100% found this document useful (4 votes)

5K views56 pagesHVAC System in 5 Star Hotels

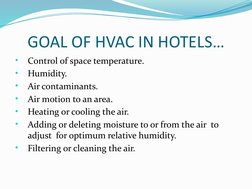

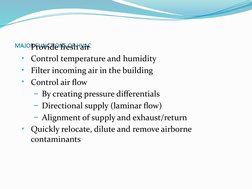

An HVAC system in a large luxury hotel with 3000 rooms requires huge mechanical, electrical and plumbing equipment to treat the temperature across the entire building. On average, a five-star hotel consumes 8.8 million kWh of energy annually for HVAC, which accounts for up to 18% of the hotel's revenue and results in annual electricity bills of around 90 lakhs. The HVAC system aims to control temperature, humidity, air quality and airflow. Different areas of the hotel such as guest rooms, lobbies, restaurants and bars require specialized HVAC designs and equipment to meet their unique ventilation and indoor air quality needs.

Uploaded by

vnitceCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (4 votes)

5K views56 pagesHVAC System in 5 Star Hotels

An HVAC system in a large luxury hotel with 3000 rooms requires huge mechanical, electrical and plumbing equipment to treat the temperature across the entire building. On average, a five-star hotel consumes 8.8 million kWh of energy annually for HVAC, which accounts for up to 18% of the hotel's revenue and results in annual electricity bills of around 90 lakhs. The HVAC system aims to control temperature, humidity, air quality and airflow. Different areas of the hotel such as guest rooms, lobbies, restaurants and bars require specialized HVAC designs and equipment to meet their unique ventilation and indoor air quality needs.

Uploaded by

vnitceCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd