0% found this document useful (0 votes)

449 views15 pagesQuality Control and Acceptance Sampling

The document discusses quality control techniques including acceptance sampling, process control, and inspection. It explains that quality control evaluates processes and outputs relative to standards and takes corrective action when needed. Acceptance sampling applies quality control to inputs and outputs while process control applies it to transformation systems. Inspection compares goods or services to standards. Control charts are used to monitor process stability and determine if variation is from common or special causes. The document outlines where to inspect in processes and defines key quality control terms.

Uploaded by

Mark Ortiz Luis OllerCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

449 views15 pagesQuality Control and Acceptance Sampling

The document discusses quality control techniques including acceptance sampling, process control, and inspection. It explains that quality control evaluates processes and outputs relative to standards and takes corrective action when needed. Acceptance sampling applies quality control to inputs and outputs while process control applies it to transformation systems. Inspection compares goods or services to standards. Control charts are used to monitor process stability and determine if variation is from common or special causes. The document outlines where to inspect in processes and defines key quality control terms.

Uploaded by

Mark Ortiz Luis OllerCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Quality Control Overview: Introduces the purpose and definition of quality control, emphasizing its role in assuring acceptable processes.

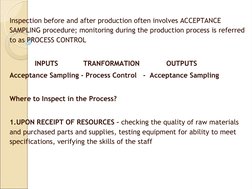

- Quality Control Techniques: Describes techniques in quality control, including acceptance sampling and process control, highlighting their application points.

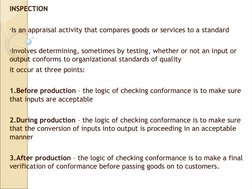

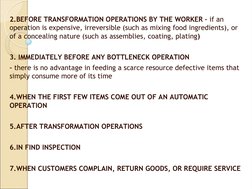

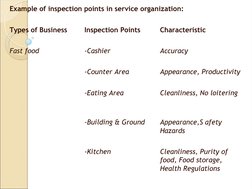

- Inspection Process: Outlines the inspection activity involved in comparing goods or services to a standard, detailing stages of production where inspections occur.

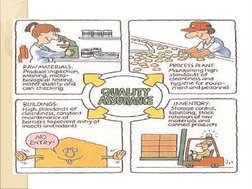

- Quality Assurance: Illustrates quality assurance measures across raw materials, process plants, buildings, and inventories with examples.

- Statistical Process Control: Focuses on using statistical methods to evaluate process outputs and maintain control over quality standards.

- Control Charts: Explains the purpose and development of control charts as tools for monitoring process variations and maintaining specification conformance.

- Process Variability: Discusses variability and capability in processes, including run tests and specification variability insights.

- Acceptance Sampling: Presents methods of inspection and sampling plans applied before and after production to ensure conformance to quality standards.