Professional Documents

Culture Documents

Pressure Measuring Instruments

Pressure Measuring Instruments

Uploaded by

Usman Baloch0 ratings0% found this document useful (0 votes)

14 views13 pages Here are some potential replacement instruments for the manifold gauge:

- Digital manifold gauge sets that can read multiple refrigerants electronically instead of analog gauges. These tend to be more accurate and provide additional diagnostic data.

- Bluetooth manifold gauges that connect to smartphone apps for remote monitoring. This allows viewing pressures away from the vehicle.

- Manifold gauge consoles that integrate vacuum pumps and refrigerant recovery/recycling for more complete AC system servicing.

- Higher end brand name gauges like Fieldpiece or Testo that are known for durability and precision.

- Direct OEM replacements like the one listed that are identical to the original for simple swaps and compatibility.

In summary,

Original Description:

Pressure measuring instrument project

Original Title

PRESSURE MEASURING INSTRUMENTS

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document Here are some potential replacement instruments for the manifold gauge:

- Digital manifold gauge sets that can read multiple refrigerants electronically instead of analog gauges. These tend to be more accurate and provide additional diagnostic data.

- Bluetooth manifold gauges that connect to smartphone apps for remote monitoring. This allows viewing pressures away from the vehicle.

- Manifold gauge consoles that integrate vacuum pumps and refrigerant recovery/recycling for more complete AC system servicing.

- Higher end brand name gauges like Fieldpiece or Testo that are known for durability and precision.

- Direct OEM replacements like the one listed that are identical to the original for simple swaps and compatibility.

In summary,

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views13 pagesPressure Measuring Instruments

Pressure Measuring Instruments

Uploaded by

Usman Baloch Here are some potential replacement instruments for the manifold gauge:

- Digital manifold gauge sets that can read multiple refrigerants electronically instead of analog gauges. These tend to be more accurate and provide additional diagnostic data.

- Bluetooth manifold gauges that connect to smartphone apps for remote monitoring. This allows viewing pressures away from the vehicle.

- Manifold gauge consoles that integrate vacuum pumps and refrigerant recovery/recycling for more complete AC system servicing.

- Higher end brand name gauges like Fieldpiece or Testo that are known for durability and precision.

- Direct OEM replacements like the one listed that are identical to the original for simple swaps and compatibility.

In summary,

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 13

PRESSURE MEASURING INSTRUMENTS

(1): AUTOMOTIVE AIR CONDITIONING MANIFOLD GUAGE SET.

(2): INFLATOR PUMP

INTRODUCTION TO MANI FOLD GUAGE

•These important tools are used to check

the pressure of gases and liquids in a

heating or cooling system MANIFOLD

MANIFOLDPRESSURE

PRESSUREGUAGE

GUAGE

•A manifold gauge is a pressure-checking

system. They are one of the most

basic HVAC tools and can be used as both

a diagnostic and service tool. ROTHENBERGER

ROTHENBERGERPLASTIC

PLASTICMANIFOLD

MANIFOLDGUAGE

GUAGE

•In diagnostics, a manifold gauge tells an

HVAC technician if the system is operating

correctly, or if there is a problem within MANIFOLD

MANIFOLDPRESSURE

PRESSUREGUAGE

GUAGEVALVE

VALVEFOR

FORGAS

GAS

the system that needs to be addressed

•When used as a service tool, a manifold

gauge can be used to release moisture and

sludge, and remove contaminated DIGITAL

DIGITALMANIFOLD

MANIFOLDGUAGE

GUAGEFOR

FORHVAC

HVACSYSTEM

SYSTEM

refrigerants from the system

PICTURE OF INSTRUMENT

What Is a Manifold Gauge Set Used For?

