Professional Documents

Culture Documents

Design and Manufacturing of Belt Grinding Machine

Uploaded by

Sumedh sonawane100%(2)100% found this document useful (2 votes)

722 views15 pagesbelt grinding machine

Original Title

ppt

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbelt grinding machine

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

722 views15 pagesDesign and Manufacturing of Belt Grinding Machine

Uploaded by

Sumedh sonawanebelt grinding machine

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 15

DESIGN AND MANUFACTURING OF

BELT GRINDING MACHINE

Presented By

Mr. PATIL SAINATH ANADA

Mr. SHEWALE HRUSHIKESH RAVINDRA

Mr. SONAWANE SUMEDH SURESH

Mr. UMBRE KRISHNA MHASU

Guide By

Prof. A. R. RASNE

Department of Mechanical Engineering

PVG’s College Of Engineering, Nashik.

Nashik-03

2020-2021

Pune Vidyarthi Griha's College Of engineering, Nashik

CONTENTS

1. Introduction

2. Literature review

3. Problem Statement

4. Objective

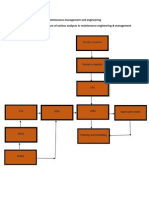

5. Proposed Methodology

6. Application

7. Components

8. Project Costing

9. Tentative Project Setup

10. Project plan

Pune Vidyarthi Griha's College Of engineering, Nashik

INTRODUCTION

Belt ginding machine we design used for ginding any

shape and object.

It used to grind machine surface to super finish and

accuracy, it ginding any shape of object like square

pipe, flat plate, rectangle shape, fillet operation etc.

In our project we arranged all component in one

frame (profile).

This machine used Horizontal as well as Vertical and

aslo 45︒ inclination Positions.

For changing position form horizontal to vertical we

desinged gears with chaine drive with arduino

system.

Pune Vidyarthi Griha's College Of engineering, Nashik

LITERATURE REVIEW

In this section the various modification and development in the

grinding machine technology are mentioned

[1]Konrad Wegener, Friedrich Bleicher, Peter Krajnik, Hans-Werner

Hoffmeister, Christian Breecher, Recent development in grinding machines,

CIRP-1703 (2017). In this paper the main objective is development of grinding

machines to improve the productivity. In this paper the detailed study of grinders is

explained. The various key points like peculiarities of grinding machines,

classification, trends in development of abrasive processes, grain technology, cost,

market developments, maintenance, digitization, trends for grinding machine,

grinding machine material structures, machine concept and simulation, adaptive

and Mechatronics system for grinding, energy efficiency, trends in auxiliary

devices, special machine developments such as ultra precision machines and its

principle applications, hybrid machines, combined machines which are capable of

executing different locations. The authors has concluded day to day in recent years

for getting more productivity in manufacturing

• [2] Dong Zhang, Chao Yun, Dezheng Song, Dexterous space optimization

for robotic belt grinder, Procedia Engineering 15 (2011) 2762-2766. In this

paper discussed a new structure of robotic grinding system in which a new robot

frame including active work piece frame and passive tool frame was presented. In

the industrial robot are recently introduced to the belt grinding of complex shape

surfaces to obtain high productive efficiency and constant surface quality. The

early development of robotic grinding focused on the robot holding a grinding

wheel to finish a part with simply geometries and with relatively low accuracy

requirements. The dexterity optimization ends are first, the establishment of an

appropriate coordinate system for the general theoretical analysis; second, the

robot placed in reasonable relative position to grinding machine ensuring that the

robot has enough dexterous space of grinding

• [3] J.F.G. Oliveria, E.J. Silva, C. Guo, F. Hashimoto, Industrial Challenges

in grinding, Manufacturing Technology 58 (2009) 663-680. This paper aims at

the analization of grinding technology development research as per industrial

demand. The author have totally focused on the grinding challenges in industries.

