Professional Documents

Culture Documents

1 Training Units PDF Free

Uploaded by

haftu gideyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Training Units PDF Free

Uploaded by

haftu gideyCopyright:

Available Formats

Training Units and Addressing

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.1

Contents Page

Training Area Setup with S7-300 ...................................................................................................... 2

Configuration of the S7-300 Training Unit ......................................................................................... 3

The Simulator ................................................................................................................................... 4

The Conveyor Model ..................................................................................................................... 5

Complete Symbol List (1) ................................................................................................................. 6

Complete Symbol List .................................................................................................................. 7

(2)

If You Want to Know More .............................................................................................................. 8

Training Area Setup with S7 - 400 .................................................................................................. 9

Configuration of the S7 - 400 Training Unit ..................................................................................... 10

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 1 Training Units and Addressing

Training Area Setup with S7 - 300

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.2

S7 - 300 Training Area The training area consists of the following components:

• An S7-300 programmable logic controller with the CPU 315-2 DP

• Digital input and output modules, analog module

• Simulator with digital and analog sections

• Conveyor model

• ET 200S distributed peripheral

• MM420 Micromaster with PROFIBUS module

• TP170B Touchpanel

• Programming device or PC

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 2 Training Units and Addressing

Configuration of the S7 - 300 Training Unit

(32-channel

I/O modules)

Module --> PS CPU DI 32 DO 32 DI8/DO8 AI 2

Slot No. --> 1 2 4 5 6 7

I/O Address --> 0 4 8 304

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.3

Configuration The programmable controller is configured with the following modules:

Slot 1: Power Supply 24V/5A

Slot 2: CPU 315-2 DP

Slot 4: Digital input 32x24V Inputs from the simulator

and thumbwheel buttons

Slot 5: Digital output 32x24V/0.5A Outputs from the simulator

and digital display

Slot 6: Digital input and output Conveyor model

module 8X24V/ 8x24V 0.5A

Slot 7: Analog input 2 AI Analog section from the simulator

Addresses For the training unit with the CPU 315-2DP and for the S7-400 training unit, you

can set the starting addresses of the modules by parameter assignment

(freely).

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 3 Training Units and Addressing

The Simulator

Potentiometers for

setting the

Digital Display analog vales

DI DO

.0 .......... .......... .0

.1 .......... .......... .1

.2 .......... .......... .2

.3 .......... .......... .3 V

.4 .......... .......... .4

.5 .......... .......... .5

.6 .......... .......... .6 -15V...+15V AI2 AO1 -15V...+15V

AI1 AO2

.7 .......... .......... .7

.0 .......... ..........

.0

.1 .......... ..........

.1 AI1 AI2

.2 .......... .......... V

.2

.3 .......... ..........

.3

.......... ..........

081 5

.4

.4

.5 .......... .......... AI1 AI2

.5 AO1 AO2

.6 .......... ..........

.6

.7 .......... ..........

.7

Switches LEDs Thumbwheel Buttons

/ Pushbuttons

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.4

Design Two cables connect the simulator to the S7-300™ or S7-400™ training unit. The

simulator is divided into the following three sections:

• Binary section with 16 switches / pushbuttons and 16 LEDs

• Digital section with 4 thumbwheel buttons and a digital display. The

thumbwheel and digital (BCD) display use BCD values,

• Analog section with a voltmeter for displaying the values at analog channels 0

and 1 or the analog outputs 0 and 1. You use the selector switch to choose

the voltage value you want to monitor. There are two separate potentiometers

for setting the values for the analog inputs.

Addressing You use the following addresses to address the inputs and outputs in your user

program :

Sensor / Actuator (DI32, DO32)

Switch / Pushb. IW 0

LEDs QW 4

Thumb. buttons IW 2

Digital display QW 6

Analog channels PIW 304/306

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 4 Training Units and Addressing

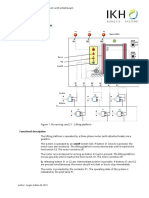

The Conveyor Model

BAY_1 BAY_2 BAY_3 I LB1

K_RT (Q 8.5) 8.5 I 8.6

Horn

K_LT (Q 8.6) I 8.7 I8.0

Q

8.7

T_Bay_1 T_Bay_2 T_FinalAssy

I 8.1 T_Bay_3 I 8.2 I 8.4

L_Bay_1 I 8.3

L_Bay_2 L_Bay_3 L_FinalAssy

Q 8.1 Q 8.2 Q 8.4

Q 8.3

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.5

Design The slide shows a diagram of the conveyor model with its sensors and

actuators.

