Professional Documents

Culture Documents

Pollution Consequences of Building Materials

Uploaded by

Mohammad Mostofa Kamal Kowshik0 ratings0% found this document useful (0 votes)

7 views12 pagesOriginal Title

pollution consequences of Building materials

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views12 pagesPollution Consequences of Building Materials

Uploaded by

Mohammad Mostofa Kamal KowshikCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 12

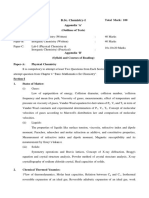

The pollution consequences of

energy use in building materials

Dr.Saiful Huque

Institute of Renewable Energy

University of Dhaka

Pollution consequence of material

production

Pollution arising from the production of

building materials arises at three levels. At the

local level (under 1 km), pollution is caused by

gases produced in the combustion of fuels,

causing health risks to workers and local

residents.

Pollution Consequence

At the regional level (up to 100 km) pollution

can cause climatic modification through

thermal effects or persistence of particles in

the atmosphere. These local and regional

effects can normally be controlled by reducing

the emission of the substances responsible,

and many governments have pollution control

or environmental protection regulations

setting required standards.

Pollution consequence

Some of the pollutants emitted in building

materials production processes also

contribute to pollution on a continental or

global scale. Sulphur dioxide resulting from

coal-burning, for example, can result in acid

rain causing acidification of lakes and

destruction of forests.

Consequence of pollution

potentially the most important effect is the

phenomenon of global warming caused by

increasing concentration of the so-called

greenhouse gases in the atmosphere.

Contributions to greenhouse warming by

various gases

• Gas Contribution to warming (percentage)

• Carbon dioxide 50

• Methane 19

• CFCs 17

• Tropospheric ozone 8

• Nitrous oxide 4

Energy intensity in building materials manufacture

• There are numerous studies estimating the energy

costs in the manufacture of various materials,

although many of them derive from the 1970s when

work on energy conservation began to betaken

seriously.

• Since in most cases these are a mixture of electrical

and thermal energy costs, the most suitable basis of

comparison is in terms of primary energy, which

includes energy used in the energy conversion and

supply system.

Energy usage in building material

The use of energy in quarrying operations and

the transporting of raw materials to the

factory also needs to be included. The range

of different estimates given in these studies is

the result in part of the different assumptions

made, but is also a reflection of the wide

range of different technologies in use for any

one material; this point will be discussed

further below.

Energy usage in building material

On the basis of the energy intensity, (the gross

energy requirement to manufacture unit

weight), building materials have been

classified into three categories: high, medium

and low-energy materials.

energy requirement of materials

High-energy materials are those with energy

intensities greater than 5 GJ/ton.

Medium-energy materials are those with

energy requirements between about 0.5 and 5

GJ/ton.

Low-energy materials are those with energy

requirements less than 0.5 GJ/ton.

Energy requirement of building material

Other ways of defining high, medium and low

are sometimes used, and it may be valuable

to define a class of very-high-energy materials

with energy intensities above 50 GJ/ton.

Thanks

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Invoice: Address: Bashundhara Area, Dhaka Mobile, Bkash, Nagad, Hotline: 01725091448Document2 pagesInvoice: Address: Bashundhara Area, Dhaka Mobile, Bkash, Nagad, Hotline: 01725091448Mohammad Mostofa Kamal KowshikNo ratings yet

- Plain Old Telephone Connectivity - Beginning of Local Telephone Network - Switching - Trunking - Creation of PSTN - Public SwitchedDocument22 pagesPlain Old Telephone Connectivity - Beginning of Local Telephone Network - Switching - Trunking - Creation of PSTN - Public SwitchedMohammad Mostofa Kamal KowshikNo ratings yet

- The Analog Telephone Voice ChannelDocument20 pagesThe Analog Telephone Voice ChannelMohammad Mostofa Kamal KowshikNo ratings yet

