Professional Documents

Culture Documents

Pressure Specifications

Uploaded by

Hamid EssarboutiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Specifications

Uploaded by

Hamid EssarboutiCopyright:

Available Formats

SUPPLEMENTARY SERVICE INFORMATION (DISASSEMBLY & ASSEMBL...

0001-UP (MACHINE)(SEBC0601 - 00) - Structure de document

Arrêter SIS

Ecran précédent

Produit: EXCAVATOR

Modèle : 320B EXCAVATOR 1CS

Configuration: SUPPLEMENTARY SERVICE INFORMATION

(DISASSEMBLY & ASSEMBLY) F 1CS00001-UP (MACHINE)

Essai et réglage

320B Excavator Hydraulic System

Numéro d'imprimé -RENR3602-01 Date de publication -01/11/2004 Date de mise à jour -08/11/2004

i01007399

Pressure Specifications

SMCS - 5050

Specifications

Note: A New specification is the performance that can be expected for a new machine. A Rebuild specification is the

performance that can be expected after rebuilding the components of a system. Performance beyond Service Limit

specifications is an indication of these problems: improper adjustment, wear, damage of relief valves and damage of

pumps.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_pa...calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp (1 sur 6)17/03/2008 13:12:24

SUPPLEMENTARY SERVICE INFORMATION (DISASSEMBLY & ASSEMBL...0001-UP (MACHINE)(SEBC0601 - 00) - Structure de document

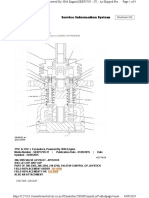

Illustration 1 g00340532

Relief valve locations

(A) Main

(B) Boom cylinder line (head end)

(C) Boom cylinder line (rod end)

(D) Stick cylinder line (head end)

(E) Stick cylinder line (rod end)

(F) Bucket cylinder line (head end)

(G) Bucket cylinder line (rod end)

(H) Swing (right)

(I) Swing (left)

(J) Left travel crossover relief valve for forward travel (upper valve)

(K) Left travel crossover relief valve for reverse travel (lower valve)

(L) Right travel crossover relief valve for forward travel (upper valve)

(M) Right travel crossover relief valve for reverse travel (lower valve)

(N) Pilot relief valve

(O) Main control valve

(P) Pilot manifold

(Q) Travel motor (right)

(R) Travel motor (left)

(S) Swing motor

Table 1

Specifications Torque for Locknut

Relief Valve

New Rebuild Service Limit

34300 ± 490 32340 to 34790

(A) Main relief valve 34300 ± 490 kPa 50 ± 10 N·m (37 ± 7

kPa (4950 ± 72 kPa (4700 to 5050

(4950 ± 72 psi) lb ft)

psi) psi)

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_pa...calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp (2 sur 6)17/03/2008 13:12:24

SUPPLEMENTARY SERVICE INFORMATION (DISASSEMBLY & ASSEMBL...0001-UP (MACHINE)(SEBC0601 - 00) - Structure de document

(B) Boom cylinder

line (head end)

(C) Boom cylinder

line (rod end)

(D) Stick cylinder line

(head end) 36800 ± 1470 33850 to 38270

36800 ± 1470 kPa 20 ± 2 N·m (14 ± 4 lb

kPa (5350 ± kPa (4920 to 5565

(E) Stick cylinder line (5350 ± 215 psi) ft)

215 psi) psi)

(rod end)

(F) Bucket cylinder

line (head end)

(G) Bucket cylinder

line (rod end)

(H) Swing relief

pressure (right) 24000 ± 980 22040 to 24980

24000 ± 980 kPa 160 ± 30 N·m (120 ±

kPa (3500 ± kPa (3200 to 3600

(I) Swing relief (3500 ± 140 psi) 22 lb ft)

140 psi) psi)

pressure (left)

(J) Left travel

crossover relief valve

(forward)

(K) Left travel

crossover relief valve

(reverse) 36800 ± 1470 33850 to 38270

36800 ± 1470 kPa 130 ± 13 N·m (95 ±

kPa (5350 ± kPa (4920 to 5565

(L) Right travel (5350 ± 215 psi) 10 lb ft)

215 psi) psi)

crossover relief valve

(forward)

(M) Right travel

crossover relief valve

(reverse)

