Professional Documents

Culture Documents

Preparation and Weaving Engineering

Uploaded by

Iqbal HossainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Preparation and Weaving Engineering

Uploaded by

Iqbal HossainCopyright:

Available Formats

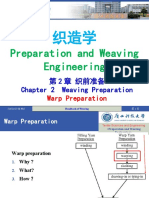

织造学

Preparation and Weaving

Engineering

第 2 章 织前准备

Chapter 2 Weaving Preparation

7/4/21 05:08 PM Handbook of Weaving 第 1页

Weaving Preparation Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

What is Weaving Preparation?

Yarn is the basic building block in weaving. Therefore, a

fter yarn manufacturing, the next successive step would be t

o weave the yarn into a fabric. However, in practice, the con

dition of yarn produced on the spinning machine is not alwa

ys good enough to be used directly for fabric formation.

Package size, yarn surface characteristics, and other fact

ors make it necessary for both filling yarn and warp yarn to

be further processed for efficient fabric formation. These pr

第 2 页

eparatory processes are called weaving preparation

7/4/21 05:08 PM Handbook of Weaving 第 2页

Weaving Preparation Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

We know that : Woven fabric

s are made of two sets of yarn

s: warp and filling.

第 3 页

7/4/21 05:08 PM Handbook of Weaving 第 3页

Weaving Preparation Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Warp and filling yarns are subjected to different conditions an

d requirements during weaving. Therefore, the preparation of

warp and filling yarns is different.

Warp yarn is subjected to higher stresses which requires extra

preparation.

The filling yarns are not subjected to the same type of stresses

as the warp yarns and thus are easily prepared for the weaving

process. Depending on the spinning method, the filling yarns

may not be prepared at all, but rather taken straight off the sp

inning process and transported to the weaving process. 第 4 页

7/4/21 05:08 PM Handbook of Weaving 第 4页

Weaving Preparation Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

The preparation process for wea

ving is divided into two parts:

1. Filling yarn preparation

2. Warp yarn Preparation

(1)Winding

(2)Warping

(3)Slashing

(4)Drawing-in or tying-in

第 5 页

7/4/21 05:08 PM Handbook of Weaving 第 5页

4.1 Winding Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Winding is basically transferri

ng a yarn from one type of pac

kage to another.

a) Winding produces a yarn p

ackage that is

suitable for further processi

ng .

b) The winding process provid

es an opportunity

to clear yarn defects. 第 6 页

7/4/21 05:08 PM Handbook of Weaving 第 6页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

There are three main regions

in winding :

Region 1. Unwinding of yarn

from the spinning package

The yarn package is held in t

he creel in an optimum positi

on for unwinding.

第 7 页

7/4/21 05:08 PM Handbook of Weaving 第 7页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Yarn withdrawal can be done in two w

ays :

1. Side withdrawal. In this method th

e spool is rotated and therefore the

yarn does not rotate during withdr

awal. As a result, the yarn twist do

es not change, which is an advanta

ge.

2. Over-end withdrawal. In this syste

m, the spool does not rotate. Theref

ore, the problems associated with r

otating a spool are avoided. The me

第 8 页

thod is simple and does not require

driving the spool.

7/4/21 05:08 PM Handbook of Weaving 第 8页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Region 2. The tensioning and c

learing region

In this region, proper tension i

s given to the yarn for a desire

d package density and body. T

he typical components of this r

egion are a tension device, a de

vice to detect thick and thin sp

ots in the yarn (clearing devic

e) and a stop motion.

第 9 页

7/4/21 05:08 PM Handbook of Weaving 第 9页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Yarn defect detection

第 10 页

7/4/21 05:08 PM Handbook of Weaving 第 10页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

There are two type

s of guides :

1. closed

2. open

第 11 页

7/4/21 05:08 PM Handbook of Weaving 第 11页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

A. Tension device. The tension device maintains a proper t

ension in the yarn to achieve a uniform package density. It

also serves as a detector for excessively weak spots in the

yarn that break under the added tension induced by the ten

sion device.