Addresses

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 5 Training Units and Addressing

Complete Symbol List (1)

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 6 Training Units and Addressing

Complete Symbol List (2)

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 7 Training Units and Addressing

If You Want to Know More

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.8

Note The following pages contain either further information or are for reference to

complete a topic.

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 8 Training Units and Addressing

Training Area Setup with S7- 400

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.9

Contents of the The training area consists of the following components:

Training Area • An S7-400 programmable logic controller with a CPU 412 or CPU 413-2 DP)

• Digital input and output modules, analog module

• Simulator with digital and analog section

• Conveyor model

• ET 200S distributed peripheral

• MM420 Micromaster with PROFIBUS module

• TP170B Touchpanel

• Programming device or PC

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 9 Training Units and Addressing

Configuration of the S7-400 Training Unit

Slot No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

PS CPU DI DI DO DO AI

32 32 32 32 8

Default Address: 28 32 36 40 1216

SIMATIC S7 Date: 18.11.2005 SITRAIN Training for

Automation and Industrial Solutions

Siemens AG 2005. All rights reserved. File: SERV2_01E.10

Design You can see the design of the S7-400 training unit in the slide above.

Configuration The UR 1 rack is configured with the following modules:

Slot 1: Power Supply 24V and 5V/20A

Slot 2: -"-

Slot 3: -"-

Slot 4: CPU 412 or other

Slot 5: vacant (when the CPU only has a single width)

Slot 6: vacant

Slot 7: vacant

Slot 8: Digital input 32x24V (from simulator)

Slot 9: Digital input 32x24V (from conveyor model)

Slot 10: Digital output 32x24V 0.5A (to simulator)

Slot 11: Digital output 32x24V 0.5A (to conveyor model)

Slot 12: Analog input 8x13 Bit (from potentiometer on

Slot 13: vacant simulator)

Slot 14: vacant

Slot 15:

Slot 16: vacant

Slot 17: vacant

Slot 18:

vacant

Addressing You have the default addresses, as shown in the slide above, as long as no

vacant

configuration or parameter settings have been made.

SITRAIN Training for ST-SERV2

Automation and Industrial Solutions Page 10 Training Units and Addressing

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Type MA9 GDocument23 pagesType MA9 Gudhay0% (1)

- 8 Digital OperationsDocument35 pages8 Digital Operationshaftu gideyNo ratings yet

- 15 Documenting Saving ArchivingDocument26 pages15 Documenting Saving Archivinghaftu gideyNo ratings yet

- 16 Communication Via MPIDocument18 pages16 Communication Via MPIhaftu gideyNo ratings yet

- 10 Introduction To PROFIBUS DP and The HMI Operator PanelDocument31 pages10 Introduction To PROFIBUS DP and The HMI Operator Panelhaftu gideyNo ratings yet

- 13 Functions and Function BlocksDocument25 pages13 Functions and Function Blockshaftu gideyNo ratings yet

- 14 Organization BlocksDocument15 pages14 Organization Blockshaftu gideyNo ratings yet

- Block Architecture and The LAD / STL / FBD Editor: OB1 FB FC FBDocument27 pagesBlock Architecture and The LAD / STL / FBD Editor: OB1 FB FC FBhaftu gideyNo ratings yet

- Hardware Configuration: Simatic S7Document32 pagesHardware Configuration: Simatic S7haftu gideyNo ratings yet

- 7 Binary OperationsDocument23 pages7 Binary Operationshaftu gideyNo ratings yet

- 3 Data Blocks PDF FreeDocument15 pages3 Data Blocks PDF Freehaftu gideyNo ratings yet

- 25 Wind Turbine Solution ENGDocument4 pages25 Wind Turbine Solution ENGhaftu gideyNo ratings yet

- 22 Automatic Star-Delta Circuit Solution ENGDocument3 pages22 Automatic Star-Delta Circuit Solution ENGhaftu gideyNo ratings yet

- 21 Lifting Platform Solution ENGDocument4 pages21 Lifting Platform Solution ENGhaftu gideyNo ratings yet

- 11 Stairway Lighting Switch Solution ENGDocument3 pages11 Stairway Lighting Switch Solution ENGhaftu gideyNo ratings yet

- 14 - Selection Circuit 1 of 3 - Solution - ENGDocument3 pages14 - Selection Circuit 1 of 3 - Solution - ENGhaftu gideyNo ratings yet

