Professional Documents

Culture Documents

The - OPC - Logger Special Project

Uploaded by

Mohd Ismail YusofOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The - OPC - Logger Special Project

Uploaded by

Mohd Ismail YusofCopyright:

Available Formats

The OPC Logger:

Triggers and Spanning Functions

Team MU: (-1)

Michael Anders

Kathleen O’Malley

Kharel Thompson

Problem of Interest

For most experiments run in DPCL, data

is analyzed from graphs.

All process variables shown on the

graph – cluttered and difficult to read!

Need better way to collect data and store

information for analysis.

What is the OPC Logger?

OPC is the industry leader in data

collection technology.

Relatively inexpensive

Compatible with multitude of software,

including DeltaV control

Offers several key functions including

triggers and spanning functions

Easy to set up and operate

Triggers

Triggers are functions set up to control

when the data gets logged

Start and stop logging based on times and

conditions

Scheduled, Recurring, and Monitored Item

options

Can perform sampling, batch runs, alarm

runs

Your data when and where you want it!

Spanning

Spanning records the data with a date

and time stamp

Helps keep data organized

Aids reading of data

Assists in observing trends and patterns

Know when your data took place!

Execution

Plan of Action

Familiarize group with OPC Logger with

Help file and Professor Heider’s assistance

Set up triggers for Experiments #1, 2, and 3

Set up spanning for same three

experiments

Ensure file with logging data opened in

Microsoft Excel

OPC Logger Screen Shots

How to Set Up Spanning

Go to the TextFileLogger

Select the spanning tab

Input the appropriate data

Spanning

Takes the data at specified intervals

Intervals are 5 secs for our purposes

Select format for displaying time

How to Set Up Triggers

Select Trigger type:

Scheduled

Recurring

Monitored

Create an OPC boolean block inside the

Delta V control studio

Input appropriate conditions for the boolean

Input expression for the variables

Trigger Box

Delta V Block

New Delta V Block

Use conditional block!

Input condition using editor…set variable

of interest greater than some number.

When this occurs, the output of the box will

be 1 and trigger will start.

If condition not met, the output of the box is

0 and the trigger does not start.

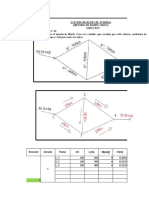

Experiment One Overview

We are controlling the level and pressure

in the tank for experiment one.

The controllers used are the level and

pressure controllers.