Manifold

Manifoldgauge

gaugesets

setscan

canbe

beused

usedinin

the

thefollowing

followingways:

ways:

Checking

Checkingpressure

pressureininAC

AClines

lines

Determining

Determiningififthere’s

there’saaleak

leak

Manifold gauges are used to monitor heating or

cooling systems, specifically the pressure of

Adding

Addingsmall

smallamounts

amountsof of

refrigerants.These tools are used to control the refrigerants

refrigerants

flow of pressure or gas. Recharging

Recharging

HVAC gauges can either be small handheld Troubleshooting

Troubleshooting

devicesor bigger machines used in a Refrigerant

Refrigerantevacuation

evacuation

professional HVAC shop. Repairing

RepairingACACand

andHVAC

HVACsystems

systems

Most gauges can be used to measure any

refrigerant pressure, but each gauge may vary

in function and specifics. A manifold gauge

must match the refrigerant used in the HVAC

system. Every heating or cooling system will

have a stamp showing what refrigerant is used.

Some gauge sets can read multiple refrigerants.

You will want to make sure you are using the

right gauge for the right refrigerant reading.

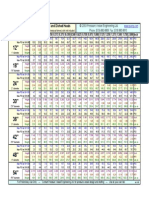

Manifold Gauge Parts

The basic parts of a standard manifold

gauge include:

While manifold gauges will differ slightly Low-pressure valve

among manufacturers most manifold

High-pressure valve

gauges have the same basic parts,

Low-pressure gauge (blue)

consisting of a high-pressure valve (red) and

a low-pressure valve (blue). Attached to High Pressure Gauge (red)

these valves are three hoses: a blue hose Low-pressure hose (blue)

connected to the low pressure valve, a red High-pressure hose (red)

hose connected to the high pressure valve Center hose (yellow)

and a yellow hose in the middle which can Center piece/manifold

be directed to either valve.

The center unit where everything is

attached together is called the manifold,

which is why this tool is called a manifold

gauge.

Manifold gauge sets can be either analog or

digital, and some may have additional

valves or functions depending on the brand

inclusions and other considerations.

PROCEDURE FOR AC GAS FILLING

AC gas is actually an easy job with the right tools and safety gear

First, on the air conditioner locate the suction line(low side) and the discharge line (high

side). These are located behind a window AC and in a split AC in the outdoor unit The suction

line is located above the discharge line and is cool the touch. While the discharge line is warm

to the touch. The suction line is used for recharging gas into the AC .inlet lines for ac gas filling

Unscrew the bolt of the suction line as shown below.

Loosen the screw inside with a Torx hex key(as shown in the picture below). This screw acts

as a valve, it won’t let refrigerant flow in or out till it is closed.

Thus, loosening this screw is important for filling AC gas.unscrewing bolt for ac gas

refillingThen remove the bolt on the left and connect the blue hose of the AC manifold gauge

to this port.

Connect the yellow hose to the vacuum pump. Remove all the air from the system. This step

is very important because any moisture inside the compressor will damage it.ac manifold

gauge for gas refilling Now, make sure all the valves of the AC manifold gauge are closed.

Then, connect the yellow hose to the refrigerant tank. Before opening the tank knob, loosen

the yellow hose slightly at the manifold end.

Then open the cylinder knob for 1 second and close it. This will remove all the air from inside

the pipes. Now, again tighten the yellow hose.Now, open the low side knob of the manifold for

3-4 seconds and close it.

Then turn ON the AC and wait till the compressor kicks in.Once the compressor starts, again

open the low side valve of the manifold. Keep the valve opened for 4 seconds and close it for 2

seconds. Note where the pressure settles on the gauge once the valve is closed. Keep opening

and closing the valve till the pressure settles between 60-70 PSI.