The very important driving force development of grinding are automotive

application. There were many problem presented by industries needs at the time

include today well developed technology such as fast and automotive wheel

balancing system, flexible and prediction systems, more application of CNC in

grinding process, multiple grinding on one step and other

Problem Statement:

“Design and manufacturing of belt ginding machine”

Objective:

The Objective of this project is to design and fabricate

an abrasive belt grinding which can be used as Special

purpose grinding machine by changing its work area

from Horizontal to Vertical with CHAIN DRIVE

Attached motor with arduino and length of the belt

could be adjustable for making belt at proper tension

Pune Vidyarthi Griha's College Of engineering, Nashik

PROPOSED METHODOLOGY:

• In this project we are going to design and fabricate a

abrasive belt grinding which can be used as special

purposse grinding machine, there are two positions

Horizontal and Vertical,

• horizontal position used to grinding or finishing long

pipes or plats etc. and vertical position fillets oprations

or other oprations are easier.

• Also there is 90 to 45 degree inclination for better

work.

Pune Vidyarthi Griha's College Of engineering, Nashik

APPLICATIONS

Belt grinding is a versatile process suitable for all

kinds of different applications

Finishing: surface roughness, removal of micro burrs,

cosmetic finishes, polishing

Deburring: radiusing, burr removal, edge breaking

Stock removal: high stock removal, cleaning (e.g. of

corrosion), eliminating mill or tool marks, dimensioning

By changing the grades of abrasive belt grinding it can be

used to grind the carbon steel, alloy steel and stainless

steel etc

COMPONENTS OF PROJECT

1. 3 phase 230V~50hz 2.2kw motor. – for rotating

grinding belt

2. Abrasive belt- for grinding.

Fig1. 3φ Motor Fig2. Abrasive Belt

Pune Vidyarthi Griha's College Of engineering, Nashik

3. Motor for rotate chaine drive

4. Arduino : to give cammand to motor to rotate chain

drive

Fig3. motor for chain

Fig4. Arduino

drive

Pune Vidyarthi Griha's College Of engineering, Nashik

5. Gears

6. Hydraulic

7. Rotaing wheels

8. Chain drive

Pune Vidyarthi Griha's College Of engineering, Nashik

Project Costing

Main parts of project

1. 3 phase 230V~50hz 2.2kw motor – Rs 4000 to 5000

2. Abrsive belt – 800 to 1000

3. Small motor – 1500 to 1800

4. Arduino – 600 to 800

5. Hydraulic – 400

6. Flat plate – 1000

7. Square pipe – 400

8. Wheel – 1500

9. Gears – 500

10. Nut and bolts – 200 to 300

OVERALL COST OF PROJECT – AROUND 15000 RS.

TENTATIVE PROJECT SETUP

Pune Vidyarthi Griha's College Of engineering, Nashik

PROJECT PLAN

PROGRESS OF

SL.NO WORK OCT NOV DEC JAN FEB MAR

1. Received the approval for

project title

2. Design and selecting

materials

3. Purchasing

4. Construct the body of the

project.

Collecting the Additional

information to complete

5. the project and painting

work

6. Report and extra work was

completed. Attending the

final evaluation

THANK

YOU

You might also like

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Mini Project Se A Mech 14-2Document22 pagesMini Project Se A Mech 14-2Rahul Shirodkar100% (1)

- PVC Pipe BendingDocument5 pagesPVC Pipe Bendingbandara123No ratings yet

- Design and Development of Manually Operated Seed Planter MachineDocument7 pagesDesign and Development of Manually Operated Seed Planter Machine113314100% (1)

- Design of Pelletizing MachineDocument4 pagesDesign of Pelletizing Machinepoulad pousheshNo ratings yet

- Thesis, Design and Fabrication of Stair Climbing Mechanism To Lift Load Over Stairs.Document63 pagesThesis, Design and Fabrication of Stair Climbing Mechanism To Lift Load Over Stairs.Muhammad ArhamNo ratings yet

- Proposal On Design and Fabrication of Teff Seiving MachineDocument6 pagesProposal On Design and Fabrication of Teff Seiving Machinelabemanza03No ratings yet

- Concrete Pipe Making MachineDocument134 pagesConcrete Pipe Making MachineYeabsraNo ratings yet

- Welding Slag CLEANING MachineDocument5 pagesWelding Slag CLEANING MachineSuganthan IasNo ratings yet

- Report of Automatic Papad Makeing MachineDocument42 pagesReport of Automatic Papad Makeing MachineAaengineering India100% (1)

