Professional Documents

Culture Documents

Training Course On Quality Control, ASME Sec. VIII Div.1 & Sec. IX

Uploaded by

Avdhut satheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Training Course On Quality Control, ASME Sec. VIII Div.1 & Sec. IX

Uploaded by

Avdhut satheCopyright:

Available Formats

Training Course on Quality Control, ASME Sec. VIII Div.1 & Sec.

IX

Date: June 13 - 15, 2011

Trainers: Mani / Zuzar / Ajimon / Visva

Day 2 : Wednesday , 01st June 2011 - ASME Sec IX + Sec VIII Div.1

Time Description

► 09.00 - 09.15 Introduction

► 09.15 -10.30 Article 1

► 10.30 - 10.45 Coffee Break

► 10.45 - 11.45 Article 2

► 11.45 - 12.00 Break

► 12.00 - 13.00 Article 3

► 13.00 - 14.00 Lunch Break

► 14.00 - 15.00 Article 4 + Mechanical Testing

► 15.00 - 15.15 Coffee Break

► 15.15 - 15.45 Q&A - ASME Sec. IX

► 15.45 - 17.00 Introduction to Sec. VIII Div. 1

Bureau Veritas Training Course on ASME Section IX 2

ASME SECTION IX

CONTENTS

• Organization, Content and Structure of Section IX

• Part QW - Welding

• Article I - Welding General Requirements

• Article II - Welding Procedure Qualifications

• Article III - Welder Performance Qualifications

• Article IV - Welding Data (only for Ref.)

• Article V - Standard Welding Procedure Specifications

• Part QB - Brazing

• Mandatory Appendix A

• Non-mandatory Appendix B (Welding and Brazing Forms)

Bureau Veritas Training Course on ASME Section IX 3

► General Overview and Background Notes

► ASME Boiler and Pressure Vessel Code

► Section IX Training Course

--------------------------------------------------------------------------------------------------------------------------

ASME Code Section IX

► Section IX of the ASME Boiler and pressure vessel Code is divided into two parts

part QW gives requirements for welding and Part QB contains requirements for brazing.

► Both parts are identically structured into the following Articles :

► General Requirements

► Procedure Qualifications

► Performance Qualifications

► Data

Bureau Veritas Training Course on ASME Section IX 4

General

WPS/PQR – Article II

WPQ /WOPQ – Article III

► This article gives general explanations on terms and definitions, but always refers to

subsequent Articles and Paragraphs where those definitions and requirements are

explained and specified in details.

► It also states that Welding Procedure Specifications (WPS) , Procedure Qualification

Records (PQR) and Welders Performance Qualification (WPQ) made in accordance with

the requirements of the 1962 edition or any later edition of section IX may be used in any

construction built to the ASME Boiler and Pressure Vessel Code or the ASME B 31 Code

for pressure piping. Procedure specifications and performance qualification records

meeting the above requirements do not need to be amended to include any variables

required by later editions and Addenda. Qualification of new procedure specifications or

performance qualifications

Bureau Veritas Training Course on ASME Section IX 5

General

Welding Data - Article IV

► This Article summarizes and gives details on variables used to qualify procedures and

personnel, This Article should only be read in conjunction with the preceding articles for

procedure and performance qualifications.

► It further shows the dimensions of test specimen, test jigs, material grouping (P number),

F and A numbers, thicknesses and diameter limitations and qualification ranges as well as

definitions on welding / brazing terms used in the Code.

Bureau Veritas Training Course on ASME Section IX 6

ASME CODES & STANDARDS

ASME Codes & Standards Organization - Headquarters in New York

► The ASME is a not for profit organization governed by a General Committee

► Responsibility for the Code sections are developed to sub committees and working groups

which decide on Code rules and changes

► These committees are made up of representatives of the

► Manufacturers

► Jurisdictions

► AIA’s

► Other interested parties – e.g. owner / operators .