Note: The AC refrigerant gas is filled in small amounts at a time because releasing all the gas

at once will damage the compressor.After reaching the 60-70 PSI range,Close the manifold

valveClose the refrigerant tank knobUnscrew the blue hose from the suction lineUnscrew the

yellow hose from the refrigerant tank

Can we replace this instrument with

another instrument? this gauge is an essential part of automotive air conditioner

repair, allowing for accurate diagnostics and monitoring of AC car

refrigerant and the AC system. High pressure gauges work with

OEMTOOLS 24530 Replacement Gauge High low pressure AC gauges in an AC recharge kit to verify the integrity

Side for A/C Manifold, Air Pressure Gauge for of the system and diagnose potential leaking. This AC pressure

gauge comes with a front facing calibration screw so you can

Cars Using R134a Refrigerant, Compatible make sure yourself that you are getting the most accurate

24527 readings possible on your OEM TOOLS R134a manifold gauge set.

Details If your R134 manifold gauge set suffered a drop or other damage,

this replacement high pressure gauge can restore your AC tools to

BrandOEMTOOLSMaterialBlendItem its normal working state. It features 1/8" NPTF Male Threads and

Dimensions LxWxH4.3 x 2.9 x 1.4 reads 0-500 PSI, 0-34 BAR. The R134a measurement readings are

inchesItem Weight0.05 Pounds compatible with the OEMTOOLS 24527 R134a Extruded

Aluminum A/C Manifold Gauge and Hose Set and other

automotive manifold gauges.

Description:

Automotive air conditioning repairs can be

expensive, and when the brave home mechanic takes on

car AC maintenance, an A/C manifold gauge set is

necessary to do the job right. When something goes wrong

with the high pressure side gauge of an AC manifold, one

might be tempted to buy an entirely new manifold.

Alternatively, you could have the cost savings and personal

satisfaction of getting the OEMTOOLS 24530 Replacement

Gauge High Side for A/C Manifold and fixing it yourself.

Don't let a busted air pressure gauge for car repairs prevent

you from properly replacing an AC compressor. As a

replacement part of an R134a gauge set, it serves as the

high pressure side on R134 gauges. With the other air

pressure accessories in an R134a AC gauge set,

INFLATOR PUMP

PUMPS: A pump is a device that moves fluids (liquids or

gases), or sometimes slurries, by mechanical action, typically

converted from electrical energy into hydraulic energy. Pumps

can be classified into three major groups according to the

method they use to move the fluid: direct lift, displacement,

and gravity pumps.

INFLATOR :A tire inflator is a specific type of air compressor

that is specialized for tires. As with air compressors, tire

inflators function by converting electric energy into potential

energy which is then stored as pressurized air. This pressurized

gas means that there is no longer a need for the strenuous

pumping of the manual tire inflators of the past

WORKING OF INFLATOR PUMP

These pumps usually attach with an automatic on/off switch and a pressure gauge (manometer).

The manometer assists in measuring the pressure inside the chamber and provides a feedback

indication to the control device. After reaching the desired pressure conditions, the feedback

signal stops the air pump by the controller.

1) Type of Location:Firstly, you need to decide either you want to use an automatic driven or a

manually driven pump. Manual-driven pumps have a low cost, but they need a person for

operation. But automatic pumps have a high price, but they don’t require a person for their

operation. The automatic pump can be operated for a long time without any manual work.

2) 2) Power Requirements:You need to consider the power requirements of your pump. If the

pumps fix in one place, it means that they are electrically operated. The portable pump has a

battery that has a rated voltage range of 12 volts or 24 volts. Battery-operated pumps must

be properly powered to ensure long life and to finish the pumping operation.

3) 3) Nozzle:The pump comes with an interchangeable pipe that can replace with a nozzle

according to our requirements. Some types of pumps may have fixed nozzles that can’t

replace. It would be best if you chose the right pump nozzle that accessories to your

requirements

4) .4) Flow Rate:You need to choose a pump that will provide the flow rate according to your

requirements. High flow rate pumps are required for applications such as blow-up parachute

balloons, inflate tires, and perform other high-speed operations. The flow rates are

determined in gallons/minute (GPM).

PICTURES OF INSTRUMENT ON

SITE

HOW TO USE TIRE INFLATOR

Once you have the tire inflator set up, take off the

valve stem caps and ensure to keep them in a safe

space. They are small and easily lost so keep track!

