Professional Documents

Culture Documents

Measurement: Measurement Is The Comparison of An Unknown Dimension To A Known Standard

Uploaded by

lienna77-10 ratings0% found this document useful (0 votes)

30 views4 pagesMeasurement involves comparing an unknown dimension to a known standard. Precise measuring instruments are crucial for high-volume production as they allow parts to be built interchangeably. Today, measuring tools are essential for machining operations from initial layout to final inspection. Measuring instruments can be classified as precision or non-precision based on their ability to measure within 0.01mm or not. They can also be direct or indirect, with direct determining actual size and indirect transferring measurement for comparison. Common devices include rules for length and calipers for between-ends dimensions.

Original Description:

02

Original Title

MI2

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMeasurement involves comparing an unknown dimension to a known standard. Precise measuring instruments are crucial for high-volume production as they allow parts to be built interchangeably. Today, measuring tools are essential for machining operations from initial layout to final inspection. Measuring instruments can be classified as precision or non-precision based on their ability to measure within 0.01mm or not. They can also be direct or indirect, with direct determining actual size and indirect transferring measurement for comparison. Common devices include rules for length and calipers for between-ends dimensions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views4 pagesMeasurement: Measurement Is The Comparison of An Unknown Dimension To A Known Standard

Uploaded by

lienna77-1Measurement involves comparing an unknown dimension to a known standard. Precise measuring instruments are crucial for high-volume production as they allow parts to be built interchangeably. Today, measuring tools are essential for machining operations from initial layout to final inspection. Measuring instruments can be classified as precision or non-precision based on their ability to measure within 0.01mm or not. They can also be direct or indirect, with direct determining actual size and indirect transferring measurement for comparison. Common devices include rules for length and calipers for between-ends dimensions.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 4

Measurement

Measurement is the comparison of an

unknown dimension to a known standard.

Good measuring instruments are a key to

high volume production. Without them, parts

could not be built accurately enough to be

interchangeable. Each assembly had to be

hand fitted together.

Today, measuring tools are essential for most

machining operations from initial part layout

to final inspection.

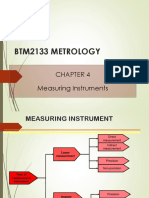

Classification of Measuring

Instruments

Precision instrument

Ability to measure within the accuracy of 0.01 mm

or more

Non-precision Instrument

Limited to the measurement of parts to a visible

line graduation on the instrument (ex Scale)

Classification of Measuring

Instruments

Direct measuring Instruments

Determine the actual dimension and size of a

work piece

Indirect measuring Instruments (comparison

instruments)

Transfer the measurement from the work piece to

the direct measuring instrument, then comparison

is made.

Classification of Measuring

Instruments

Line measuring devices

measurement along the length (steel rule)

End measuring devices

Measurement between the two ends (vernier

caliper)

You might also like

- Measuring Instruments LectureDocument35 pagesMeasuring Instruments LectureMAHESH SINGH100% (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Procesos de VariablesDocument2 pagesProcesos de VariablesDarel HernándezNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- MeasurementDocument20 pagesMeasurementrishabh mishraNo ratings yet

- Sensors and TransducersDocument27 pagesSensors and TransducersKRISHNAVINODNo ratings yet

- Measurement and InspectionDocument33 pagesMeasurement and InspectionSri RNo ratings yet

- ME8501 Metrology and Measurements Notes 2 by WWW - Studymaterialz.inDocument49 pagesME8501 Metrology and Measurements Notes 2 by WWW - Studymaterialz.insrknotesNo ratings yet

- Unit 1: Generalized Measurement SystemDocument51 pagesUnit 1: Generalized Measurement Systemanadinath sharmaNo ratings yet

- Metrology & Quality Assurance (Lab) : Submitted By: Hafiz Muhammad Abdullah Submitted ToDocument4 pagesMetrology & Quality Assurance (Lab) : Submitted By: Hafiz Muhammad Abdullah Submitted ToMuhammad AbdullahNo ratings yet