(N) Pilot relief valve 4100 ± 200 kPa 4100 ± 200 kPa 4100 ± 200 kPa 16 ± 1 N·m (12 ± 1 lb

(595 ± 29 psi) (595 ± 29 psi) (595 ± 29 psi) ft)

Adjustment Procedures

Table 2

Required Tools

Part Number Description Qty

6V-2100 Multitach group 1

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_pa...calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp (3 sur 6)17/03/2008 13:12:24

SUPPLEMENTARY SERVICE INFORMATION (DISASSEMBLY & ASSEMBL...0001-UP (MACHINE)(SEBC0601 - 00) - Structure de document

6V-4161 Hydraulic testing group 1

8T-0470 Thermometer group 1

Table 3

Relief Valves Pressure change With One Turn Of Adjustment Screw

Main valves

14400 kPa (2100 psi)

Line relief valve

11000 kPa (1600 psi)

Swing relief valve

11200 kPa (1625 psi)

Travel crossover relief valve 3050 kPa (440 psi)

Pilot relief valve 690 kPa (100 psi)

Preparation For Relief Valve Adjustment

Illustration 2 g00542589

Pump compartment

(1) Pressure tap (power shift pressure)

(2) Pressure tap (front pump delivery pressure)

(3) Pressure tap (rear pump delivery pressure)

1. Position the machine on level ground.

2. Stop the engine.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_pa...calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp (4 sur 6)17/03/2008 13:12:24

SUPPLEMENTARY SERVICE INFORMATION (DISASSEMBLY & ASSEMBL...0001-UP (MACHINE)(SEBC0601 - 00) - Structure de document

3. Release the pressure in the hydraulic system. Refer to Testing And Adjusting, "Hydraulic System Pressure -

Release".

4. Connect a 60000 kPa (8700 psi) pressure gauge to pressure tap (2). Connect a 60000 kPa (8700 psi) pressure

gauge to pressure tap (3) .

5. Connect a 4000 kPa (580 psi) pressure gauge to pressure tap (1) .

6. Start the engine.

7. Increase the hydraulic oil temperature to 55° ± 5°C (131° ± 9°F).

8. Place the machine controls at the following settings: Power Mode, engine speed dial "10" and AEC switch

OFF.

Reference: Make reference to Testing And Adjusting, "Operational Checks" for engine rpm settings.

Note: Normal operations of the engine and pumps are necessary for the pressure adjustments. If the results of the

pressure adjustment are not correct, then the engine and the pump characteristic curve needs to be checked. Slow

output flow from the pump is an indication of air in the hydraulic system. Make sure that no air is present in the

hydraulic system. Refer to Testing And Adjusting, "Hydraulic System Pressure - Release".

Temporary Setting Of The Main Relief Valve

Note: A temporary setting of the main relief valve is required before any line relief valve can be adjusted.

Illustration 3 g00341013

Top of main control valve

(4) Adjustment screw

(5) Locknut

(6) Main relief valve

1. Open the bucket until the bucket cylinder rod is at the full retraction.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_pa...calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp (5 sur 6)17/03/2008 13:12:24

SUPPLEMENTARY SERVICE INFORMATION (DISASSEMBLY & ASSEMBL...0001-UP (MACHINE)(SEBC0601 - 00) - Structure de document

2. Be sure that the main relief valve pressure is set at 34300 ± 490 kPa (4975 ± 72 psi).

Note: Always make final pressure adjustments on pressure rise.

3. Loosen locknut (5). Turn the adjustment screw (4) clockwise for one half turn. Tighten locknut (5) .

Copyright 1993 - 2008 Caterpillar Inc. Mon Mar 17 13:12:09 UTC 2008

Tous droits réservés.

Réseau privé pour utilisateurs autorisés de SIS.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_pa...calledpage=/sisweb/sisweb/techdoc/techdoc_print_page.jsp (6 sur 6)17/03/2008 13:12:24

You might also like

- C11 y C13 Caterpillar EspecificacionesDocument48 pagesC11 y C13 Caterpillar EspecificacionesIsrael Garcia100% (12)

- Control Valve D8R..Document2 pagesControl Valve D8R..SyahdiNo ratings yet

- Brake System (KENR8395-13)Document29 pagesBrake System (KENR8395-13)Anderson Oliveira SilvaNo ratings yet