There are three major types of tension devices

a)Capstan (or multiplicative) tensioner

b) Additive tensioner 第 12 页

c) Combined tensioner

7/4/21 05:08 PM Handbook of Weaving 第 12页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

第 13 页

7/4/21 05:08 PM Handbook of Weaving 第 13页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

第 14 页

7/4/21 05:08 PM Handbook of Weaving 第 14页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

第 15 页

7/4/21 05:08 PM Handbook of Weaving 第 15页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

B.Yarn clearers. The purpose of a yarn detector is to r

emove thin and thick places. Yarn detectors are usuall

y two types:

1.mechanical

2.electronic

第 16 页

7/4/21 05:08 PM Handbook of Weaving 第 16页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

A mechanical clearer may be as simple as two parallel blades

第 17 页

7/4/21 05:08 PM Handbook of Weaving 第 17页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Electronic detectors are

mainly two types:

capacitive

photo-electric

第 18 页

7/4/21 05:08 PM Handbook of Weaving 第 18页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

C. Stop motion. The purpose of a stop motion is to stop winding

when the yarn breaks or runs out. Stop motions vary from machi

ne to machine.

In general, a mechanical stop motion consists of a counter we

ighted or spring loaded sensing device which is held in an inactiv

e position if the yarn is present. Breakage or running out causes t

he absence of this restraining yarn and allows the sensing device

to activate. Electronic stop motions simply sense the existence of t

he yarn without mechanical contact.

第 19 页

7/4/21 05:08 PM Handbook of Weaving 第 19页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Region 3. The winding r

egion—In this region, th

e yarn package which is

suitable for further proc

essing is wound.

第 20 页

7/4/21 05:08 PM Handbook of Weaving 第 20页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

The yarn is wound on the pac

kage by only rotating the pac

kage. Consider a disc of radi

us R, rotating at an angular v

elocity ω (Figure 4.12). Then,

the linear velocity (or the tan

gential speed) of any point on

the circumference of the pack

age is

第 21 页

7/4/21 05:08 PM Handbook of Weaving 第 21页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

The rotation of the package may be accomplished in two ways:

spindle drive and friction drive.

1) Spindle drive winder

2) Friction drive winder

第 22 页

7/4/21 05:08 PM Handbook of Weaving 第 22页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

1) Spindle drive winder

第 23 页

7/4/21 05:08 PM Handbook of Weaving 第 23页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

2) Friction drive win

der

第 24 页

7/4/21 05:08 PM Handbook of Weaving 第 24页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Traversing Mechanisms

第 25 页

7/4/21 05:08 PM Handbook of Weaving 第 25页

4.1.1 Winding Process Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Types of Packages

第 26 页

7/4/21 05:08 PM Handbook of Weaving 第 26页

4.1.2 Quill Winding Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

第 27 页

7/4/21 05:08 PM Handbook of Weaving 第 27页

4.1.3 Winding Machines Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

Cross winding machines are used for cross winding of tubes,

cones and bobbins with one or two flanges. Yarn laying and pa

ckage drive are achieved by a grooved drum. In cross-winding,

the stability of the package is provided by the acute crossing a

ngle. The package ends can be tapered as well.

第 28 页

7/4/21 05:08 PM Handbook of Weaving 第 28页

4.1.4 Precision Winding Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

第 29 页

7/4/21 05:08 PM Handbook of Weaving 第 29页

Questions Textile Sciences and Engineering

<Preparation and Weaving

Engineering>

1. What is Tension device?

2. How many are types of are Tension device?

3. What is Yarn clearers?

4. How many are types of are yarn clearers?

第 30 页

7/4/21 05:08 PM Handbook of Weaving 第 30页

You might also like

- Practical Research 1 SlideshowDocument96 pagesPractical Research 1 SlideshowGresel GabawanNo ratings yet

- A319 - AWM - IntroductionDocument76 pagesA319 - AWM - Introductionklallali31100% (3)

- Quality Control ProcedureDocument12 pagesQuality Control ProcedureZiya Ahmed100% (6)

- Technology of Short Staple SpinningDocument88 pagesTechnology of Short Staple SpinningThilinaAbhayarathneNo ratings yet