Bureau Veritas Training Course on ASME Section IX 7

NATIONAL BOARD OF BOILER AND PRESSURE

VESSEL INSPECTORS

National Board of Boiler and Pressure Vessel Inspectors

► Headquarters in Columbus, Ohio

► Chief Inspectors of Jurisdictions

► National Board Inspection Code (NBIC) ANSI/nb 23

► Training, examination and commissioning of Authorized Inspectors

► Certification of relief valves

► Registration of Code stamped boilers and pressure vessels

► Issue and Control of ‘R’ stamp holders for the inspection and certification of repairs,

alterations and re-ratings of pressure equipment .

Bureau Veritas Training Course on ASME Section IX 8

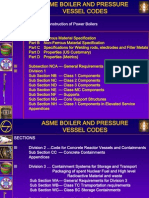

ASME CONSTRUCTION CODES

CONSTRUCTION Codes

► SECTION I - Rules for Construction of Power Boilers

► SECTION IV - Rules for Construction of Heating Boilers

► SECTION VIII - Rules for Construction of Pressure Vessels

► DIVISION 1

► DIVISION 2 - Alternative Rules

► DIVISION 3 - Alternative Rules for Construction of High Pressure Vessels

► SECTION X - Fiber Reinforced Plastic Pressure Vessels

► SECTION XII - Rules for Construction and Continued Services of Transport Tanks

Bureau Veritas Training Course on ASME Section IX 9

ASME CODES FOR MATERIALS,WELDING & NDE

REFERENCE Codes

► SECTION II - Materials

► Part A

► Part B

► Part C

► Part D

► SECTION V - Nondestructive Examination

► SECTION IX - Welding and Brazing Qualifications .

Bureau Veritas Training Course on ASME Section IX 10

Article 1 - Welding General Requirements

► Contains general information and definitions

Definition of welders, brazers and welding & brazing operators

Definition of WPS, PQR and WPQ

Responsibility of manufacturer

Weld orientation and test positions

Groove and fillet welds, plate and pipe

► Type and purpose of tests and examinations

► Mechanical tests (tension, bend, impact, fillet and stud weld tests)

► Special examination for welders (radiographic examination)

► Visual examination.

► Specimen types and acceptance criteria

► Other tests and examinations

► Radiographic examination

► Stud weld, resistance, laser beam and flash welding tests.

Bureau Veritas Training Course on ASME Section IX 11

QW- 424 Base Metals Used for Procedure

► Qualification

► QW- 424.1 Base metals are assigned P- Numbers in table QW/QB-422; metals

that do not appear in table QW/QB-422 are considered to be unassigned metals

except as otherwise defined for base metals having the same UNS numbers.

► Unassigned metals shall be identified in the WPS and on the PQR by

specification, type and grade, or by chemical analysis and mechanical

properties.

► The minimum tensile strength shall be defined by the organization that specified

the unassigned metal if the tensile strength of that metal is not defined by the

material specification.

Bureau Veritas Training Course on ASME Section IX 12

QW- 420 MATERIAL GROUPINGS

► P-Numbers assigned to Base Metals for the purpose of reducing the number of

welding and brazing procedure qualifications required. P-Numbers are

Alphanumeric designations.

► In addition, ferrous base metals have been assigned Group Numbers creating

subsets of P-Numbers and S-Numbers that are used when WPS’s are required

to be qualified by impact testing by other Sections or Codes.

► These assignments are based essentially on comparable base metal

characteristics, such as composition, weldability and mechanical properties,

where this can logically be done.

► These assignments do not imply that base metals may be indiscriminately

substituted for a base metal that was used in the qualification test without

consideration of compatibility from the standpoint of metallurgical properties,

Post Weld Heat Treatment (PWHT), design, mechanical properties, and service

requirements.

