cost of the foundation

Nonplastic cohesionless silt exhibits most of the characteristics of fine sand.

Foundations on Sand and Nonplastic Silt

DP 19.2

Footings on Sand

BASIS FOR DESIGN

Typical load-settlement relationships for footings of different widths on

the surface of a homogeneous sand deposit are shown in Fig. 19.1a

The wider the footing, the

greater the ultimate capacity

per unit area. However, for a

given settlement S1 , such as1

inch, the soil pressure is

greater for a footing of

intermediate width Bb than for

a large footing with a width Bc ,

or for a narrow footing with

width Ba . The pressures

corresponding to the three

widths are indicated by points

Figure 19.1a b, c, and a, respectively.

Foundations on Sand and Nonplastic Silt

Footings on Sand

The same data may be used to plot Fig. 19.1b, which shows the load q1 per

unit area corresponding to a given settlement S1 as a function of the width of

the footing. The soil pressure for settlement S1 increases with increasing

width of footing if the footings are relatively small, reaches a maximum at an

intermediate width.

On the other hand, a small

change in the pressure on a

wide footing has little influence

on the settlements as small as

S1 ; moreover, the value of q1

corresponding to S1 is far

Figure 19.1b below that which would

produce a bearing-capacity

failure of the wide footing.

Foundations on Sand and Nonplastic Silt

Footings on Sand

CONSIDERATIONS OF SETTLEMENT

The soil pressure that produces a given settlement S1 on a loose sand is

obviously smaller than the soil pressure tat produces the same settlement

on a dense sand. Hence, on a rough way, there should be a relation

between the soil pressure to produce the given settlement and the N-values

from the standard penetration test.

Figure 19.3

Foundations on Sand and Nonplastic Silt

Footings on Sand

Figure 19.3 sets a the design chart for proportioning shallow footings on

sand. Each line corresponds to a particular N-value and indicates the soil

pressure corresponding to a settlement of 1 in. the lines are drawn for the

condition that the water table is at greater depths.

Figure 19.3

Foundations on Sand and Nonplastic Silt

Footings on Sand

CONSIDERATIONS OF BEARING CAPACITY

It has been pointed out that, for narrow footings, small increases in soil

pressure may lead to such large increases in settlement that the movement

would be considered a bearing-capacity failure. Hence, any acceptable

procedure for proportioning footings on sand must provide assurance that,

even if the settlement under the anticipated conditions would appear not to

exceed 1 in., the margin against a bearing –capacity failure would be ample

in spite of the inevitable differences between anticipated and real conditions.

Moreover, under some circumstances even large settlement of wide

footings or piers may be acceptable if the possibility of an outright failure of

the supporting sand is excluded. Hence, a knowledge of the ultimate

bearing capacity is essentials for design. Reasonable estimates can be

based on theoretical considerations.

Foundations on Sand and Nonplastic Silt

Footings on Sand

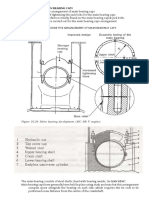

Figure 19.4 represents a cross section through a long footing with width B,

resting at depth Dƒ below the ground surface on deep deposit of sand. If the

footing fails by breaking into the ground, a zone a0’a’,within which the sand

cannot slip with respect to the base of the footing because of the roughness

of the base , moves downward as a unit.

Figure 19.4

Foundations on Sand and Nonplastic Silt

Footings on Sand

As it moves it displaces the adjacent material. Consequently, the sand in

two symmetrical zones a0’bde, one of which is illustrated on the left side of

Fig. 19.4, is subjected to severe shearing distortions and slides outward and

upward along boundaries 0’bd.The movement is resisted by the shearing

strength of the sand along 0’bd and the weight of the sand in the sliding

masses.

Figure 19.4

Foundations on Sand and Nonplastic Silt

Footings on Sand

Figure 19.4. Cross section through long footing on sand showing (left side)

pattern of displacements during bearing-capacity failure, and (right side)

idealized conditions assumed for analysis.

Figure 19.4

Foundations on Sand and Nonplastic Silt

Footings on Sand

The results of such studies indicate that the gross ultimate bearing capacity

may be expressed as

‘= Eq. 19.1

And the net ultimate bearing capacity as

=‘

= Eq. 19.2

Foundations on Sand and Nonplastic Silt

Footings on Sand

In these equations, and are dimensionless bearing-capacity factors

depending primarily on . They may be evaluated by means of the chart in

Figure 19.5

Figure 19.5. Curves

showing the relationship

between bearing-capacity

factors and as

determined by theory,

and rough empirical

relationship between

bearing capacity factors

or and values of

standard penetration

resistance N.

