CAHRS Workshop

Testing for Crash & Safety Simulation

Hubert Lobo DatapointLabs

New York, USA

TestPaks.com

�DatapointLabs

Research quality material testing ISO 17025 production environment Results in 5 days (48 hour RUSH service) Web-based quotation & data delivery Domain expertise in CAE material calibration

TestPaks.com

�expert material testing

Your CAE data conversion

materials testing

TestPaks = Materials testing + CAE material parameter conversion

metal, plastic, foam, rubber, composites over 20 CAE software codes

TestPaks.com

�Topics

A test philosophy for representing rate dependency of materials Experimental technique including sampling and specimen geometries Assessment of crash material data quality, expected trends & validation Specific comments for unfilled and fiberfilled polymers, foams, rubber and metals.

TestPaks.com

�Getting pertinent properties

Importance of measuring the right property Artifact free data

Properly designed experiments eg. not using crosshead displacement to calculate strain

Traceable data (ISO 17025)

NIST traceable instruments Certified trained technicians

TestPaks.com

�Getting the right samples

Spatial variation

Properties vary with location Forming, stretching, molding

Environmental variation

Ageing and conditioning

Process variation

Degradation from processing Recycled materials

TestPaks.com

�Metals

Relatively well behaved Models designed to match behavior Challenges lie with post yield nonMises failure envelopes Scaling of yield surface with strain rate Work of Nakajima, Dubois, Hooputra

TestPaks.com

�Plastics

Not well behaved Models not designed for plastics crash simulation Complex models are expensive Can we develop best practices for adapting common models to plastics

TestPaks.com

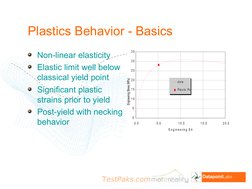

�Plastics Behavior - Basics

Non-linear elasticity Elastic limit well below classical yield point Significant plastic strains prior to yield Post-yield with necking behavior

35 30 25 Engineering Stress (MPa) 20 15 10 5 0 0 .0 5 .0 1 0 .0 1 5 .0 2 0 .0 E n g in e e r in g S tr a in ( % )

d a ta P la s tic Po in t

TestPaks.com

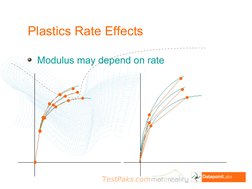

�Plastics Rate Effects

Modulus may depend on rate

TestPaks.com

�Plastics Rate Effects

Fail strain may be rate dependent

TestPaks.com

�Material Testing

Instron servo-hydraulic UTM Dynamic load cell Test at 0.01, 0.1, 1. 10, 100/s strain rates Temperatures: -40 to 150C

tens_slow.mpg

Tens.mpg

TestPaks.com

�Test Specimens

ASTM D638Type V Preparation

CNC from plaque CNC from part Molded

E2

gate region

E1

Variability

processing orientation thickness

TestPaks.com

�Modeling simple ductile plastics

Modulus is not rate dependent Large strains to failure Post-yield necking Plasticity curves vary with strain rate Failure strain independent of strain rate LS-DYNA, ANSYS, ABAQUS, PAMCRASH

TestPaks.com

�Choosing EMOD

35 30 Engineering Stress (MPa) 25 20 15 10 5 0 0.0 5.0 10.0 Engineering Strain (%) 15.0 20.0

data Plastic Point

TestPaks.com

�Post-yield with necking (Deihl)

70 60 50 Stress MPa 40

yield point

neck propagation

necking starts

30 20 10 0 0 0.2 0.4 0.6 0.8 Strain mm/mm 1 1.2 1.4 1.6

UTM1-39.62-1 UTM1-39.62-2

TestPaks.com

�Fail Limitations

When FAIL f(strain rate)

TestPaks.com

�Modeling Rate Dependency

Cowper Symonds

Tensile Strength (MPa)