- Brake CaliperDocument6 pagesBrake CaliperMuhammad AfnanNo ratings yet

- OJTDocument19 pagesOJTKiran PadalaNo ratings yet

- Lecture 2 2022Document56 pagesLecture 2 2022abdallaNo ratings yet

- 01 Introduction To MetrologyDocument27 pages01 Introduction To MetrologyMazhar HussainNo ratings yet

- Metrology Notes 5Document30 pagesMetrology Notes 5Midhun SukumaranNo ratings yet

- Familiarization With Basic Measuring Instruments: Module Name: ME2024 Semester: 3Document12 pagesFamiliarization With Basic Measuring Instruments: Module Name: ME2024 Semester: 3Awishka EashanNo ratings yet

- Vernier Calipers & Micrometer Screw GaugeDocument26 pagesVernier Calipers & Micrometer Screw GaugeNurlailie Md Jamil100% (1)

- ME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsDocument19 pagesME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsAniket SankpalNo ratings yet

- Me TrologyDocument33 pagesMe TrologySnekaNo ratings yet

- EMM Unit I - 1.7.19Document91 pagesEMM Unit I - 1.7.19Udhaya KumarNo ratings yet

- Chapter 1 - Introduction and Basic ConceptsDocument8 pagesChapter 1 - Introduction and Basic ConceptsYeevön LeeNo ratings yet

- Lecture 1 MeasurementDocument30 pagesLecture 1 Measurementakash258456No ratings yet

- Experimental Stress Analysis Two Marks With AnswersDocument24 pagesExperimental Stress Analysis Two Marks With Answersmatrixrajiv34100% (2)

- Lec 6 - MeasurementsDocument38 pagesLec 6 - Measurementsعمر عادل عبدالتواب ابوزيدNo ratings yet

- BTM2133-Chapter 4 Measuring InstrumentsDocument61 pagesBTM2133-Chapter 4 Measuring InstrumentsAswaja3130% (1)

- WWW - Learnengineering.In: Me8501 Metrology and Measurements Unit I Basics of MetrologyDocument49 pagesWWW - Learnengineering.In: Me8501 Metrology and Measurements Unit I Basics of MetrologybhuvansparksNo ratings yet

- MeasurmentDocument29 pagesMeasurmentسيمو بشيريNo ratings yet

- Short and Long QuestionsDocument14 pagesShort and Long Questionsdream breakerNo ratings yet

- ME 6504 Metrology & Measurement All Unit NotesDocument91 pagesME 6504 Metrology & Measurement All Unit NotesKannan KamalNo ratings yet

- Unit 1 - BS - MamDocument34 pagesUnit 1 - BS - MamRohit GuptaNo ratings yet

- Unit-Ii 3Document30 pagesUnit-Ii 3k.ghanemNo ratings yet

- ME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsDocument19 pagesME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsAtul GaurNo ratings yet

- Chap2 (A) MetrologyDocument17 pagesChap2 (A) MetrologyjojoNo ratings yet

- Metrology Uniit IDocument44 pagesMetrology Uniit Irramesh2k8712No ratings yet

- 1537326530linear & Angular MeasurementDocument49 pages1537326530linear & Angular MeasurementAl MamunNo ratings yet

- Probing Cycles: Workpiece Measurement With TS Touch ProbeDocument4 pagesProbing Cycles: Workpiece Measurement With TS Touch Probeemo_waggyNo ratings yet

- Heidenhain Touch ProbeDocument72 pagesHeidenhain Touch ProbeHoho Hahov100% (1)

- Unit 1 Concept of MeasurementDocument69 pagesUnit 1 Concept of MeasurementMallikarjunaMakanaNo ratings yet

- Lab Report 1Document5 pagesLab Report 1mamoona noreenNo ratings yet

- Measurement & InstrumentationsDocument90 pagesMeasurement & Instrumentationsioeolympic123456789No ratings yet

- Unit - 1 - MMDocument64 pagesUnit - 1 - MMR.Arivazhagan Assistant Professor - MHTNo ratings yet