- Unit - Iv: Milling MachineDocument74 pagesUnit - Iv: Milling MachineDevarakonda KondayyaNo ratings yet

- 05.15 Quotation of Automatic Sachet Filling and Sealing MachineDocument6 pages05.15 Quotation of Automatic Sachet Filling and Sealing MachineJean Pool C SNo ratings yet

- Kyambogo University: Group: Next LevelDocument27 pagesKyambogo University: Group: Next LevelAthiyo MartinNo ratings yet

- Introduction To Manufacturing ProcessDocument12 pagesIntroduction To Manufacturing ProcessSrini Kalmula100% (2)

- Project On Protable Grass Cutter MachineDocument11 pagesProject On Protable Grass Cutter MachineNayon HalderNo ratings yet

- Mounting Methods of Punches and DiesDocument1 pageMounting Methods of Punches and DiesPeter Nomikos100% (1)

- Industrial Visit To Nashik Thermal Power Station (NTPS)Document12 pagesIndustrial Visit To Nashik Thermal Power Station (NTPS)ULHAS KADAM100% (2)

- Centrifugal Pump - Project Reportcopy-1Document40 pagesCentrifugal Pump - Project Reportcopy-1DR SHNGM0% (1)

- Wire Drawing: Profile No.: 115 NIC Code: 24108Document10 pagesWire Drawing: Profile No.: 115 NIC Code: 24108Sabhaya ChiragNo ratings yet

- Design and Development of Cold Press Expeller Machine PDFDocument10 pagesDesign and Development of Cold Press Expeller Machine PDFTANKO BAKO0% (1)

- Hydraulic Press MachineDocument1 pageHydraulic Press MachineDebashishParidaNo ratings yet

- Design and Fabrication of Automatic Pneumatic Ramming MachineDocument3 pagesDesign and Fabrication of Automatic Pneumatic Ramming MachineLAKKANABOINA LAKSHMANARAONo ratings yet

- Jwell PipeDocument31 pagesJwell PipeRajiv Sanghavi100% (1)

- Operation Manual: Ssep148 Twin Screw ExtruderDocument22 pagesOperation Manual: Ssep148 Twin Screw ExtruderradhoinezerellyNo ratings yet

- Design and Fabrication of Seed Sowing and Spraying Machine For AgricultureDocument8 pagesDesign and Fabrication of Seed Sowing and Spraying Machine For AgricultureIJRASETPublicationsNo ratings yet

- Thesis FinalDocument119 pagesThesis Finalyamlakbelete321100% (1)

- Lecture Notes ON Plant Layout and Material Handling: B.Tech Viiii Sem JNTUH R15 - 2018-2019Document78 pagesLecture Notes ON Plant Layout and Material Handling: B.Tech Viiii Sem JNTUH R15 - 2018-2019Austin Edwin100% (1)

- 11.fabrication of Hydralic Brake Shoe Riveting MachineDocument3 pages11.fabrication of Hydralic Brake Shoe Riveting MachineDinesh Kumar67% (3)

- Addisalem MekonnenDocument84 pagesAddisalem MekonnenTamru gebregeorgisNo ratings yet

- Project Report Tissue PaperDocument5 pagesProject Report Tissue PaperShadow PrinceNo ratings yet

- Fabrication of Pneumatic Plastic Injection Moulding Machine (Projects)Document41 pagesFabrication of Pneumatic Plastic Injection Moulding Machine (Projects)Aravind Aruchamy100% (4)

- Machining ProcessesDocument82 pagesMachining Processesv2brother50% (2)

- Design and Fabrication of Pneumatic Bar Bending MachineDocument4 pagesDesign and Fabrication of Pneumatic Bar Bending MachineAnonymous kw8Yrp0R5rNo ratings yet

- The Plastic Manufacturing ProcessDocument2 pagesThe Plastic Manufacturing Processskiran_56No ratings yet

- Specification of MIG Welding MachineDocument3 pagesSpecification of MIG Welding Machinenyaungzin100% (3)

- Sand Sieving Final AbstractDocument46 pagesSand Sieving Final Abstract18E3457 MukundiniNo ratings yet

- Hydraulic Sheet Bending MachineDocument14 pagesHydraulic Sheet Bending MachineManoj43% (7)