Experiment One: Excel Data

LAB1/FC1- LAB1/FC1- LAB1/FC1- LAB1/LC1- LAB1/LC1- LAB1/LC1- LAB1/PC1- LAB1/PC1-

Timestamp 1/OUT.CV 1/PV.CV 1/SP.CV 1/OUT.CV 1/PV.CV 1/SP.CV 1/OUT.CV 1/PV.CV LAB1/PC1-1/SP.CV

06:55.9 99.24592 0.152241 0.6 1 10.62321 50 0 0.165681 5

07:00.9 99.24592 0.992238 0.6 1 11.08362 50 0 0.167701 5

07:05.9 99.24592 1.048034 0.6 1 14.73118 50 0 0.168487 5

07:10.9 99.24592 1.055485 0.6 1 16.68434 50 0 0.168712 5

07:15.9 99.24592 1.049783 0.6 1 17.85982 50 0 0.169686 5

07:20.9 99.24592 1.041922 0.6 1 19.63914 50 0 0.169959 5

07:25.9 99.24592 1.042224 0.6 1 20.77319 50 0 0.170732 5

07:30.9 99.24592 1.042251 0.6 1 23.8534 50 0 0.170732 5

07:35.9 99.24592 1.059029 0.6 1 25.19835 50 0 0.171742 5

07:40.9 99.24592 1.058355 0.6 1 26.14813 50 0 0.17177 5

07:45.9 99.24592 1.040904 0.6 1 27.54046 50 0 0.172753 5

07:50.9 99.24592 1.052819 0.6 1 30.55703 50 0 0.173242 5

07:55.9 99.24592 1.041861 0.6 1 31.80226 50 0 0.173763 5

08:00.9 99.24592 1.056543 0.6 1 33.49319 50 0 0.174055 5

08:05.9 99.24592 1.064811 0.6 1 34.04341 50 0 0.174773 5

08:10.9 99.24592 1.064048 0.6 1 36.72429 50 0 0.175475 5

08:15.9 99.24592 1.058757 0.6 1 38.20936 50 0 0.175783 5

08:20.9 99.24592 1.050173 0.6 1 39.84107 50 0 0.175807 5

08:25.9 99.24592 1.049309 0.6 1 41.04131 50 0 0.176774 5

08:30.9 99.24592 0.302486 0.6 1 41.30848 50 0 0.176794 5

08:35.9 99.24592 0.173293 0.6 1 40.49702 50 0 0.177512 5

08:40.9 99.24592 0.164977 0.6 1 39.83445 50 0 0.177804 5

08:45.9 99.24592 0.16607 0.6 1 38.59704 50 0 0.177804 5

08:50.9 99.24592 0.167015 0.6 1 37.11844 50 0 0.177989 5

Experiment Two Overview

In experiment two, we have a cross-flow

heat exchanger.

We have two inputs, hot water and cold

water.

We can control the output temperature of

the water stream by varying the flow of

the input cold and hot water streams.

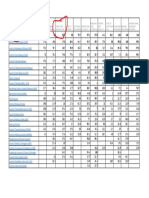

Experiment Two: Excel Data

LAB2/FC2- LAB2/FC2- LAB2/FC2- LAB2/FC2- LAB2/FC2- LAB2/FC2- LAB2/TC2- LAB2/TC2- LAB2/TC2-

Timestamp 1/OUT.CV 1/PV.CV 1/SP.CV 2/OUT.CV 2/PV.CV 2/SP.CV 3/OUT.CV 3/PV.CV 3/SP.CV

4:01:59 AM 95.02735 0.268181 0.35 98.85146 0 0 0 4.616438 34.56931

4:02:04 AM 56.44401 1.055768 0.35 98.85146 0 0 0 4.590205 34.72095

4:02:09 AM 37.72517 0.718991 0.35 98.85148 0 0 0 4.607888 30.15244

4:02:14 AM 39.1097 0.33904 0.35 98.85149 0 0 0 4.66469 30.22445

4:02:19 AM 41.24991 0.324542 0.35 98.85151 0 0 0 4.658128 30.2528

4:02:24 AM 40.66117 0.361338 0.35 98.85152 0 0 0 4.639576 30.96997

4:02:29 AM 39.99916 0.365999 0.35 98.85154 0 0 0 4.652265 31.055

4:02:34 AM 39.81884 0.354454 0.35 98.85155 0 0 0 4.660453 30.62521

4:02:39 AM 40.12429 0.3445 0.35 98.85157 0 0 0 4.645218 30.60582

Experiment Three Overview

In experiment three, we maintain

constant flow to a particular valve by

varying the incoming flow from two

upstream valves.