- Lec Tel Eng 7Document14 pagesLec Tel Eng 7Mohammad Mostofa Kamal KowshikNo ratings yet

- Metals Insulators and SemiconductorsDocument4 pagesMetals Insulators and SemiconductorsMohammad Mostofa Kamal KowshikNo ratings yet

- The Extrinsic SemiconductorDocument3 pagesThe Extrinsic SemiconductorMohammad Mostofa Kamal KowshikNo ratings yet

- 21 Based SyllabusDocument2 pages21 Based SyllabusMohammad Mostofa Kamal KowshikNo ratings yet

- Power ElectronicDocument36 pagesPower ElectronicMohammad Mostofa Kamal KowshikNo ratings yet

- Uncontrolled Rectifier: Single-Phase Half-Wave RectifierDocument8 pagesUncontrolled Rectifier: Single-Phase Half-Wave RectifierMohammad Mostofa Kamal KowshikNo ratings yet

- Assumption and ConclusionDocument1 pageAssumption and ConclusionMohammad Mostofa Kamal KowshikNo ratings yet

- Assumption and ConclusionDocument4 pagesAssumption and ConclusionMohammad Mostofa Kamal KowshikNo ratings yet

- Tonyplot QT: User'S ManualDocument126 pagesTonyplot QT: User'S ManualMohammad Mostofa Kamal KowshikNo ratings yet

- Ijas 8Document15 pagesIjas 8gopicryoNo ratings yet

- Wind EnergyDocument20 pagesWind EnergyMohammad Mostofa Kamal KowshikNo ratings yet

- Q Bank 1st - Sem 105 - MRET PMRET PDFDocument3 pagesQ Bank 1st - Sem 105 - MRET PMRET PDFMohammad Mostofa Kamal KowshikNo ratings yet

- Motors and GeneratorsDocument29 pagesMotors and GeneratorsAnonymous JamqEgqqh1No ratings yet

- EEE 437: Telecommunications Engineering: Prof. Kazi Mohiuddin Ahmed Fall Semester, 2016Document39 pagesEEE 437: Telecommunications Engineering: Prof. Kazi Mohiuddin Ahmed Fall Semester, 2016Mohammad Mostofa Kamal KowshikNo ratings yet

- Acyclic MachinesDocument9 pagesAcyclic MachinesMohammad Mostofa Kamal KowshikNo ratings yet

- Exp 01Document6 pagesExp 01Mohammad Mostofa Kamal KowshikNo ratings yet

- Application of PiezoelectricityDocument30 pagesApplication of PiezoelectricityMohammad Mostofa Kamal KowshikNo ratings yet

- Report-Major Satellite Communications SystemDocument36 pagesReport-Major Satellite Communications SystemMohammad Mostofa Kamal KowshikNo ratings yet

- Step by StepDocument18 pagesStep by StepAncil CleetusNo ratings yet

- Step by StepDocument18 pagesStep by StepAncil CleetusNo ratings yet

- Questions AnswersDocument2 pagesQuestions AnswersMohammad Mostofa Kamal KowshikNo ratings yet

- Questions AnswersDocument2 pagesQuestions AnswersMohammad Mostofa Kamal KowshikNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Satmagan Description and II Info Oct 2005Document7 pagesSatmagan Description and II Info Oct 2005Ingridh D Quispe ChuanNo ratings yet

- Revista PTQ Refineria-PetroquimicaDocument132 pagesRevista PTQ Refineria-PetroquimicaElimar RojasNo ratings yet

- Cblm-Smaw-Nc IiDocument80 pagesCblm-Smaw-Nc IiERIC NARAGANo ratings yet

- Cambridge O Level: Physics 5054/11Document20 pagesCambridge O Level: Physics 5054/11iman jamilNo ratings yet