► The QW-422 table shows the assignment groups for various Ferrous and Non

ferrous materials

Bureau Veritas Training Course on ASME Section IX 13

► S-Numbers, In 2009 S-Numbers were removed from the table QB/QW 422

S-Numbers were assigned to materials that were acceptable for use by the

ASME B31 Code for Pressure Piping, or by selected Boiler and Pressure

Vessel Code Cases, but which are not included within ASME Boiler and

Pressure Vessel Code Material Specifications (Section II). Material previously

assigned S-Numbers were reassigned the P-Numbers or P-Number plus

Group Number

► There are instances where materials assigned to one P or S-Number or Group

Number have been reassigned to a different P or S-Number or Group number

in later editions. Procedure and Performance qualifications qualified under the

previous P or S-Number or Group Number assignment may continued to be

used under the new or P-Number or Group Number assignment , provided the

WPS is revised to limit the materials qualified for welding to those assigned to

new P or S-Number and Group Number for the specific material originally used

for the Procedure Qualification test coupon.

Bureau Veritas Training Course on ASME Section IX 14

QW- 430 F-NUMBERS

► QW-431 General

► The F-Number grouping of Electrodes and Welding rods in table QW-432 is

based essentially on their usability characteristics, which fundamentally

determine the ability of welders and welding operators to make satisfactory

weldment with a given filler metal.

► This grouping is made to reduce the number of Welding procedure and

performance qualifications, where this can logically be done.

► The grouping does not imply that Base metals or Filler Metals within a group

may be indiscriminately substituted for filler metal that was used in the

qualification test without consideration of the compatibility of Base and Filler

metals from the standpoint of metallurgical properties, Post Weld Heat

Treatment ,design and service requirements, and Mechanical properties

Bureau Veritas Training Course on ASME Section IX 15

Article II - Welding Procedure Qualification

QW 200.1,Welding Procedure Specification – A WPS is a written

qualified welding procedure prepared to provide direction for making

production welds to Code requirements

► Contents of a WPS – The completed WPS shall describe all of the

essential , Non essential, and, when required , supplementary essential

variables for each welding process used in the WPS

► Changes to WPS – Changes may be made in the non essential

variables of WPS to suit production requirements without requalification

provided such changes are documented with respect to the essential,

nonessential, and, when required supplementary essential variables

for each process

QW 200.2 Procedure Qualification Record – A PQR is a record of the

welding data used to test weld coupon. The PQR is a record of variable

recorded during the welding of the test coupon.

Bureau Veritas Training Course on ASME Section IX 16

Article II - Welding Procedure Qualification

► Contents of the PQR – The completed PQR shall document all

essential and, when required, supplementary essential variables of QW

250 through QW 280 for each welding process used during the welding

of test coupon. Non essential variables or other variables used during

the coupon welding may be recorded.

► Certification of PQR – PQR shall be certified by the contractor or

Manufacturer. The Manufacturer or Contractor may not subcontract

certification function. This certification is intended to be the Manufacturer

or Contractor verification that the information in the PQR is true record of

the variables used during the welding of test coupon and that the

resulting tensile, bend, or macro test results are in compliance with

Section IX.

► Changes to PQR – Changes to PQR are not permitted except as

described below. It is a record of what happened during a particular

welding test. Editorial corrections or Addenda to the PQR are permitted.

All changes to PQR require recertification by the Manufacturer or

Contractor.

Bureau Veritas Training Course on ASME Section IX 17

Article II - Welding Procedure Qualification

QW-200.4 Combination of Welding Procedures

► (a)More than one WPS having different essential, supplementary

essential, or nonessential variables may be used in a single production

joint. Each WPS may include one or a combination of processes, filler

metals, or other variables. Where more than one WPS specifying

different processes, filler metals, or other essential or supplementary

essential variables is used in a joint, QW-451 shall be used to

determine the range of base metal thickness and maximum weld metal

thickness qualified for each process, filler metal, or set of variables, and

those limits shall be observed. Alternatively, qualification of WPSs for

root deposits only may be made in accordance withQW-200.4(b).

