Professional Documents

Culture Documents

Measurements - 06 - Pressure and Velocity Measurements

Measurements - 06 - Pressure and Velocity Measurements

Uploaded by

ahmed gamal0 ratings0% found this document useful (0 votes)

12 views32 pagesMeasurements

Original Title

Measurements_06_Pressure and Velocity Measurements

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMeasurements

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views32 pagesMeasurements - 06 - Pressure and Velocity Measurements

Measurements - 06 - Pressure and Velocity Measurements

Uploaded by

ahmed gamalMeasurements

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 32

Basics of Engineering

Measurements

(AGE 2340)

Dr. Nasser Mohamed Shelil

Assistant Professor, Mechanical Engineering Dept.,

College of Applied Engineering, King Saud University

B.Sc. & M.Sc. , Suez Canal University; PhD, Cardiff University/UK

Course Contents

Chapter 1: Basic Concepts of Measurement Methods

Chapter 2: Uncertainty Analysis

Chapter 3: Electrical Devices and Measurements

Chapter 4: Measurements of Length, Time and Mass

Chapter 5: Temperature Measurements

Chapter 6: Pressure and Velocity Measurements

Chapter 7: Flow Measurements

Chapter 8: Strain and Force Measurements

Chapter 9: Power and Energy Measurements

Applied Mechanical Engineering Program

Basics of Engineering Measurements Contents

Chapter 6:

Pressure and Velocity Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Chapter 6:

Pressure and Velocity Measurements

6.1 Pressure Concepts

6.2 Pressure Reference Instruments

6.3 Pressure Transducers

6.4 Fluid Velocity Measuring Systems

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements Pressure and Velocity

Pressure

P = F/A ≡ N/m2 (Pa)

Pabs = Patm + Pgage

Pvac = Patm – Pabs

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Pressure Units

1 bar = 105 Pa = 0.1 MPa = 100 kPa

1 atm = 101,325 Pa = 101.325 kPa = 1.01325 bars

1 kgf/cm2 = 9.807 N/cm2 = 9.807x104 N/m2 = 9.807x104 Pa

1 atm = 14.696 psi = 760 Torr

1 Torr = 1 mmHg

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Hydrostatic-equivalent pressure head and pressure

P = gh

= h ≡ N/m2 (Pa)

Pabs = Patm + gh

: density [ kg/m3 ]

: specific gravity [ N/m3 ]

g : gravitational acceleration = 9.81 m/s2.

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Example:

Determine the absolute and gauge pressures and the equivalent pressure

head at a depth of 10 m below the free surface of a pool of water at 20 oC.

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Pressure Reference Instruments

Barometer

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Pressure Reference Instruments

Manometer

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

U-tube manometer

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Inclined tube manometer

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Bellows

Potentiometer pressure transducer

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Pressure Sensors

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

1. DEFLECTION TYPE PRESSURE SENSOR

This sensor uses an elastic material to convert pressure to

displacement

The displacement will be proportionate to the value of pressure

exerted.

Suitable to be used in an automatic control system.

The main element used is in the shape of Bourdon tube, bellow

or diaphragm.

The secondary element is the element that will convert the

displacement to electrical signals where the displacement can be

detected through resistivity change, inductance or capacitance.

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Pressure Transducers

Applied Mechanical Engineering Program Chapter 6

Basics ofElastic elements

Engineering used as

Measurements pressure sensors P & v Measurements

Bourdon Tube

Bourdon tube pressure gauge

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Example :

i. Bellow-resistance pressure sensor

• The pressure is proportionate to the resistivity.

• The resistance change is detected by displacement of sliding

contact in the resistance element.

Bellows Calibrated spring Sliding contact

Resistance Output Signal

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Example :

ii. Bellow-inductance pressure sensor

• The pressure is proportionate to the inductance change which is

detected from the displacement of the core in the wire coil.

• The core movement will produce AC signal output which will give

the value and direction of inductance.

• LVDT (linear variable differential transformer) demodulator is

used to convert the AC output to DC.

Bellows Core Output Signal

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

iii. Diaphragm-capacitance pressure sensor

• The pressure is proportionate to the capacitance change at the

output through dielectric change.