Experiment Three: Excel Data

LAB3/FC3- LAB3/FC3- LAB3/FC3- LAB3/FC3- LAB3/FC3- LAB3/FC3- LAB3/PC3- LAB3/PC3-

Timestamp 1/OUT.CV 1/PV.CV 1/SP.CV 2/OUT.CV 2/PV.CV 2/SP.CV 1/OUT.CV 1/PV.CV LAB3/PC3-1/SP.CV

58:22.7 100 0 0.2 0.207092 1.043832 0.2 87.68621 19.83952 10.00185

58:27.7 100 0 0.2 19.23947 0.177237 0.2 73.53087 24.35226 10.00431

58:32.6 100 0 0.2 33.09737 0.073007 0.2 64.48715 22.02985 10.00676

58:37.6 100 0 0.2 33.15008 0.203739 0.2 56.187 20.43075 10.00921

58:42.6 100 0.085505 0.2 29.8406 0.217401 0.2 56.26463 11.30149 10.01166

58:47.6 68.69844 0.464158 0.2 41.69254 0.068689 0.2 62.44071 7.498592 9.944753

58:52.6 23.70159 0.672262 0.2 38.91836 0.249685 0.2 59.98335 11.38603 9.857679

58:57.6 21.69339 0.215264 0.2 19.69161 0.405098 0.2 49.63456 18.91353 9.797675

59:02.6 31.87822 0.103757 0.2 24.96922 0.14398 0.2 41.40157 18.75233 9.800552

59:07.6 36.60348 0.141166 0.2 35.57446 0.086747 0.2 45.1008 8.967288 9.800091

59:12.6 41.12893 0.150497 0.2 41.46033 0.137039 0.2 47.99527 7.597999 9.800541

59:17.6 40.97397 0.198615 0.2 39.38166 0.218448 0.2 50.52176 7.089647 9.788873

59:22.6 38.38322 0.23404 0.2 36.31914 0.227625 0.2 49.64458 9.791812 9.772105

59:27.6 34.15519 0.241858 0.2 36.91217 0.195853 0.2 46.60043 12.29662 9.75308

59:32.6 35.62847 0.180229 0.2 36.51828 0.204221 0.2 45.83599 10.48918 9.739523

59:37.6 40.45423 0.149228 0.2 38.58218 0.175203 0.2 47.78149 8.478426 9.734376

59:42.6 40.5996 0.198435 0.2 40.31724 0.184513 0.2 49.72393 7.705642 9.725233

59:47.6 38.89269 0.219021 0.2 38.52082 0.22128 0.2 50.63193 8.396667 9.709104

59:52.6 36.92933 0.223507 0.2 35.45347 0.230783 0.2 48.97683 10.82395 9.6916

59:57.6 35.42597 0.216241 0.2 35.81721 0.195969 0.2 46.1795 12.11237 9.674126

Conclusions

Benefits

Data from first three experiments logged to

Excel file

Graphs can be generated from data for

specific items of interest

Time stamp on each data point

Triggered logging allows for collection only

when necessary

Industry Use of the OPC Logger

OPC DataLogger has been around as a product for 6 years and

is in use in Asia, Australia, Africa, Europe, & North America by

major global users.

Some industrial users are:

AK Steel Pfizer

Atlas Copco Siemens

Baxter Healthcare Sony

Delta Corporation Southwest Gas

Dow Chemical Veolia Water

General Electric Verso Paper

Georgia Pacific

Morningstar Foods

Nasa http://www.opcdatalogger.

com/html/users.html

Group Responsibilities

Michael Anders

Assisted with initial setup of triggers

Helped in preparation of Power Point slides.

Kathleen O’Malley

Assisted with correcting trigger controls

Helped in preparation of Power Point slides

Kharel Thompson

Helped to implement the triggers and spanning

Helped in preparation of Power Point slides

Questions?

Does anyone have any questions

regarding our project?

You might also like

- FHL Jason Fladlien Event PresentationDocument94 pagesFHL Jason Fladlien Event PresentationCoreul Mex83% (6)

- Design Concepts in Software EngineeringDocument61 pagesDesign Concepts in Software EngineeringYogaNandham0% (1)

- Geh 6005Document439 pagesGeh 6005hartman_mdNo ratings yet

- The Design and Construction of An Electric Bicycle PDFDocument70 pagesThe Design and Construction of An Electric Bicycle PDFJessah Mae E. Reyes43% (7)

- Glo Core Digital Twins in Logistics PDFDocument39 pagesGlo Core Digital Twins in Logistics PDFRafael GimenoNo ratings yet

- MFDM AI The RenaissanceDocument2 pagesMFDM AI The RenaissanceSravya Sravs0% (1)

- DeltaV To Excel Tutorial v11Document8 pagesDeltaV To Excel Tutorial v11Mohd Ismail YusofNo ratings yet

- Homework AHP SolutionDocument2 pagesHomework AHP SolutionMr. JarmenNo ratings yet

- Homework AHP SolutionDocument2 pagesHomework AHP SolutionMr. JarmenNo ratings yet

- Mod DEx D3Document4 pagesMod DEx D3Jesús FloresNo ratings yet

- Queue TemplateDocument10 pagesQueue Template______.________No ratings yet

- Table Content: Tittle: Running Speed StudyDocument9 pagesTable Content: Tittle: Running Speed StudygagdgsgsdgsdgNo ratings yet

- Excel Canal Trapezoidal FLUJO CRITICODocument7 pagesExcel Canal Trapezoidal FLUJO CRITICOmarco vasquez lavadoNo ratings yet

- Excel MHCDocument5 pagesExcel MHCYordan FalconNo ratings yet

- Dynamic Modification FactorDocument12 pagesDynamic Modification Factoranthropolozist entertainNo ratings yet

- Formula GeomekDocument6 pagesFormula Geomekfasedan prosesNo ratings yet

- Simulation Exercise 1Document2 pagesSimulation Exercise 1LouieNo ratings yet

- Inflasi ARIMA ModelDocument7 pagesInflasi ARIMA ModelAnto TomodachiRent SusiloNo ratings yet

- Looriegelman and Comp. Application in BiopharmaceuticsDocument22 pagesLooriegelman and Comp. Application in BiopharmaceuticsTushar Bambharoliya100% (1)

