Professional Documents

Culture Documents

Poster

Uploaded by

WOMDVIIaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster

Uploaded by

WOMDVIIaCopyright:

Available Formats

ASSESSMENT OF THE ALLOY

SYSTEMS, CORRESPONDING TO

HYPOEUTECTIC CAST IRON AND

FACULTY OF FOUNDRY ENGINEERING CHROMIUM CAST IRON, USING THE

XXXVII INTERNATIONAL SCIENTIFIC CALPHAD METHOD

CONFERENCE

FOUNDRYMAN‘S DAY 2013 M. Wróbel

Krakow, 28 – 29 Nov. 2013 AGH University of Science and Technology

Faculty of Foundry Engineering.

Reymonta 23, 30-059 Krakow, Poland

marek.wrobel@agh.edu.pl

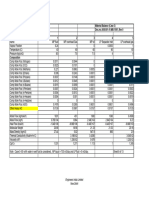

T = 1290°C Moles Mass [g]

M2B_TETR 0.00541 0.21494

Composition

Component Mole Fraction Mass Fraction

Fe 0.37216 0.52329

Cr 0.29476 0.38589

B 0.33300 0.09064

Mo 0.00007 0.00018

T = 1290°C Moles Mass [g]

M7C3 0.15040 6.17027

Composition

Component Mole Fraction Mass Fraction

Cr 0.43705 0.55393

Fe 0.25950 0.35326

C 0.30000 0.08783

Mn 0.00309 0.00414

Mo 0.00036 0.00084 For greater amounts of Ti Mass % Ti = 0.2 Mo = 0.2

T = 1250°C Moles Mass [g]

another FCC phase appears FCC_A1#2 0.00243 0.07610

at lower temperatures with Composition

composition given in table. Component Mole Fraction Mass Fraction

Ti 0.41013 0.62770

C 0.47962 0.18414

Cr 0.09862 0.16391

S = 0.013 Linear (S = 0.013)

S = 0.09 Linear (S = 0.09)

Mole fraction of primary austenite

0.46

0.44

0.42

0.4

0.38

0.36

0.34

0.76 0.77 0.78 0.79 0.8 0.81 0.82 0.83

Eutectic saturation Sc

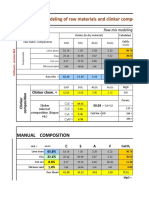

Possibilities of CALPHAD calculations:

• Determination of amount of primary austenite as a function of

eutectic saturation Sc.

• Finding influence of sulphur concentration on amount of primary

austenite and liquidus temperature.

• Estimation of inoculants’ amount for proper carrying out the

process.

• Computation of amount and temperature range for phases being a

substrates for nucleation to appear.

• Determination of role of other elements delivered to the system

together with inoculants.

Conclusions:

Given relationships are very helpful if not necessary in modelling,

both micro and macro, of the crystallization process. Knowing the

T = 1270°C Moles Mass [g] sequence and amount of each solidifying phase one can derive the

FCC_A1

Component

0.00066 0.03257

Mole Fraction Mass Fraction

speed of moving phase boundary for known conditions. The function

Nb 0.41746 0.78388 of amount of the fraction solid vs. temperature is being used in macro

C 0.49035 0.11903

Cr 0.08949 0.09405 modelling.

Fe

Mn

0.00264

0.00006

0.00298

0.00007

Moreover presented results show the area where the CALPHAD

method can be employed in the industry. Apart from precise

information on liquidus and solidus temperature, the results of

calculations for phases performing substrates for nucleation role are

demonstrated – one can estimate amount of inoculant needed for the

process or the temperature at which it would work properly.

Acknowledgements: This work was supported by AGH statutory project no. 15.11.170.483.

You might also like

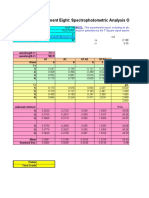

- Experiment.4 Uv/Vis Spectrophotometry: Department of Chemistry University of Bahrain CHEMY310Document6 pagesExperiment.4 Uv/Vis Spectrophotometry: Department of Chemistry University of Bahrain CHEMY310Zahra Al-BasriNo ratings yet

- Absorbance at λmax 260nm for PBS: Calibration curvesDocument3 pagesAbsorbance at λmax 260nm for PBS: Calibration curvesNaveedNo ratings yet

- Figure 1. Plot of R vs. PDocument5 pagesFigure 1. Plot of R vs. PKaye CaqNo ratings yet

- Part A - Plot of Absorbance vs. Mole Fraction of Iron (II)Document2 pagesPart A - Plot of Absorbance vs. Mole Fraction of Iron (II)Remjohn MagtaasNo ratings yet

