Professional Documents

Culture Documents

Protected Cultivation of Vegetable Crops: Session 3

Uploaded by

AgriStudy Materials0 ratings0% found this document useful (0 votes)

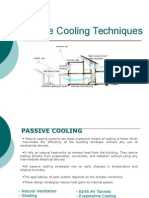

21 views23 pagesThis document describes different active cooling systems used in greenhouses, including fan-and-pad systems, fog cooling systems, convection tube cooling, and horizontal air flow cooling. Fan-and-pad systems use fans to move air across wet cooling pads to lower air temperature via evaporation. Fog cooling systems disperse fine water droplets to cool air throughout the greenhouse. Convection tube and horizontal air flow cooling use fans to circulate cold outside air from inlets to exhaust fans to achieve uniform cooling.

Original Description:

Original Title

Module-1-S3-F

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes different active cooling systems used in greenhouses, including fan-and-pad systems, fog cooling systems, convection tube cooling, and horizontal air flow cooling. Fan-and-pad systems use fans to move air across wet cooling pads to lower air temperature via evaporation. Fog cooling systems disperse fine water droplets to cool air throughout the greenhouse. Convection tube and horizontal air flow cooling use fans to circulate cold outside air from inlets to exhaust fans to achieve uniform cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views23 pagesProtected Cultivation of Vegetable Crops: Session 3

Uploaded by

AgriStudy MaterialsThis document describes different active cooling systems used in greenhouses, including fan-and-pad systems, fog cooling systems, convection tube cooling, and horizontal air flow cooling. Fan-and-pad systems use fans to move air across wet cooling pads to lower air temperature via evaporation. Fog cooling systems disperse fine water droplets to cool air throughout the greenhouse. Convection tube and horizontal air flow cooling use fans to circulate cold outside air from inlets to exhaust fans to achieve uniform cooling.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 23

Center for Smart Agriculture

Protected cultivation of vegetable crops

Module 1: Control of temperature

Session 3: Greenhouse cooling

Active summer cooling systems

• The process of evaporation requires heat

that is removed from the air surrounding

the evaporating water.

• The two active summer cooling systems in

use presently are fan-and pad and fog

systems

Fan-and Pad cooling system:

• Available since 1954

• H20 is passed through a pad that is usually

placed vertically in the wall

.

• Distance of 30 to 61m

• Traditionally – Pad - excelsior (wood shreds)

• Today - a cross-fluted cellulose material some

what similar in appearance to corrugated card

board

• Khus-khus grass mats can also be used as

cooling pads.

• Exhaust fans - opposite wall.

Pump circulating water through and over a porous pad

• Warm outside air is drawn in through the

pad.

• The supplied water in the pad - process of

evaporation - absorbs heat (cooling effect)

• As the air moves across the house to the

fans, it picks up heat from solar radiation,

plants, and soil, and the temperature of air

increases gradually.

• Fans: Regardless of the type of pad material

used, the fans should have the capacity to

provide a minimum of one air change per

minute in the greenhouse. Equip the fans

with automatic shutters to eliminate back

drafts when a fan is not operating.

• The greater the range of the crop's

temperature tolerance, the greater the distance

between pad and fans can be. It is not

practical to separate the pad and exhaust fans

by more than 200 feet. A distance of 150 feet

or less is preferred.

• Problems with cooling pads: They lose

efficiency due to clogging from impurities in

the water, algae growth and decay. If the pad

material is clogged or decomposed its ability

to function as designed is impaired.

Ventilation and cooling fans equipped

with anti-back draft shutters

Fog cooling system

• Introduced in green houses in 1980,

• same cooling principle as the fan and pad

cooling system but uses quite different

arrangement

• A high pressure pumping apparatus

generates fog (mean size of <10 microns)

using suitable nozzles.

• These droplets are sufficiently small to stay

suspended in air while they are evaporating

• Fog is dispersed throughout the green house,

cooling the air everywhere.

• As this system does not wet the foliage, there

is less scope for disease and pest attack.

