Professional Documents

Culture Documents

Midterms

Midterms

Uploaded by

Ghonel Root0 ratings0% found this document useful (0 votes)

1 views8 pagesThe document discusses factors that influence the corrosion and corrosion rate of metals. It lists 11 factors including the type of metal, heat treatment, presence of electrolytes, temperature, and time of exposure to corrosive environments. It also discusses selecting the appropriate non-destructive inspection (NDI) method for aircraft parts based on manufacturer specifications and an understanding of different NDI techniques and their effectiveness. Common NDI methods mentioned are visual inspection, tap test, liquid penetrant inspection, magnetic particle inspection, eddy current, ultrasonic, and x-ray.

Original Description:

Original Title

midterms

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses factors that influence the corrosion and corrosion rate of metals. It lists 11 factors including the type of metal, heat treatment, presence of electrolytes, temperature, and time of exposure to corrosive environments. It also discusses selecting the appropriate non-destructive inspection (NDI) method for aircraft parts based on manufacturer specifications and an understanding of different NDI techniques and their effectiveness. Common NDI methods mentioned are visual inspection, tap test, liquid penetrant inspection, magnetic particle inspection, eddy current, ultrasonic, and x-ray.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views8 pagesMidterms

Midterms

Uploaded by

Ghonel RootThe document discusses factors that influence the corrosion and corrosion rate of metals. It lists 11 factors including the type of metal, heat treatment, presence of electrolytes, temperature, and time of exposure to corrosive environments. It also discusses selecting the appropriate non-destructive inspection (NDI) method for aircraft parts based on manufacturer specifications and an understanding of different NDI techniques and their effectiveness. Common NDI methods mentioned are visual inspection, tap test, liquid penetrant inspection, magnetic particle inspection, eddy current, ultrasonic, and x-ray.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 8

WEEK 1

FACTORS WHICH INFLUENCE METAL

CORROSION AND RATE OF CORROSION

1. Type of metal 7. Availability of oxygen

2. Heat treatment and grain 8. Presence of biological

direction organisms

3. Presence of a dissimilar, less 9. Mechanical stress on the

corrodible metal corroding metal

4. Anodic and cathodic surface 10. Time of exposure to a

areas corrosive environment

5. Temperature 11. Lead/graphite pencil marks

6. Presence of electrolytes on aircraft surface metals

Selecting the NDI Methods

• The NDI method and procedure to be used for any specific part or

component will generally be specified in the aircraft or component

manufacturer’s maintenance or overhaul manuals, SSID’s, SB’s, or in

AD’s.

• The appropriate NDI method may consist of several separate

inspections. Making the correct NDI method selection requires an

understanding of the basic principles, limitations, and advantages and

disadvantages of the available NDI methods and an understanding of

their comparative effectiveness and cost.

Non-Destructive Inspection

• Visual Inspection

• Tap Test

• Liquid Penetrate Inspection

• Magnetic Particle Inspection

• Eddy Current

• Ultrasonic

• X-ray

DETECTION METHODS

Aircraft Zones

Major Zones

100 - Lower Half of Fuselage

200 - Upper Half of Fuselage

300 - Empennage and Body Section 48

400 - Power Plants and Nacelle Struts

500 - Left Wing

600 - Right Wing

700 - Landing Gear and Landing Gear Doors (Fixed)

800 - Doors

CORROSION-PRONE AREAS

• ENGINE EXHAUST AREA • FUEL TANKS

• BATTERY COMPARTMENTS AND • PIANO HINGES

VENTS • BILGE AREAS

• LAVATORIES AND FOOD • LANDING GEAR BOXES

SERVICE AREAS

• ENGINE MOUNT STRUCTURE

• WHEEL WELLS AND LANDING

GEAR • CONTROL CABLES

• EXTERNAL SKIN AREAS • WELDED AREAS

• ENGINE INLET AREAS • ELECTRONIC EQUIPMENT

You might also like

- Engineering Materials PDFDocument24 pagesEngineering Materials PDFPradeepkumarKatgiNo ratings yet

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsFrom EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsNo ratings yet

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Syllabus Assistant Manager-2Document2 pagesSyllabus Assistant Manager-2swarupkumarnayakNo ratings yet

- Amp New SyllabusDocument3 pagesAmp New Syllabussimon rosarioNo ratings yet

- Other NDT TechniquesDocument12 pagesOther NDT TechniquesabyNo ratings yet

- Self-Study On API RP 571 - Damage MechanismDocument84 pagesSelf-Study On API RP 571 - Damage Mechanismrosli2503100% (2)