- Supplemental Guidance For The Determination of Biochemical Oxygen Demand (BODs) and Carbonaceous BOD (CBODs) in Water and Wastewater (PDFDrive)Document62 pagesSupplemental Guidance For The Determination of Biochemical Oxygen Demand (BODs) and Carbonaceous BOD (CBODs) in Water and Wastewater (PDFDrive)Thoriq RamadhanNo ratings yet

- Worksheet 3: Von Mises Practice Problems: X y XyDocument6 pagesWorksheet 3: Von Mises Practice Problems: X y XyMouad Thf100% (1)

- Science of The Total EnvironmentDocument11 pagesScience of The Total EnvironmentfranklinNo ratings yet

- Copper Alloy Continuous Castings: Standard Specification ForDocument9 pagesCopper Alloy Continuous Castings: Standard Specification ForRed RedNo ratings yet

- Export RoHS 20210115 18504050Document2 pagesExport RoHS 20210115 18504050DzeminSinNo ratings yet

- Synthesis of CamphorDocument1 pageSynthesis of CamphorangelofgloryNo ratings yet

- Ann Occup Hyg 2005 Hedmer 629 37Document9 pagesAnn Occup Hyg 2005 Hedmer 629 37Athirah BidinNo ratings yet

- Dental Cements fiNALDocument50 pagesDental Cements fiNALJyoti TripathiNo ratings yet

- Chemistry Total Mark: 100 Appendix A' (Outlines of Tests)Document8 pagesChemistry Total Mark: 100 Appendix A' (Outlines of Tests)Iqra AfzalNo ratings yet

- Brochure Rilsan-PA11 2005Document32 pagesBrochure Rilsan-PA11 2005idleffarzadsNo ratings yet

- Flash TanksDocument3 pagesFlash TanksnincitoNo ratings yet

- Sicilian Lemon OilDocument12 pagesSicilian Lemon OilbabithyNo ratings yet

- Industrial Microbiology and BiotechnologyDocument36 pagesIndustrial Microbiology and BiotechnologyMyra Wardati SNo ratings yet

- Biological Treatment of Palm Oil Mill Effluent (Pome) Using An Up-Flow Anaerobic SludgeDocument53 pagesBiological Treatment of Palm Oil Mill Effluent (Pome) Using An Up-Flow Anaerobic SludgeJim ChongNo ratings yet

- Virtual Field Trip 1Document1 pageVirtual Field Trip 1nicoNo ratings yet

- Paths To Low-Cost Hydrogen Energy at A Scale For TDocument22 pagesPaths To Low-Cost Hydrogen Energy at A Scale For Trgh19No ratings yet

- BearingsDocument4 pagesBearingsPraveen Kumar100% (1)

- Preservation of Specimens ObjectivesDocument3 pagesPreservation of Specimens ObjectivesKlenn OrtezaNo ratings yet

- Rene 41Document66 pagesRene 41sunsirNo ratings yet

- Method Statement - Chemical CleaningDocument12 pagesMethod Statement - Chemical Cleaningdadz mingiNo ratings yet

- Giw Corporate Brochure DataDocument7 pagesGiw Corporate Brochure DataALAAN89No ratings yet

- Peter Thompson-Design More Effective Sessions With New Interval TrainingDocument10 pagesPeter Thompson-Design More Effective Sessions With New Interval TrainingChris NickinsonNo ratings yet

- Cylone - Lab Report - FinalizeDocument19 pagesCylone - Lab Report - FinalizeSiti Khairunnur LaderlahNo ratings yet

- Long-Term Aerobic Granular Sludge Stability Through Anaerobic Slow FeedingDocument12 pagesLong-Term Aerobic Granular Sludge Stability Through Anaerobic Slow Feedingsamuel campos carvalhoNo ratings yet

- Influence of Different Inducers On Ligninolytic Enzyme ActivitiesDocument7 pagesInfluence of Different Inducers On Ligninolytic Enzyme ActivitiesAlina CoralinaNo ratings yet

- Astm A239Document6 pagesAstm A239CeliaNo ratings yet