• The fan-and pad system can lower the

temperature of incoming air by about 80% of

the difference between the dry and wet bulb

temperatures while the fog cooling system

can lower the temperature by nearly 100 %

difference.

Active winter cooling systems

• Excess heat can be a problem during the winter.

In the winter, the ambient temperature will be

below the desired temperature inside the green

house. Owing to the green house effect the

entrapment of solar heat can rise the

temperature to an injurious level if the green

house is not ventilated.

• The actual process in winter cooling is

tempering the excessively cold ambient air

before it reaches the plant zone. Otherwise, hot

and cold spots in the green house will lead to

uneven crop timing and quality.

• This mixing of low temperature ambient air

with the warm inside air cools the green

house in the winter.

• The actual process in winter cooling is

tempering the excessively cold ambient air

before it reaches the plant zone. Otherwise,

hot and cold spots in the green house will

lead to uneven crop timing and quality.

• This mixing of low temperature ambient air

with the warm inside air cools the green

house in the winter.

Convection tube cooling

• The general components of convection tube

are the louvered air inlet, a polyethylene

convection tube with air distribution holes, a

pressurizing fan to direct air in to the tube

under pressure, and an exhaust fan to create

vacuum.

• When the air temperature inside the green

house exceeds the set point, the exhaust fan

starts functioning thus creating vacuum

inside the green house.

• The louver of the inlet in the gable is then

opened through which cold air enters due to

the vacuum.

• The pressurizing fan at the end of the clear

polyethylene convection tube, operates to pick

up the cool air entering the louver.

• A proper gap is available for the air entry, as

the end of the convection tube is separated

from the louvered inlet by 0.3 to 0.6m and the

other end of the tube is sealed.

• Round holes of 5 to 8 cm in diameter are

provided in pairs at opposite sides of the tube

spaced at 0.5 to 1m along the length of the tube

• Cold air under pressure in the convection

tube shoots out of holes on either side of the

tube in turbulent jets.

• cool mixed air, being heavier gently flows

own to the floor level, effects the complete

cooling of the plant area.

Horizontal air flow cooling

• HAF cooling system uses small horizontal fans

for moving the air mass and is considered to be an

alternative to convection tube for the air

distribution.

• In this method the green house may be visualized

as a large box containing air and the fans located

strategically moves the air in a circular pattern.

• Move air at 0.6 to 0.9 m3/min/m2 of the green

house floor area

• Fractional HP of fans is 31 to 62 W (1/30 to

1/15hp) with a blade diameter of 41cm are

sufficient for operation.

• Fans - 0.6 to 0.9m above pht & 15m

Intervals

• They are arranged such that the air flow is

directed by one row of the fans along the

length of the GH down one side to the

opposite end and then back along the other

side by another row of fans

• Temperatures at plant height are more uniform

• same exhaust fans, inlet louvers and controls as

the convection tube system.

• only difference is the use of HAF fans in the

place of convection tubes for the air

distribution

• Cold air entering through the louvers located at

the higher level in the gables of the green

house is drawn by the air circulation created by

the net work of HAF fans and to complete the

cycle, proper quantity of air is let out through

the exhaust fans.

• The combined action of louvered inlet, HAF

fans and the exhaust fans distribute the cold air

throughout the greenhouse.

• Cold air entering through the louvers

located at the higher level in the

gables of the green house is drawn

by the air circulation created by the

net work of HAF fans and to complete

the cycle, proper quantity of air is let

out through the exhaust fans.

• The combined action of louvered

inlet, HAF fans and the exhaust fans

distribute the cold air throughout the

greenhouse.

