Professional Documents

Culture Documents

6-Heat Treatable Low-Alloy Steels

Uploaded by

Munim Dar100%(1)100% found this document useful (1 vote)

41 views17 pagesHTLA steels have high hardenability and require low-hydrogen welding procedures with sufficient preheat to prevent hydrogen cracking. They are typically welded in the annealed condition and then heat treated as a whole to the desired strength. Various HTLA steel compositions are provided with carbon ranging from 0.25-0.45%. Matching filler metals are available and postweld heat treatment depends on preheat temperature to transform austenite without cracking.

Original Description:

Original Title

6-Heat treatable low-alloy steels

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHTLA steels have high hardenability and require low-hydrogen welding procedures with sufficient preheat to prevent hydrogen cracking. They are typically welded in the annealed condition and then heat treated as a whole to the desired strength. Various HTLA steel compositions are provided with carbon ranging from 0.25-0.45%. Matching filler metals are available and postweld heat treatment depends on preheat temperature to transform austenite without cracking.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

41 views17 pages6-Heat Treatable Low-Alloy Steels

Uploaded by

Munim DarHTLA steels have high hardenability and require low-hydrogen welding procedures with sufficient preheat to prevent hydrogen cracking. They are typically welded in the annealed condition and then heat treated as a whole to the desired strength. Various HTLA steel compositions are provided with carbon ranging from 0.25-0.45%. Matching filler metals are available and postweld heat treatment depends on preheat temperature to transform austenite without cracking.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 17

CHAPTER -6

DESCRIPTION

Heat‑treatable low alloy (HTLA) steels have high

hardenability and are susceptible to hydrogen cracking

in the weld metal and heat‑affected zone (HAZ).

Low‑hydrogen welding procedures must be used with

sufficient preheat and interpass temperature to

prevent hydrogen cracking.

DESCRIPTION

HTLA steels frequently are welded in the annealed

condition.

The entire weldment is then heat treated to the desired

strength or hardness.

The high hardness of HTLA steels prohibits welding

them in the hardened condition.

COMPOSITION AND PROPERTIES

The compositions of several HTLA steels that have

been welded, then quenched and tempered, are

given in Table.

The carbon contents of these steels generally range

from about 0.25 to 0.45%, versus 0.10 to 0.25 % for the

quenched and tempered low‑alloy steels.

Compositions of Typical

Heat‑Treatable Low‑Alloy

Common Steels Composition

Designation C Mn Si Ni Cr Mo V

4027 0.25‑0.30 0.70‑0.90 0.15‑0.35 ‑ ‑ 0.20‑0.30 ‑

4037 0.35‑0.40 0.70‑0.90 0.15‑0.35 ‑ ‑ 0.20‑0.30 ‑

4130 0.28‑0.33 0.40‑0.60 0.15‑0.35 ‑ 0.80‑1.10 0.15‑0.25 ‑

4135 0.33‑0.38 0.70‑0.90 0.15‑0.35 ‑ 0.80‑1.10 0.15‑0.25 ‑

4140 0.38‑0.43 0.75‑1.00 0.15‑0.35 ‑ 0.80‑1.10 0.15‑0.25 ‑

4320 0.17‑0.22 0.45‑0.65 0.15‑0.35 1.65‑2.00 0.40‑0.60 0.20‑0.30 ‑

4340 0.38‑0.43 0.60‑0.80 0.15‑0.35 1.65‑2.00 0.70‑0.90 0.20‑0.30 ‑

5130 0.28‑0.33 0.70‑0.90 0.15‑0.35 ‑ 0.80‑1.10 ‑ ‑

5140 0.38‑0.43 0.70‑0.90 0.15‑0.35 ‑ 0.70‑0.90 ‑ ‑

8630 0.28‑0.33 0.70‑0.90 0.15‑0.35 0.40‑0.70 0.40‑0.60 0.15‑0.25 ‑

8640 0.38‑0.43 0.75‑1.00 0.15‑0.35 0.40‑0.70 0.40‑0.60 0.15‑0.25 ‑

8470 0.38‑0.43 0.75‑1.00 0.15‑0.35 0.40‑0.70 0.40‑0.60 0.20‑0.30 ‑

AMS6434 0.31‑0.38 0.60‑0.80 0.20‑0.35 1.65‑2.00 0.65‑0.90 0.30‑0.40 0.17‑0.23

300M 0.40‑0.46 0.65‑0.90 1.45‑1.80 1.65‑2.00 0.70‑0.95 0.30‑0.45 0.05 min

D‑6a 0.42‑0.48 0.60‑0.80 0.15‑0.30 0.40‑0.70 0.90‑1.20 0.90‑1.10 0.05‑0.10

COMPOSITION AND PROPERTIES

HTLA steels have sufficient carbon and alloy content

to give them high hardenability, and they can be heat

treated to high strength and hardness.