- Fabric Manufacturing: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchDocument229 pagesFabric Manufacturing: Nurunnabi Lecturer National Institute of Textile Engineering & Researchfuad ahmed100% (1)

- The Rieter Manual of Spinning Vol. 7 2451-v1 en Original 68509 PDFDocument78 pagesThe Rieter Manual of Spinning Vol. 7 2451-v1 en Original 68509 PDFVishnuMaliNo ratings yet

- The Ok Mill: More Versatile and Larger Than Ever: Flsmidth A/S, Copenhagen, DenmarkDocument8 pagesThe Ok Mill: More Versatile and Larger Than Ever: Flsmidth A/S, Copenhagen, DenmarkKenny RuizNo ratings yet

- The Rieter Manual of Spinning LL Textilestudycenter - Com LL v-3 (Spinning Preparation)Document80 pagesThe Rieter Manual of Spinning LL Textilestudycenter - Com LL v-3 (Spinning Preparation)Durjoy Roy100% (1)

- The Rieter Manual of SpinningDocument80 pagesThe Rieter Manual of SpinningHashinclude Iostream Int MainNo ratings yet

- Deep ExcavationDocument59 pagesDeep ExcavationIsbelNo ratings yet

- Impact of Piecing Index On Combed Yarn QualityDocument4 pagesImpact of Piecing Index On Combed Yarn QualityEditor IJTSRD100% (1)

- Electronic Document Management System of RMTUDocument6 pagesElectronic Document Management System of RMTUDaniel BachillarNo ratings yet

- Nanotechnology Applications to Telecommunications and NetworkingFrom EverandNanotechnology Applications to Telecommunications and NetworkingNo ratings yet

- Standard Specification Webbing For Slings WB-1Document10 pagesStandard Specification Webbing For Slings WB-1adventmanurung100% (1)

- Fix Api: Developers GuideDocument36 pagesFix Api: Developers GuideAlex CurtoisNo ratings yet

- Introduction To Weaving Preparatory ProcessesDocument21 pagesIntroduction To Weaving Preparatory ProcessesZakeesh FatimaNo ratings yet

- Sizing BasicsDocument38 pagesSizing BasicsAmir YasinNo ratings yet

- The Rieter Manual of Spinning Vol. 1-Pages 40 PDFDocument80 pagesThe Rieter Manual of Spinning Vol. 1-Pages 40 PDFAbdul RafayNo ratings yet

- 2.weaving Preparation-3Document18 pages2.weaving Preparation-3Iqbal HossainNo ratings yet

- 2.weaving Preparation-2Document17 pages2.weaving Preparation-2Iqbal HossainNo ratings yet

- W Warping NotesDocument35 pagesW Warping NoteslokeshNo ratings yet

- Prep. Process For Weaving: Fabric Manufacturing - II by Dr. Nazakat Ali Buitems Lec-ADocument11 pagesPrep. Process For Weaving: Fabric Manufacturing - II by Dr. Nazakat Ali Buitems Lec-ANazakat Ali KhosoNo ratings yet

- Now ReadDocument144 pagesNow ReadNil RoyNo ratings yet

- Book FMT TW 224Document160 pagesBook FMT TW 224Rabia RehmanNo ratings yet

- ProjectDocument12 pagesProjectJoshi ParthNo ratings yet

- Shuttle - Less Loom Weaver - AirjetDocument221 pagesShuttle - Less Loom Weaver - AirjetDeepanshu GuptaNo ratings yet

- Winding Defects PDFDocument279 pagesWinding Defects PDFsonuNo ratings yet

- Full Book TPSPDocument120 pagesFull Book TPSPDeenaNo ratings yet

- Effect of Core Draft On The Properties o PDFDocument40 pagesEffect of Core Draft On The Properties o PDFDyeing DyeingNo ratings yet

- Fabric Manufacturing I Introduction of WeavingDocument2 pagesFabric Manufacturing I Introduction of WeavingSudipta BainNo ratings yet

- Rieter Special Print Recycling 3379 v1n en 02 PDFDocument44 pagesRieter Special Print Recycling 3379 v1n en 02 PDFMohamed NaeimNo ratings yet