- Kurva Hubungan Antara Konsentrasi Larutan Na S O Dengan Waktu (1/t)Document2 pagesKurva Hubungan Antara Konsentrasi Larutan Na S O Dengan Waktu (1/t)Mulia Sri RahmawatiNo ratings yet

- Absorbance BB at 618 NM: Absorbance Molarity (Mol L)Document16 pagesAbsorbance BB at 618 NM: Absorbance Molarity (Mol L)Stegi IlanthiraianNo ratings yet

- Chem 112 Cu AnalysisDocument2 pagesChem 112 Cu Analysismiami14No ratings yet

- Full Download Solutions Manual To Accompany Water and Wastewater Technology 7th Edition 9780135114049 PDF Full ChapterDocument30 pagesFull Download Solutions Manual To Accompany Water and Wastewater Technology 7th Edition 9780135114049 PDF Full Chapterformyl.luffermto8100% (18)

- (KW) (KW) (M /H) : Unit Settings: Si C Kpa KJ Mass Deg (KJ/KG K) (KJ/KG K) (KJ/KG)Document1 page(KW) (KW) (M /H) : Unit Settings: Si C Kpa KJ Mass Deg (KJ/KG K) (KJ/KG K) (KJ/KG)Calos Andres GonzalezNo ratings yet

- 1 PDFDocument1 page1 PDFCalos Andres GonzalezNo ratings yet

- Graph Molar Conductivity Vs ConcDocument5 pagesGraph Molar Conductivity Vs ConckimsyaNo ratings yet

- MO 1 2 1 6DIPS 1PPM (60min) Bandgap3hrs 3.02Document1 pageMO 1 2 1 6DIPS 1PPM (60min) Bandgap3hrs 3.02markNo ratings yet

- Estimation of Magnetic Susceptibility of Two Noncentrosymmetric Crystals Using Quincke's and Guoy MethodDocument11 pagesEstimation of Magnetic Susceptibility of Two Noncentrosymmetric Crystals Using Quincke's and Guoy Methodsuriya extazeeNo ratings yet

- T (N) V (M/S) Vs T (N) Chart Title V (M/S) Vs T (N)Document2 pagesT (N) V (M/S) Vs T (N) Chart Title V (M/S) Vs T (N)Carlos GarcíaNo ratings yet

- LNCVSTDocument6 pagesLNCVSTReal PonixNo ratings yet

- Kurva Kalbrasi Waktu TampakDocument1 pageKurva Kalbrasi Waktu Tampakirzaaprilian12No ratings yet

- Lab AnalysisDocument4 pagesLab AnalysisErnestasBlaževičNo ratings yet

- MO 1 2 1 6DIPS 1PPM (60mins) Bandgap4hrs 2.98Document1 pageMO 1 2 1 6DIPS 1PPM (60mins) Bandgap4hrs 2.98markNo ratings yet

- Experiment Eight: Spectrophotometric Analysis of A Complex MixtureDocument12 pagesExperiment Eight: Spectrophotometric Analysis of A Complex MixtureMark AwNo ratings yet

- CCO2, G Vs T: VARIASI C Alga, L, 0 0.05 0.1 0.2 0.3 0.4Document5 pagesCCO2, G Vs T: VARIASI C Alga, L, 0 0.05 0.1 0.2 0.3 0.4Azhar AdityaNo ratings yet

- Rate Expression: - Rate Law and Order of ReactionDocument31 pagesRate Expression: - Rate Law and Order of ReactionemilyNo ratings yet

- Atomic Absorption Spectroscopy: CHEMY 313 Analytical ChemistryDocument7 pagesAtomic Absorption Spectroscopy: CHEMY 313 Analytical ChemistryJassim123 SabtNo ratings yet

- Computer Modelling of A 245Kv 40ka H Ybrid Gas Circuit BreakerDocument20 pagesComputer Modelling of A 245Kv 40ka H Ybrid Gas Circuit Breakerbylee3894No ratings yet

- Chem 112 Beers LawDocument1 pageChem 112 Beers Lawmiami14No ratings yet

- Results and DiscussionsDocument8 pagesResults and DiscussionsSalihah AbdullahNo ratings yet

- Perbandingan Laju Absorpsi Ga Naoh Dan Ga Na2Co3 Terhadap Waktu Perbandingan Konsentrasi Na2Co3 Inlet Dan Oulet Terhadap WaktuDocument3 pagesPerbandingan Laju Absorpsi Ga Naoh Dan Ga Na2Co3 Terhadap Waktu Perbandingan Konsentrasi Na2Co3 Inlet Dan Oulet Terhadap WaktuIqbalMuhammadNo ratings yet