Because of their high hardenability, it is necessary

to preheat these steels properly for welding in order

to avoid hydrogen cracking and to obtain a sound

weld.

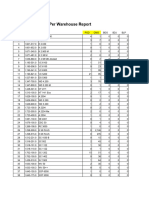

Approximate Heat-Treating Conditions

for Several Low-Alloy Steels

COMPOSITION AND PROPERTIES

The specific tempering temp required in any

given case varies depending on the following 04

factors:

(1) Thickness of the weldment

(2) Composition of the particular heat of steel

(3) Prior processing of the steel

(4) Method of tempering

COMPOSITION AND PROPERTIES

Proper control of sulfur and phosphorus is very

important because:

their presence in excess of about 0.020% increases

the crack sensitivity of steel.

Sulfur increases the sensitivity of the weld metal to

hot cracking.

Phosphorus reduces ductility and toughness, and it

increases the sensitivity to cold cracking in both the

base metal and the weld metal.

Welding HTLA Steels

Preheating

Min preheat & interpass temp required to prevent

cracking with a given steel depends on:

Its carbon and alloy content

Condition of heat treatment

Section thickness or amount of joint restraint

Available hydrogen during welding

Table 6.12: Recommended minimum Preheat and Interpass Temperatures for several

AISI Low-Alloy Steels

Minimum Preheat and Interpass

Thickness Range

Temperature*

AISI In. mm ºF ºC

4027 Upto 0.5 Upto 13 50 10

0.6-1.0 156-26 150 66

1.1-2.0 27-51 250 121

4037 Upto 0.5 Upto 13 100 38

0.6-1.0 15-26 200 93

1.1-2.0 27-51 300 149

4130, 5140 Upto 0.5 Upto 13 300 149

0.6-1.0 15-26 400 204

1.1-2.0 27-51 450 232

4135, 4140 Upto 0.5 Upto 13 350 177

0.6-1.0 15-26 450 232

1.1-2.0 27-51 500 260

4320, 5130 Upto 0.5 Upto 13 200 93

0.6-1.0 15-26 300 149

1.1-2.0 27-51 400 204

4340 Upto 0.5 Upto 51 550 288

8630 Upto 0.5 Upto 13 200 93

0.6-1.0 15-26 250 121

1.1-2.0 27-51 300 149

8640 Upto 0.5 Upto 13 200 93

0.6-1.0 15-26 300 149

1.1-2.0 27-51 350 177

8740 Upto 1.0 Upto 26 300 149

1.1-2.0 27-51 400 204

*Low-hydrogen welding processes only.

Filler Metals

Covered electrodes, bare electrodes and flux cored

electrodes that deposit matching weld metal are

available for welding some heat‑treatable low‑alloy

(HTLA) steels that are quenched and tempered after

welding.

These include AISI 4130 and 4340 steels.

Filler Metals

The electrode manufacturers should be consulted

regarding their recommendations for specific

applications, particularly for multiple‑pass

operations in which high joint strength is required

and dilution is limited.

Filler Metals

Filler metals matching the composition and

properties of HTLA steels are available commercially,

and they are covered by AMS specifications 6457A

(4130), 6452 (4140), and 6456 (4340).

Typical mechanical properties in various

heat‑treatment conditions are listed in Table

Postweld Heat Treatment

The heat treatment required immediately after arc welding of these

steels depends on the preheat and interpass temperature.

When the preheat and interpass temperature is the Ms temperature

of the steel (the tempera, the weld must not be cooled to room

temperature until after it is given a thermal treatment to avoid

cracking.

When immediate stress relief after welding is not practical, the

welded joint should be heated from the preheat temperature to 50

to 100 ºF (28 to 56 ºC) above the Ms temperature of the steel.

The remaining austenite will transform to a reasonably ductile

bainitic structure after about one hour at temperature.

Then, the weldment can be cooled to room temperature without

danger of cracking.

