Professional Documents

Culture Documents

Operation Process and Flow Process Chart (With

Uploaded by

Jahmmil A RamastaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation Process and Flow Process Chart (With

Uploaded by

Jahmmil A RamastaCopyright:

Available Formats

Operation Process and Flow

Process Chart (With Diagram)

• This is also known as outline process chart and it provides a compact over all

view of the whole system of operations involved in the production of a

product. In this chart only the main activities (i.e. operations and inspections)

carried out to complete a job are recorded in the sequence of their occurrence

but irrespective of where they are performed and who performs them.

• Thus only symbols of process chart are used in preparing it. Sometimes a

brief note about the nature each activity (may be operation or inspection) and

the time allowed are mentioned by the side of symbols. The processing to

material i.e. various activities are shown vertically on the entry or purchase of

material by horizontal lines as shown in Fig 18.1. (The operation process chart

for the fabrication of a riveted assembly

An operation process chart has

following advantages:

• To improve shop/plant layout

• Helps in specifying the basic

manufacturing system.

• Helps in determining sequence of

assembly and the scheduling activities

regarding dates of purchased material

and completion dates for fabricated

parts.

• To introduce the new technical personal

with the manufacturing system.

Flow process chart

are of three types:

Man, Machine and Material. These charts are shown in

Flow Process Chart: Figs. 18.3, 18.4 and 18.5.

The man type flow process chart shows the process from

the point of view of man/operator. It indicates the

activities of man throughout the process.

• A flow process chart is a chart showing The machine type flow process chart shows the activities

the sequence of the flow of a product by from the point of view of machines involved. A chart for

way of recording all activities/events example of a boring machine will ignore the whole of

under review with appropriate symbols. activities except the past in which boring machine is

This chart is similar to operation process involved. It will not indicate any movement of men or

chart with the difference that it utilizes materials.

symbols of operation, transportation, The material type flow process chart shows the process

inspection, delay and permanent storage. from the materials point of view utilized during the

The operation times and distances moved process. It shows the introduction of all materials whether

are also recorded along the symbols side.

raw material or finished components and represents all

information regarding operations and inspections carried

out on the during process diagrammatically.

Flow Diagram:

A flow diagram is a pictorial layout of buildings and floors on which locations of all

the activities as given on the flow lines representing the movement of men and

materials are shown. Such pictorial layout is valuable in incorporating

improvements in the method.

The number of movements if minimized result viz. a lot of saving both in cost as

well as efforts required to perform a job Fig. 18.3 shows a simple flow diagram in

which raw material from the store moves to work station P where an operation is

performed the semi-finished product moves to work place Q where another

operation is carried out hence it moves to work place R for inspection and is

further sent to location S where it waits for a short period and ultimately goes out

of the unit.

You might also like

- Assg 03 1Document7 pagesAssg 03 1Abdul ShakoorNo ratings yet

- VIII SEM I.E.Lab Exp 3-4Document9 pagesVIII SEM I.E.Lab Exp 3-4Raghvendra Singh ShaktawatNo ratings yet

- Record Work StudyDocument86 pagesRecord Work StudyAman SuranaNo ratings yet

- Adams Abdulrasheed Anbjujyinde: Industrial Engineering and Ergonomics Assignment 2Document3 pagesAdams Abdulrasheed Anbjujyinde: Industrial Engineering and Ergonomics Assignment 2Rebecca JohnsonNo ratings yet

- Adams Abdulrasheed Ayinde: Industrial Engineering and Ergonomics Assignment 2Document3 pagesAdams Abdulrasheed Ayinde: Industrial Engineering and Ergonomics Assignment 2Rebecca JohnsonNo ratings yet

- Assignment 3 Work StudyDocument10 pagesAssignment 3 Work StudyPiyush BhandariNo ratings yet

- Fdocuments - in - Recording Techniques Used in Method StudyDocument49 pagesFdocuments - in - Recording Techniques Used in Method StudyManash DeyNo ratings yet

- Wa0026Document49 pagesWa0026getbibinonline98No ratings yet

- Description: An Operation Process Chart Provides The Chronological Sequence of All OperationsDocument7 pagesDescription: An Operation Process Chart Provides The Chronological Sequence of All Operationsfrances beeNo ratings yet

- Operation BreakdownDocument21 pagesOperation BreakdownNikita JainNo ratings yet

- Experiment No: - 03: Figure 2.1: Example of Flow Diagram (Material Type)Document5 pagesExperiment No: - 03: Figure 2.1: Example of Flow Diagram (Material Type)Kushal TamboliNo ratings yet