- 116102005Document4 pages116102005mohan smrNo ratings yet

- Afmm WorkbookDocument56 pagesAfmm WorkbookDuaa Shahid100% (1)

- Federal TVET Institute Textile and Apparel Fashion Technology DivisionDocument24 pagesFederal TVET Institute Textile and Apparel Fashion Technology DivisionGurumurthy BRNo ratings yet

- Course: Yarn Manufacturing 2Document24 pagesCourse: Yarn Manufacturing 2fekadeNo ratings yet

- Importance of Spindle Speed in Ring Frame: Research Article ISSN: 2637-4595Document3 pagesImportance of Spindle Speed in Ring Frame: Research Article ISSN: 2637-4595Arif HasanNo ratings yet

- 6650-Article Text-19343-1-10-20151128Document8 pages6650-Article Text-19343-1-10-20151128Mr AdibNo ratings yet

- Influence of Weave Design and Yarn Types On Mechanical and Surface Properties of Woven FabricDocument4 pagesInfluence of Weave Design and Yarn Types On Mechanical and Surface Properties of Woven FabricChinedu ObasiNo ratings yet

- Spinning ProcessDocument4 pagesSpinning ProcessTharushi NiwarthanaNo ratings yet

- 116102038Document3 pages116102038SantoshNo ratings yet

- ProductivityDocument57 pagesProductivityAamir Ashraf100% (2)

- Fdocuments - in - Analysis of Rejected Ring Cops in Autoconer Winding MachineDocument49 pagesFdocuments - in - Analysis of Rejected Ring Cops in Autoconer Winding MachineAbel TayeNo ratings yet

- 10.1515 - Secm 2022 0212Document9 pages10.1515 - Secm 2022 0212Huy KieuNo ratings yet

- Basics of Warping in Textile SectorDocument11 pagesBasics of Warping in Textile SectorAlhajAliNo ratings yet

- Motorized Jacquard Technology For Multilayer Weaving Damages Study and Reduction: Shed Profile and Close Shed ProfileDocument11 pagesMotorized Jacquard Technology For Multilayer Weaving Damages Study and Reduction: Shed Profile and Close Shed ProfileRajesh KumarNo ratings yet

- Internship Report YTMDocument21 pagesInternship Report YTMAli abbasNo ratings yet

- The Rieter Manual of Spinning Vol. 1 1921-V3 en Original 68489Document80 pagesThe Rieter Manual of Spinning Vol. 1 1921-V3 en Original 68489singhgirendra20001523No ratings yet

- 25.thaw Tar Tun, MTUDocument4 pages25.thaw Tar Tun, MTUThet TinNo ratings yet

- AutoclaveDocument47 pagesAutoclaveTomble BravoNo ratings yet

- 3 Standard Procedure and TimeDocument7 pages3 Standard Procedure and TimeebrahimbutexNo ratings yet

- GoodDocument22 pagesGoodRuchira WijesenaNo ratings yet

- Effect of Twist On Yarn PropertiesDocument6 pagesEffect of Twist On Yarn Propertiesali4300136No ratings yet

- Complete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Document98 pagesComplete - Short Course - Textile Design and Weaving - DR Kashif Bangash - 7-4-2019Muhammad IlyasNo ratings yet

- Compact SpinningDocument7 pagesCompact Spinningag015708No ratings yet

- Uster Imperfections of 35% Cotton and 65% Polyester Blended Yarn For 40ne, 50ne and 60ne Ring Spun YarnDocument7 pagesUster Imperfections of 35% Cotton and 65% Polyester Blended Yarn For 40ne, 50ne and 60ne Ring Spun YarnGobu SKNo ratings yet

- Analysis of The Imperfection Index (Ipi) Value of Carded Yarn Produced by Using Different Diameter Spacers On The Ring Frame Spinning MachineDocument7 pagesAnalysis of The Imperfection Index (Ipi) Value of Carded Yarn Produced by Using Different Diameter Spacers On The Ring Frame Spinning MachineUtsho ParvezNo ratings yet

- Huynh 2020Document7 pagesHuynh 2020Brigitte Paula Paredes AvilaNo ratings yet

- Study On CCI Warping Machine.Document5 pagesStudy On CCI Warping Machine.Naimul HasanNo ratings yet