• Pressure from the sensor element causes the diaphragm to

move towards the plate and produces dielectric change.

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Capacitance Type Resistance Type

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

2. STRAIN GAUGE PRESSURE SENSOR

• Strain gauge is a type of resistive transduction.

• Pressure measurement is obtained from displacement of

elastic element.

• Pressure is measured through force that is exerted on the

diaphragm where the force will be detected by the strain

gauge and resistance change will be produced.

• Wheatstone Bridge circuit is used to detect the change in

pressure and an amplifier is used to amplify the small output

signals.

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

FLUID VELOCITY

MEASURING SYSTEMS

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Pitot - Pitot static and impact probes

The basic principle of the Pitot and Pitot static tube is that the pressure

of a flowing fluid will increase when it is brought to rest at a stagnation

point of the probe.

The pressure at the stagnation point is the stagnation pressure.

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

Applied Mechanical Engineering Program Chapter 6

Basics of Engineering Measurements P & v Measurements

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Basic Engineering Measurement AGE 2310Document21 pagesBasic Engineering Measurement AGE 2310ahmed gamalNo ratings yet

- Lectures ProblemsDocument53 pagesLectures Problemsahmed gamalNo ratings yet

- Tutorial 2 Problem 1Document4 pagesTutorial 2 Problem 1ahmed gamalNo ratings yet

- Basic Measurement Engineering Tutorial 1: Exercise 1Document5 pagesBasic Measurement Engineering Tutorial 1: Exercise 1ahmed gamalNo ratings yet

- Basic Measurement Engineering Tutorial 1: Exercise 1Document3 pagesBasic Measurement Engineering Tutorial 1: Exercise 1ahmed gamalNo ratings yet

- Basic Engineering Measurement AGE 2310Document20 pagesBasic Engineering Measurement AGE 2310ahmed gamalNo ratings yet

- Basics of Engineering Measurements: Course ContentsDocument18 pagesBasics of Engineering Measurements: Course Contentsahmed gamalNo ratings yet

- Basic Engineering Measurement AGE 2310Document17 pagesBasic Engineering Measurement AGE 2310ahmed gamalNo ratings yet

- Basic Engineering Measurement AGE 2310Document30 pagesBasic Engineering Measurement AGE 2310ahmed gamalNo ratings yet

- EPR 364 Lecture3Document38 pagesEPR 364 Lecture3ahmed gamalNo ratings yet

- Engineering Mechanics: Lect 11: Kinetics of ParticlesDocument33 pagesEngineering Mechanics: Lect 11: Kinetics of Particlesahmed gamalNo ratings yet

- Lect 14 Kinematics of Ridig BodiesDocument7 pagesLect 14 Kinematics of Ridig Bodiesahmed gamalNo ratings yet

- Lect 7 Center of Mass - CentroidDocument22 pagesLect 7 Center of Mass - Centroidahmed gamalNo ratings yet

- Measurments Sheet 4 AnswersDocument5 pagesMeasurments Sheet 4 Answersahmed gamalNo ratings yet

- Basics of Engineering Measurements (2340AGE) Lab Report 3Document3 pagesBasics of Engineering Measurements (2340AGE) Lab Report 3ahmed gamalNo ratings yet

- EPR 364: Electrical & Electronic Measurements: Lecture 8B Dr. Hussein KotbDocument8 pagesEPR 364: Electrical & Electronic Measurements: Lecture 8B Dr. Hussein Kotbahmed gamalNo ratings yet

- Cholinergic ReceptorsDocument121 pagesCholinergic ReceptorsambroceNo ratings yet

- Special Paid Bundle PDF High Level Puzzles Seating QuestionsDocument25 pagesSpecial Paid Bundle PDF High Level Puzzles Seating QuestionsDev SinghNo ratings yet

- TEMPLATE FOR GEOLOGY REPORT FinalDocument59 pagesTEMPLATE FOR GEOLOGY REPORT FinalDELA CERNA, Eunice F. ExplorersNo ratings yet

- 04-Pet Eng Design - PTE - 470 - Hardness and TestingDocument22 pages04-Pet Eng Design - PTE - 470 - Hardness and TestingHassan KhalifeNo ratings yet