- D9R Tractor With 3408E Engine Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagesD9R Tractor With 3408E Engine Electrical System: Electrical Schematic Symbols and Definitionsssinokrot100% (2)

- 3408C & 3412C Electrical System Marine Auxillary Generator SetDocument2 pages3408C & 3412C Electrical System Marine Auxillary Generator SetHamid Essarbouti100% (1)

- 3408C & 3412C Electrical System Marine Auxillary Generator SetDocument2 pages3408C & 3412C Electrical System Marine Auxillary Generator SetHamid Essarbouti100% (1)

- 320D-336D Excavator Elec. Control SysDocument38 pages320D-336D Excavator Elec. Control Sysjlrodriguezma91% (46)

- Hydraulic SymbolsDocument5 pagesHydraulic SymbolsBharathprabhu100% (4)

- Heat load calculation for proposed MV and control room buildingsDocument24 pagesHeat load calculation for proposed MV and control room buildingspsn_kylmNo ratings yet

- D PWT D6riii PDFDocument2 pagesD PWT D6riii PDFDennis Olaya100% (1)

- Injector Solenoid Circuit - Test: TroubleshootingDocument13 pagesInjector Solenoid Circuit - Test: TroubleshootingGolbert GolbiNo ratings yet

- Electrico 938GDocument4 pagesElectrico 938Grjan7pe100% (6)

- 14M Hydraulic SchematicDocument2 pages14M Hydraulic SchematicKhaled Kamel67% (3)

- 14M Hydraulic SchematicDocument2 pages14M Hydraulic SchematicKhaled Kamel67% (3)

- Diagrama Hidraulico D11R CATERPILLAR 1Document2 pagesDiagrama Hidraulico D11R CATERPILLAR 1julio cesar100% (7)

- Troubleshooting Komatsu ExcavatorDocument5 pagesTroubleshooting Komatsu ExcavatorLatif Sukmawan93% (30)

- Piston Pump (Brake, Hydraulic Fan)Document7 pagesPiston Pump (Brake, Hydraulic Fan)EVER DAVID SAAVEDRA HUAYHUANo ratings yet

- Entire Group Ref. Note Part No. Part Name 292-9964-PRODUCT Pump Gp-GearDocument3 pagesEntire Group Ref. Note Part No. Part Name 292-9964-PRODUCT Pump Gp-GearLenin GullapalliNo ratings yet

- 12H - Specs0Document5 pages12H - Specs0Marco OlivettoNo ratings yet

- 320D Excavator Hydraulic System SpecsDocument4 pages320D Excavator Hydraulic System SpecsKJDNKJZEFNo ratings yet

- Electronic Control System ComponentsDocument4 pagesElectronic Control System ComponentsThein Htoon lwinNo ratings yet

- Aspen SimulationDocument25 pagesAspen SimulationDineshNo ratings yet

- Engine Performance - Test - Engine Speed: Testing and AdjustingDocument2 pagesEngine Performance - Test - Engine Speed: Testing and AdjustingDANIEL VARGAS RODRIGUEZ100% (1)

- Camion 789DDocument14 pagesCamion 789Ddinny blanco rojasNo ratings yet

- Camion 789DDocument14 pagesCamion 789Ddinny blanco rojasNo ratings yet

- 324D Hyd PDFDocument11 pages324D Hyd PDFdemetrio castillo obleaNo ratings yet

- 3412 Peec Emcp2Document4 pages3412 Peec Emcp2Pedro Zafra100% (1)

- 318B PumpDocument15 pages318B Pumpsamir kadriNo ratings yet

- Oilphase: Single - Phase Sample Bottle (SSB)Document23 pagesOilphase: Single - Phase Sample Bottle (SSB)farajNo ratings yet

- 416C Backhoe Loader 1WR08116-10736 (MACHINE) POWERED BY 3054 Engine (SEBP2888 - 47) - Documentación PDFDocument10 pages416C Backhoe Loader 1WR08116-10736 (MACHINE) POWERED BY 3054 Engine (SEBP2888 - 47) - Documentación PDFFelix Tolentino ANo ratings yet

- Hydraulic Excavator 325dl PDFDocument32 pagesHydraulic Excavator 325dl PDFacarisimovic100% (1)

- Skid Vibration ProblemsDocument16 pagesSkid Vibration ProblemsarturomNo ratings yet