Foundations on Sand and Nonplastic Silt

Footings on Sand

The unit weights of most sands, whether

dry, moist, or saturated, lie within a fairly

narrow range. Therefore the unit weight of

the sand is in itself not an important

variable in the determination of the

bearing capacity of the footing. However, if

the sand is located below the free water

surface, only its submerged weight is

effective in producing friction. Thus, the

position of the water table is of

outstanding practical importance in

establishing the bearing capacity of a

footing on sand.

Foundations on Sand and Nonplastic Silt

Footings on Sand

It should be understood that the relationship between N and (Fig. 19.5) is only

approximate. Nevertheless, the relationship between is based primarily on the

theory and is much more reliable. Hence, if is determined by a procedure more

refined than the use of the standard penetration test, may still be utilized to

evaluate

Equation 19.2 can be expressed in the form.

= Eq. 19.3a

An for a given factor of safety F against a bearing-capacity failure,

= Eq. 19.3b

Foundations on Sand and Nonplastic Silt

Footings on Sand

= Eq. 19.3a

= Eq. 19.3b

For a particular value of and a given deposit of sand, the expression within the

brackets is a constant. Thus, the relation between the width of footing and the

net soil pressure for a given factor of safety can be expressed in a plot such as

Figure 19.3 as a family of straight lines radiating from the origin. Each line

corresponds to a sand having a different N-value.

Foundations on Sand and Nonplastic Silt

Footings on Sand

DESIGN CHART FOR FOOTINGS ON SAND

The considerations of settlement and bearing capacity discussed in the

preceding subheadings define the right-and-left branches of the curves shown

in Fig. 19.3. The curves constitute a convenient means for proportioning

footings on sand.

Foundations on Sand and Nonplastic Silt

Footings on Sand

Figure 19.3 considerations…

1. The chart is based on the behavior of shallow footings of the normal

dimensions and depths below the ground surface.

Fig. 19.6. Chart

for correction of

N-values for

influence of

overburden

pressure

Foundations on Sand and Nonplastic Silt

Footings on Sand

(cont.) Figure 19.3 considerations…

2. No deposit of natural sand is perfectly uniform. To assure that the least

favorable subsurface conditions are taken into account, the penetration

resistance for the sand at a given site should be determined by making borings

with standard penetration tests at a number of joints, preferably at least one

boring for every or footings.

3. It has been shown that a rise of the water table from a depth greater than

about B below the base of the footing up to the top of the surcharge has the

effect of reducing the bearing capacity to about one half of its value for moist,

dry, or saturated sand.

Foundations on Sand and Nonplastic Silt

Footings on Sand

For a depth to groundwater level equal to Dw, measured from the surface of the

surcharge surrounding the footing, the correction factor may be obtained with

sufficient accuracy by linear interpolation, or

= Eq. 19.4

Foundations on Sand and Nonplastic Silt

Footings on Sand

DESIGN PROCEDURE BASED on CHART for FOOTINGS on SAND

Since the permeability of sands is high enough to permit rapit adjustment to

changes in load, the behavior of a foundation on sand is likely to reflect the

influence of the maximum rather than the long-term average loads. This

characteristics should be given consideration in choosing the loads which the

footings are to be proportioned.

In practical foundation design it is customary to proportion all footings for

the same net soil pressure except for a few that may have to be treated as

special cases. If the soil pressure for the design is influenced by the presence

of water table, the largest footing is likely to require the greatest correction.

Hence, the soil pressure should be determined for the footing to be subhected

to the greatest design load.

Foundations on Sand and Nonplastic Silt

Footings on Sand

(cont.)

DESIGN PROCEDURE BASED on CHART for FOOTINGS on SAND

After the dimensions of each of the smaller footings have been determined

on the basis of the soil pressure selected for the largest footing, Fig. 19.3 is

entered with the width B and the approximate value of Df / B of each of the

smaller footings to check whether the allowable soil pressure for the footing

may be governed by the bearing capacity; i.e., whether the value of B

corresponds to the left-hand rising branch of the design curve. If it does the

footing must be reproportioned for the for the smaller pressure.

Foundations on Sand and Nonplastic Silt

Footings on Sand

FOOTINGS with ECCENTRIC LOADING

Beneath retaining walls and some other types of structures subjected to

lateral loads, the calculation distribution of pressure against the base may be

triangular (Fig. 19.7). The soil pressure at the toes is then twice the average

pressure.

Fig. 19.7. Diagram

illustrating method for

estimating allowable soil

pressure beneath toe of

eccentrically loaded

footing.

Foundations on Sand and Nonplastic Silt

Footings on Sand

(cont.) FOOTINGS with ECCENTRIC LOADING

However, inasmuch as relatively high pressures act over only part of the

base, the allowable soil pressure can be estimated on the assumption that the

effective with B of the footing is less than the real with b.

