Professional Documents

Culture Documents

De Salting

Uploaded by

Sivakumar0 ratings0% found this document useful (0 votes)

14 views22 pagesCopyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views22 pagesDe Salting

Uploaded by

SivakumarCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 22

Desalting & Dehydration

Desalting also takes place during

Dehydration

• First step in the produced gas separation

process is to separate crude and gas

• If the salt content of the crude is greater than

10 lb/1000 bbl (expressed as NaCl), the crude

requires desalting to minimize fouling and

corrosion caused by salt deposition on heat

transfer surfaces and acids formed by

decomposition of chloride salts.

Purpose of Dehydration

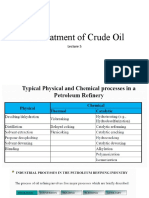

REMOVES NEGATIVE DOWNSTREAM EFFECT

• Salt • Fouling

• Solid metals • Scaling

• Water • Catalyst Poisoning

• Amines • Unit Upset

• Suspended

Particles

Methods

• Gravity or Mechanical Method

• Electrochemical Method

• Ultra-sonic Method

• Chemical Method

• Filtering Hot Crude Using Diatomaceous Earth

Types

• Chemical and Electrostatic separation:

Washing crude oil with water

Water phases are separated

Adding chemicals to assist in breaking up emulsion

Application of electrostatic field to collapse the droplets

1. Chemical separator:

Water and chemical surfactant (demulsifiers)

Heated

2. Electric separator:

Under charge condition polar molecules get oriented and

get separated.

Process

• The crude oil feedstock is heated to 65-180°C

to reduce viscosity and surface tension for

easier mixing and separation of the water.

• In all methods chemicals may be added.

• Ammonia is often used to reduce corrosion.

• Caustic or acid may be added to adjust the pH

of the water wash

Design Calculation

• Maximum quantity of water requires for desalting

(Salt Specification)

• Cso = salt content of the oil, lbm/1,000 bbl

• Csw = concentration of salt in produced water, ppm

• γw = specific gravity of produced water

• fw = volume fraction of water in crude oil

Mixing efficiency

• The fraction of wash water that actually mixes

with the produced water

• Bypasses the desalting stag

• Depending Parameters

Mixing intensity and duration

Diffusion transport

Inter-drop-collision frequency

Water recycle

• Collision frequency, between drops of

dispersed brine and dilution water is

proportional to the drop populations

• Factors affecting are

Recycle ratio

Temperature

pH

Dilution water

• To satisfy mass-balance requirements for diluting the

dispersed brine enough that the salt specification can be

met

• It must have low enough salt content to achieve the

required equilibrium

• Water must not contain

Coke particles

Suspended solids

Iron sulfide

Emulsified oil

Analytical Methods

• Extraction

• Aqueous layer (Jar Test)

• Spectro-photometric

Single stage

Single stage Gravity Settler

Cross Section

Mechanism

Two-Stage

Hybrid

Working of Electrostatic Coalescer

• Distributor injects crude just below multiple

layers of electrostatic grids.

• Water droplets present in the crude are

exposed to the electrostatic field that

rearranges the (salt) ions within the droplets.

• Droplets will then attract each other and as a

result, they coalesce, grow in size, and then

fall out of the upward flowing crude.

AC Current

• Coalescers are designed using alternating

current (AC), which is a proven and reliable

technology.

• Other types of power supply are DC, AC+DC

• Significant drawbacks are tendency for arcing

(short-circuiting) and electrical complexity.

References

• Warren, K.W. 1993. Reduction of Corrosion through Improvements in

Desalting. Paper presented at the Benelux Refinery Symposium,

Lanaken, Belgium, 2–3 December.

• ASTM D-96-88, Standard Test Methods for Water and Sediment in

Crude Oil by Centrifuge Method (Field Procedure). 1988. West

Conshohocken, Pennsylvania: ASTM.

• ASTM D-4007-02, Standard Test Methods for Water and Sediment in

Crude Oil by Centrifuge Method (Laboratory Procedure). 2002. West

Conshohocken, Pennsylvania: ASTM.

• ASTM D-3230-05, Test Method for Salts in Crude Oil (Electrometric

Method). 2005. West Conshohocken, Pennsylvania: ASTM.

• API RP-45, Recommended Practice for Analysis of Oilfield Waters, third

edition. 1998. Washington, DC: API.

