0% found this document useful (0 votes)

2K views17 pagesPicking

- Picking is the process of inserting the weft yarn through the warp yarns during weaving. It can be done using various mechanisms like cone over-pick, cone under-pick, and side lever/shaft under-pick.

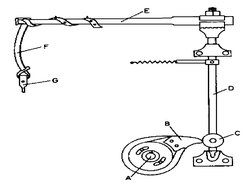

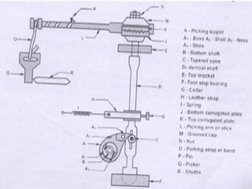

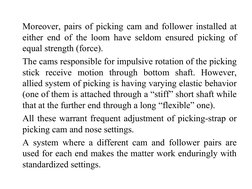

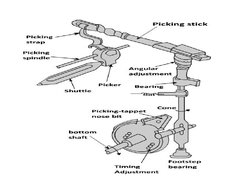

- Cone over-pick mechanisms use a picking cam on the bottom shaft to rotate a picking shaft and swing the picking stick over the loom to throw the shuttle. Cone under-pick mechanisms operate similarly but with the picking stick located below the shuttle trajectory.

- The type of picking mechanism used depends on factors like loom size, fabric weight, and desired production speed.

Uploaded by

Sivakumar KCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views17 pagesPicking

- Picking is the process of inserting the weft yarn through the warp yarns during weaving. It can be done using various mechanisms like cone over-pick, cone under-pick, and side lever/shaft under-pick.

- Cone over-pick mechanisms use a picking cam on the bottom shaft to rotate a picking shaft and swing the picking stick over the loom to throw the shuttle. Cone under-pick mechanisms operate similarly but with the picking stick located below the shuttle trajectory.

- The type of picking mechanism used depends on factors like loom size, fabric weight, and desired production speed.

Uploaded by

Sivakumar KCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

- Picking Introduction: Introduces the concept of picking as the second primary motion in weaving.

- Objective of Picking: Explains the purpose and action of picking in weaving including lateral set of yarns.

- Types of Picking Mechanism: Distinguishes between conventional/negative and unconventional/positive picking mechanisms.

- Classification of Shuttle Picking Mechanism: Classifies shuttle picking mechanisms into over and under-pick mechanisms.

- Cone Over-Pick Mechanism: Details the cone over-pick mechanism, its function, and components in weaving.

- Features of Over Picking Mechanism: Lists the features and advantages of the over-picking mechanism in looms.

- Cone Under-Pick Mechanism: Describes the cone under-pick mechanism and its use in automatic looms.

- Features of Under Picking Mechanism: Highlights the features and limitations of the under-picking mechanism.