Fig. 19.7. Diagram

illustrating method for

estimating allowable soil

pressure beneath toe of

eccentrically loaded

footing.

Foundations on Sand and Nonplastic Silt

DP 19.3

Rafts on Sand

SOIL PRESSURE

Because of the larger size of rafts compared to that of footings, the factor of

safety against a bearing-capacity failure of the underlying sand is always very

great. With increasing width of the raft or increasing relative density of the

sand, the ultimate bearing capacity increases rapidly. Hence, the danger with a

large raft may break into a sand foundation is too remote to require

consideration.

On account of the larger size of rafts, the stresses in the underlying sand

are likely to be relatively high to considerable depth. Therefore, the net soil

pressure at the base of the raft is:

= Eq. 19.6

Foundations on Sand and Nonplastic Silt

Rafts on Sand

= Eq. 19.6

Where Q = total weight of the structure plus live load

A = base area of raft

qb = gross soil pressure or contact pressure at the base of the raft.

Foundations on Sand and Nonplastic Silt

DP 19.4

Piers on Sand

CONDITIONS for USE of PIERS

Piers may be established on a bed of dense sand at a considerable depth

below the ground surface if the overlying materials are too soft or compressible

for the support of the structure or if they may be removed by scour. In these

respects, the conditions under which pier foundations are appropriate are

similar to those who piles(Art.19.5),and the choice between piers or piles

depends primarily on economy and on certain details that influence the

construction procedure. For example, if the overlaying material contains ample,

if the overlaying material contains organic deposits that include trunks of trees,

or if there are likely to be numerous large boulders above the bearing stratum,

it may not be possible to drive piles to the necessary depth. Under these

conditions, a pier foundation may be indicated. On the other hand, the

excavation for a pier is likely to lead to some loosening of the sand deposit on

which the structure is to rest, whereas driving piles into the sand tends to

compact the bearing stratum. Because of these conditions, a pile foundation

may be preferable.

Foundations on Sand and Nonplastic Silt

Piers on Sand

BEARING CAPACITY and SETTLEMENT OF PIERS

The ultimate bearing capacity of piers exceeds that calculated on the basis

of eq.19.2 because the shearing resistance along the surface bd through the

surcharge(Fig.19.4)is no longer negligible, as assumed in the derivation of eq.

19.2. However, if the material above the level of the base of the piers is weak or

compressible, the increase in bearing capacity may be small. Moreover, if there

is a possibility that the surrounding material may even occasionally be

removed by scour, its beneficial influence must be neglected. Therefore, in

general, it is conservative and justifiable to determine the safe bearing capacity

by means of eq. 19.2 with an appropriate factor of safety. In many instances the

weight of a concrete pier itself is a large fraction of the total load transferred by

the pier to the sand, but the settlement that occurs before the pier is completed

may be of no significance. The bases of tall pier shafts supporting bridge

spans, for example, may be allowed to settle appreciably, while the concrete of

the shafts is being placed, with no detrimental effects.

Foundations on Sand and Nonplastic Silt

Piers on Sand

BEARING CAPACITY and SETTLEMENT OF PIERS

Under these circumstances the weight of the pier can be subtracted from

the total net load before the base area is determined by the procedures

described in the preceding paragraph. The requirements for an adequate factor

of safety, however, must be satisfied for the total net load, including the weight

of the pier.

Foundations on Sand and Nonplastic Silt

DP 19.5

Piles on Sand

USE OF PILES IN SAND

1. Piles may be driven through soft or compressible materials into a layer of

dense sand to which they may transfer the weight of structure.

2. They may be driven into loose sand to compact it and increase its

bearing capacity.

3. They may be driven into a bed sand to establish the foundation below

the greatest depth to which the sand may be removed by scour.

Foundations on Sand and Nonplastic Silt

Piles on Sand

PILES DRIVEN TO BEARING IN DENSE SAND

When the material directly beneath foundation level is too compressible or

unstable to support the foundation, he weight of the structure should, if

possible, be transferred to a more suitable stratum at a lower level. If this

stratum consists of sand, piles are often driven through the soft materials and

far enough into the sand to develop adequate carrying capacity. If the sand is

moderately loose, the piles may be have to be driven into it for a considerable

distance. If it is fairly dense, it may not be possible to obtain more than a few

feet of penetration. In either event, the support provided to the piles by the sand

is derived partly from the resistance of the point to further penetration and

partly from skin friction between the lower part of the piles and the sand.

Foundations on Sand and Nonplastic Silt

Piles on Sand

(cont.)