- Hydroulic Sitajj ReportDocument7 pagesHydroulic Sitajj ReporthamidNo ratings yet

- Pesos y Medidas de ComponentesDocument10 pagesPesos y Medidas de ComponentesPercy Herrera ZeballosNo ratings yet

- Chart Title: Jumlah Defect 0,00125 X Kecepatan Mesin 2Document9 pagesChart Title: Jumlah Defect 0,00125 X Kecepatan Mesin 2Adrian Fikta NugrahaNo ratings yet

- Excel Kota LamaDocument4 pagesExcel Kota Lamadewi NaNo ratings yet

- Group A - Exp 7 - RTD - CSTRDocument8 pagesGroup A - Exp 7 - RTD - CSTRAkhilesh ChauhanNo ratings yet

- Red de Alcantarillado SanitarioDocument5 pagesRed de Alcantarillado SanitarioRoxana Rodriguez GomezNo ratings yet

- Case: Winter Park Hotel (Current System) : Queuing Model M/M/s (Exponential Service Times)Document35 pagesCase: Winter Park Hotel (Current System) : Queuing Model M/M/s (Exponential Service Times)Gajendra SinghNo ratings yet

- Tracking LogDocument99 pagesTracking LoghellocproNo ratings yet

- Group 3 - Rtu Lab ReportDocument19 pagesGroup 3 - Rtu Lab ReportUI Career ExpoNo ratings yet

- Admn2607 SD2Document21 pagesAdmn2607 SD2Thomas-Jay DerbyshireNo ratings yet

- Uji Sifat Fisik: Wn Ww Ws Wo σn σs σd SG App Sg Tr W (%) A S n% n/100 e (%)Document5 pagesUji Sifat Fisik: Wn Ww Ws Wo σn σs σd SG App Sg Tr W (%) A S n% n/100 e (%)Dodhy SetiawanNo ratings yet

- Triaxal MutikDocument114 pagesTriaxal MutikMuhammad RaflyNo ratings yet

- Calculo Y Diseño Estructural de Cruce Aereo 80.00M: X Y CF YfDocument4 pagesCalculo Y Diseño Estructural de Cruce Aereo 80.00M: X Y CF YfJesus SolorzanoNo ratings yet

- NO V Eksperimen T B V Teori (Vte-Vex) 2 (Vavg-Vexp) 2: Waktu (Detik)Document2 pagesNO V Eksperimen T B V Teori (Vte-Vex) 2 (Vavg-Vexp) 2: Waktu (Detik)Cakra Bayu PamungkasNo ratings yet

- Course: Soil Mechanics II Code: CVNG 2009 Lab: Consolidation Name: Adrian Rampersad I.D:809001425Document16 pagesCourse: Soil Mechanics II Code: CVNG 2009 Lab: Consolidation Name: Adrian Rampersad I.D:809001425Adrian Mufc RampersadNo ratings yet

- Sistem PDB IVP-EulerDocument9 pagesSistem PDB IVP-EulerMuhammad RizaldiNo ratings yet

- Juan Diego Saltarin CaroDocument7 pagesJuan Diego Saltarin CaroBarrera AfricanoNo ratings yet

- Lampiran C Data Perhitungan TeoritisDocument2 pagesLampiran C Data Perhitungan TeoritisKagak AjekNo ratings yet

- Book 1Document2 pagesBook 1Andri SonjayaNo ratings yet

- 5th Girder Normal TrafficDocument33 pages5th Girder Normal TrafficRenxiang LuNo ratings yet

- Example 4 Properties in Column With Blanks Great DataDocument8 pagesExample 4 Properties in Column With Blanks Great DataMyta CytaNo ratings yet

- A) Number of Arrivals Against TimeDocument32 pagesA) Number of Arrivals Against TimeQandeelNo ratings yet

- Cross TuberiaDocument18 pagesCross TuberiaBlinderMNo ratings yet

- Assignment of Traffic Flow Theory DR Ashar LodhiDocument8 pagesAssignment of Traffic Flow Theory DR Ashar LodhiZAIN AHMEDNo ratings yet

- Formula GeomekanikaDocument9 pagesFormula GeomekanikaFsocietyNo ratings yet

- Boston Realty DataDocument51 pagesBoston Realty DataCyprian OchiengNo ratings yet