You might also like

- MdmaDocument50 pagesMdmaYour dudeNo ratings yet

- Group Seminar On DesalterDocument21 pagesGroup Seminar On Desalterinderdip75% (4)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Arizona State University Water Soft Ner StudyDocument41 pagesArizona State University Water Soft Ner StudychusnuhNo ratings yet

- NatalyStephany Pinguil - Copy of IonicBondsSEDocument5 pagesNatalyStephany Pinguil - Copy of IonicBondsSEnataly natiNo ratings yet

- 1 DesalterDocument20 pages1 DesalterDucViking80% (5)

- Crude Oil DesaltingDocument5 pagesCrude Oil DesaltingAhmed Mohamed Khalil0% (1)

- Water Treatment Process OverviewDocument68 pagesWater Treatment Process OverviewApsara Katugaha100% (3)

- Oilfield Water 1671721735Document26 pagesOilfield Water 1671721735dhyko pratama levi100% (3)

- Desalter TheoryDocument10 pagesDesalter TheoryPraneethNo ratings yet

- Crude Oil DesaltingDocument25 pagesCrude Oil DesaltingNaumanNo ratings yet

- Desalting of Crude OilDocument14 pagesDesalting of Crude OilHammad Hashmi100% (4)

- Hydrocarbon ProcessingDocument54 pagesHydrocarbon Processingjgascoine011No ratings yet

- Water Softening MethodsDocument34 pagesWater Softening MethodsAjitsingh Jagtap100% (1)

- Dispersed Phase Surface Area As A Function of Drop SizeDocument3 pagesDispersed Phase Surface Area As A Function of Drop SizegrabettyNo ratings yet

- Gas DehydrationDocument61 pagesGas Dehydrationraja.mtNo ratings yet

- Pre-Treatment of Crude OilDocument25 pagesPre-Treatment of Crude OilAbhisek AgarwalNo ratings yet

- BOILER WATER TREATMENT GUIDEDocument36 pagesBOILER WATER TREATMENT GUIDERajendran SrnNo ratings yet

- Oil MudsDocument66 pagesOil MudsMes JcNo ratings yet

- PPE - Feed Water Treatment SystemDocument6 pagesPPE - Feed Water Treatment SystemSandeep ChhabraNo ratings yet

- ADU Desalting PDFDocument100 pagesADU Desalting PDFHARSHA DEEPTHI GUNANA (N150434)No ratings yet

- Demineralisation of WaterDocument140 pagesDemineralisation of WaterAshwani Dogra67% (6)

- Water Softening and Demineralization: Pengolahan Air Dan Limbah Industri DTK 2019Document97 pagesWater Softening and Demineralization: Pengolahan Air Dan Limbah Industri DTK 2019Aldi RahmatNo ratings yet

- Deminerlise PlantDocument34 pagesDeminerlise PlantSyed Safiur Rahman100% (1)

- OJT 6 - Boiler Water TreatmentDocument26 pagesOJT 6 - Boiler Water TreatmentAzizul IshakNo ratings yet

- Eletrochemicaldesalter 191231094907Document6 pagesEletrochemicaldesalter 191231094907ShakerMahmoodNo ratings yet

- Module 2Document85 pagesModule 2Suhil IrshadNo ratings yet

- Chap 3B PetroDocument39 pagesChap 3B Petrokishoreprithika100% (1)

- AcidizingDocument58 pagesAcidizingHamid Reza BabaeiNo ratings yet

- Boiler Water TreatmentDocument43 pagesBoiler Water TreatmentmasoodismNo ratings yet

- Desalting and Dehydration VIDocument22 pagesDesalting and Dehydration VISivakumarNo ratings yet

- Desalting and DehydrationDocument10 pagesDesalting and DehydrationRizwan umerNo ratings yet

- Lec.1 Desalting ProcessDocument30 pagesLec.1 Desalting ProcessAhmed RedaNo ratings yet

- Crude Oil DistillationDocument6 pagesCrude Oil DistillationLakshya SaxenaNo ratings yet

- Evn SDocument31 pagesEvn SMathaneshan RajagopalNo ratings yet

- Water Quality Requirements and Auxiliary Chemicals For DyeingDocument27 pagesWater Quality Requirements and Auxiliary Chemicals For DyeingMegatronNo ratings yet

- DesaltingDocument25 pagesDesaltingOmar GamalNo ratings yet

- Boiler Feed Water: Aijaz AliDocument33 pagesBoiler Feed Water: Aijaz AliAnonymous q9eCZHMuSNo ratings yet

- IMP3Document44 pagesIMP3Hamza MasoodNo ratings yet

- Petroleum Crude Preparation TechniquesDocument23 pagesPetroleum Crude Preparation TechniquesAkashNo ratings yet

- 3-Discussed The Distillation-13-01-2022 (13-Jan-2022) Material - I - 13-01-2022 - LECTURE - 3 - Basics - in - DistillationDocument47 pages3-Discussed The Distillation-13-01-2022 (13-Jan-2022) Material - I - 13-01-2022 - LECTURE - 3 - Basics - in - Distillationish guptaNo ratings yet