- Process Thermodynamic Steam Trap PDFDocument9 pagesProcess Thermodynamic Steam Trap PDFhirenkumar patelNo ratings yet

- Process For Setting Up The Work Tool: Testing and AdjustingDocument31 pagesProcess For Setting Up The Work Tool: Testing and AdjustingMbahdiro KolenxNo ratings yet

- CAT 789D Truck Cooling SystemDocument2 pagesCAT 789D Truck Cooling SystemAbdul KhaliqNo ratings yet

- CAT 789D Truck Cooling SystemDocument2 pagesCAT 789D Truck Cooling SystemAbdul KhaliqNo ratings yet

- CAT 789D Truck Cooling SystemDocument2 pagesCAT 789D Truck Cooling SystemAbdul KhaliqNo ratings yet

- Ata CodesDocument10 pagesAta CodesIvo SilvaNo ratings yet

- Manual de Partes Motosoldadora Lincoln SAE 400Document60 pagesManual de Partes Motosoldadora Lincoln SAE 400Percy CárdenasNo ratings yet

- Code Defaut Pc200 Komatsu-ExcavatorDocument5 pagesCode Defaut Pc200 Komatsu-ExcavatorHamid EssarboutiNo ratings yet

- CS54 Cs533e en PDFDocument16 pagesCS54 Cs533e en PDFXavier Millan100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document8 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Hamid EssarboutiNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document8 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Hamid EssarboutiNo ratings yet

- IC December 2016Document60 pagesIC December 2016edsonbdasilvajuniorNo ratings yet

- Schematic Electric System Cat D8T Vol1Document33 pagesSchematic Electric System Cat D8T Vol1Andaru Gunawan100% (1)

- Performance Test D8R (9EM)Document6 pagesPerformance Test D8R (9EM)ahmad ruyaniNo ratings yet

- Fuels: Classification and Calorific ValueDocument79 pagesFuels: Classification and Calorific ValueRahul Reddy100% (1)

- Overiew of Comb Cycle Rev 6.0 - Part 1Document73 pagesOveriew of Comb Cycle Rev 6.0 - Part 1SamNo ratings yet

- Drum and Blade Attachment Under Platform: CS56B, CP56B, CS68B, and CP68B Hydraulic System Vibratory Soil CompactorsDocument2 pagesDrum and Blade Attachment Under Platform: CS56B, CP56B, CS68B, and CP68B Hydraulic System Vibratory Soil CompactorsAndresCorreaNo ratings yet

- Renr3646renr3646-03 - Sis 320c Akh Hidraulic PumpDocument8 pagesRenr3646renr3646-03 - Sis 320c Akh Hidraulic PumpGabriely MuriloNo ratings yet

- Abu Dhabi Municipallity Building Code Guidelines 2011Document348 pagesAbu Dhabi Municipallity Building Code Guidelines 2011rshyams100% (1)

- RENR9980RENR9980 07 SIS - DesbloqueadoDocument13 pagesRENR9980RENR9980 07 SIS - DesbloqueadoArturo AndNo ratings yet

- 345C Excavator Electrical System: Area ADocument4 pages345C Excavator Electrical System: Area Acandido vargas gutierrezNo ratings yet

- Excavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Document17 pagesExcavadora Hidraulica 345b (Relief Valve Pruebas - y - Ajustes)Maquinaria Pesada ServisNo ratings yet

- As 2660-1991 Hose and Hose Assemblies - Air Water - For Underground Coal MinesDocument5 pagesAs 2660-1991 Hose and Hose Assemblies - Air Water - For Underground Coal MinesSAI Global - APACNo ratings yet

- Cat 307D Pilot Pump TestDocument5 pagesCat 307D Pilot Pump TestkahandawalaNo ratings yet

- Plano de La Excavadora 324DDocument12 pagesPlano de La Excavadora 324Dedwin100% (1)

- 009.2 CAT-6040 FS-AttachmentDocument27 pages009.2 CAT-6040 FS-AttachmentWillian Ticlia Ruiz100% (1)

- Important Information: Testing and AdjustingDocument16 pagesImportant Information: Testing and AdjustingDeyvi Cconocuyca Huallparimachi100% (1)

- What Is The Difference Between Graft and CorruptionDocument3 pagesWhat Is The Difference Between Graft and CorruptionPrince Khalid67% (3)