Thank You…

You might also like

- Met Corrected PDFDocument87 pagesMet Corrected PDFRaveena Sharma100% (1)

- GSUJ Vertical Geothermal Unit Features and BenefitsDocument2 pagesGSUJ Vertical Geothermal Unit Features and Benefitsapi-21574340No ratings yet

- TM1 - Western Countries Trail MapDocument26 pagesTM1 - Western Countries Trail MapZane Smith100% (2)

- Marine Meteorology PDFDocument274 pagesMarine Meteorology PDFMeraz Rifat100% (2)

- Aiga 085 - 13 Liquid Oxygen, Nitrogen and Argon Cryogenic Tanker Loading System GuideDocument15 pagesAiga 085 - 13 Liquid Oxygen, Nitrogen and Argon Cryogenic Tanker Loading System GuideFahmi FahreziNo ratings yet

- Cold Weather (CWLC and ALIT) Student HandoutDocument364 pagesCold Weather (CWLC and ALIT) Student HandoutcwojournalNo ratings yet

- Lec 04Document7 pagesLec 04Gursimran SinghNo ratings yet

- 16 - Air Conditionng Systems - Vaishnavi C. KambleDocument13 pages16 - Air Conditionng Systems - Vaishnavi C. KambleVaishnavi KambleNo ratings yet

- Alliant EnergyDocument4 pagesAlliant EnergyOscar MagdalenoNo ratings yet

- Central Air Conditioning System-Converted - 2Document24 pagesCentral Air Conditioning System-Converted - 2gmusama1No ratings yet

- ECM216 BUILDING SERVICES Bab 2.2 Air ConditioningDocument8 pagesECM216 BUILDING SERVICES Bab 2.2 Air ConditioningAZUAN BIN AHMAD FAUZI100% (3)

- Passive Cooling TechniquesDocument15 pagesPassive Cooling TechniquesmadhurimaroyNo ratings yet

- Lecture 5Document23 pagesLecture 5Shubham SinghNo ratings yet

- Concept Note - Earth Air TunnelDocument3 pagesConcept Note - Earth Air TunnelLalit JainNo ratings yet

- Air Handling Units: Report by Vaishnavi Chandrakant Kamble B (Voc) - Int Sem IIIDocument7 pagesAir Handling Units: Report by Vaishnavi Chandrakant Kamble B (Voc) - Int Sem IIIVaishnavi KambleNo ratings yet

- Architectural Building Services: Vedita Bhat Roll No-03Document8 pagesArchitectural Building Services: Vedita Bhat Roll No-03Vedita Bhat100% (1)

- Air Conditioning: GS, AP, ME DeptDocument35 pagesAir Conditioning: GS, AP, ME DeptSourav KumarNo ratings yet

- Climogroundcoolingppt 141103225308 Conversion Gate02Document14 pagesClimogroundcoolingppt 141103225308 Conversion Gate02priyankaNo ratings yet

- HVAC COOLING SYSTEM U2 c4Document19 pagesHVAC COOLING SYSTEM U2 c4arshadeee202No ratings yet

- Split Air Conditoner:: Outdoor UnitDocument4 pagesSplit Air Conditoner:: Outdoor UnitMuhammad Jamshaid KhanNo ratings yet

- Passive Cooling TechniquesDocument16 pagesPassive Cooling TechniquesPrakhar JainNo ratings yet

- Air Conditioning in Interior Design: Ar. Amit MehtaDocument31 pagesAir Conditioning in Interior Design: Ar. Amit MehtaAr Amit MehtaNo ratings yet

- Types of Air-Conditioning SystemDocument9 pagesTypes of Air-Conditioning SystemkimNo ratings yet

- Central Air ConditioningDocument14 pagesCentral Air ConditioningHashim MuhammedNo ratings yet

- Heat Ventilation and Air Conditioning (HVAC)Document46 pagesHeat Ventilation and Air Conditioning (HVAC)Sagar GoyalNo ratings yet

- Earth Air Tubes 2007-07-02Document6 pagesEarth Air Tubes 2007-07-02experthvachomeNo ratings yet

- Vent IllationDocument86 pagesVent Illation73 Tanmay JanawadeNo ratings yet

- Air Conditioning Report.Document15 pagesAir Conditioning Report.Ethan XavierNo ratings yet

- Air MovementDocument16 pagesAir Movementanupama021No ratings yet

- Greenhouse Heating and Distribution SystemsDocument22 pagesGreenhouse Heating and Distribution SystemsvickysimhaNo ratings yet