- Unit Settings: Si C Kpa KJ Mass Deg (KJ/KG K) (KJ/KG K) (KJ/KG) (Kpa) (Kpa) (Kpa) (Kpa) (Kpa) (Kpa) (KW) (KW) (C) (C) (C) (C) (M /H) (KG/M)Document1 pageUnit Settings: Si C Kpa KJ Mass Deg (KJ/KG K) (KJ/KG K) (KJ/KG) (Kpa) (Kpa) (Kpa) (Kpa) (Kpa) (Kpa) (KW) (KW) (C) (C) (C) (C) (M /H) (KG/M)Calos Andres GonzalezNo ratings yet

- 2 PDFDocument1 page2 PDFCalos Andres GonzalezNo ratings yet

- M (KG) LF (M) X (M) F (N) M: M (KG) t1(s) t2(s) t3(s) Tprom(s) T(S) T 2 (S 2)Document2 pagesM (KG) LF (M) X (M) F (N) M: M (KG) t1(s) t2(s) t3(s) Tprom(s) T(S) T 2 (S 2)DANIEL BERNAL GOMEZNo ratings yet

- Lab # 08Document5 pagesLab # 08Muhammad AdnanNo ratings yet

- Lab Report Batch Reactor GGDocument25 pagesLab Report Batch Reactor GGFrost Orchid100% (1)

- Hub Waktu Dengan Konsentrasi Sel Dan GlukosaDocument6 pagesHub Waktu Dengan Konsentrasi Sel Dan GlukosaThyolaNo ratings yet

- MaterialBalance ggs1Document3 pagesMaterialBalance ggs1rssmartinvestNo ratings yet

- Absorption of CO Unit: Assumption: CO2 Removal in CO2 Absorber 97% Assumption: CO2 Removal in Flash Separtor 99%Document7 pagesAbsorption of CO Unit: Assumption: CO2 Removal in CO2 Absorber 97% Assumption: CO2 Removal in Flash Separtor 99%Muhammad Umer RanaNo ratings yet

- Practica 6: Fuerza de Pretensado Inicial y Fuerza de Pretensado FinalDocument10 pagesPractica 6: Fuerza de Pretensado Inicial y Fuerza de Pretensado FinalWilsonNo ratings yet

- Chart Title: Kelaruta N PBCL (G/L)Document2 pagesChart Title: Kelaruta N PBCL (G/L)Adhara OllshopNo ratings yet

- Tabel As Ar Condicion A DoDocument60 pagesTabel As Ar Condicion A DoJanaynaNo ratings yet

- Experimental Data - ATS Leaching - 2019 - ISTDocument14 pagesExperimental Data - ATS Leaching - 2019 - ISTBigNo ratings yet

- Properties of SFRC in Hardened StateDocument31 pagesProperties of SFRC in Hardened StateAbdul WadoodNo ratings yet

- Hitungan Di Lab BahanDocument5 pagesHitungan Di Lab BahanvanilivaniliNo ratings yet

- Enzyme DataDocument36 pagesEnzyme DataSamuel HastingsNo ratings yet

- PHYS 252 Lab E3 - Ohm's Law: Coil #4 DataDocument8 pagesPHYS 252 Lab E3 - Ohm's Law: Coil #4 DataOndra LabíkNo ratings yet

- WAFO - A MATLAB Toolbox For Random Waves and Loads: Sofia AbergDocument21 pagesWAFO - A MATLAB Toolbox For Random Waves and Loads: Sofia Abergesttif02No ratings yet

- ResultsDocument6 pagesResultsNora ZuraNo ratings yet

- Spring Grade 52cr4mo2v ChemicalDocument1 pageSpring Grade 52cr4mo2v ChemicalSujin SujiNo ratings yet

- Bass-Barrera SV E1 U2Document12 pagesBass-Barrera SV E1 U2Sofia BassNo ratings yet

- Nakayasu CiperoDocument2 pagesNakayasu CiperoSamuelZgly100% (1)

- Određivanje Cu U Čeliku: Co (510 NM)Document4 pagesOdređivanje Cu U Čeliku: Co (510 NM)marijanaNo ratings yet

- Grafi K CL Terhadap AlphaDocument3 pagesGrafi K CL Terhadap AlphaDesy RamadhaniNo ratings yet

- TB 1 Anstruk 3 Tahap 1 - Sulaiman New 2Document14 pagesTB 1 Anstruk 3 Tahap 1 - Sulaiman New 2Jasmine ElynNo ratings yet

- Klinker Composition CalculationProt 231bDocument28 pagesKlinker Composition CalculationProt 231bPedjaNo ratings yet

- Results and DiscussionDocument3 pagesResults and DiscussionShaoline LungaoNo ratings yet

- Kinetika Disolusi Menurut Crowell - Hixson Pada Paracetamol GenerikDocument4 pagesKinetika Disolusi Menurut Crowell - Hixson Pada Paracetamol GenerikWikaNo ratings yet