- LK 1: Lembar Kerja Belajar MandiriDocument4 pagesLK 1: Lembar Kerja Belajar MandiriFenny IndrianiNo ratings yet

- 3d Optical Data Storage TechnologyDocument16 pages3d Optical Data Storage TechnologyNagarjuna Siddhu50% (2)

- Thesis For Boy in The Striped PajamasDocument7 pagesThesis For Boy in The Striped Pajamasdwfp5m7d100% (2)

- NCERT Solutions For Class 8 Social Science Geography Chapter 5 IndustriesDocument4 pagesNCERT Solutions For Class 8 Social Science Geography Chapter 5 IndustriesYuki ShizukuNo ratings yet

- KKDocument15 pagesKKFanstaNo ratings yet

- Engineering Data Analysis Learning MaterialDocument10 pagesEngineering Data Analysis Learning MaterialRex Marvin LlenaNo ratings yet

- Oct Test 2Document12 pagesOct Test 2Sayar U A FourNo ratings yet

- WCC - Detailed Lesson Plan TemplateDocument10 pagesWCC - Detailed Lesson Plan TemplateArvin James BarawidNo ratings yet

- Shear Failure Mechanism in Concrete Beams: SciencedirectDocument6 pagesShear Failure Mechanism in Concrete Beams: SciencedirectAnand JadoenathmisierNo ratings yet

- 9180 31125 2 PBDocument11 pages9180 31125 2 PBQothrotunnidha AlmaulidiyahNo ratings yet

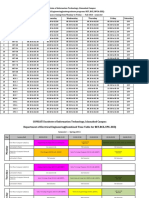

- Midterm Exam ScheduleDocument8 pagesMidterm Exam ScheduleHammad SattiNo ratings yet

- Reflective LetterDocument6 pagesReflective Letterapi-658683346No ratings yet

- Saving The Cheetah Essay 2Document5 pagesSaving The Cheetah Essay 2api-582936685No ratings yet

- FRANC3D V7.4 Download InstallDocument13 pagesFRANC3D V7.4 Download InstallKrishnaBatraNo ratings yet

- 3vl4740 1se36 0aa0Document4 pages3vl4740 1se36 0aa0Sidney SantosNo ratings yet

- Lesson 3 - EIA Regulatory FrameworksDocument29 pagesLesson 3 - EIA Regulatory FrameworksKim Bob G. FernandezNo ratings yet

- KKurt Lewin Force Field Theory - EditedDocument6 pagesKKurt Lewin Force Field Theory - EditedMORRIS ANUNDA0% (1)

- Full U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeDocument4 pagesFull U-Band Rectangular Waveguide-to-Microstrip Transition Using E-Plane ProbeSanjib MandalNo ratings yet

- Atomic Spectra Worksheet Answer Key 05-06Document3 pagesAtomic Spectra Worksheet Answer Key 05-06Anonymous E9ESAecw8x33% (3)

- (Englsih) 2023 Fall Admissions Guide - Incheon National UniversityDocument20 pages(Englsih) 2023 Fall Admissions Guide - Incheon National UniversityDilshodbek AbdusoliyevNo ratings yet

- 4V Circuit DiagramDocument1 page4V Circuit DiagramwjcbaaNo ratings yet

- Democracy and Human Rights: David BeethamDocument1 pageDemocracy and Human Rights: David Beethammoazinkhan.mkNo ratings yet

- Migration and Urban ProblemsDocument19 pagesMigration and Urban ProblemsRaghuNo ratings yet

- Ghosting.: Bianglala Andriadewi, M.Psi., PsikologDocument18 pagesGhosting.: Bianglala Andriadewi, M.Psi., PsikologNurul Fatiha BerhedNo ratings yet

- Science, Technology, and Society: World History: Chapter OutlineDocument7 pagesScience, Technology, and Society: World History: Chapter OutlineRhea PicaNo ratings yet

- GENG 300 Numerical Methods: Qatar UniversityDocument2 pagesGENG 300 Numerical Methods: Qatar University0verflowNo ratings yet