Postweld Heat Treatment

If the weldment is to be stress relieved in the 1100 to 1250 ºF (593 to

677 ºC) range immediately after welding, it should first be cooled

from the preheat temperature to a lower temperature where

transformation of austenite to martensite will be essentially

complete, as determined from the isothermal transformation

diagram for the steel.

Then the weldment should be immediately heated to the stress-

relieving temperature where the martensite in the welded joint will

be tempered and softened.

After holding it at temperature for the specified time, the weldment

can be cooled to room temperature without danger of cracking.

You might also like

- Pipe ChartDocument2 pagesPipe ChartabdulNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Duplex Stainless SteelDocument17 pagesDuplex Stainless SteelthunderNo ratings yet

- Spec SCAPSA Metallic Material Selected StdsDocument107 pagesSpec SCAPSA Metallic Material Selected StdsSwath M MuraliNo ratings yet

- Stainless Steel Pipe DesignationsDocument4 pagesStainless Steel Pipe DesignationsSTL Pipe & SupplyNo ratings yet

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- iGCSE Chemistry Revision SheetsDocument26 pagesiGCSE Chemistry Revision SheetsPanagiotis ScordisNo ratings yet

- BRE 462 Steel Structures Supporting Composite Floor Slabs FireDocument12 pagesBRE 462 Steel Structures Supporting Composite Floor Slabs FireUmmar FarooqNo ratings yet

- Is 1030 GR340-570WDocument2 pagesIs 1030 GR340-570WAnkit Singh100% (1)

- Scale InhibitorDocument17 pagesScale InhibitorNihad S ZainNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Material SpecDocument456 pagesMaterial SpecAyush Narang70% (10)

- Concepts of Electric Arc Furnace Fume ControlDocument5 pagesConcepts of Electric Arc Furnace Fume ControlAshutosh SinghNo ratings yet

- Stainless Steels An Introduction and Their Recent DevelopmentsqqwDocument11 pagesStainless Steels An Introduction and Their Recent Developmentsqqwaghosh704100% (2)

- Grade 8, Quarter 3Document39 pagesGrade 8, Quarter 3Leisor Euqirdnam Oyacnub94% (16)

- Forward How To Guide - FinalDocument12 pagesForward How To Guide - FinalMunim DarNo ratings yet

- Stainless Steel GradesDocument8 pagesStainless Steel Gradesnathan1979No ratings yet

- Alloy 4047 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 4047 Weld Data Sheet: Typical ApplicationsMarcoAntonioNo ratings yet

- Chemical Composition Limits For Aluminum AlloysDocument2 pagesChemical Composition Limits For Aluminum AlloysDeep SharmaNo ratings yet

- Is4522. GR5Document10 pagesIs4522. GR5kaushikNo ratings yet

- Chemical - Composition SSDocument1 pageChemical - Composition SSSuman PawarNo ratings yet

- En 10268Document4 pagesEn 10268Alex LacerdaNo ratings yet

- Chemical Compositions of Stainless SteelsDocument2 pagesChemical Compositions of Stainless Steelsmohamed faragNo ratings yet

- Compositon of Martensitic SteelDocument1 pageCompositon of Martensitic SteelMahesh PandyaNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- Valores de Dureza Aluminio Todos Las DurezasDocument31 pagesValores de Dureza Aluminio Todos Las DurezasOscar AlbaNo ratings yet

- Forged Steel PropertiesDocument2 pagesForged Steel Propertiesrumabiswas853No ratings yet

- STD, Inch Sizes TCM 12-163226Document13 pagesSTD, Inch Sizes TCM 12-163226SHANENo ratings yet

- ASTM A789 Duplex Stainless TubingDocument10 pagesASTM A789 Duplex Stainless Tubingmathew holeyNo ratings yet

- Machining Conditions: APKT 100308 PDTR LT 3130 M0004470 MetricDocument2 pagesMachining Conditions: APKT 100308 PDTR LT 3130 M0004470 MetricDedik HandokoNo ratings yet

- Lab 01 Report - EEX4332Document25 pagesLab 01 Report - EEX4332Chamaka PiyumalNo ratings yet

- 1N4099 1N4135, 1N4614 1N4627Document4 pages1N4099 1N4135, 1N4614 1N4627tommy99No ratings yet

- CHEMISTRY Raw MaterialDocument6 pagesCHEMISTRY Raw Materialaditya18decNo ratings yet