► (b) For GTAW, SMAW, GMAW, PAW, and SAW, or combinations of

these processes, a PQR for a process recording a test coupon that was

at least 1⁄2 in. (13 mm)

Bureau Veritas Training Course on ASME Section IX 18

Article II - Welding Procedure Qualification

► (b) For GTAW, SMAW, GMAW, PAW, and SAW, or combinations of

these processes, a PQR for a process recording a test coupon that was

at least 1⁄2 in. (13 mm) thick may be combined with one or more other

PQRs recording another welding process and any greater base metal

thickness. In this case, the process recorded on the first PQR may be

used to deposit the root layers using the process(es) recorded on that

PQR up to 2t (for short circuiting type of GMAW, see QW-404.32) in

thickness on base metal of the maximum thickness qualified by the

other PQR(s) used to support the WPS. The requirements of Note (1) of

tables QW-451.1 and QW-451.2 shall apply.

Bureau Veritas Training Course on ASME Section IX 19

Article II - Welding Procedure Qualification

QW-201 Manufacturer’s or Contractor’s Responsibility

► Each manufacturer or contractor shall list the parameters applicable to

welding that he performs in construction of weldments built in

accordance with this Code. These parameters shall be listed in a

document known as a Welding Procedure Specification (WPS).

► Each manufacturer or contractor shall qualify the WPS by the welding of

test coupons and the testing of specimen (as required in this Code),

and the recording of the welding data and test results in a document

known as a Procedure Qualification Record (PQR).

► The welders or welding operators used to produce weldments to be

tested for qualification of procedures shall be under the full supervision

and control of the manufacturer or contractor during the production of

these test weldments.

Bureau Veritas Training Course on ASME Section IX 20

Article II - Welding Procedure Qualification

► The weldments to be tested for qualification of procedures shall be

welded either by direct employees or by individuals engaged by

contract for their services as welders or welding operators under the full

supervision and control of the manufacturer or contractor. It is not

permissible for the manufacturer or contractor to have the supervision

and control of welding of the test weldments performed by another

organization.

► It is permissible, however, to subcontract any or all of the work of

preparation of test metal for welding and subsequent work on

preparation of test specimens from the completed weldment,

performance of nondestructive examination, and mechanical tests,

provided the manufacturer or contractor accepts the responsibility for

any such work.

► QW 253 depicts details of Variable for Shielded Metal Arc Welding

Bureau Veritas Training Course on ASME Section IX 21

Article II - Welding Procedure Qualification

Bureau Veritas Training Course on ASME Section IX 22

Bureau Veritas Training Course on ASME Section IX 23

Bureau Veritas Training Course on ASME Section IX 24

Bureau Veritas Training Course on ASME Section IX 25

Bureau Veritas Training Course on ASME Section IX 26

Bureau Veritas Training Course on ASME Section IX 27

Bureau Veritas Training Course on ASME Section IX 28

Bureau Veritas Training Course on ASME Section IX 29

Bureau Veritas Training Course on ASME Section IX 30

Bureau Veritas Training Course on ASME Section IX 31

Bureau Veritas Training Course on ASME Section IX 32

Bureau Veritas Training Course on ASME Section IX 33

Bureau Veritas Training Course on ASME Section IX 34

Bureau Veritas Training Course on ASME Section IX 35

Bureau Veritas Training Course on ASME Section IX 36

Article III - Welding Performance Qualification

► QW-300.1 This Article lists the welding processes separately, with the

essential variables that apply to welder and welding operator

performance qualifications. The welder qualification is limited by the

essential variables given for each welding process. These variables are

listed in QW-350, and are defined in Article IV Welding Data. The

welding operator qualification is limited by variables given in QW-360

for each type of weld.

► QW-300.2 The welders or welding operators used to produce such weldments

shall be tested under the full supervision and control of the manufacturer,

contractor, assembler, or installer during the production of these test weldments.