- Crude OilDocument19 pagesCrude Oilsupriya guptaNo ratings yet

- Oilfield ScaleDocument22 pagesOilfield ScaleFaniyi Hussein KehindeNo ratings yet

- Emulsions Treating TheoryDocument45 pagesEmulsions Treating TheoryJagdish annayaNo ratings yet

- Chemistry FullDocument273 pagesChemistry FullVraj ShahNo ratings yet

- Water Treatment Plant & Its OperationDocument34 pagesWater Treatment Plant & Its Operationengjamesbond007No ratings yet

- 4-Discussed The Crude Desalting Process and Properties of Crude-24-01-2022 (24-Jan-2022) Material - I - 24-01-2022 - LECTURE - 3 - Basics - in - DisDocument50 pages4-Discussed The Crude Desalting Process and Properties of Crude-24-01-2022 (24-Jan-2022) Material - I - 24-01-2022 - LECTURE - 3 - Basics - in - Disish guptaNo ratings yet

- Crude Distillation ProcessesDocument32 pagesCrude Distillation ProcessesIzziyyahNo ratings yet

- ES 639 Pretreatment for Thermal Power Plant WaterDocument18 pagesES 639 Pretreatment for Thermal Power Plant WaterRahul AhujaNo ratings yet

- 1 DesalterDocument20 pages1 Desaltershyam_anupNo ratings yet

- Softening Methods IDocument22 pagesSoftening Methods IermiasNo ratings yet

- Chemical Process Indusrty: Introduction of VenturimeterDocument18 pagesChemical Process Indusrty: Introduction of VenturimeterAnanya DaveNo ratings yet

- Unit - I: Water TreatmentDocument127 pagesUnit - I: Water TreatmentAnu ShanthanNo ratings yet

- Evaporative Condenser Passivation: Cameron Klein Strand Associates, IncDocument27 pagesEvaporative Condenser Passivation: Cameron Klein Strand Associates, IncMax JunghannsNo ratings yet

- Crude Oil Desalting Iip Sept 2016 Short DurationDocument136 pagesCrude Oil Desalting Iip Sept 2016 Short Durationcutewolf211No ratings yet

- Lecture 5Document16 pagesLecture 5Omar Al-KubaisiNo ratings yet

- Boiler Damage - Advice To The Surveyor 2017Document3 pagesBoiler Damage - Advice To The Surveyor 2017redaNo ratings yet

- Desalting Process in GOSP1 - ٠٤١٩٣١Document13 pagesDesalting Process in GOSP1 - ٠٤١٩٣١elkasehoNo ratings yet

- Fuel Oil & WTPDocument27 pagesFuel Oil & WTPpntripathiNo ratings yet

- Produced Water Treating SystemsDocument51 pagesProduced Water Treating SystemsJagdish annayaNo ratings yet

- Characterisation of Particle SiceDocument25 pagesCharacterisation of Particle SiceSivakumarNo ratings yet

- Determine Salt Content in Crude Oil Using Conductivity MethodDocument10 pagesDetermine Salt Content in Crude Oil Using Conductivity MethodSivakumarNo ratings yet

- Unit 3Document9 pagesUnit 3SivakumarNo ratings yet

- UNIT2Document20 pagesUNIT2SivakumarNo ratings yet

- 17BPE224 - Transport Phenomena: Hours: 10Document2 pages17BPE224 - Transport Phenomena: Hours: 10SivakumarNo ratings yet

- Unit 5Document4 pagesUnit 5SivakumarNo ratings yet

- Characterization of Crude Oil Properties and TestsDocument35 pagesCharacterization of Crude Oil Properties and TestsSivakumarNo ratings yet

- TP U3Document14 pagesTP U3Vignesh KNo ratings yet

- Transport Phenomena Introduction and First Law of Thermodynamics: Unit-I Philosophy and Fundamentals of Transport PhenomenaDocument11 pagesTransport Phenomena Introduction and First Law of Thermodynamics: Unit-I Philosophy and Fundamentals of Transport PhenomenaSivakumarNo ratings yet

- Print TP UNIT-1Document11 pagesPrint TP UNIT-1SivakumarNo ratings yet

- JCHPS 03Document3 pagesJCHPS 03SivakumarNo ratings yet

- TP U3Document14 pagesTP U3Vignesh KNo ratings yet

- UNIT2Document20 pagesUNIT2SivakumarNo ratings yet

- 2014 Journal of Nanostructure in Chemistry PDFDocument9 pages2014 Journal of Nanostructure in Chemistry PDFSivakumarNo ratings yet

- Process Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineDocument3 pagesProcess Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineSivakumarNo ratings yet

- JCHPS 15Document3 pagesJCHPS 15SivakumarNo ratings yet

- Kf/Cao Nanocatalyst For The Production of Biodiesel From Animal Fat Through Single-Step ProcessDocument3 pagesKf/Cao Nanocatalyst For The Production of Biodiesel From Animal Fat Through Single-Step ProcessSivakumarNo ratings yet