Connect the air pressure hose to the tire’s air

valve system.

Turn on the tire inflator and wait until the desired

pressure is reached. Depending on how much

inflation is needed you should be able to see it

working.

If the tire is near flat or has lost a large

percentage of the PSI you should see the inflation

quickly, however if it is merely the monthly refill of

1 or so PSI,

you might not see a difference. If the tire is not

inflating check for punctures as you would need

professional assistance to help solve that problem.

Once the correct PSI is reached reattach the

valve stem caps and you are ready to drive safely.

Tire inflators are the perfect tool to help you

maintain your car, have great fuel efficiency, and

ensure that you can be safe on the go.

A tire inflator in your car will give you peace of

mind on long road trips and give you the freedom

to take care of your car yourself

WE CAN REPLACE TIRE INFLATOR BY AIR

COMPRESSOR INSTRUMENT

An air compressor is a pneumatic device that

converts power (using an electric motor, diesel

or gasoline engine, etc.) into potential energy

stored in pressurized air go (i.e., compressed

air). By one of several methods, an air

compressor forces more and more air into a

storage tank, increasing the pressure. When the

tank's pressure reaches its engineered upper

limit, the air compressor shuts off. The

compressed air, then, is held in the tank until

called into use. The energy contained in the

compressed air can be used for a variety of

applications, utilizing the kinetic energy of the

air as it is released and the tank depressurizes.

When tank pressure reaches its lower limit, the

air compressor turns on again and re-

pressurizes the tank. An air compressor must be

differentiated from a pump because it works for

any gas/air, while pumps work on a liquid .

Arrange itYour Way

With custom layouts you design

your own slide arrangements. You

can create new kinds of documents

with PowerPoint. Easily create

everything from business pitchbooks

to family photo albums.

You might also like

- Air Conditioning Gauges - How Does HVAC Gauges WorksDocument4 pagesAir Conditioning Gauges - How Does HVAC Gauges WorksIsramanNo ratings yet

- CMX Puesta en Marcha y Trouble ShootingDocument15 pagesCMX Puesta en Marcha y Trouble ShootingMauricio Ariel H. OrellanaNo ratings yet

- Modification of BB1 Pump Vibration To Meet API-610Document18 pagesModification of BB1 Pump Vibration To Meet API-610Shreenidhi100% (1)

- Finding Problems in HVAC R Refrigeration CycleDocument4 pagesFinding Problems in HVAC R Refrigeration CyclejotalopecincoNo ratings yet

- Stepless Clearance Pocket: Oil & GasDocument4 pagesStepless Clearance Pocket: Oil & Gasshank100No ratings yet

- Design Two-Phase Separators Within The Right LimitsDocument8 pagesDesign Two-Phase Separators Within The Right Limitschipiloo100% (1)

- Sampling ProbeDocument5 pagesSampling Probetriminhdang_phar6701No ratings yet

- Fundamentals of Compressed Air and Reciprocating CompressorsDocument115 pagesFundamentals of Compressed Air and Reciprocating CompressorsAmit Kumar Jaiswal100% (1)

- T&C Method StatementDocument16 pagesT&C Method StatementMohd Salleh Zainal79% (24)

- Hydraulic&PneumaticsDocument217 pagesHydraulic&PneumaticsRickey PandeyNo ratings yet

- Operation and MaintenanceDocument76 pagesOperation and Maintenancesaie_1No ratings yet

- Piping GuideDocument10 pagesPiping GuidezenpraveenNo ratings yet

- Air Conditioning CH 21: Training Manual B767-3S2F Ata 21-00Document131 pagesAir Conditioning CH 21: Training Manual B767-3S2F Ata 21-00David OwenNo ratings yet

- Process Safety Analysis - Aspen HysysDocument51 pagesProcess Safety Analysis - Aspen HysysNadia BahloulNo ratings yet

- Mevira CROSS2014 PDFDocument516 pagesMevira CROSS2014 PDFFajar RofandiNo ratings yet