It is not permissible for the manufacturer, contractor, assembler, or installer to

have the welding performed by another organization. It is permissible, however,

to subcontract any or all of the work of preparation of test materials for welding

and subsequent work on the preparation of test specimens from the completed

weldments, performance of nondestructive examination and mechanical tests,

provided the manufacturer, contractor, assembler, or installer accepts full

responsibility for any such work

Bureau Veritas Training Course on ASME Section IX 37

Article III - Welding Performance Qualification

► QW-302 Type of Test Required

► QW-302.1 Mechanical Tests. Except as may be specified for special

processes (QW-380), the type and number of test specimens required for

mechanical testing shall be in accordance with QW-452. Groove weld test

specimens shall be removed in a manner similar to that shown in figures

QW-463.2(a) through QW-463.2(g). Fillet weld test specimens shall be

removed in a manner similar to that shown in figures QW-462.4(a) through

QW-462.4(d) and figure QW-463.2(h).

► All mechanical tests shall meet the requirements prescribed in QW-160 or

QW-180, as applicable.

► QW-302.2 Volumetric NDE. When the welder or welding operator is

qualified by volumetric NDE, as permitted in QW-304 for welders and QW-

305 for welding operators, the minimum length of coupon(s) to be examined

shall be 6 in. (150 mm) and shall include the entire weld circumference for

pipe(s), except that for small diameter pipe, multiple coupons may be

required, but the number need not exceed four consecutively made test

coupons.

Bureau Veritas Training Course on ASME Section IX 38

Article III - Welding Performance Qualification

► QW-322 Expiration and Renewal of Qualification

► QW-322.1 Expiration of Qualification. The performance qualification

of a welder or welding operator shall be affected when one of the

following occurs:

When he has not welded with a process during a period of 6 months or

more, his qualifications for that process shall expire; unless, within the 6

month period, prior to his expiration of qualification

(1) the welder has welded with that process using manual or

semiautomatic welding, under the supervision and control of the

qualifying manufacturer or contractor or participating organization(s) as

identified in QW-300.3;that will extend his qualification for an additional

6 months

Bureau Veritas Training Course on ASME Section IX 39

Article III - Welding Performance Qualification

(2) the welding operator has welded with that process using machine or

automatic welding, under the supervision and control of the qualifying

manufacturer or contractor or participating organization(s) as identified

in QW-300.3; that will extend his qualification for an additional 6 months

► (b) When there is a specific reason to question his ability to make welds

that meet the specification, the qualifications that support the welding

he is doing shall be revoked. All other qualifications not questioned

remain in effect .

► Refer Table QW 353 for essential variables applicable to welder

Process : Shielded Metal - Arc Welding

Bureau Veritas Training Course on ASME Section IX 40

Article III - Welding Performance Qualification

Bureau Veritas Training Course on ASME Section IX 41

Test Positions for Plate and Pipe - PQR

Bureau Veritas Training Course on ASME Section IX 42

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 43

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 44

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 45

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 46

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 47

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 48

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 49

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 50

Mechanical tests for procedure Qualification

Bureau Veritas Training Course on ASME Section IX 51

Bureau Veritas Training Course on ASME Section IX 52

You might also like

- Asme Sec Ix - Short Notes ReferenceDocument29 pagesAsme Sec Ix - Short Notes Referencekart_rl0% (1)

- ASME Sec IX Welding Qualification GuideDocument176 pagesASME Sec IX Welding Qualification GuideUtkarsh GautamNo ratings yet

- Asme Sec Ix - Short NotesDocument20 pagesAsme Sec Ix - Short NotesParvee K NakwalNo ratings yet

- TÜV SÜD South Asia Training Program on ASME Sec IX Welding Procedures and Welder QualificationDocument177 pagesTÜV SÜD South Asia Training Program on ASME Sec IX Welding Procedures and Welder QualificationM A67% (3)

- WPS& WQRDocument132 pagesWPS& WQRAby Jacob Mathews100% (3)

- Basic of Asme Sec IxDocument116 pagesBasic of Asme Sec IxHamid Mansouri100% (2)

- Welder and Procedure QualificationDocument25 pagesWelder and Procedure QualificationRamón G. Pacheco100% (3)

