0% found this document useful (0 votes)

474 views23 pagesSAP MM Subcontracting Process Guide

Here are the key steps to complete the subcontracting process and procurement cycle as described in the case study:

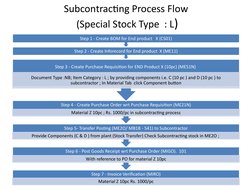

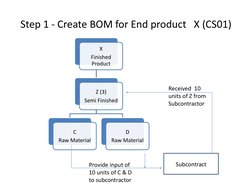

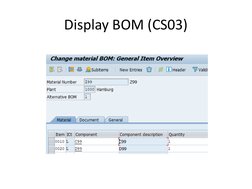

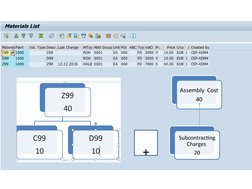

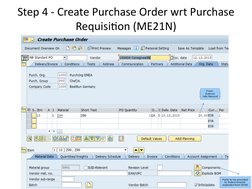

1. Create a BOM for the end product Z## including components C## and D##.

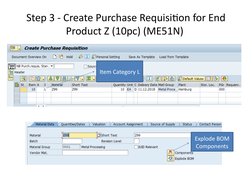

2. Create a purchase requisition for the end product Z##. Select item category L.

3. Create a purchase order for component C##. Check the SC vendor indicator and enter subcontractor vendor ID in delivery address.

4. Post goods receipt for C##. It will go to subcontracting stock.

5. Do a stock transfer of D## from your storage location to subcontracting stock at subcontractor's premises.

6. Do a stock transfer of

Uploaded by

Saurabh RaneCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

474 views23 pagesSAP MM Subcontracting Process Guide

Here are the key steps to complete the subcontracting process and procurement cycle as described in the case study:

1. Create a BOM for the end product Z## including components C## and D##.

2. Create a purchase requisition for the end product Z##. Select item category L.

3. Create a purchase order for component C##. Check the SC vendor indicator and enter subcontractor vendor ID in delivery address.

4. Post goods receipt for C##. It will go to subcontracting stock.

5. Do a stock transfer of D## from your storage location to subcontracting stock at subcontractor's premises.

6. Do a stock transfer of

Uploaded by

Saurabh RaneCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

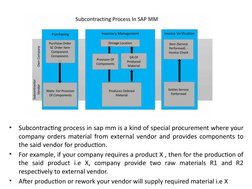

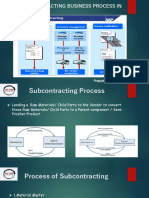

- Introduction to Subcontracting in SAP MM

- Subcontracting Process Overview

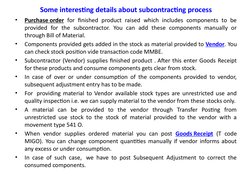

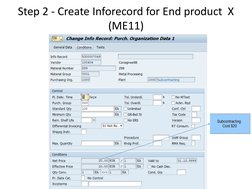

- Detailed Steps in Subcontracting Process

- Adjustments and Case Study