PILES DRIVEN TO BEARING IN DENSE SAND

In particular, if part of the dynamic resistance of a single pile is developed

in the overlying soft layers, this resistance should not mislead the engineer into

believing that the bearing capacity of the pile under static load in the foundation

will be as great as the load-test value.

Foundations on Sand and Nonplastic Silt

Piles on Sand

COMPACTION PILES

Driving piles into a bed of loose sand compacts the materials, partly

because of the decrease in void ratio necessary to compensate for the

compacting effect of the vibrations produced by pile driving. Once the piles are

driven, the settlements of the structure are approximately the same as those

estimated according to the procedures described for footings and rafts on

relatively dense sand.

Inasmuch as the purpose of compaction piles is merely to increase the

density of the sand, the structural strength of the piles themselves is of little

consequence.

The length of compaction piles is also difficult to predict. It decreases

markedly with increasing taper. Piles of 20- to 30- ton capacity, having a taper

of 1 in. in 2.5 ft. rarely penetrate more than 25 ft even in loose sand.

Foundations on Sand and Nonplastic Silt

Piles on Sand

PILES IN VERY FINE SAND AND SILT

In the foregoing discussions it has been assumed that the sand into or

through which the piles are driven is previous enough to permit dissipation of

the pore pressures due to driving almost as rapidly as they develop. This

condition is not satisfied in fine sand and silts. The consequences depend on

whether the soil loose or dense. As successive piles are driven into such soils

in a loose state, the pore pressures accumulate, reduce the effective stresses

between the particles, and correspondingly reduce the shearing resistance of

the soil. If the pore pressures become large enough, the soil is transformed into

a viscous liquid in which previously driven piles are readily displaced laterally

and upward. Timber or hollow-shell may in extreme cases actually float. Such

behavior is especially undesirable if the piles are intended to derive their

support from an underlying bearing stratum.

Foundations on Sand and Nonplastic Silt

Piles on Sand

UPLIFT RESISTANCE OF PILES IN THE SAND

The resistance to uplift of a pile driven into a sand depends on the relative

density of the sand, the length, diameter, and taper of the pile, the use or

absence of jetting, and several other factors. For this reason realiable values of

the uplift resistance can be obtained only by means of load tests.

Foundations on Sand and Nonplastic Silt

DP 19.6

Excavation on Sand

SAND ABOVE WATER TABLE

No construction problems of consequence are encouraged in making

excavations for footing or raft foundations in sand above water table

LARGE EXCAVATIONS BELOW WATER TABLE

If excavations for a basement or for a establishment of a foundation must

extend below water table in sand, the water level must be lowered. This may be

done either by pumping the water out of the excavation itself, or by predrainage

of the site.

Foundations on Sand and Nonplastic Silt

Excavation on Sand

ESTABLISHMENT OF PIERS BELOW WATER TABLE

Piers may be carried below water level in open shafts or by means of

caissons. Excavation of an open shaft through sand below water table may

often be accomplished from pumping from sumps if the sand is of medium to

high density. However, the sand is likely to be loosened and, consequently, its

bearing capacity impaired. Use of well points or deep wells before excavation is

usually preferable.

Foundations on Sand and Nonplastic Silt

DP 19.7

EFFECTS OF VIBRATIONS

IMPORTANCE

Vibrations constitute the most effective means for compacting deposits of

loose sand. By the same token, they constitute one of the most serious causes

of excessive settlement of foundations located on loose sands.

COMPACTION

If the relative density of a deposit of sand is too low for the establishment of

a raft or footing foundation, it may be increased by several means. One of

these is the driving of compaction piles. Another is the use of the patented

method known as the vibroflotation process.

Foundations on Sand and Nonplastic Silt

EFFECTS OF VIBRATIONS

Vibroflotation process:

In this method, a heavy steel capsule containing an internal vibrator is lowered into

the deposit of sand. At the same time, powerful jets of water are forced into the sand

beneath the capsule. Under the combined action of jetting and vibration the device sinks

rapidly and creates a crater in the ground surface. As the crater develops, it is filled with

sand. Compaction to the depth of penetration for a diameter of 6 to 8 ft is generally quite

satisfactory. The procedure may, under some circumstances, be less expensive than

driving piles. It is most effective in clean medium to coarse sands, but is not an effective

in silty sands or silts.

Foundations on Sand and Nonplastic Silt

EFFECTS OF VIBRATIONS

SETTLEMENT

Many types of machines subject the subsoil to periodic vibrations; these

include air compressors, diesel engines for production of electric power, and

turbo generators. The amplitude of the vibrations and the accompanying

settlement of the foundation for such a machine depend for a given installation

on the frequency. Near a critical frequency the amplitudes may be greatly

reinforced by a phenomenon related to resonance. Hence, especially if the

subsoil consists of loose sand, a resonant condition must be avoided if

possible.