- Xr-100T-Cdte: AmptekDocument4 pagesXr-100T-Cdte: AmptekPrashant SharmaNo ratings yet

- Sirona DAC Autoclave - User ManualDocument74 pagesSirona DAC Autoclave - User Manualehab emamNo ratings yet

- System Settings Best Practices TerrainMapper V14.02.2020Document25 pagesSystem Settings Best Practices TerrainMapper V14.02.2020イルヴァン シャーロニNo ratings yet

- Electronics Engineering Board ChallengeDocument109 pagesElectronics Engineering Board ChallengeEarlJaysonAlvaranNo ratings yet

- 6 Nyquist DiagramsDocument8 pages6 Nyquist DiagramsulaganathanNo ratings yet

- 01 132kV FEEDER HALDIA DUPLEXDocument55 pages01 132kV FEEDER HALDIA DUPLEXhbj1990No ratings yet

- Semiconductor Technical Data: L SuffixDocument12 pagesSemiconductor Technical Data: L SuffixSuwandra I Gede PutuNo ratings yet

- Rel 003Document0 pagesRel 003Bence M ZoltanNo ratings yet

- Bs100 SpecDocument3 pagesBs100 SpecGus HdezNo ratings yet

- SB150 Terminal Layout PDFDocument4 pagesSB150 Terminal Layout PDFHiLman SyahirNo ratings yet

- Cisco Dpc2100 Docsis 2Document10 pagesCisco Dpc2100 Docsis 2manuel viloriaNo ratings yet

- Eng DS 1308242 T92 0421Document5 pagesEng DS 1308242 T92 0421David ProsperoNo ratings yet

- User+Manual XDL-S+series Eng V1.0 PDFDocument250 pagesUser+Manual XDL-S+series Eng V1.0 PDFkaahif nazirNo ratings yet

- DLL - Science 5 - Q3 - W7Document8 pagesDLL - Science 5 - Q3 - W7Lellaine G. Canieso LptNo ratings yet

- Batteries and Battery Cabinets 110 Ah Sealed Lead-Acid Batteries and Compatible Battery Cabinet (Without Charger)Document2 pagesBatteries and Battery Cabinets 110 Ah Sealed Lead-Acid Batteries and Compatible Battery Cabinet (Without Charger)Jhonny SilvaNo ratings yet

- Ic 7279Document10 pagesIc 7279Andi HarsonoNo ratings yet

- Panasonic Ey7440 Manual de Usuario Páginas 10 12Document3 pagesPanasonic Ey7440 Manual de Usuario Páginas 10 12Mr. Gonza M.No ratings yet

- Coluna Luminosa e SirenesDocument22 pagesColuna Luminosa e SirenesthiagobodosNo ratings yet

- Catalogue Havells Residential Solar Grid Tie InverterDocument8 pagesCatalogue Havells Residential Solar Grid Tie InverterAnkur SheelNo ratings yet

- Z8 EncoreDocument18 pagesZ8 EncoreEduardoNo ratings yet

- Identifying Motherboard Hardware Parts and Its FunctionDocument31 pagesIdentifying Motherboard Hardware Parts and Its FunctionNhil Cabillon Quieta100% (1)

- The G4Zu.... Spider Beam...... SkypperDocument1 pageThe G4Zu.... Spider Beam...... SkypperMarckos FrancoNo ratings yet

- Nsn-Flexi Multi Radio 10 Datasheet Online 01062011Document2 pagesNsn-Flexi Multi Radio 10 Datasheet Online 01062011marialuizakunertNo ratings yet

- HUAWEI Selfie Stick Quick Start Guide - (CF33,01, En)Document78 pagesHUAWEI Selfie Stick Quick Start Guide - (CF33,01, En)Ashhar SiddiquiNo ratings yet

- Resume: Syed Samee HussainDocument3 pagesResume: Syed Samee HussainSyedSameeNo ratings yet

- PB 01 Electrical Ayala RonnieDocument4 pagesPB 01 Electrical Ayala RonnieColeen IrisNo ratings yet

- Type 2 Sound Level Meter Kits: Choice of NIST Certified KitDocument1 pageType 2 Sound Level Meter Kits: Choice of NIST Certified KitJuan RamirezNo ratings yet

- Spare Bushing Work FilesDocument16 pagesSpare Bushing Work FilesBarry79xNo ratings yet

- Samsung 931bw Manual PDFDocument59 pagesSamsung 931bw Manual PDFFlorian MihailescuNo ratings yet