- Control & InstrumentationDocument80 pagesControl & InstrumentationDeep SYNo ratings yet

- Case Study Failure of Boiler Feed Water Pump-ADocument13 pagesCase Study Failure of Boiler Feed Water Pump-Akirany58No ratings yet

- Safe and Efficient Flare Gas RecoveryDocument10 pagesSafe and Efficient Flare Gas RecoveryMike PowerNo ratings yet

- MAN-BW L16-24 Project-Guide PDFDocument202 pagesMAN-BW L16-24 Project-Guide PDFJevgenij ChupinNo ratings yet

- Lab ReportDocument6 pagesLab Reportsanduni33% (3)

- Manual de PartesDocument340 pagesManual de PartesJuan RafaelNo ratings yet

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Document8 pagesLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255No ratings yet

- Typical Uses:: Gas ProcessingDocument4 pagesTypical Uses:: Gas ProcessingsanthoshnlNo ratings yet

- Surge Warning SystemDocument19 pagesSurge Warning SystemKajal PrajapatiNo ratings yet

- Cooling (2.4L)Document30 pagesCooling (2.4L)Ruhu royNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBChanNo ratings yet

- CFS PICV Brochure 16pp V2 LO-RES PDFDocument16 pagesCFS PICV Brochure 16pp V2 LO-RES PDFLeo_1982No ratings yet

- Flow Sensors PDFDocument44 pagesFlow Sensors PDFSilva NumaNo ratings yet

- 03 Measurement TechnologyDocument5 pages03 Measurement TechnologyVitor FreitasNo ratings yet

- Calibration Tools & SoftwareDocument9 pagesCalibration Tools & SoftwareJosé RodríguezNo ratings yet

- Reciprocating Compressor Suction and Discharge Valve MonitoringDocument6 pagesReciprocating Compressor Suction and Discharge Valve MonitoringqgfmNo ratings yet

- 4940 Calibration BrochureDocument9 pages4940 Calibration BrochureYusuff YuzuakkNo ratings yet

- Tubing Wallmaster Umac.002.0003.eDocument8 pagesTubing Wallmaster Umac.002.0003.eAbhijith S AnchanNo ratings yet

- Valves & Component RevisionDocument4 pagesValves & Component RevisionMarco RamosNo ratings yet

- DB Calibrator Microtrak OmnitrakDocument4 pagesDB Calibrator Microtrak OmnitrakKikie KieeNo ratings yet

- ARCA Fly ReglerInstr GBDocument6 pagesARCA Fly ReglerInstr GBavikbhaiNo ratings yet

- 4 - Test Console For Pneulatic De-Icer BondingDocument2 pages4 - Test Console For Pneulatic De-Icer BondingLuis Enrique La Font FrancoNo ratings yet

- Sitrans CV Ap01 Us 2016Document10 pagesSitrans CV Ap01 Us 2016muggle1357No ratings yet

- Hyundai Excel X2 1989-1998 Air Conditioning PDFDocument53 pagesHyundai Excel X2 1989-1998 Air Conditioning PDFAamir Nasir KhanNo ratings yet

- Brochure Oil Gas Flow Solutions For Fiscal Measurement Daniel en 44088Document5 pagesBrochure Oil Gas Flow Solutions For Fiscal Measurement Daniel en 44088josecordova2014No ratings yet

- Monitoring Strategy of LNG Reciprocating CompressorsDocument4 pagesMonitoring Strategy of LNG Reciprocating Compressorsalhumaid28No ratings yet

- 0246BDI-UK ORS Engineering-OSC SS R0 17Document1 page0246BDI-UK ORS Engineering-OSC SS R0 17li geneNo ratings yet

- Gascon Systems Auto Change-Over Manifold Maintenance InstructionsDocument11 pagesGascon Systems Auto Change-Over Manifold Maintenance InstructionsNasro JuvNo ratings yet