Foundations on Sand and Nonplastic Silt

EFFECTS OF VIBRATIONS

(cont.)

SETTLEMENT

Repeated vibrations or impact at frequencies other than in the resonant

range may also eventually produce large cumulative settlements, even

onsands of moderately high relative density. Moreover, settlements are likely to

be greater if the ground water table is high.

Foundations on Sand and Nonplastic Silt

THE END

THANK YOU

Foundations on Sand and Nonplastic Silt

You might also like

- Pile FoundationsDocument36 pagesPile FoundationsAya S AbuRabeeNo ratings yet

- 1135 PDF C01Document9 pages1135 PDF C01Rezwan NiloyNo ratings yet

- 08 Chapter 9 - Sheet Pile Walls-MDocument70 pages08 Chapter 9 - Sheet Pile Walls-MAnonymous 1HFV185Sl4100% (1)

- Pile CalcDocument11 pagesPile CalcADHAM HAMZANo ratings yet

- Foundation Resistance Analysis of Cisomang BridgeDocument7 pagesFoundation Resistance Analysis of Cisomang BridgerullyirwandiNo ratings yet

- Studi Pengaruh Penambahan Tanah Lempung A-7 Terhadap Kuat Geser Tanah Pasir SungaiDocument7 pagesStudi Pengaruh Penambahan Tanah Lempung A-7 Terhadap Kuat Geser Tanah Pasir SungaiRizhalLoudoeNo ratings yet

- Design and Construction of Shallow Foundations: General Requirements (IS1904-1986)Document32 pagesDesign and Construction of Shallow Foundations: General Requirements (IS1904-1986)razorNo ratings yet

- Bearing Capacity of Geosynthetic Reinforced Sand Bed On Problematic SoilDocument9 pagesBearing Capacity of Geosynthetic Reinforced Sand Bed On Problematic SoilJEETENDRA PRAKASHNo ratings yet

- (P'o + Y F T: Su C S PDocument1 page(P'o + Y F T: Su C S PFernando FanteNo ratings yet

- Fig. 4.17 Bearing Capacity Factors of Berezantsev Et AlDocument1 pageFig. 4.17 Bearing Capacity Factors of Berezantsev Et AlVardhanNo ratings yet

- NQ Values - M J Tomlinson PDFDocument1 pageNQ Values - M J Tomlinson PDFVardhanNo ratings yet

- RCC Isolated Footings DesignDocument25 pagesRCC Isolated Footings DesignShaikh Muhammad Ateeq100% (1)

- BEARING CAPACITY OF SHALLOW FOUNDATIONSDocument140 pagesBEARING CAPACITY OF SHALLOW FOUNDATIONSAS PALACENo ratings yet

- CH 7 Footing and Pile CapsDocument24 pagesCH 7 Footing and Pile Caps秦瑋駿No ratings yet

- Establishing Thickness Tolerances For Parking Lot Slabs ACI July 2021Document11 pagesEstablishing Thickness Tolerances For Parking Lot Slabs ACI July 2021Bernd CastellarNo ratings yet

- Bearing Capacity of Soil-OKDocument31 pagesBearing Capacity of Soil-OKinovasisinergi.sttgNo ratings yet

- Trench Fill Foundation Design DecisionsDocument1 pageTrench Fill Foundation Design DecisionsKenneth OkoyeNo ratings yet

- Shallow Foundation DesignDocument32 pagesShallow Foundation Designsivabathy100% (1)

- Pile Foundation and Earth Anchors Using Cavity Expansion MethodDocument2 pagesPile Foundation and Earth Anchors Using Cavity Expansion MethodMuhammad SiddiqNo ratings yet

- Bearing Capacity of Soil: Factors, Failure Modes, and Field TestsDocument31 pagesBearing Capacity of Soil: Factors, Failure Modes, and Field TestsLeon FouroneNo ratings yet

- ECV 411 - 4 - Design of FoundationsDocument12 pagesECV 411 - 4 - Design of Foundationskipnixonf9No ratings yet

- Simple method for checking flexural capacity of rigid piles of stable embankmentDocument10 pagesSimple method for checking flexural capacity of rigid piles of stable embankmentPaul LeeNo ratings yet

- Pseudo Static vs. Performance Based Seismic Bearing Capacity of Footings (Liquefaction)Document8 pagesPseudo Static vs. Performance Based Seismic Bearing Capacity of Footings (Liquefaction)Alexandros ValsamisNo ratings yet

- Federal Highway Administration Research and TechnologyDocument50 pagesFederal Highway Administration Research and TechnologyRajesh KhadkaNo ratings yet

- NM Hib. H B: Q M CXN MDocument1 pageNM Hib. H B: Q M CXN MFernando FanteNo ratings yet

- Ground Improvement Using Sand Columns To Mitigate Liquefaction - A Case StudyDocument4 pagesGround Improvement Using Sand Columns To Mitigate Liquefaction - A Case StudyAnshuman SinghNo ratings yet

- Friction Coefficient For Concrete Cast On SoilDocument2 pagesFriction Coefficient For Concrete Cast On SoilBogdanB100% (2)

- Effects of Scour and Hydraulic Gradient on Slope StabilityDocument14 pagesEffects of Scour and Hydraulic Gradient on Slope StabilitymarsinNo ratings yet

- Vacuum Preloading Increases Shear StrengthDocument9 pagesVacuum Preloading Increases Shear StrengthNguyen DuongNo ratings yet

- Contact Pressure: Elastic Properties of FootingDocument8 pagesContact Pressure: Elastic Properties of FootingdhivyaNo ratings yet

- Vibro Compaction and Stone Columns for Ground ImprovementDocument69 pagesVibro Compaction and Stone Columns for Ground Improvementvijjikewlguy7116100% (2)

- Research Article: A Simplified Calculation Method For The Near-Slope Laterally Loaded Pile Based On A Passive Wedge ModelDocument11 pagesResearch Article: A Simplified Calculation Method For The Near-Slope Laterally Loaded Pile Based On A Passive Wedge ModelGijsPNo ratings yet

- Foundation 2k11 Sep 2020 AnsDocument8 pagesFoundation 2k11 Sep 2020 AnsManu MHNo ratings yet

- Soil-Bearing Capacity For Shallow FoundationsDocument9 pagesSoil-Bearing Capacity For Shallow FoundationsNguyễn Thanh TrựcNo ratings yet

- Plaxis 15Document7 pagesPlaxis 15Smail ZennoucheNo ratings yet

- Design Strip Spread Footings Under 40Document30 pagesDesign Strip Spread Footings Under 40Raja SahaNo ratings yet

- Numerical simulation of a vibratory roller on cohesionless soilDocument23 pagesNumerical simulation of a vibratory roller on cohesionless soilshravan38No ratings yet

- Unit 05 Shallow FoundationDocument6 pagesUnit 05 Shallow FoundationSandy TrumpNo ratings yet

- Evaluation of Liquefaction Potential of Sabkha Soil in Aziziyah Area, Khobar, KSADocument4 pagesEvaluation of Liquefaction Potential of Sabkha Soil in Aziziyah Area, Khobar, KSAIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Safe Bearing Capacity and Settlement PresentationaDocument39 pagesSafe Bearing Capacity and Settlement PresentationaFaisal RehmanNo ratings yet

- Lecture Notes On Stone ColumnsDocument48 pagesLecture Notes On Stone ColumnsPratik ParekhNo ratings yet

- Foundation On Collapsible and Expansive SoilsDocument43 pagesFoundation On Collapsible and Expansive Soilsbinu johnNo ratings yet

- 168 Resistance of Piles To Compressive Loads: Figure 4.13 Bearing Capacity Factors of Berezantsev Et AlDocument1 page168 Resistance of Piles To Compressive Loads: Figure 4.13 Bearing Capacity Factors of Berezantsev Et AlriyadhNo ratings yet

- Engelhardt 1975Document9 pagesEngelhardt 1975jorge.jimenezNo ratings yet

- 20.9.2 Most Susceptible To Liquefaction: SoilsDocument18 pages20.9.2 Most Susceptible To Liquefaction: SoilsYenifer AraujoNo ratings yet

- Bearing Capacity of Shalow FoundationDocument73 pagesBearing Capacity of Shalow FoundationMè ŘąNo ratings yet

- Keller-Liquefaction Potential Around Pile FoundationsDocument24 pagesKeller-Liquefaction Potential Around Pile FoundationsnumspyNo ratings yet

- 07 Spread Footing Geotechnical Ultimate Limit StateDocument35 pages07 Spread Footing Geotechnical Ultimate Limit StateHukry AingNo ratings yet

- 6 Some Important Features of Stone Column TreatmentDocument7 pages6 Some Important Features of Stone Column TreatmentBilal Ahmed BarbhuiyaNo ratings yet

- Lees Ali 2023 Surfacebcapstronggranlayeronweakersand ICEDocument11 pagesLees Ali 2023 Surfacebcapstronggranlayeronweakersand ICEOum MahmdNo ratings yet

- Bearing CapacityDocument8 pagesBearing CapacityDesalegn TamirNo ratings yet

- 3D Numerical Modeling of Pile Embankment Performance On Soft SoilDocument8 pages3D Numerical Modeling of Pile Embankment Performance On Soft SoilVelumani sNo ratings yet