- DNV RisoDocument6 pagesDNV RisoVon A. DamirezNo ratings yet

- Graficas Ejercicios ExpoDocument32 pagesGraficas Ejercicios ExpoTamara Michelle NaulaNo ratings yet

- Example 5 Properties in Column With Redundant and Bad DataDocument10 pagesExample 5 Properties in Column With Redundant and Bad DataMyta CytaNo ratings yet

- Reliability Graph PlotterDocument6 pagesReliability Graph PlotterStructural SpreadsheetsNo ratings yet

- A.13.1 Valentina Cañon Y Alejandro OsorioDocument260 pagesA.13.1 Valentina Cañon Y Alejandro OsorioAlejandro OsorioNo ratings yet

- Ejercicios en Clase Gráficos de ControlDocument5 pagesEjercicios en Clase Gráficos de ControlDiego TavizónNo ratings yet

- Liani Bishop E 1Document11 pagesLiani Bishop E 1ciaNo ratings yet

- Taller 1Document6 pagesTaller 1Jiss PiconNo ratings yet

- Data Tray DryingDocument7 pagesData Tray DryingV HipsterNo ratings yet

- Kunci Uap FrontierDocument6 pagesKunci Uap FrontierKatelya PutriNo ratings yet

- Base de Datos Completa - ChoneDocument6 pagesBase de Datos Completa - ChoneMiguel GuevaraNo ratings yet

- Tramo Cámara C Tiempo de Duracion SUP INF Te L (M) : Datos: T 5 Años N 0.013 C 0.5Document14 pagesTramo Cámara C Tiempo de Duracion SUP INF Te L (M) : Datos: T 5 Años N 0.013 C 0.5Cristian RomeroNo ratings yet

- No T Ca (T) Ca (t+1) No TDocument15 pagesNo T Ca (T) Ca (t+1) No Tbyun baekNo ratings yet

- HW01 Proy 003Document18 pagesHW01 Proy 003Juan Diego Medina MedinaNo ratings yet

- 28.10.2019-MeWo OA, Up3,4 - ExportDocument9 pages28.10.2019-MeWo OA, Up3,4 - ExportAndrei AlexandruNo ratings yet

- Tabelas EstatísticasDocument5 pagesTabelas EstatísticasGabriel FariavieraNo ratings yet

- Name of Spaces No. of User Sports Complex SIT: Admin Lobby 150 67.5Document52 pagesName of Spaces No. of User Sports Complex SIT: Admin Lobby 150 67.5Gerald LomocsoNo ratings yet

- 2 Microwave System Design CalculationDocument9 pages2 Microwave System Design Calculationmonica mamitagNo ratings yet

- Contoh IVP Sistem PDBDocument6 pagesContoh IVP Sistem PDBMuhammad RizaldiNo ratings yet

- Six Sigma Practice BookDocument6 pagesSix Sigma Practice BookBaburao patilNo ratings yet

- TPAbsorptionnDocument2 pagesTPAbsorptionnMariame KouchaouiNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- OPC Data Logger: Start Up InstructionsDocument12 pagesOPC Data Logger: Start Up InstructionsMohd Ismail YusofNo ratings yet

- What Is SCADA System-SCADA Hardware, Software Architecture and WorkingDocument10 pagesWhat Is SCADA System-SCADA Hardware, Software Architecture and WorkingMohd Ismail YusofNo ratings yet

- Single - Pump - Station / CPU - 312 (CPU 312) / Program Blocks: Main (OB1)Document1 pageSingle - Pump - Station / CPU - 312 (CPU 312) / Program Blocks: Main (OB1)Mohd Ismail YusofNo ratings yet

- Vanessa Albert PLCDCSDocument26 pagesVanessa Albert PLCDCSAnonymous zLwP4FjLNo ratings yet

- GPB01 / CPU - 312 (CPU 312) / Program Blocks: Main (OB1)Document1 pageGPB01 / CPU - 312 (CPU 312) / Program Blocks: Main (OB1)Mohd Ismail YusofNo ratings yet

- I. I T Ii. N Iii. I Iv. C A: Ndex Erms Omenclature Ntroduction Onclusion CknowledgmentDocument1 pageI. I T Ii. N Iii. I Iv. C A: Ndex Erms Omenclature Ntroduction Onclusion CknowledgmentMohd Ismail YusofNo ratings yet

- ME451Lab SyllabusDocument5 pagesME451Lab SyllabusMohd Ismail YusofNo ratings yet