- Kinetika Disolusi Menurut Crowell - Hixson Pada Paracetamol GenerikDocument4 pagesKinetika Disolusi Menurut Crowell - Hixson Pada Paracetamol GenerikWikaNo ratings yet

- Thermo Lab 1 Temperature GradientDocument3 pagesThermo Lab 1 Temperature GradientBill YiiNo ratings yet

- Chart Title Larutan Pembanding: CR (NO) .9H ODocument2 pagesChart Title Larutan Pembanding: CR (NO) .9H OCameliaNo ratings yet

- Chem Lab 7Document4 pagesChem Lab 7Norayr GulumainNo ratings yet

- Ejercicio 01: SolucionDocument30 pagesEjercicio 01: SolucionJorge Aurelio Menacho YanacNo ratings yet

- Lecture 8-Emissions Notes 2023Document10 pagesLecture 8-Emissions Notes 2023RianyanchaberaNyamesNo ratings yet

- Chapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Document44 pagesChapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Tommy RamazzottoNo ratings yet

- Tractor Price and Speci Cations: Tractors in IndiaDocument4 pagesTractor Price and Speci Cations: Tractors in Indiatrupti kadamNo ratings yet

- Coarse DispersionsDocument35 pagesCoarse Dispersionsraju narayana padala0% (1)

- Missoula County Fairgrounds Phase 2Document10 pagesMissoula County Fairgrounds Phase 2Olivia IversonNo ratings yet

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehNo ratings yet

- A Cook's Journey To Japan - Fish Tales and Rice Paddies 100 Homestyle Recipes From Japanese KitchensDocument306 pagesA Cook's Journey To Japan - Fish Tales and Rice Paddies 100 Homestyle Recipes From Japanese KitchensEthan F.100% (1)

- Catalogue CV. Traka Abadi UniversalDocument15 pagesCatalogue CV. Traka Abadi UniversalHackers StevenNo ratings yet

- Schematic Diagram For Pharmaceutical Water System 1652323261Document1 pageSchematic Diagram For Pharmaceutical Water System 1652323261Ankit SinghNo ratings yet

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksDocument2 pagesComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINANo ratings yet

- Lesson Plan PPEDocument3 pagesLesson Plan PPEErika Jean Moyo ManzanillaNo ratings yet

- TherabandDocument1 pageTherabandsuviacesoNo ratings yet

- Onuaguluchi1996 1Document10 pagesOnuaguluchi1996 1IkaSugihartatikNo ratings yet

- Hubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangDocument7 pagesHubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangNanda MaisyuriNo ratings yet

- Universal ING - LA.Boschi Plants Private LimitedDocument23 pagesUniversal ING - LA.Boschi Plants Private LimitedAlvaro Mendoza MaytaNo ratings yet

- Chapter One - FiveDocument118 pagesChapter One - FivePrecious AnthonyNo ratings yet

- Rigging: GuideDocument244 pagesRigging: Guideyusry72100% (11)

- Doingwell Coaching ServicesDocument4 pagesDoingwell Coaching ServicesPaweł PawełNo ratings yet

- Vaccination Schedule in Dogs and CatsDocument3 pagesVaccination Schedule in Dogs and CatsAKASH ANANDNo ratings yet

- Plumbing Breakup M 01Document29 pagesPlumbing Breakup M 01Nicholas SmithNo ratings yet

- LIC Jeevan Labh Plan (836) DetailsDocument12 pagesLIC Jeevan Labh Plan (836) DetailsMuthukrishnan SankaranNo ratings yet

- Mobrey CLT PDFDocument18 pagesMobrey CLT PDFAnonymous Oydnu9No ratings yet

- Kingdom of AnimaliaDocument6 pagesKingdom of AnimaliaBen ZerepNo ratings yet

- BS 65-1981Document27 pagesBS 65-1981jasonNo ratings yet

- Essay Type ExaminationDocument11 pagesEssay Type ExaminationValarmathi83% (6)

- MCQ Homework: PeriodonticsDocument4 pagesMCQ Homework: Periodonticsفراس الموسويNo ratings yet

- Olivares VsDocument2 pagesOlivares VsDebbie YrreverreNo ratings yet

- 10 Chapter 3 Occupancy Classification AnDocument10 pages10 Chapter 3 Occupancy Classification AnMatt BaronNo ratings yet

- Bioplan Nieto Nahum)Document6 pagesBioplan Nieto Nahum)Claudia Morales UlloaNo ratings yet

- Family Stress TheoryDocument10 pagesFamily Stress TheoryKarina Megasari WinahyuNo ratings yet

- PV2R Series Single PumpDocument14 pagesPV2R Series Single PumpBagus setiawanNo ratings yet