40 35 30 25 20 15 10 5 0 1.E-02 1.E-01 1.E+00 Strain Rate(/s) 1.E+01 1.E+02

Does not correlate well with plastics rate dependency

LCSR

Capture model independent behavior

data Cowper Symonds Eyring

TestPaks.com

�Eyring Model

Eyring Model

Yield stress v. log strain rate is linear Best form for plastics

Fit yield stress v. log strain rate data to Eyring equation Can submit to LSDYNA MAT24 as table using LCSR

TestPaks.com

�MAT24 validation

60 50

LS-DYNA Simulation

40

Stress (MPa)

Tensile Experiment MAT 24 Model

30

20

10

0 0 0.05 0.1 0.15

Strain (mm/mm)

0.2

0.25

0.3

TestPaks.com

�Brittle plastics

Modulus is rate dependent Small strains to failure Brittle failure Failure strain decreases with increasing strain rate LSDYNA MAT19

TestPaks.com

�Methodology for MAT 19

Determine elastic limit at quasi-static strain rate Use elastic limit for vonMises yield Define failure

failure stress v. strain rate table

TestPaks.com

�Ductile-brittle transitions

Non-linear behavior Failure depends on strain rate Models

LS-DYNA MAT89 PAMCRASH 103 Abaqus *ELASTIC *PLASTIC,Rate

TestPaks.com

�Fiber Filled Plastics

Digimat MX

Material model reverse engineered from standard experiment

Perform injection-molding simulation Apply Digimat material model to transfer data to crash simulation Crash model has spatially oriented properties

TestPaks.com

�Basic Digimat TestPak Protocol

Mold 100X300X3.16mm plaques

Edge gated on 100 mm end Long flow length Fully developed flow Highly fiber orientation

Cut test specimens by CNC 5 specimens each (0, 90 ) Obtain true stress-strain data

TestPaks.com

�Advanced Models

MATSAMP (LS-DYNA) Standard rate dependent model Add non-mises failure envelope

Compression Shear

Add triaxiality

Post yield transverse strain

Add unloading

TestPaks.com

�Pros and Cons

Better failure envelope modeling Greater cost More complex model Greater simulation accuracy in difficult cases Cost-benefit not certain for general use

TestPaks.com

�Foams

Different deformation modes

Crushable Elastic with or without damage Visco-elastic

Large volumetric strain component

TestPaks.com

�Effect of Poissons Ratio = 0

Material compacts by eliminating air No lateral deformation Poissons Ratio -> 0 Axial strain volumetric strain True for

open cell foams crushable foams

May not be true for

closed cell foams elastomeric foams

TestPaks.com

�Typical Stress-Strain Data

0.050 0.045 0.040 Engineering Stress (MPa) 0.035 Zone 1 0.030 0.025 0.020 0.015 0.010 0.005 0.000 0 20 40 60 80 100 Engineering Strain (%)

Zone 2

Zone 3

TestPaks.com

�Test Strategy

Compressive stress-strain

5 decades of strain rate

.01, .1, 1, 10, 100 /s

Temperatures

-100 to 150C

Hisp_comp.mpg

Optional tests

Tensile (for cut-off stress) Shear (as required)

TestPaks.com

�Test Instruments

TestPaks.com

�PU Foam-stress strain

0 .0 4 0 .0 3 5 0 .0 3 0 .0 2 5 Stress (MPa) 0 .0 2 0 .0 1 /s fi t 0 .1 /s fit 1 /s fi t 1 0 /s fi t 1 0 0 /s fi t

0 .0 1 5 0 .0 1 0 .0 0 5 0 0 0 .1 0 .2 0 .3 0 .4 0 .5 0 .6 0 .7 S tr a i n ( m m /m m ) 0 .8 0 .9 1

TestPaks.com

�PU Foam- rate effects

TestPaks.com

�PU Foam recovery

0.030 0.025 Engineering Stress (MPa)

Load

0.020 0.015 0.010 0.005 0.000 0 20 40 60

Unload

80

100

Engineering Strain (%)

TestPaks.com

�Conclusions

Choice of material model depends on

material test data situation complexity

Proper selection = reasonable model Simple improvements can add power Validated models represent baseline Models can be tuned for multi-axial loadings

TestPaks.com

�TestPaks.com

�TestPaks.com

�TestPaks.com