- Ac How It WorksDocument4 pagesAc How It Workshassanain_100No ratings yet

- 7th Lecture - Humidifiers and Its TypesDocument21 pages7th Lecture - Humidifiers and Its TypesHaseeb RazaNo ratings yet

- Dasar Teori PendinginDocument64 pagesDasar Teori PendinginsuhandywNo ratings yet

- EvaporatorDocument17 pagesEvaporatorJudith EspenidoNo ratings yet

- Air Conditioning EfficiencyDocument3 pagesAir Conditioning EfficiencyVed PrakashNo ratings yet

- Types of Air Conditioning: Qus 3206 / MDM Nurul AiniDocument56 pagesTypes of Air Conditioning: Qus 3206 / MDM Nurul AiniMalik MussaNo ratings yet

- Air ConditioningDocument12 pagesAir ConditioningSNo ratings yet

- Refrigeration System Components: - Vishakh GaneshDocument34 pagesRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanNo ratings yet

- Packages Air ConditonersDocument11 pagesPackages Air ConditonersRadhika RajeevNo ratings yet

- Hvac Systems ComponentsDocument28 pagesHvac Systems ComponentsArvind RNo ratings yet

- Passive Cooling TechniquesDocument21 pagesPassive Cooling TechniquestaapsiiiNo ratings yet

- Water Cooler, Types of Air Conditioning, and Window Air ConditionerDocument51 pagesWater Cooler, Types of Air Conditioning, and Window Air ConditionerSHREYA SHARMA IET Lucknow StudentNo ratings yet

- Evaporative CoolingDocument11 pagesEvaporative CoolingziadNo ratings yet

- DehumidificationDocument31 pagesDehumidificationmohammed hussienNo ratings yet

- HuhDocument8 pagesHuhVaishnavi KambleNo ratings yet

- Heat Pipe ApplicationDocument3 pagesHeat Pipe ApplicationAnonymous mRBbdopMKfNo ratings yet

- Reading Lecture 5-6 Mechanical VentilationDocument13 pagesReading Lecture 5-6 Mechanical VentilationMd. Rizwan Hasan Kabir ShovonNo ratings yet

- Passive Cooling TechniquesDocument16 pagesPassive Cooling TechniquesSANDALI RATHORENo ratings yet

- Types of Air Conditioning SystemsDocument19 pagesTypes of Air Conditioning Systemsa_mohid17No ratings yet

- Heat Ventilating and Air Conditioning (Hvac)Document3 pagesHeat Ventilating and Air Conditioning (Hvac)Den Mas DeepNo ratings yet

- Air ConditioningDocument23 pagesAir ConditioningKudzai ManyanyeNo ratings yet

- Centralised20ac20system 190120171416Document23 pagesCentralised20ac20system 190120171416Saba ArifNo ratings yet

- Earth Air TunnelDocument2 pagesEarth Air TunnelPal MehtaNo ratings yet

- Airconditioning: Ventilation in Buildings Types of Fans Types of Air ConditionersDocument51 pagesAirconditioning: Ventilation in Buildings Types of Fans Types of Air ConditionersSassyNo ratings yet

- Principle of VRFDocument5 pagesPrinciple of VRFghazanfarhayat456No ratings yet

- Air Conditioning BasicsDocument47 pagesAir Conditioning BasicsVIJUKUMARNo ratings yet

- Week 10 - Passive Cooling Techniques - 2021Document31 pagesWeek 10 - Passive Cooling Techniques - 2021Ken Mendoza SencillaNo ratings yet

- RAC - Unit 5 - Working of Window ACDocument11 pagesRAC - Unit 5 - Working of Window ACSAATVIK JAINNo ratings yet

- On Air ConditioningDocument26 pagesOn Air ConditioningTej KalyanNo ratings yet

- Grou5 AirConditioner Assignment5Document17 pagesGrou5 AirConditioner Assignment5AnkurMahantyNo ratings yet

- Types of Air Conditioning SystemDocument5 pagesTypes of Air Conditioning SystemLArry Vasquez100% (2)