- Corrosion NotesDocument9 pagesCorrosion NotesRuffa Mae CalimagNo ratings yet

- Section 6 Advanced NDT TechniquesDocument48 pagesSection 6 Advanced NDT Techniquesariyamanjula2914100% (1)

- Intro To NDTDocument61 pagesIntro To NDTzubairsarwar912No ratings yet

- Non Destructive Testing IntroductionDocument60 pagesNon Destructive Testing Introductionzubair_mechanicalsNo ratings yet

- PMI ProcedureDocument9 pagesPMI ProcedureKarrar TalibNo ratings yet

- Traning Steam Engineer Grade 2 & 1Document2 pagesTraning Steam Engineer Grade 2 & 1Mohd Khoushaini Mohd NaimNo ratings yet

- Corrosion Prevention and Control MergedDocument33 pagesCorrosion Prevention and Control MergedDarwin LomibaoNo ratings yet

- PHM - Aircraft Corrosion Maintenance and Sustainment Fritz FriedersdorfDocument11 pagesPHM - Aircraft Corrosion Maintenance and Sustainment Fritz FriedersdorfSamarNo ratings yet

- Syllabus Compendium For PCN Aerospace Sector ExaminationsDocument27 pagesSyllabus Compendium For PCN Aerospace Sector ExaminationstomcanNo ratings yet

- Corrosion & Cathodic Protection Terminals & Storage Tanks Online TrainingDocument4 pagesCorrosion & Cathodic Protection Terminals & Storage Tanks Online TrainingBassam AbdelazeemNo ratings yet

- CH 20Document17 pagesCH 20Shonar KellaNo ratings yet

- Coating & Painting Inspections Fundamentals: Pdhonline Course M478 (5 PDH)Document78 pagesCoating & Painting Inspections Fundamentals: Pdhonline Course M478 (5 PDH)Corrosion Factory100% (1)

- Fab & Erection Pro 20000klR1Document17 pagesFab & Erection Pro 20000klR1Gandhi OnoNo ratings yet

- ARCProcedure Guide MetalsDocument11 pagesARCProcedure Guide MetalsAlejandro Pedraza SuarezNo ratings yet

- 3-Corrosion Control Documents-An Essential Element of A Mechanical Integrity and Risk-Based Inspection ProgramDocument24 pages3-Corrosion Control Documents-An Essential Element of A Mechanical Integrity and Risk-Based Inspection Programesamhamad100% (1)

- 4.1 Materials and MetallurgyDocument16 pages4.1 Materials and MetallurgyVijayKumarNo ratings yet

- 3 Day Theory of HydraulicsDocument3 pages3 Day Theory of HydraulicsbrNo ratings yet

- Electrical Maintenance Principles & ApplicationsDocument17 pagesElectrical Maintenance Principles & Applicationswas00266100% (1)

- Define Difference in QA and QCDocument9 pagesDefine Difference in QA and QCyesuplus2No ratings yet

- ICS Rules & Regulations and GuidanceDocument2 pagesICS Rules & Regulations and GuidancekhabiranNo ratings yet

- 4 API 653 AST Inspector CourseDocument4 pages4 API 653 AST Inspector CourseshaajiNo ratings yet

- Lockhart 653Document7 pagesLockhart 653oluninjaaNo ratings yet

- Astm D 3276 - 00 PowerpoinDocument11 pagesAstm D 3276 - 00 Powerpoinmeddi febiyantoNo ratings yet

- 21 - Corrosion Monitoring in Oil & Gas IndustryDocument5 pages21 - Corrosion Monitoring in Oil & Gas IndustryMohamed F. OmarNo ratings yet

- Handouts: Kongunadu College of Engineering and Technology (Autonomous)Document59 pagesHandouts: Kongunadu College of Engineering and Technology (Autonomous)Akilesh SNo ratings yet

- Testing and Commissioning ofDocument11 pagesTesting and Commissioning ofsushant_2525100% (1)

- Non Destructive TestingDocument7 pagesNon Destructive TestingDanish IqbalNo ratings yet

- Welding Insp Part 4Document3 pagesWelding Insp Part 4irwanNo ratings yet

- Velammal Engineering College: OML751 Testing of MaterialsDocument37 pagesVelammal Engineering College: OML751 Testing of MaterialsSrikanth PalaniswamyNo ratings yet