- Presentation Asme Sec Ix Wps PQR WPQDocument177 pagesPresentation Asme Sec Ix Wps PQR WPQsiva92% (26)

- ASME IX ExplanationsDocument13 pagesASME IX ExplanationsManju Juno100% (4)

- WPS, PQR & WPQTDocument14 pagesWPS, PQR & WPQTSky RNo ratings yet

- ch4 - API 574 PDFDocument6 pagesch4 - API 574 PDFRAMADOSSNo ratings yet

- Weld Fit Up Inspection Employee TrainingDocument10 pagesWeld Fit Up Inspection Employee TrainingBadiuzzama Azmi100% (1)

- Answers To The Cweng, Parts 1 and 2 Sample Questions Only: Part 1 Basic Fundamentals of Science ExaminationDocument1 pageAnswers To The Cweng, Parts 1 and 2 Sample Questions Only: Part 1 Basic Fundamentals of Science Examinationsandeepkumar63No ratings yet

- (1-VI) - Rules For Welding - 2013 PDFDocument302 pages(1-VI) - Rules For Welding - 2013 PDFKhoirulRamadhanNo ratings yet

- 2019 ASME Section IX SynopsisDocument31 pages2019 ASME Section IX SynopsisFaiez GhrabNo ratings yet

- Welding Standard Tolerances GuideDocument2 pagesWelding Standard Tolerances GuidewahyuNo ratings yet

- Sample Questions - Mechanical General - AnswerDocument16 pagesSample Questions - Mechanical General - AnswermanojballaNo ratings yet

- General Mechanical Questionnaire Without AnswersDocument7 pagesGeneral Mechanical Questionnaire Without AnswersDaniel Jimenez MerayoNo ratings yet

- Welding Inspection Guide for SteelsDocument132 pagesWelding Inspection Guide for SteelsfahreezNo ratings yet

- Asme 9 TipsDocument13 pagesAsme 9 TipsnasrpkNo ratings yet

- Understanding WPS, PQR, WPQRDocument4 pagesUnderstanding WPS, PQR, WPQRYousef Adel HassanenNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument95 pagesASME SECTION IX INTERPRETATIONSnizam1372No ratings yet

- Asme Ix Wps PQR ChecklistDocument0 pagesAsme Ix Wps PQR ChecklistaghussrNo ratings yet

- Wps PQR GuideDocument40 pagesWps PQR GuideBalakumar100% (10)

- Essential Weld Fit-Up ChecksDocument10 pagesEssential Weld Fit-Up ChecksManoj KumarNo ratings yet

- UG Piping, Hydro QC List-InterviewDocument6 pagesUG Piping, Hydro QC List-InterviewSyed M. Imran Ali100% (1)

- Weld Procedures ExplainedDocument11 pagesWeld Procedures ExplainednamasralNo ratings yet

- Welding Procedures and Welders QualificationDocument41 pagesWelding Procedures and Welders QualificationHamid MansouriNo ratings yet

- SCWI BokDocument2 pagesSCWI Bokrajeshmohana100% (1)

- Welding Repair Procedure for JG Summit ProjectDocument12 pagesWelding Repair Procedure for JG Summit ProjectDarrel Espino AranasNo ratings yet

- I Can Do That WPS'S, PQR's and WQ'sDocument93 pagesI Can Do That WPS'S, PQR's and WQ'sKo NSNo ratings yet

- CSWIP-WI-6-92 14th Edition April 2017Document17 pagesCSWIP-WI-6-92 14th Edition April 2017mullanjiNo ratings yet

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Document4 pagesCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)nike_y2k85% (13)

- Thickness Range For Welder Qualification and Procedure QualificationDocument4 pagesThickness Range For Welder Qualification and Procedure QualificationvirajNo ratings yet