- Specification 320CDocument7 pagesSpecification 320CSteven ManuputtyNo ratings yet

- Relief Valve (Line) - Test and Adjust: Shutdown SISDocument10 pagesRelief Valve (Line) - Test and Adjust: Shutdown SISMbahdiro KolenxNo ratings yet

- Pruebas y Ajustes 330d Sistema HidarulicoDocument4 pagesPruebas y Ajustes 330d Sistema HidarulicoVictorDjChiqueCastillo100% (1)

- Presiones Trabajo m322cDocument10 pagesPresiones Trabajo m322cYO MERONo ratings yet

- 330D L Excavator Pilot Hydraulic System DocumentationDocument8 pages330D L Excavator Pilot Hydraulic System DocumentationMiguel Angel Garrido CardenasNo ratings yet

- Brake Pressure - TestDocument7 pagesBrake Pressure - TestHendra MonoNo ratings yet

- Pressure Limiter Valve - Test: Essai Et RéglageDocument6 pagesPressure Limiter Valve - Test: Essai Et RéglagechakrouneNo ratings yet

- Engine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemDocument3 pagesEngine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemEm sulistio100% (1)

- d8r Poor Reponse Throttle PDFDocument4 pagesd8r Poor Reponse Throttle PDFEd CalheNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document20 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Terry JwNo ratings yet

- 320c & 320c L Excavators Amc00001-Up (Machine) Powered by 3066 Engine (... Page 1 of 2Document2 pages320c & 320c L Excavators Amc00001-Up (Machine) Powered by 3066 Engine (... Page 1 of 2soelist teo100% (1)

- Starting Parts 777DDocument4 pagesStarting Parts 777DGerald BoyNo ratings yet

- Moto 14G-16GDocument21 pagesMoto 14G-16GRafael RodriguezNo ratings yet

- 1 Main Hydraulic SystemDocument6 pages1 Main Hydraulic SystemZawminhtunNo ratings yet

- 950G Wheel Loader Electro-Hydraulic SystemDocument45 pages950G Wheel Loader Electro-Hydraulic SystemAlha DNo ratings yet

- Groupon Vale CatDocument4 pagesGroupon Vale CatLuis Carlos RamosNo ratings yet

- 325 Hydraulic SystemDocument7 pages325 Hydraulic SystemUMA AKANDU UCHENo ratings yet

- Excavator Return HydDocument5 pagesExcavator Return HydSherlock HolmesNo ratings yet

- Disassemble Fuel Transfer PumpDocument4 pagesDisassemble Fuel Transfer PumpAnonymous cS9UMvhBqNo ratings yet

- Hammer System 3 SOTADocument126 pagesHammer System 3 SOTAYoungmi Franchesca Vladimir LizbetNo ratings yet

- Hydraulic Schematic of Main Control ValveDocument8 pagesHydraulic Schematic of Main Control ValveWaridi RidiNo ratings yet

- 2.main Hydraulic SystemDocument10 pages2.main Hydraulic Systemhendra hardyNo ratings yet

- Main Relief 302.5Document11 pagesMain Relief 302.5Yudi setiawanNo ratings yet

- Cat Rope ShowelDocument2 pagesCat Rope ShowelGanapati HegdeNo ratings yet

- Escavadeira CAT 320Document20 pagesEscavadeira CAT 320LucasNo ratings yet

- Thursday, July 9, 2015: Main Electrical SystemDocument3 pagesThursday, July 9, 2015: Main Electrical Systemjohn ayengahNo ratings yet

- Hydraulic System Pressure - ReleaseDocument5 pagesHydraulic System Pressure - Releasemekanicobucaro100% (2)

- 320B 322B and 325B Excavators Maintenance Intervals PDFDocument79 pages320B 322B and 325B Excavators Maintenance Intervals PDFAnonymous L0MgezUGBK100% (2)

- Power Train: 6Y-2303 Clutch Gp-TransmissionDocument19 pagesPower Train: 6Y-2303 Clutch Gp-TransmissionDANIEL VARGAS RODRIGUEZNo ratings yet

- SD160, SD200: Volvo Single Drum CompactorsDocument4 pagesSD160, SD200: Volvo Single Drum CompactorstoufikNo ratings yet