- Bearing capacity and failure theories of soil foundationsDocument8 pagesBearing capacity and failure theories of soil foundationspandianNo ratings yet

- Pile capacity calculation and load testingDocument45 pagesPile capacity calculation and load testingAhmadAliAKbarPhambraNo ratings yet

- Foro IngDocument7 pagesForo IngLuis Carlos Florez AceroNo ratings yet

- Evaluation of Cyclic Softening in Clays PDFDocument2 pagesEvaluation of Cyclic Softening in Clays PDFBárbara RodríguezNo ratings yet

- Granular PilesDocument16 pagesGranular Pilessgaluf5No ratings yet

- Pile FoundationDocument82 pagesPile FoundationNfs TarTonNo ratings yet

- 2016 Pamana Updates ProfilesDocument38 pages2016 Pamana Updates ProfilesDave KhylNo ratings yet

- University of Southeastern Philippines Surigao Del Sur State UniversityDocument1 pageUniversity of Southeastern Philippines Surigao Del Sur State UniversityDave KhylNo ratings yet

- COMPRESSION MEMBERS HandoutDocument17 pagesCOMPRESSION MEMBERS HandoutDave KhylNo ratings yet

- University of Southeastern Philippines Surigao Del Sur State UniversityDocument2 pagesUniversity of Southeastern Philippines Surigao Del Sur State UniversityDave KhylNo ratings yet

- StatementDocument3 pagesStatementDave KhylNo ratings yet

- PAMANA-SLP Status Across CyclesDocument15 pagesPAMANA-SLP Status Across CyclesDave KhylNo ratings yet

- Set For HealthDocument8 pagesSet For HealthDave KhylNo ratings yet

- Photosynthesis & Respiration ReviewDocument2 pagesPhotosynthesis & Respiration ReviewDave KhylNo ratings yet

- Principles of ManagementDocument2 pagesPrinciples of ManagementDave KhylNo ratings yet

- Proposed Two-Storey School Dormitory Load CombinationsDocument11 pagesProposed Two-Storey School Dormitory Load CombinationsDave KhylNo ratings yet

- FayolDocument2 pagesFayolDave KhylNo ratings yet

- Proposed Public Library Location MapDocument1 pageProposed Public Library Location MapDave KhylNo ratings yet

- Proposed School Dormitory Structural AnalysisDocument8 pagesProposed School Dormitory Structural AnalysisDave KhylNo ratings yet

- English 1 PDFDocument192 pagesEnglish 1 PDFWilma Villanueva100% (1)

- Edukasyonsa Pagpapakatao 6 FIRSTQUARTERMELCwith LRDocument2 pagesEdukasyonsa Pagpapakatao 6 FIRSTQUARTERMELCwith LRDave KhylNo ratings yet

- Left ElevationDocument1 pageLeft ElevationDave KhylNo ratings yet

- Plate 3Document14 pagesPlate 3Dave KhylNo ratings yet

- Foundations On Sand and Nonplastic Silt: Dave Khyl J. BosqueDocument41 pagesFoundations On Sand and Nonplastic Silt: Dave Khyl J. BosqueDave KhylNo ratings yet

- The National Library of The Philippines PDFDocument14 pagesThe National Library of The Philippines PDFDave KhylNo ratings yet

- Plate 4Document10 pagesPlate 4Dave KhylNo ratings yet

- Site Development PlanDocument1 pageSite Development PlanDave KhylNo ratings yet

- Plate 2Document6 pagesPlate 2Dave KhylNo ratings yet

- Foundations On Sand and Nonplastic SiltDocument24 pagesFoundations On Sand and Nonplastic SiltDave KhylNo ratings yet

- The National Library of The PhilippinesDocument14 pagesThe National Library of The PhilippinesDave KhylNo ratings yet

- Chapter 4 Research Data PresentationDocument6 pagesChapter 4 Research Data PresentationDave Khyl100% (1)

- The National Library of The PhilippinesDocument14 pagesThe National Library of The PhilippinesDave KhylNo ratings yet

- National Library of The PhilippinesDocument5 pagesNational Library of The PhilippinesDave KhylNo ratings yet

- Steel Design WorksheetsDocument5 pagesSteel Design WorksheetsDave KhylNo ratings yet

- Grammarian'S Certificate: University of Southeastern Philippines Bislig Campus Maharlika, Bislig CityDocument1 pageGrammarian'S Certificate: University of Southeastern Philippines Bislig Campus Maharlika, Bislig CityDave KhylNo ratings yet