- WeldingDocument9 pagesWeldingkiraneluruNo ratings yet

- Pressure Equipment Safety Authority Welding Exam Reference SyllabusDocument8 pagesPressure Equipment Safety Authority Welding Exam Reference SyllabusSiva Sankara Narayanan SubramanianNo ratings yet

- Introduction To Welding API 577 Capter 7Document12 pagesIntroduction To Welding API 577 Capter 7Edo Destrada100% (1)

- ASME IX Interpretation Part1 PDFDocument51 pagesASME IX Interpretation Part1 PDFalisyalala100% (3)

- Introduction To Welding - MetallurgyDocument15 pagesIntroduction To Welding - Metallurgyramkishore_87100% (1)

- PWHTDocument25 pagesPWHTBruce leeNo ratings yet

- Review of Current Practice for Welding of Grade 92Document13 pagesReview of Current Practice for Welding of Grade 92pipedown456100% (1)

- API 510 Preparatory TrainingDocument362 pagesAPI 510 Preparatory TrainingAnonymous ACFRCjZNo ratings yet

- Note 1 Approving Welding Procedure - Process FlowDocument26 pagesNote 1 Approving Welding Procedure - Process FlowMohamad Yusuf HelmiNo ratings yet

- Preheat PDFDocument4 pagesPreheat PDFKamal UddinNo ratings yet

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Document68 pagesTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistNo ratings yet

- Welding Inspection VT Course-New PDFDocument82 pagesWelding Inspection VT Course-New PDF7okaz100% (2)

- ASME P-Numbers PDFDocument1 pageASME P-Numbers PDFFahri Risfa ZulfiNo ratings yet

- Module 1Document30 pagesModule 1mahmoud aliNo ratings yet

- ASME SEC IX Welding Qualification GuideDocument79 pagesASME SEC IX Welding Qualification Guideabdelkader bensatal100% (1)

- Factory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Document29 pagesFactory Production Control System - Welding Quality Manual 23-01-17 - Issue 1Scott Trainor100% (2)

- Solved Paper On Section IxDocument25 pagesSolved Paper On Section IxNasir Javed90% (20)

- Welding QuestionnairesDocument2 pagesWelding Questionnairesasif712100% (2)

- TOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1Document1 pageTOP 250+ QC Welding Inspector Interview Questions and Answers 11 February 2021 - QC Welding Inspector Interview Questions - Wisdom Jobs India1kokaanilkumarNo ratings yet

- Section IX WeldingDocument6 pagesSection IX WeldingAhmedNo ratings yet

- Welder and Procedure Qualification ReviewDocument26 pagesWelder and Procedure Qualification ReviewSlim EL-EUCHNo ratings yet

- Welder and Procedure QualificationDocument26 pagesWelder and Procedure Qualification'Izzad AfifNo ratings yet

- Section IX of The ASME Boiler and Pressure Vessel CodeDocument6 pagesSection IX of The ASME Boiler and Pressure Vessel CodeMR FIKRINo ratings yet

- WpsDocument39 pagesWpsAkhilesh Kumar100% (1)

- 08CLecture - Welding Codes StandardsDocument15 pages08CLecture - Welding Codes StandardsDavid HuamanNo ratings yet

- Sections: I Rules For Construction of Power BoilersDocument68 pagesSections: I Rules For Construction of Power BoilersAnonymous VohpMtUSN100% (1)

- Rotating Machineries - Aspects of Operation and Maintenance (PDFDrive)Document110 pagesRotating Machineries - Aspects of Operation and Maintenance (PDFDrive)paulo cesar hernandez mijangosNo ratings yet

- Lifts 150324053755 Conversion Gate01 PDFDocument43 pagesLifts 150324053755 Conversion Gate01 PDFAjay JainNo ratings yet

- BoostLi Energy Storage Module ESM-48100U2 User ManualDocument51 pagesBoostLi Energy Storage Module ESM-48100U2 User Manualsoulmuh75% (4)