- IJSR PaperFormatDocument2 pagesIJSR PaperFormatAnonymous 0QumXG6NNo ratings yet

- JTEC FormatDocument2 pagesJTEC FormatMohd Ismail YusofNo ratings yet

- The Undergraduate Modular System at The University of Hull - Key FeaturesDocument1 pageThe Undergraduate Modular System at The University of Hull - Key FeaturesMohd Ismail YusofNo ratings yet

- COPC V9 Final PDFDocument2 pagesCOPC V9 Final PDFMohd Ismail YusofNo ratings yet

- COPC V9 Final PDFDocument2 pagesCOPC V9 Final PDFMohd Ismail YusofNo ratings yet

- COPC V9 Final PDFDocument2 pagesCOPC V9 Final PDFMohd Ismail YusofNo ratings yet

- Details QS Asia Data For Malaysian UniversitiesDocument1 pageDetails QS Asia Data For Malaysian UniversitiesMohd Ismail YusofNo ratings yet

- 6762792 (1)Document2 pages6762792 (1)BenjaNo ratings yet

- CPNIDocument2 pagesCPNIFederal Communications Commission (FCC)No ratings yet

- Creating New Portal Display RulesDocument14 pagesCreating New Portal Display RulesAnonymous Yw2XhfXvNo ratings yet

- Laser Based Intruder AlarmDocument25 pagesLaser Based Intruder Alarmdivyaa76No ratings yet

- Capacity Monitoring Guide: Issue 01 Date 2016-03-07Document50 pagesCapacity Monitoring Guide: Issue 01 Date 2016-03-07fayoyiwa babajideNo ratings yet

- 90 Blue Plus ProgrammingDocument2 pages90 Blue Plus ProgrammingDaniel TaradaciucNo ratings yet

- JUMO mTRON T - Your System: The Scalable Measuring, Control and Automation SystemDocument33 pagesJUMO mTRON T - Your System: The Scalable Measuring, Control and Automation SystemJaime HernandezNo ratings yet

- Governor Limit in SalesforceDocument3 pagesGovernor Limit in SalesforceSantpa TechnologiesNo ratings yet

- Audit Work Program (500 Club Asia)Document4 pagesAudit Work Program (500 Club Asia)tineNo ratings yet

- 14JE000423-Rajat Kumar Jain - B.Tech (Computer Science and Engineering)Document2 pages14JE000423-Rajat Kumar Jain - B.Tech (Computer Science and Engineering)AshNo ratings yet

- LT5012 PCB BroInside Final PDFDocument39 pagesLT5012 PCB BroInside Final PDFDavid LopezNo ratings yet

- CS50 PSET5 Images and FormatsDocument87 pagesCS50 PSET5 Images and FormatsX Hai HoangNo ratings yet

- MTA: Database Fundamentals: Lab Exercises & NotesDocument24 pagesMTA: Database Fundamentals: Lab Exercises & NotesMA MaalejNo ratings yet

- Data Warehouse 21regDocument2 pagesData Warehouse 21regPonni S100% (1)

- D StarDocument32 pagesD Starshikha jainNo ratings yet

- AMR WB Speech and HSPA PS Interactive RAB CombinationDocument6 pagesAMR WB Speech and HSPA PS Interactive RAB Combinationpote100% (1)

- Eaton VFDDocument94 pagesEaton VFDsalimskaini1990No ratings yet

- Digitalk: An Analysis of Linguistic Features and Their Functions in Filipino Computer-Mediated CommunicationDocument6 pagesDigitalk: An Analysis of Linguistic Features and Their Functions in Filipino Computer-Mediated CommunicationEvan UmaliNo ratings yet

- Assessment Guideline July 2021Document10 pagesAssessment Guideline July 2021Seminar Group09No ratings yet

- Datasheet IFP9850-3Document2 pagesDatasheet IFP9850-3jaiat22No ratings yet

- Application of The AHP in Project ManagementDocument9 pagesApplication of The AHP in Project Managementapi-3707091100% (2)

- ZW3D CAD Tips How To Design A A Popular QQ DollDocument10 pagesZW3D CAD Tips How To Design A A Popular QQ DollAbu Mush'ab Putra HaltimNo ratings yet

- AX40 DatamodelDocument156 pagesAX40 Datamodelaxapta7No ratings yet

- Tutorial - Making Spur Gear in AutoCAD - GrabCADDocument10 pagesTutorial - Making Spur Gear in AutoCAD - GrabCADAnkushNo ratings yet