- Barg and BaraDocument6 pagesBarg and BaraGhali_the_monsterNo ratings yet

- 0405 QS026 - 2 PDFDocument6 pages0405 QS026 - 2 PDFNandNo ratings yet

- Design Steps For Continuous BeamsDocument5 pagesDesign Steps For Continuous BeamsSabbir Hossain RoneyNo ratings yet

- 041157X99Z RE18318-20 CompressedDocument2 pages041157X99Z RE18318-20 CompressedmhasansharifiNo ratings yet

- Instruction Sheet V-152 Relief Valve: Important Receiving InformationDocument14 pagesInstruction Sheet V-152 Relief Valve: Important Receiving InformationRODRIGO RODRIGUEZNo ratings yet

- Full Download Solutions Manual For Engineering Vibration 4th by Inman 0132871696 PDF Full ChapterDocument36 pagesFull Download Solutions Manual For Engineering Vibration 4th by Inman 0132871696 PDF Full Chapterpolelessfeck8avz100% (16)

- Wind Turbines: Types and Momentum TheoryDocument4 pagesWind Turbines: Types and Momentum TheoryDanial KhanNo ratings yet

- Sizing Optimization of Grid-Connected Hybrid PV-Wind Energy Systems: State of Art Review and PerspectivesDocument5 pagesSizing Optimization of Grid-Connected Hybrid PV-Wind Energy Systems: State of Art Review and PerspectivesHmaedNo ratings yet

- EE3251 Electric Circuit Analysis Lesson PlanDocument6 pagesEE3251 Electric Circuit Analysis Lesson PlanrajalakshmiNo ratings yet

- Measuring Trench Structures with Model-Based Infrared ReflectometryDocument4 pagesMeasuring Trench Structures with Model-Based Infrared ReflectometryWilson CheinNo ratings yet

- Lab 5 - AC Motor BasicsDocument10 pagesLab 5 - AC Motor Basicsmister8829No ratings yet

- GD 07 06 Thermal CalibrationDocument29 pagesGD 07 06 Thermal CalibrationSamiran SenNo ratings yet

- Data Sheet PLIED - 1500 MM X 1250-5 PlyDocument1 pageData Sheet PLIED - 1500 MM X 1250-5 PlySales support TechnicalNo ratings yet

- Soal Tugas B.inggrisDocument3 pagesSoal Tugas B.inggriscynthiaNo ratings yet

- GSE - RODE-1 - 8.5in - Fishing OperationDocument10 pagesGSE - RODE-1 - 8.5in - Fishing OperationMansour MohamedTNo ratings yet

- Built-in Air Conditioner Saves EnergyDocument11 pagesBuilt-in Air Conditioner Saves EnergyAtchaya SivanthinathanNo ratings yet

- ECO 244 Chapter 21Document15 pagesECO 244 Chapter 21Humayun Kabir 1411281630No ratings yet

- CHE 4613 Radfrac ModelingDocument6 pagesCHE 4613 Radfrac ModelingHuda AlkhouriNo ratings yet

- The Thermodynamics of Refrigeration - Principles of Natural Gas Cryogenic Process PDFDocument13 pagesThe Thermodynamics of Refrigeration - Principles of Natural Gas Cryogenic Process PDFRatnin PanityingNo ratings yet

- Main BearingDocument28 pagesMain BearingCadet Aviral Jha [9335]100% (1)

- Class 10 Remedial Classes SyllabiDocument3 pagesClass 10 Remedial Classes Syllabisiddhisharma0708No ratings yet

- The Physics of WeldingDocument8 pagesThe Physics of WeldingnitinNo ratings yet

- Kobelev Vladimir Durability of SpringsDocument291 pagesKobelev Vladimir Durability of Springsаримотома аримотомаNo ratings yet

- Assess The Fire Resistance of Intumescent Coatings by Equivalent Constant Thermal ResistanceDocument19 pagesAssess The Fire Resistance of Intumescent Coatings by Equivalent Constant Thermal ResistanceMatheus CiveiraNo ratings yet

- KBTU 2022: SAGD Thermal Oil RecoveryDocument45 pagesKBTU 2022: SAGD Thermal Oil RecoveryАлиNo ratings yet

- Commercial Cold Test ProColdDocument8 pagesCommercial Cold Test ProColdpolNo ratings yet

- En GJS 400 15CDocument1 pageEn GJS 400 15CCAT MINING SHOVELNo ratings yet

- Kappa Anina Seidemo 2023 Utan SignDocument99 pagesKappa Anina Seidemo 2023 Utan SignjohnnyNo ratings yet

- Sma 2304 Ordinary Differential Equations 1Document2 pagesSma 2304 Ordinary Differential Equations 1Joe NjoreNo ratings yet

- Proakis ch05Document81 pagesProakis ch05OHNo ratings yet