- Report - Hydraulic Pipe Bending MachineDocument2 pagesReport - Hydraulic Pipe Bending MachinedhirajNo ratings yet

- Report Project CompleteDocument41 pagesReport Project CompletesitijarahmadzinNo ratings yet

- Blow Molding Project ReportDocument6 pagesBlow Molding Project Reportperu1975100% (2)

- Assignment 1 - Machine DesignDocument1 pageAssignment 1 - Machine DesignmrinalsinghrawatNo ratings yet

- T-MEET 316 Group 3 Egg Breaker Yolk Separator MachineDocument14 pagesT-MEET 316 Group 3 Egg Breaker Yolk Separator MachineVoonz Pinca100% (1)

- Final Year Research Project & Innovation: Semi Auto Pesticide Sprayer For GreenhouseDocument67 pagesFinal Year Research Project & Innovation: Semi Auto Pesticide Sprayer For GreenhouseSyahirah Shafek100% (2)

- Recent Trends in Non-Traditional Machining Processes: Unit - 5Document12 pagesRecent Trends in Non-Traditional Machining Processes: Unit - 5DISHA VNo ratings yet

- Machine For Concretepropo-2Document18 pagesMachine For Concretepropo-2birhanu morkaNo ratings yet

- Tool Room Project ReportDocument49 pagesTool Room Project Reportlokeshkrkushwaha67% (3)

- Rotavator Multipurpose Tillage ImplementDocument12 pagesRotavator Multipurpose Tillage ImplementkhetiGaadiNo ratings yet

- BX-B2 Semi-Automatic Bottle Blowing Machine: 1. Brief IntroductionDocument4 pagesBX-B2 Semi-Automatic Bottle Blowing Machine: 1. Brief IntroductionAriantoNo ratings yet

- Production Planning & ControlDocument24 pagesProduction Planning & ControlHari Prasad Reddy Yedula100% (1)

- Water Bottling PlantDocument12 pagesWater Bottling PlantStephen Ngigi KaranjaNo ratings yet

- Design and Developement of Chaff CutterDocument21 pagesDesign and Developement of Chaff Cutterjoselinjebaraj694100% (2)

- Design and Fabrication of Rolling Machine With SplinesDocument41 pagesDesign and Fabrication of Rolling Machine With SplinestadiwosNo ratings yet

- Manually Operated Hydraulic Pipe Bending MachineDocument16 pagesManually Operated Hydraulic Pipe Bending MachineRohitNo ratings yet

- MFT - II Lab ManualDocument33 pagesMFT - II Lab ManualMohan Prasad.M0% (1)

- Automatic Plastering Machine: Arivazhagan.BDocument7 pagesAutomatic Plastering Machine: Arivazhagan.BEr Shaan SekharNo ratings yet

- Belt Grinding MachineDocument16 pagesBelt Grinding MachineSumedh SonawaneNo ratings yet

- Share 'SYNOPSIS (2) .Docx'Document14 pagesShare 'SYNOPSIS (2) .Docx'Lokesh HarodeNo ratings yet

- Share 'Synopsis (2) .Docx'Document14 pagesShare 'Synopsis (2) .Docx'Lokesh HarodeNo ratings yet

- FYP-Proposal-form - 2019 OrgiDocument7 pagesFYP-Proposal-form - 2019 OrgiFazal khanNo ratings yet

- Recycle Bin Tin CrusherDocument39 pagesRecycle Bin Tin CrusherggombekNo ratings yet

- Application of Chain Drive and Its Selection Method in AutomobileDocument18 pagesApplication of Chain Drive and Its Selection Method in AutomobileSumedh sonawaneNo ratings yet

- Forging and Press 1Document18 pagesForging and Press 1Sumedh sonawane100% (1)

- Forging and Press 1Document18 pagesForging and Press 1Sumedh sonawane100% (1)

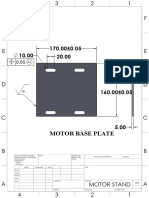

- Motor Base PlateDocument1 pageMotor Base PlateSumedh sonawaneNo ratings yet

- Lecture 11 - Performance AppraisalsDocument23 pagesLecture 11 - Performance AppraisalsCard CardNo ratings yet