- Astm A493 16Document2 pagesAstm A493 16wongNo ratings yet

- Ligas de Aco DZ UltraDocument2 pagesLigas de Aco DZ Ultraaldofernandes100% (1)

- Bk130 Series: FeaturesDocument5 pagesBk130 Series: FeaturestecjadirNo ratings yet

- What Is A Pitting Resistance Equivalent Number (PREN) - Unified AlloysDocument10 pagesWhat Is A Pitting Resistance Equivalent Number (PREN) - Unified AlloysromerobernaNo ratings yet

- Deviation Plot For HT Model Predictions of Liquid Density: Temperature, KDocument33 pagesDeviation Plot For HT Model Predictions of Liquid Density: Temperature, KRachmat Tri AnggaraNo ratings yet

- Soft Magnetic Iron-Nickel AlloysDocument9 pagesSoft Magnetic Iron-Nickel AlloysmiguelNo ratings yet

- Stainless Steel 441 UNS S43940Document5 pagesStainless Steel 441 UNS S43940Enrique Ruiz HonoratoNo ratings yet

- Article - Calculation of Pitting Resistance Equivalent Numbers (PREN)Document3 pagesArticle - Calculation of Pitting Resistance Equivalent Numbers (PREN)eugenio.gutenbertNo ratings yet

- ChemicalComposition FBDocument1 pageChemicalComposition FBSibasish SarkhelNo ratings yet

- Commercial Pipe Sizes and Wall ThicknessDocument2 pagesCommercial Pipe Sizes and Wall ThicknessabdulNo ratings yet

- Trumpf Laser Cut Speeds and Nozzle ChartDocument12 pagesTrumpf Laser Cut Speeds and Nozzle ChartAntal GálNo ratings yet

- Brosur KHIDocument16 pagesBrosur KHIpangalengan zaxNo ratings yet

- ALC-10025B AlcoTec Corporate BrochureDocument20 pagesALC-10025B AlcoTec Corporate Brochurelth770310No ratings yet

- Astm A790 A790mDocument4 pagesAstm A790 A790mGangatharan RamarajNo ratings yet

- HSS & Cobalt Drill Speed - FeedDocument1 pageHSS & Cobalt Drill Speed - FeedPuneeth KumarNo ratings yet

- Casting HandbookDocument18 pagesCasting HandbookGaurav NarulaNo ratings yet

- Specifications For Plates: Specification GradeDocument15 pagesSpecifications For Plates: Specification Gradeppd9890No ratings yet

- BQ PlateDocument2 pagesBQ PlateAvishay TufikianNo ratings yet

- asme-ii-part-c-ed2019-specifications-for-welding-rods-electrodes-and-filler-metals-CHEMICAL COMPOSITIONpdfDocument1 pageasme-ii-part-c-ed2019-specifications-for-welding-rods-electrodes-and-filler-metals-CHEMICAL COMPOSITIONpdfBentles WrokNo ratings yet

- B221M 1388261-1Document16 pagesB221M 1388261-1hh774747No ratings yet

- Lincoln 2Document2 pagesLincoln 2kien phamNo ratings yet

- Hardy Cross Method Solved ExampleDocument4 pagesHardy Cross Method Solved ExamplejajajajNo ratings yet

- Stainless Steel Properties PDFDocument8 pagesStainless Steel Properties PDFprajash007No ratings yet

- Asme BPVC - Ii.c-2015 Sfa-5.9/sfa-5.9mDocument1 pageAsme BPVC - Ii.c-2015 Sfa-5.9/sfa-5.9mpuwarin najaNo ratings yet

- 41xx SteelDocument2 pages41xx Steelkumar rajaNo ratings yet

- Aalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51Document3 pagesAalco Metals LTD Aluminium Alloy en Standards For Rolled Aluminium 51AnwarNo ratings yet

- Surface Coating - Powders For Use in Laser Cladding - 1975HOGDocument2 pagesSurface Coating - Powders For Use in Laser Cladding - 1975HOGStefanoNo ratings yet

- 8950P229 SampleDocument5 pages8950P229 SamplecarlosNo ratings yet

- Catalogue 25Document1 pageCatalogue 25Le MinhNo ratings yet

- MetalfaesDocument2 pagesMetalfaesviyfNo ratings yet

- ParametersDocument3 pagesParametersfireball9877No ratings yet

- Feb, 26-2024 Unit KarcherDocument6 pagesFeb, 26-2024 Unit Karcherroni roniNo ratings yet