- SUMSEM-2021-22 MEE1014 TH VL2021220701509 Reference Material II 28-07-2022 Recording TechniquesDocument22 pagesSUMSEM-2021-22 MEE1014 TH VL2021220701509 Reference Material II 28-07-2022 Recording TechniquesSai gokulNo ratings yet

- Lecture 19 Operation Process ChartsDocument20 pagesLecture 19 Operation Process ChartsrbansalNo ratings yet

- Operation and Maintenance in Home EconomicsDocument11 pagesOperation and Maintenance in Home EconomicsIvyFacultadNo ratings yet

- Work StudyDocument70 pagesWork StudyAditya PrakashNo ratings yet

- Process Analysis: IENG 301 Fundamentals of Work Study and ErgonomicsDocument20 pagesProcess Analysis: IENG 301 Fundamentals of Work Study and ErgonomicsRashedNo ratings yet

- Unit Ii.2Document17 pagesUnit Ii.2R Màhá LâkshmîNo ratings yet

- PR 1-2Document7 pagesPR 1-2mech bhabhaNo ratings yet

- Information Recording TechniquesDocument10 pagesInformation Recording TechniquesabdulghaforNo ratings yet

- Pptonflowprocesschart Abhi 130212083812 Phpapp02Document17 pagesPptonflowprocesschart Abhi 130212083812 Phpapp02Anam ShoaibNo ratings yet

- Process ChartDocument21 pagesProcess ChartSrinivas KronosNo ratings yet

- QCR ManualDocument54 pagesQCR ManualBiswajeet kumarNo ratings yet

- Unit 3 Charting and Diagramming Techniques For Operations AnalysisDocument19 pagesUnit 3 Charting and Diagramming Techniques For Operations Analysisleonard dela cruzNo ratings yet

- Unit 3 Charting and Diagramming Techniques For Operations AnalysisDocument19 pagesUnit 3 Charting and Diagramming Techniques For Operations AnalysisVictoria Asuncion RodriguezNo ratings yet

- Advantages of Work Study & Recording TechniquesDocument18 pagesAdvantages of Work Study & Recording TechniquesDinesh GNo ratings yet

- Work Study&Ergonomics 2Document38 pagesWork Study&Ergonomics 2YahyaNo ratings yet

- WSE Unit 3 Diagrams-ChartsDocument48 pagesWSE Unit 3 Diagrams-ChartsVishal MeenaNo ratings yet

- Work Study - Method Study: ExamplesDocument38 pagesWork Study - Method Study: ExamplesP K JainNo ratings yet

- Process Chart Symbols: OperationDocument7 pagesProcess Chart Symbols: OperationAnurag PolshettiwarNo ratings yet

- CHAPTER 3 - Recording and Analysis ToolDocument18 pagesCHAPTER 3 - Recording and Analysis ToolMary Jeannette JuanNo ratings yet

- Tools and Techniques of Plant LayoutDocument24 pagesTools and Techniques of Plant LayoutNikhil Sankhe80% (5)

- Dr. Goutam Sen: Indian Institute of Technology (IIT) Kharagpur West Bengal, IndiaDocument39 pagesDr. Goutam Sen: Indian Institute of Technology (IIT) Kharagpur West Bengal, IndiaSiddharthPutuvelyNo ratings yet

- Section A (I)Document69 pagesSection A (I)Tashmeet SinghNo ratings yet

- Work DesignDocument47 pagesWork DesignDeepali Singhai JainNo ratings yet

- Process Routing SheetDocument4 pagesProcess Routing SheetRaj RajendranNo ratings yet

- PROCESS SEQUENCES Includes The Following CHARTSDocument38 pagesPROCESS SEQUENCES Includes The Following CHARTSengr_rpcurbano0% (1)

- Improve Work Study TechniquesDocument10 pagesImprove Work Study TechniquesmalleshgnNo ratings yet

- Cha-2 Flow Pattern NewDocument69 pagesCha-2 Flow Pattern NewTesfa TeshomeNo ratings yet

- Understand Quality Tools with Visio, Excel & MinitabDocument56 pagesUnderstand Quality Tools with Visio, Excel & MinitabM Umair MuzaffarNo ratings yet

- The application of process diagrams in the bakery industryDocument18 pagesThe application of process diagrams in the bakery industryCarlos SanchezNo ratings yet

- How To Do Value Stream MappingDocument10 pagesHow To Do Value Stream MappingAnuj SrivastavaNo ratings yet