- JCHPS 15Document3 pagesJCHPS 15SivakumarNo ratings yet

- Sample Abstract PDFDocument1 pageSample Abstract PDFjesf_2014No ratings yet

- Process Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineDocument3 pagesProcess Parameter Optimization and Performance Analysis of Raphanus Sativus Methyl Ester in Diesel EngineSivakumarNo ratings yet

- 220 L TIGHT HEAD STEEL DRUM SPECIFICATIONS ELIPSE A Grate 1Document2 pages220 L TIGHT HEAD STEEL DRUM SPECIFICATIONS ELIPSE A Grate 1kavatmohandNo ratings yet

- Techniques For Controlling Pathogenic MicroorganismsDocument17 pagesTechniques For Controlling Pathogenic MicroorganismsMäê MedrosoNo ratings yet

- Solution Manual Principles of ElectronicDocument26 pagesSolution Manual Principles of Electronic謝亮瑩No ratings yet

- PCR Identification System For The Genus Aspergillus ADocument5 pagesPCR Identification System For The Genus Aspergillus AsalvadorNo ratings yet

- Tarnish & CorrosionDocument18 pagesTarnish & CorrosionPreeti AgarwalNo ratings yet

- Smooth and Granular Endoplasmic Reticulum RibosomesDocument26 pagesSmooth and Granular Endoplasmic Reticulum RibosomesArfiNo ratings yet

- Calcium chloride preparation from calcium carbonate and hydrochloric acid reactionDocument1 pageCalcium chloride preparation from calcium carbonate and hydrochloric acid reactionAshrafNo ratings yet

- BIOMOLECULES Note (1st Class)Document10 pagesBIOMOLECULES Note (1st Class)Soumyadeep ChatterjeeNo ratings yet

- Organic Chemistry: Unique Natures of Carbon AtomDocument13 pagesOrganic Chemistry: Unique Natures of Carbon AtomSANDEEP SINGHNo ratings yet

- Microchannel Fluid Coils - Technical ManualDocument26 pagesMicrochannel Fluid Coils - Technical Manualgreyhound726415No ratings yet

- USP-NF Oxidized CelluloseDocument2 pagesUSP-NF Oxidized CelluloseVõ Đức TrọngNo ratings yet

- 05 - Cast Iron PDFDocument26 pages05 - Cast Iron PDFAnonymous gIHkWPNo ratings yet

- Introduction to Solid State Chemistry Focuses on Chemical BondingDocument34 pagesIntroduction to Solid State Chemistry Focuses on Chemical BondingFeliciaPutriNo ratings yet

- 2021 06 22 PVC Briefing FINALDocument33 pages2021 06 22 PVC Briefing FINALPierluigi GhioneNo ratings yet

- 2012, Asian J Exp Biol Sci, RogojanDocument8 pages2012, Asian J Exp Biol Sci, RogojanMihaela BalasNo ratings yet

- Insect Remover: Phase Ingredients % W/WDocument1 pageInsect Remover: Phase Ingredients % W/Wdaya vashishtNo ratings yet

- 5A. Gas TurbinesDocument4 pages5A. Gas TurbinesKathlyn Kyle MoralesNo ratings yet

- Flame Photometry - An Overview - ScienceDirect TopicsDocument5 pagesFlame Photometry - An Overview - ScienceDirect Topicsحمزه محسن عبد علي / مسائي / ANo ratings yet

- Sulphuric Acid 15-51% MSDS AcinorDocument13 pagesSulphuric Acid 15-51% MSDS AcinormagnusNo ratings yet

- Mole ObjectiveDocument26 pagesMole ObjectiveDevil WalkerNo ratings yet

- Astm D 4952Document3 pagesAstm D 4952humayun KabirNo ratings yet

- Atoms Combine Due to Octet RuleDocument27 pagesAtoms Combine Due to Octet RuleBabli BanerjeeNo ratings yet

- ASTM D4006 - 16e1Document11 pagesASTM D4006 - 16e1Angel MurilloNo ratings yet

- Oxygen PlantDocument16 pagesOxygen PlantArsen GrigoryanNo ratings yet

- Glyphosate Biodegradation and Potential Soil Bioremediation by Bacillus Subtilis Strain Bs-15Document14 pagesGlyphosate Biodegradation and Potential Soil Bioremediation by Bacillus Subtilis Strain Bs-15Com DigfulNo ratings yet

- 5070 s09 QP 3Document8 pages5070 s09 QP 3Sherlock Wesley ConanNo ratings yet

- Eagle Burgmann API Seal PlansDocument55 pagesEagle Burgmann API Seal PlansNasim Mammadov100% (2)