- 12.2-WMK Investment Advisory Services-B1Document6 pages12.2-WMK Investment Advisory Services-B1Munim Dar100% (1)

- R3 Marketing Analysis Toolkit Situation AnalysisDocument10 pagesR3 Marketing Analysis Toolkit Situation AnalysisSakshi ShuklaNo ratings yet

- 6-Carbon SteelsDocument20 pages6-Carbon SteelsMunim DarNo ratings yet

- Welding Defects: Wanda S. Benton Florence-Darlington Technical CollegeDocument12 pagesWelding Defects: Wanda S. Benton Florence-Darlington Technical CollegejieNo ratings yet

- Aquifers of Dera Ghazi KhanDocument12 pagesAquifers of Dera Ghazi KhanArslan geoscientistNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument12 pagesCambridge International Advanced Subsidiary and Advanced LevelTerTalks ChikweyaNo ratings yet

- Stiinta-Solului 2009 1Document73 pagesStiinta-Solului 2009 1Florin f.0% (1)

- Zipper Pull Strength 80 N: Test Results Buyer RequirementDocument1 pageZipper Pull Strength 80 N: Test Results Buyer Requirementyogesh123789No ratings yet

- Safety Data Sheet: 1. IdentificationDocument6 pagesSafety Data Sheet: 1. IdentificationJessie O.BechaydaNo ratings yet

- FT-NIR For PIRDocument13 pagesFT-NIR For PIRDovganNo ratings yet

- NCI - MV Cables CatalogueDocument75 pagesNCI - MV Cables Cataloguemughees_itcompNo ratings yet

- Silicon Run 1 QuestionsDocument1 pageSilicon Run 1 QuestionsedWVMNo ratings yet

- ERT 206/4 Thermodynamics: The First Law and Other Basic ConceptsDocument31 pagesERT 206/4 Thermodynamics: The First Law and Other Basic ConceptsMuhammed FuadNo ratings yet

- Worksheet#9.2 - Ampere's Law Solutions - 2Document5 pagesWorksheet#9.2 - Ampere's Law Solutions - 2Joseph SadderntillionsenNo ratings yet

- Thawing 1 RACUDocument66 pagesThawing 1 RACURfsdjr AceNo ratings yet

- Tream Paper 2.8.editedDocument5 pagesTream Paper 2.8.editedPartho BasakNo ratings yet

- Chapter 3 Deep FoundationDocument2 pagesChapter 3 Deep FoundationTeaMeeNo ratings yet

- Domos Volcanicos y Mineralizacion de Oro en El DisDocument21 pagesDomos Volcanicos y Mineralizacion de Oro en El DisfacflNo ratings yet

- Experiment 8: Properties of Organic Compounds With Carbonyl GroupDocument7 pagesExperiment 8: Properties of Organic Compounds With Carbonyl GroupMarita AlcansadoNo ratings yet

- 9701 w03 QP 1Document16 pages9701 w03 QP 1Hubbak KhanNo ratings yet

- The Refining Process: Cracking Reforming Isomerisation Alkylation PolymerisationDocument15 pagesThe Refining Process: Cracking Reforming Isomerisation Alkylation Polymerisationdana mohammedNo ratings yet

- Po Ram Gian Paschal - Activity 2.7 - Experiment 2 (PRE-LABORATORY)Document2 pagesPo Ram Gian Paschal - Activity 2.7 - Experiment 2 (PRE-LABORATORY)Po Ram Gian PaschalNo ratings yet

- SCS Filtration Water Separators - NPDocument1 pageSCS Filtration Water Separators - NPSebastian GanciNo ratings yet

- Optical Mineralogy: Lab 11 - Fall, 2012 Feldspars: Exsolution, Zoning, and TwinningDocument23 pagesOptical Mineralogy: Lab 11 - Fall, 2012 Feldspars: Exsolution, Zoning, and TwinningDhany RizkyNo ratings yet

- Eum 20230918Document31 pagesEum 20230918Govend BarNo ratings yet

- Test Certificate: Counto Microfine Products Private LimitedDocument1 pageTest Certificate: Counto Microfine Products Private LimitedSiddhesh Kamat MhamaiNo ratings yet

- Green Solvents PresDocument74 pagesGreen Solvents PresTDSNo ratings yet

- Bohler - w302 SuperiorDocument8 pagesBohler - w302 SuperiorHugo Mario Ariza Palacio100% (1)