- Fields of Textiles: Tree DiagramDocument24 pagesFields of Textiles: Tree Diagramsarwat yaseenNo ratings yet

- Exp 01 CorrectedDocument14 pagesExp 01 CorrectedIstiak Ahmed TussharNo ratings yet

- Sr. No Page NoDocument33 pagesSr. No Page NoAmor ELHAJAHMEDNo ratings yet

- Comparative Analysis of Fabrics Made From Eli-TwisDocument5 pagesComparative Analysis of Fabrics Made From Eli-TwisMễro ĢANo ratings yet

- Operation Pretreatment Process of TextileDocument15 pagesOperation Pretreatment Process of Textileaqsa imranNo ratings yet

- Clean Filament Winding: Process OptimisationDocument274 pagesClean Filament Winding: Process OptimisationHassan HabibNo ratings yet

- Are We Ready For Robot SexDocument17 pagesAre We Ready For Robot SexkaiNo ratings yet

- Neuroeconomics 1Document3 pagesNeuroeconomics 1mihaela irofteNo ratings yet

- IoDocument1 pageIopamminorNo ratings yet

- A Review of Material Flow AnalysisDocument8 pagesA Review of Material Flow AnalysisRoberto PanizzoloNo ratings yet

- Oral Communication in Context Module Based On MELC Summative TestDocument6 pagesOral Communication in Context Module Based On MELC Summative TestAimee Lasaca0% (1)

- The Steps How To Use Theodolite For SurveyingDocument2 pagesThe Steps How To Use Theodolite For Surveyinglong bottomNo ratings yet

- Arduino YunDocument1 pageArduino YunTerrance MasterNo ratings yet

- Ethm1 Op Int 2020-03-05 4f512412Document27 pagesEthm1 Op Int 2020-03-05 4f512412Maciej CNo ratings yet

- Inset Narrative ReportDocument4 pagesInset Narrative ReportJuvy Vale BustamanteNo ratings yet

- Learning Outcomes RaDocument11 pagesLearning Outcomes Raapi-349210703No ratings yet

- Evaluation of Prosthetic Marginal Fit and Implant SurvivalDocument12 pagesEvaluation of Prosthetic Marginal Fit and Implant SurvivalGustavo IsmaelNo ratings yet

- Speech Act Approach (Revised)Document15 pagesSpeech Act Approach (Revised)Udiana Puspa DewiNo ratings yet

- Adding Library Objects To Sbuilder BY Jon Masterson Scruffyduck SceneryDocument17 pagesAdding Library Objects To Sbuilder BY Jon Masterson Scruffyduck SceneryInterim InterimNo ratings yet

- Us - Dot - Bureau of Transportation Statistics - Us - Dot - Bureau of Transportation Statistics - The Changing Face of Transportation - EntireDocument368 pagesUs - Dot - Bureau of Transportation Statistics - Us - Dot - Bureau of Transportation Statistics - The Changing Face of Transportation - Entireprowag0% (1)

- Aprea 2002Document14 pagesAprea 2002VIKNESWARAN S KNo ratings yet

- Joint Department Admin Order No. 2Document8 pagesJoint Department Admin Order No. 2business permits and licenses div.No ratings yet

- C-4DS & C-4DL Electric Bed User Manual-Rev180810Document30 pagesC-4DS & C-4DL Electric Bed User Manual-Rev180810hector raffaNo ratings yet

- CSS 211Document173 pagesCSS 211Adikwu Anyebe OwoichoNo ratings yet

- Happy Birthday, Madame Chapeau Hat ActivityDocument2 pagesHappy Birthday, Madame Chapeau Hat ActivityAbrams BooksNo ratings yet

- GRM 1Document55 pagesGRM 1Mady RadaNo ratings yet

- Archmodels Vol.06Document5 pagesArchmodels Vol.06JJ PeterNo ratings yet

- TroubleshootingDocument28 pagesTroubleshootingRisoSilvaNo ratings yet

- Infrastructure Man TemplateDocument1 pageInfrastructure Man Template1namillied08No ratings yet