- Industrial Process - Rev1 - DigitalDocument4 pagesIndustrial Process - Rev1 - DigitalsrashmiiiscNo ratings yet

- Danfoss Dynamic Valve SizingDocument7 pagesDanfoss Dynamic Valve SizingShane ChagparNo ratings yet

- Effects of Non Standard Operating Conditions On The Accuracy of Orifice MetersDocument5 pagesEffects of Non Standard Operating Conditions On The Accuracy of Orifice MetersDaniel VictorNo ratings yet

- Flow Dampers & VAV System: Shaharin A. Sulaiman, UTPDocument20 pagesFlow Dampers & VAV System: Shaharin A. Sulaiman, UTPAlif AimanNo ratings yet

- DRUVA O&G - Hydraulic - RegulatorDocument12 pagesDRUVA O&G - Hydraulic - RegulatormauroNo ratings yet

- Quadruplex Systems 3 PDFDocument2 pagesQuadruplex Systems 3 PDFEng.Gihad EladlNo ratings yet

- Plant Design and Economics: LogotypeDocument6 pagesPlant Design and Economics: LogotypeM VenkatNo ratings yet

- Turbomachinery Automation Anti Surge Control For All Axial and Centrifugal Compressors EngDocument6 pagesTurbomachinery Automation Anti Surge Control For All Axial and Centrifugal Compressors EngVahid MostajerNo ratings yet

- Tescom-Topworx Flow MeasurementDocument18 pagesTescom-Topworx Flow MeasurementGrupoMecatrónicaNo ratings yet

- Oil & Petrochemical Brochure - 2016Document2 pagesOil & Petrochemical Brochure - 2016santhoshnlNo ratings yet

- Regulators For Gas SupplyDocument36 pagesRegulators For Gas Supplyimm2cuteNo ratings yet

- Type of ControllerDocument2 pagesType of ControllerDivyashini MohanNo ratings yet

- Variable Speed Chillers With PicvDocument1 pageVariable Speed Chillers With PicvPradeep SukumaranNo ratings yet

- Nirmal Products: Natural Gas Pre-Heaters Are Classified As Under: Direct Type Pre-HeatersDocument8 pagesNirmal Products: Natural Gas Pre-Heaters Are Classified As Under: Direct Type Pre-HeatersConcept -CEPLNo ratings yet

- The Babcock and Wilcox Company Section VDocument97 pagesThe Babcock and Wilcox Company Section VAmarsen ShrivastavaNo ratings yet

- Samson: Plant Design and Control Valve Selection Under Increasing Cost and Time Pressure Part I and Part IIDocument16 pagesSamson: Plant Design and Control Valve Selection Under Increasing Cost and Time Pressure Part I and Part IIDiego Martínez FernándezNo ratings yet

- Oil-Less Scroll Air Compressor System With Desiccant Air TreatmentDocument2 pagesOil-Less Scroll Air Compressor System With Desiccant Air TreatmentroyvindasNo ratings yet

- PF - SCD - Scroll With Dessicant DryerDocument2 pagesPF - SCD - Scroll With Dessicant DryerEmanuel Naskosi Santiz AguilarNo ratings yet

- Book 1Document12 pagesBook 1Ravindra ChougaleNo ratings yet

- Liebherr A380 Air Management PosterDocument1 pageLiebherr A380 Air Management PosterSathiya SeelanNo ratings yet

- OJ Air Pressure GB 0422Document7 pagesOJ Air Pressure GB 0422Ronald FloresNo ratings yet

- PRO026 FloatTankGaugingDocument5 pagesPRO026 FloatTankGaugingNithin GNo ratings yet

- Be Productive: Automation Intelligence From Wellhead To DistributionDocument8 pagesBe Productive: Automation Intelligence From Wellhead To DistributionGibran TorresNo ratings yet

- Petrochemical Industry Calibration SolutionsDocument2 pagesPetrochemical Industry Calibration SolutionsAnonymous IXswcnWNo ratings yet