- Caterpillar Cat 16H Motor Grader (Prefix ATS) Service Repair Manual (ATS00001 and Up)Document28 pagesCaterpillar Cat 16H Motor Grader (Prefix ATS) Service Repair Manual (ATS00001 and Up)kfm8seuudu100% (1)

- std preser hyd c7Document4 pagesstd preser hyd c7NartoNo ratings yet

- 320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - DocumentaciónDocument6 pages320B & 320B L TRACK-TYPE EXCAVATORS 6CR00001-UP (MACHINE) POWERED BY 3066 ENGINE (XEBP7645 - 03) - Documentaciónjohana ruiz cervantesNo ratings yet

- 320C Specifications 1Document8 pages320C Specifications 1Daniel TekleNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Hamid EssarboutiNo ratings yet

- Chapter 8 - Swing System: Service ManualDocument26 pagesChapter 8 - Swing System: Service ManualHamid Essarbouti100% (1)

- Komatsu Technical Operator Training v6Document7 pagesKomatsu Technical Operator Training v6Hamid Essarbouti100% (2)

- Jjkgfhkijdeghsxgfjuhfgyy 4Document1 pageJjkgfhkijdeghsxgfjuhfgyy 4chakrouneNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document8 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Hamid EssarboutiNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document10 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Hamid EssarboutiNo ratings yet

- Uenr7872uenr7872 SisDocument2 pagesUenr7872uenr7872 SisHamid EssarboutiNo ratings yet

- Calibración de Válvulas D11TDocument5 pagesCalibración de Válvulas D11TJavier AntillaqueNo ratings yet

- Calibración de Válvulas D11TDocument5 pagesCalibración de Válvulas D11TJavier AntillaqueNo ratings yet

- Pay utility bills for power, gas and water onlineDocument13 pagesPay utility bills for power, gas and water onlineshahid2opuNo ratings yet

- Instruction Manual: Dossena S.N.CDocument12 pagesInstruction Manual: Dossena S.N.CRazvan SasuNo ratings yet

- Specification For 460 Volt MCCDocument4 pagesSpecification For 460 Volt MCCMrNo ratings yet

- Trommel: PerformanceDocument1 pageTrommel: PerformanceFrancisco Javier López BarrancoNo ratings yet

- Electric Field and Flux ReviewDocument20 pagesElectric Field and Flux ReviewJinja DelNo ratings yet

- b1600IEC PDFDocument36 pagesb1600IEC PDFGeancarlo RamosNo ratings yet

- Indian Oil Corporation LTDDocument11 pagesIndian Oil Corporation LTDsaz786chemicalNo ratings yet

- TNB - NEM Customer Load Profile FormDocument1 pageTNB - NEM Customer Load Profile FormKian Keong YeeNo ratings yet

- UCC39421 3.3-V SEPIC Evaluation Board: User's GuideDocument7 pagesUCC39421 3.3-V SEPIC Evaluation Board: User's GuidebensumbbNo ratings yet

- Đề luyện 20Document6 pagesĐề luyện 20Anh ThưNo ratings yet

- Graphene Oxide Based P-N Junctions: SciencedirectDocument3 pagesGraphene Oxide Based P-N Junctions: SciencedirectBLOGKUAULIANo ratings yet

- Potential To Produce Biogas From Tannery Waste: SSRN Electronic Journal July 2018Document6 pagesPotential To Produce Biogas From Tannery Waste: SSRN Electronic Journal July 2018sasabarnicNo ratings yet

- DUAL NATURE - PHOTOELECTRIC EFFECTDocument6 pagesDUAL NATURE - PHOTOELECTRIC EFFECTjagatdhatriNo ratings yet

- Centrala de Tratare Aer Proklima 11000 MCH DetentaDocument11 pagesCentrala de Tratare Aer Proklima 11000 MCH Detentageorgianconstantin100% (1)

- The Basics: Equipment Maintenance and SafetyDocument32 pagesThe Basics: Equipment Maintenance and Safetyrussel1435No ratings yet

- Liability For Payment. - X X X: It Shall Not Allow Unless The Commissioner Has Certified That The Taxes ImposedDocument31 pagesLiability For Payment. - X X X: It Shall Not Allow Unless The Commissioner Has Certified That The Taxes ImposedShaiNo ratings yet

- RRB ALP Syllabus 2017 - Subjects & TopicsDocument5 pagesRRB ALP Syllabus 2017 - Subjects & TopicsABHILASHNo ratings yet