- Retirement 01Document2 pagesRetirement 01Nonema Casera JuarezNo ratings yet

- Huawei Switch - Service - ConfigDocument5 pagesHuawei Switch - Service - ConfigTranHuuPhuocNo ratings yet

- AZ 103T00A ENU TrainerHandbook PDFDocument403 pagesAZ 103T00A ENU TrainerHandbook PDFlongvietmt100% (2)

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocument11 pages2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusNo ratings yet

- AT ChapIDocument48 pagesAT ChapIvigneshwaranbeNo ratings yet

- PhotometryDocument2 pagesPhotometryHugo WNo ratings yet

- SR# Call Type A-Party B-Party Date & Time Duration Cell ID ImeiDocument12 pagesSR# Call Type A-Party B-Party Date & Time Duration Cell ID ImeiSaifullah BalochNo ratings yet

- The Role of Needs Analysis in Adult ESL Programme Design: Geoffrey BrindleyDocument16 pagesThe Role of Needs Analysis in Adult ESL Programme Design: Geoffrey Brindleydeise krieser100% (2)

- Pedagogical Leadership. Baird - CoughlinDocument5 pagesPedagogical Leadership. Baird - CoughlinChyta AnindhytaNo ratings yet

- DD 3334Document2 pagesDD 3334FAQMD2No ratings yet

- Practical Research 2.9Document22 pagesPractical Research 2.9Michael GabertanNo ratings yet

- Excel Crash Course PDFDocument2 pagesExcel Crash Course PDFmanoj_yadav735No ratings yet

- 05-11 Trainer Interview QuestionsDocument8 pages05-11 Trainer Interview QuestionsqulaityNo ratings yet

- Design of CouplingDocument75 pagesDesign of CouplingVatsal BhalaniNo ratings yet

- Test Report: Tested By-Checked byDocument12 pagesTest Report: Tested By-Checked byjamilNo ratings yet

- Time Table & Instruction For Candidate - Faculty of Sci & TechDocument3 pagesTime Table & Instruction For Candidate - Faculty of Sci & TechDeepshikha Mehta joshiNo ratings yet

- VPZ M BrochureDocument2 pagesVPZ M BrochuresundyaNo ratings yet

- 3-Waves of RoboticsDocument2 pages3-Waves of RoboticsEbrahim Abd El HadyNo ratings yet

- ER288 090714 5082 CV OKP (089) Method Statement For Plate Baring TestDocument3 pagesER288 090714 5082 CV OKP (089) Method Statement For Plate Baring TestWr ArNo ratings yet

- On The Importance of Learning Statistics For Psychology StudentsDocument2 pagesOn The Importance of Learning Statistics For Psychology StudentsMadison HartfieldNo ratings yet

- TOA Project Presentation (GROUP 5)Document22 pagesTOA Project Presentation (GROUP 5)Khadija ShahidNo ratings yet

- Hooke's LawDocument1 pageHooke's LawAnan BarghouthyNo ratings yet

- Watershed Conservation of Benguet VisDocument2 pagesWatershed Conservation of Benguet VisInnah Agito-RamosNo ratings yet

- 4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsDocument4 pages4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsRUSSELNo ratings yet

- AB-005-2020 Dated 10.09.2020 (SKF-Prestine)Document3 pagesAB-005-2020 Dated 10.09.2020 (SKF-Prestine)AliasgarNo ratings yet

- Describe an English lesson you enjoyed.: 多叔逻辑口语,中国雅思口语第一品牌 公共微信: ddielts 新浪微博@雅思钱多多Document7 pagesDescribe an English lesson you enjoyed.: 多叔逻辑口语,中国雅思口语第一品牌 公共微信: ddielts 新浪微博@雅思钱多多Siyeon YeungNo ratings yet

- Agenda - Meeting SLC (LT) - 27.06.2014 PDFDocument27 pagesAgenda - Meeting SLC (LT) - 27.06.2014 PDFharshal1223No ratings yet

- Power-Miser 12 Water Heater ManualDocument32 pagesPower-Miser 12 Water Heater ManualClaudeVanDammNo ratings yet

- Overview of MEMDocument5 pagesOverview of MEMTudor Costin100% (1)