- Semester III Instruments & Measurements Course Code: EEC313: Prepared By:Pradeep KR VermaDocument11 pagesSemester III Instruments & Measurements Course Code: EEC313: Prepared By:Pradeep KR Verma002Pradeep002No ratings yet

- Metrology and MeasurementsDocument140 pagesMetrology and MeasurementsVivekanand SriramNo ratings yet

- MeasurementDocument21 pagesMeasurementyogesh.20222066No ratings yet

- Precision Measuring InstrumentsDocument2 pagesPrecision Measuring InstrumentsmartindinglasanNo ratings yet

- Met - 1Document132 pagesMet - 1Ashwani KaninaNo ratings yet

- Unit I - Basics of Metrology: Paavai Institutions Department of MechanicalDocument7 pagesUnit I - Basics of Metrology: Paavai Institutions Department of MechanicalpceautohodNo ratings yet

- BenchworkDocument31 pagesBenchworkJohn Felix PalenciaNo ratings yet

- Metrology Lecture 01Document31 pagesMetrology Lecture 01Getachew G/AmlakNo ratings yet

- Metrology Manual (2012)Document46 pagesMetrology Manual (2012)Saibabu RollaNo ratings yet

- Lecture 3Document8 pagesLecture 3Sherif SaidNo ratings yet

- Me2304 NolDocument51 pagesMe2304 NolRaj KiranNo ratings yet

- Process Instrumentation Module 1Document44 pagesProcess Instrumentation Module 1ibuddhaNo ratings yet

- Measuremen T: MeasurementDocument20 pagesMeasuremen T: MeasurementEasy TechNo ratings yet

- Unit 1 Concept of Measurement: M.Tech., Mba., (PHD)Document79 pagesUnit 1 Concept of Measurement: M.Tech., Mba., (PHD)Arun SanthoshNo ratings yet

- SameerDocument5 pagesSameerKhushi SalgaonkarNo ratings yet

- MMM Lecture - Unit 1 - Intro To MeasurementsDocument37 pagesMMM Lecture - Unit 1 - Intro To MeasurementsAlanka BhanuNo ratings yet

- Nonconforming Product: C06L4 - Non Conformity Assessment PengajarDocument2 pagesNonconforming Product: C06L4 - Non Conformity Assessment Pengajarlienna77-1No ratings yet

- How To Use A Cylinder Bore Gauge To MeasureDocument5 pagesHow To Use A Cylinder Bore Gauge To Measurelienna77-1No ratings yet

- Dial Bore Gauge: Automotive Engines: Theory and Servicing, 6/eDocument1 pageDial Bore Gauge: Automotive Engines: Theory and Servicing, 6/elienna77-1No ratings yet

- How To Use A Cylinder Bore Gauge To Measure Cylinder BlockDocument2 pagesHow To Use A Cylinder Bore Gauge To Measure Cylinder Blocklienna77-1No ratings yet

- Procedure For Cal. MicrometerDocument4 pagesProcedure For Cal. Micrometerlienna77-1No ratings yet

- Measuring InstrumentsDocument2 pagesMeasuring Instrumentslienna77-1No ratings yet

- Procedure For Cal. MicrometerDocument4 pagesProcedure For Cal. Micrometerlienna77-1No ratings yet

- Procedure For Cal. MicrometerDocument4 pagesProcedure For Cal. Micrometerlienna77-1No ratings yet

- Testing Flat-Surface Optical ComponentsDocument40 pagesTesting Flat-Surface Optical Componentswavelet5No ratings yet

- Testing Flat-Surface Optical ComponentsDocument40 pagesTesting Flat-Surface Optical Componentswavelet5No ratings yet

- JCGM 200 2012Document108 pagesJCGM 200 2012MathiasNo ratings yet

- Nota MetroDocument1 pageNota Metrolienna77-1No ratings yet

- ChecklistDocument65 pagesChecklistlienna77-1No ratings yet

- ChecklistDocument65 pagesChecklistlienna77-1No ratings yet