- Soliman 2010Document5 pagesSoliman 2010rizkyseprinalfiNo ratings yet

- NFS2-3030 - NCA-2 - LCM - Upgrade Instructions October 2016Document2 pagesNFS2-3030 - NCA-2 - LCM - Upgrade Instructions October 2016João CustódioNo ratings yet

- Project DirectionDocument1 pageProject DirectionAnh NguyễnNo ratings yet

- DX 5000 Plus User Manual NewDocument17 pagesDX 5000 Plus User Manual NewclaudiodelbiancoNo ratings yet

- VTOL MQP 2020 SignedDocument116 pagesVTOL MQP 2020 SignedtfNo ratings yet

- Replacement AlgoDocument13 pagesReplacement AlgoTejaswi SuryaNo ratings yet

- Railml® 3 Simple Example Step Part 2: Interlocking Railml® 3.1 Tutorial Simple Example Step-By-Step Part 2: Interlocking StepDocument68 pagesRailml® 3 Simple Example Step Part 2: Interlocking Railml® 3.1 Tutorial Simple Example Step-By-Step Part 2: Interlocking Steptap.jackson6255No ratings yet

- Microprocessor & Assembly Language Lab ManualDocument49 pagesMicroprocessor & Assembly Language Lab ManualMAHMOUD CERAYNo ratings yet

- GHG 2014 Electrical Guide M2Document46 pagesGHG 2014 Electrical Guide M2cristian picado100% (3)

- Digital Signal and Image Processing FundamentalsDocument51 pagesDigital Signal and Image Processing FundamentalsLaxmi VathariNo ratings yet

- CM6650 User ManualDocument254 pagesCM6650 User Manualacjp1979No ratings yet

- CR 300Document128 pagesCR 300Francisco José Fontelles ObelenisNo ratings yet

- CS 4700: Foundations of Artificial Intelligence - 1-Nearest Neighbor ModelsDocument9 pagesCS 4700: Foundations of Artificial Intelligence - 1-Nearest Neighbor ModelsDivira Iga FirdiantiNo ratings yet

- Advantages and Disadvantages of TechnologyDocument2 pagesAdvantages and Disadvantages of TechnologyArim Arim100% (1)

- 5 Collaborative ProjectDocument26 pages5 Collaborative ProjectCabagnot Piolo JuliusNo ratings yet

- First American Grand Prix - The Savannah Auto Races, 1908-1911, The - Tanya A. BaileyDocument239 pagesFirst American Grand Prix - The Savannah Auto Races, 1908-1911, The - Tanya A. BaileyFilipeBouraNo ratings yet

- Cisco System Managing de Supply ChainDocument7 pagesCisco System Managing de Supply ChainNorberto VarasNo ratings yet

- CATIA Piping TutorialDocument37 pagesCATIA Piping TutorialDSM CikarangNo ratings yet

- Vocalist Live 4 - Owner's Manual (English)Document38 pagesVocalist Live 4 - Owner's Manual (English)Zeca VieiraNo ratings yet

- Cse 2017 PDFDocument300 pagesCse 2017 PDFSREE VALSANNo ratings yet

- Multimedia Audio or Video Lesson IdeaDocument2 pagesMultimedia Audio or Video Lesson Ideaapi-657584830No ratings yet

- SAP License DefinitionsDocument1 pageSAP License DefinitionsshubendubarweNo ratings yet

- Directional Driller X CVDocument2 pagesDirectional Driller X CVMino MinoNo ratings yet

- 8086 MicroprocessorDocument24 pages8086 Microprocessorsamrat kumar100% (1)

- Solidworks SyllabusDocument7 pagesSolidworks SyllabusSelvaNo ratings yet

- Exam C1000-100 IBM Cloud Solution Architect v4 Sample TestDocument4 pagesExam C1000-100 IBM Cloud Solution Architect v4 Sample TestMax LeeNo ratings yet

- 3 - SQUARE D Model 6 Motor Control Center Profibus DPDocument4 pages3 - SQUARE D Model 6 Motor Control Center Profibus DPSalvatierra Rojas MoisesNo ratings yet