- Gojan School of Business and Technology: Department of Aeronautical Engineering Ae6010-Airframe Maintenance and RepairDocument1 pageGojan School of Business and Technology: Department of Aeronautical Engineering Ae6010-Airframe Maintenance and RepairKishore CrazeNo ratings yet

- MCET 226 - Module No.1 - Introduction To Welding and SafetyDocument40 pagesMCET 226 - Module No.1 - Introduction To Welding and SafetyahmedNo ratings yet

- L-3-Over View of Various NDT MethodsDocument15 pagesL-3-Over View of Various NDT MethodsvigneshNo ratings yet

- Dash Utrtmtptvt Bro 2014Document6 pagesDash Utrtmtptvt Bro 2014dashNo ratings yet

- Nondestructive Inspection Book 1Document54 pagesNondestructive Inspection Book 1Marco AucancelaNo ratings yet

- NASA Plating PaperDocument142 pagesNASA Plating PaperRussell ShacklefordNo ratings yet

- Xxiii. Non-Destructive Testing in Power Plant MaintenanceDocument11 pagesXxiii. Non-Destructive Testing in Power Plant MaintenanceRaja RamNo ratings yet

- CPWI 3 of 4Document50 pagesCPWI 3 of 4Jorge SobrevillaNo ratings yet

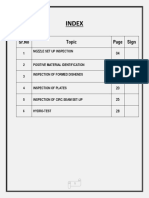

- Index: SR - No Topic Page SignDocument33 pagesIndex: SR - No Topic Page SignDev ManeNo ratings yet

- Non Destructive Testing (NDT L-2) Course ContentsDocument2 pagesNon Destructive Testing (NDT L-2) Course ContentsHarminder KumarNo ratings yet

- 2012-08-22 C Ikeagu and A Seton of Subsea 7 - Material Selection For Subsea PipelinesDocument26 pages2012-08-22 C Ikeagu and A Seton of Subsea 7 - Material Selection For Subsea PipelineshamidrezaettelaieNo ratings yet

- An Overview of The Noncyanide Metal Stripper Program Conducted at Kelly Air Force BaseDocument7 pagesAn Overview of The Noncyanide Metal Stripper Program Conducted at Kelly Air Force BaseamicjhcjyNo ratings yet

- NDT Anfd Failure AnalysisDocument65 pagesNDT Anfd Failure AnalysisAgung SudrajatNo ratings yet

- Materials For Construction For Process Equipment and Piping Systems - Selection and In-Service PerformanceDocument7 pagesMaterials For Construction For Process Equipment and Piping Systems - Selection and In-Service PerformanceZoebairNo ratings yet

- Metallurgy & Materials Engineering: Bilal Hassan Saad Rafique Javed Iqbal Saqib Fraz AmanullahDocument12 pagesMetallurgy & Materials Engineering: Bilal Hassan Saad Rafique Javed Iqbal Saqib Fraz Amanullahbilal378No ratings yet

- VSFC IdDocument58 pagesVSFC IdDhananjay NandanpawarNo ratings yet

- Analisis de ParticulasDocument60 pagesAnalisis de ParticulasManel MontesinosNo ratings yet

- Exam Aramco ExcelDocument32 pagesExam Aramco Excelmohamed elmasry100% (3)

- API 510 Pressure Vessel Inspector Certification Preparation CourseDocument4 pagesAPI 510 Pressure Vessel Inspector Certification Preparation CoursejbsantoNo ratings yet

- Failure AnalysisDocument84 pagesFailure AnalysismaterialmindedNo ratings yet

- Pengantar NDT 2003Document27 pagesPengantar NDT 2003Dimas AnugrahNo ratings yet

- Production ElectivesDocument20 pagesProduction ElectivesAdhi ThyanNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Finals 2Document15 pagesFinals 2Ghonel RootNo ratings yet

- Week 2Document11 pagesWeek 2Ghonel RootNo ratings yet

- Finals 1Document8 pagesFinals 1Ghonel RootNo ratings yet

- Processes of Ideal GasesDocument9 pagesProcesses of Ideal GasesGhonel RootNo ratings yet

- Week 1Document10 pagesWeek 1Ghonel RootNo ratings yet

- Week 6Document16 pagesWeek 6Ghonel RootNo ratings yet

- Week 4Document8 pagesWeek 4Ghonel RootNo ratings yet