- Unit-3 - Energy Efficiency in BuildingsDocument39 pagesUnit-3 - Energy Efficiency in BuildingsNmg KumarNo ratings yet

- How It Works?Document2 pagesHow It Works?saimunNo ratings yet

- GREENHOUSE GARDENING FOR BEGINNERS: Your Ultimate Guide to Creating a Flourishing Greenhouse Garden (2024)From EverandGREENHOUSE GARDENING FOR BEGINNERS: Your Ultimate Guide to Creating a Flourishing Greenhouse Garden (2024)No ratings yet

- SolutionDocument68 pagesSolutionSIDHU RECORDSNo ratings yet

- I. Mulitple Choice:: A. Flows Perpendicular To The Pressure Gradient ForceDocument17 pagesI. Mulitple Choice:: A. Flows Perpendicular To The Pressure Gradient ForceMARINO III SAYSONNo ratings yet

- METEOROLOGY - Mohamed ElgharibDocument17 pagesMETEOROLOGY - Mohamed ElgharibmahmooodgaaberNo ratings yet

- Legends of Unusual Phenomena Before Earthquakes: - Wisdom or Superstition?Document19 pagesLegends of Unusual Phenomena Before Earthquakes: - Wisdom or Superstition?Marc LesterNo ratings yet

- Irrigation Principles and Practices (IPP)Document306 pagesIrrigation Principles and Practices (IPP)Secret DuhhhNo ratings yet

- Q9 - Humidity & Precipitation - IVDocument8 pagesQ9 - Humidity & Precipitation - IVprash_hingeNo ratings yet

- Human Eye 5Document7 pagesHuman Eye 5NanditaNo ratings yet

- Environmental HydrologyDocument60 pagesEnvironmental HydrologyAbelNo ratings yet

- Proposal For Anti-Smog Gun 30. Tata Projects. (00000003)Document9 pagesProposal For Anti-Smog Gun 30. Tata Projects. (00000003)Navdeep Singh GrewalNo ratings yet

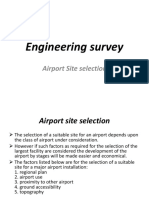

- How To Choose The Airport SiteDocument7 pagesHow To Choose The Airport SiteEmran Banat95No ratings yet

- D-Fog System Description - Donaldson PDFDocument8 pagesD-Fog System Description - Donaldson PDFUdhayakumar VenkataramanNo ratings yet

- Oxford QuestionsDocument77 pagesOxford Questionsndprajapati100% (1)

- Fire Streams: 11/18/2019 Dixon High School Fire Department 1Document62 pagesFire Streams: 11/18/2019 Dixon High School Fire Department 1theguy 21No ratings yet

- Met SurendraDocument56 pagesMet SurendraVivek ChandraNo ratings yet

- Hyper Mist System - Regulations, Working and MaintenanceDocument8 pagesHyper Mist System - Regulations, Working and MaintenanceOctavian DinuNo ratings yet

- Chapter - 16 WaterDocument3 pagesChapter - 16 Water8460No ratings yet

- 2 MeteorologyDocument93 pages2 MeteorologyMiho BoskovicNo ratings yet

- CSP 18Document17 pagesCSP 18Mai Trương Vũ NgọcNo ratings yet

- Nom 009 Ener 2014Document12 pagesNom 009 Ener 2014Mauricio RodriguezNo ratings yet

- Shadow UAV HandbookDocument57 pagesShadow UAV HandbookGasMaskBob100% (2)

- PPL (A) : Part-FCL Question BankDocument30 pagesPPL (A) : Part-FCL Question BankPilotMuayad AviationNo ratings yet

- Fog ScreenDocument3 pagesFog ScreenVidya VaradarajuNo ratings yet

- Astm D5894 2010 PDFDocument4 pagesAstm D5894 2010 PDFDino PedutoNo ratings yet

- EASA PPL Learning Objectives Part-FCLDocument30 pagesEASA PPL Learning Objectives Part-FCLJohnNo ratings yet

- BBC Weather Forecast QuizDocument6 pagesBBC Weather Forecast QuizChiaraMazzoleniNo ratings yet