- A Novel Method of Using A Control Valve For Measurement and Control of Flow - Instrumentation and Measurement, IEEE Transactions OnDocument3 pagesA Novel Method of Using A Control Valve For Measurement and Control of Flow - Instrumentation and Measurement, IEEE Transactions OnBhuvanaNo ratings yet

- MAGNA3 Circulator Pump: Characteristic FeaturesDocument2 pagesMAGNA3 Circulator Pump: Characteristic FeaturesLe HieuNo ratings yet

- ASHRAE Guideline 36-2018-ASHRAE - Journal - Making - VAV - Great - AgainDocument6 pagesASHRAE Guideline 36-2018-ASHRAE - Journal - Making - VAV - Great - AgainSergio Motta GarciaNo ratings yet

- Lab Project # 1: Title: To Determine The Resultant of Force in EquilibriumDocument5 pagesLab Project # 1: Title: To Determine The Resultant of Force in EquilibriumUsman BalochNo ratings yet

- Lab ProjectDocument12 pagesLab ProjectUsman BalochNo ratings yet

- Civil Engineering Material (Cv-213) : Assignment ProjectDocument11 pagesCivil Engineering Material (Cv-213) : Assignment ProjectUsman BalochNo ratings yet

- Civil Engineering Material (Cv-213) : Assignment ProjectDocument11 pagesCivil Engineering Material (Cv-213) : Assignment ProjectUsman BalochNo ratings yet

- Flange Valves: Flange Mounted Pressure ControlsDocument64 pagesFlange Valves: Flange Mounted Pressure ControlsDanielEscobarMontecinosNo ratings yet

- Turbo Lux 3 Technical Data SheetDocument4 pagesTurbo Lux 3 Technical Data Sheetaashiq2006No ratings yet

- (2018) Final Exam +solutions PDFDocument23 pages(2018) Final Exam +solutions PDFTman LetswaloNo ratings yet

- Pressure SpecificationsDocument6 pagesPressure SpecificationsHamid EssarboutiNo ratings yet

- 48.01.SH.01.TP.004 Punch ListDocument6 pages48.01.SH.01.TP.004 Punch ListcgnanaponNo ratings yet

- Kompressor PanasonicDocument6 pagesKompressor PanasonicBudiJuwiNo ratings yet

- Hydraulic Training by AvinashDocument28 pagesHydraulic Training by Avinashpumba2011No ratings yet

- 49 ApuDocument200 pages49 ApuEduardo LunaNo ratings yet

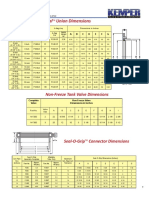

- Hammers and Seals Kemper PDFDocument1 pageHammers and Seals Kemper PDFmichNo ratings yet

- Control Valve Data SheetDocument1 pageControl Valve Data SheetKelly Perez LopezNo ratings yet

- Series PV: Axial Piston PumpsDocument14 pagesSeries PV: Axial Piston PumpspawaNo ratings yet

- Valve Test Control Sheet - 20200522Document5 pagesValve Test Control Sheet - 20200522Nhật HoàngNo ratings yet

- Spare Parts DC Pro XT V.en Rev.14Document31 pagesSpare Parts DC Pro XT V.en Rev.14serkan çakmakNo ratings yet

- S 2000 ASME Ratio Flanged and Dished HeadsDocument4 pagesS 2000 ASME Ratio Flanged and Dished Headsdzat_sudrazatNo ratings yet

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and PowertrainDocument12 pages004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and PowertrainhectorNo ratings yet

- Steel Pipe VesselDocument258 pagesSteel Pipe VesselmaubochNo ratings yet

- API 610 BB5 Barrel PumpDocument4 pagesAPI 610 BB5 Barrel Pumpcandra trisilawatiNo ratings yet

- Checking List & IndexDocument17 pagesChecking List & IndexJulian Ramon JrNo ratings yet

- VSH2 UnitsDocument20 pagesVSH2 UnitsHimanshu KesarwaniNo ratings yet