- Work Map (Non-Rehearse)Document21 pagesWork Map (Non-Rehearse)Ihza Ramadhanni DhaniNo ratings yet

- Industrial Engineering Laboratory ManualDocument27 pagesIndustrial Engineering Laboratory ManualsatishNo ratings yet

- Industrial Engineering - Lab Manual - 06052016 - 054139AM PDFDocument58 pagesIndustrial Engineering - Lab Manual - 06052016 - 054139AM PDFSaya100% (1)

- Charts Used in Method StudyDocument13 pagesCharts Used in Method StudyAnonymous 3rajW3TK9No ratings yet

- Process Flow DiagramDocument3 pagesProcess Flow DiagramSergio SánchezNo ratings yet

- Process Flow Chart or Process Flow DiagramDocument12 pagesProcess Flow Chart or Process Flow DiagramsnabilNo ratings yet

- Dr. R.Dhinakaran Professor Dept. of Mechanical Engineering Pondicherry Engineering College Puducherry - 605014Document69 pagesDr. R.Dhinakaran Professor Dept. of Mechanical Engineering Pondicherry Engineering College Puducherry - 605014Seenu CnuNo ratings yet

- Line of BalanceDocument4 pagesLine of Balancekalley minogNo ratings yet

- Prepare Operation Process Chart (OPC) for assembly experimentDocument4 pagesPrepare Operation Process Chart (OPC) for assembly experimentKushal TamboliNo ratings yet

- Me 404 Industrial Engineering: Santhu Varghese Thomas Assistant Professor Mangalam College of EngineeringDocument80 pagesMe 404 Industrial Engineering: Santhu Varghese Thomas Assistant Professor Mangalam College of Engineeringe tutorNo ratings yet

- Pom5 - IIDocument8 pagesPom5 - IIYashveer ChopraNo ratings yet

- I.E. NotesDocument8 pagesI.E. Notesvarun5tripathiNo ratings yet

- Assignment: Supply Chain Management Prof. Zia Ur Rehman Submitted By: Tehreem Athar MC - 018Document7 pagesAssignment: Supply Chain Management Prof. Zia Ur Rehman Submitted By: Tehreem Athar MC - 018Taimoor AtharNo ratings yet

- Method StudyDocument50 pagesMethod StudyArp JainNo ratings yet

- 7 tools statistical process control SPCDocument3 pages7 tools statistical process control SPCSachin MethreeNo ratings yet

- Make or Buy Process DesignDocument10 pagesMake or Buy Process DesignFaisal Saleh RazaNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- How to Create Continuous Production Flow?: Toyota Production System ConceptsFrom EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Ib Ra 11058 Tesda OshcDocument3 pagesIb Ra 11058 Tesda OshcJahmmil A RamastaNo ratings yet

- Jahmmil As Yamada Final ExamDocument2 pagesJahmmil As Yamada Final ExamJahmmil A RamastaNo ratings yet

- Exam #1 EMDocument2 pagesExam #1 EMJahmmil A RamastaNo ratings yet

- P Series Volume 59 FULL LISTDocument78 pagesP Series Volume 59 FULL LISTAngel Manalo0% (1)

- Quantitative Tools, Worker and Machine RelationshipsDocument12 pagesQuantitative Tools, Worker and Machine RelationshipsJahmmil A RamastaNo ratings yet

- Explanatory Tools - Pareto Analysis, Fish Diagrams, Gantt Chart, PERT ChartDocument20 pagesExplanatory Tools - Pareto Analysis, Fish Diagrams, Gantt Chart, PERT ChartJahmmil A RamastaNo ratings yet

- January 26-2021 History of Industrial EngineeringDocument2 pagesJanuary 26-2021 History of Industrial EngineeringJahmmil A RamastaNo ratings yet

- Operation AnalysisDocument22 pagesOperation AnalysisJahmmil A RamastaNo ratings yet

- January 22-2020 What Is Work StudyDocument3 pagesJanuary 22-2020 What Is Work StudyJahmmil A RamastaNo ratings yet

- Floor Plan CabalanDocument2 pagesFloor Plan CabalanJahmmil A RamastaNo ratings yet

- C 0.8 Reference Manual: ArdpeekDocument60 pagesC 0.8 Reference Manual: ArdpeekMarcos FidelisNo ratings yet

- General Mathematics: Functions and RelationsDocument22 pagesGeneral Mathematics: Functions and RelationsImie FloresNo ratings yet

- Superagent: A Customer Service Chatbot For E-Commerce WebsitesDocument12 pagesSuperagent: A Customer Service Chatbot For E-Commerce WebsitesAisha AnwarNo ratings yet

- Gi 6.008 Restriction of Portable Electrical - ElectronicDocument5 pagesGi 6.008 Restriction of Portable Electrical - ElectronicAhmed ShoreemNo ratings yet

- GRADE 11 Mock ExamDocument7 pagesGRADE 11 Mock ExamRashawn WilkinsonNo ratings yet

- 300+ Angular Interview QuestionsDocument64 pages300+ Angular Interview QuestionsAmit Naik100% (1)

- 4 Const Prob. and Sol. Burj KhalifaDocument5 pages4 Const Prob. and Sol. Burj Khalifaprakriti goyalNo ratings yet

- Accuracy TestDocument8 pagesAccuracy Testnilamrohit07No ratings yet

- Aliens RulebookDocument28 pagesAliens RulebookTsudakis Prod Ld100% (6)

- From a CDS View to an OData Service for AnalyticsDocument18 pagesFrom a CDS View to an OData Service for AnalyticsParesh GanganiNo ratings yet

- Digital Footprint and Data Protection NotesDocument18 pagesDigital Footprint and Data Protection NotesSohail AkramNo ratings yet

- NTC Form ApplicationDocument2 pagesNTC Form ApplicationIvan c TanegaNo ratings yet

- REVIT FAB Parts DataDocument20 pagesREVIT FAB Parts Dataavinash3479No ratings yet

- Air Control 3: ManualDocument72 pagesAir Control 3: ManualNihat RustamliNo ratings yet

- MAXIMIZING YOUR VIDEO BUDGET ON YOUTUBEDocument12 pagesMAXIMIZING YOUR VIDEO BUDGET ON YOUTUBENontonFilemNo ratings yet

- FSOG 13-005 General Insp TenarisDocument10 pagesFSOG 13-005 General Insp TenarisJanderson Sanchez Castañeda0% (1)

- BoltightDocument1 pageBoltightREZA ASGARINo ratings yet

- © Jitesh Khurkhuriya - Azure ML Online CourseDocument27 pages© Jitesh Khurkhuriya - Azure ML Online Coursedhrit_wNo ratings yet

- Strategic MGMT Lec Quiz 5Document3 pagesStrategic MGMT Lec Quiz 5Wennie NgNo ratings yet

- Intelligent Functional Testing: White PaperDocument9 pagesIntelligent Functional Testing: White PaperSahodara reddyNo ratings yet

- Datasheet DT35S-B15551 1122103 enDocument8 pagesDatasheet DT35S-B15551 1122103 enROSSNo ratings yet

- III - D S BDTM921 - T V M: ATA Heet WO Alve AnifoldDocument2 pagesIII - D S BDTM921 - T V M: ATA Heet WO Alve Anifoldrob.careyNo ratings yet

- Activity 1.3 MMWDocument2 pagesActivity 1.3 MMWJ Saint BadeNo ratings yet

- Aviatrix ACEDocument25 pagesAviatrix ACEDavid Patterson100% (1)

- Study On Fatigue Failure Analysis On Ic Engine PistonDocument35 pagesStudy On Fatigue Failure Analysis On Ic Engine PistonRavi Parkhe100% (1)

- Apply Looping Structure in A Program: Specialized Training Workshop in Ict Season 4/ May 25-27, 2020Document46 pagesApply Looping Structure in A Program: Specialized Training Workshop in Ict Season 4/ May 25-27, 2020Lorena TeofiloNo ratings yet

- VDOSH Expands Portfolio With Investment in JETSWEATDocument2 pagesVDOSH Expands Portfolio With Investment in JETSWEATPR.comNo ratings yet

- Ghibson ButterflyDoubleEccentric BrochureDocument9 pagesGhibson ButterflyDoubleEccentric Brochurejhon jairo arangoNo ratings yet

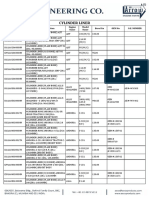

- Cylinder Liner: Item Code Item Description Engine Name Model Name Bore Dia Oem No O.E. NumberDocument49 pagesCylinder Liner: Item Code Item Description Engine Name Model Name Bore Dia Oem No O.E. NumberDuvacy0% (1)

- NAPARS News No 21 Feb 2022-1 TracesDocument12 pagesNAPARS News No 21 Feb 2022-1 TracesarstjunkNo ratings yet