SAP MM Special Procurement Guide

Uploaded by

Mallu LoharSAP MM Special Procurement Guide

Uploaded by

Mallu Lohar- 1. Sub Contract Scenarios: Explores special procurement processes involving subcontract scenarios, detailing pre-requisites and steps.

- 2. Vendor Consignment: Explains vendor consignment processes, including settings and steps for handling consignment liabilities.

- 3. Pipe Line Scenario: Outlines how the pipeline process manages material deliveries autonomously and continuously.

- 4. External Service Management (ESM): Describes the entirety of external service management, including creation and control of service processes.

- 5. RTP (Returnable Transport Packaging) Material: Covers the handling of returnable transport packaging materials and their associated business processes.

- 6. Split Valuation: Details the concept of split valuation, including configuration steps and practical applications.

- 7. Serial Number Management: Focuses on the management and assignment of serial numbers to materials, detailing steps to implement the process.

- 8. Batch Management: Explains the batch management setup and how to maintain it for various material types and transactions.

- 9. Stock Transport Order (STO): Describes the processes involved in stock transport orders, including intra-company and inter-company stock movements.

- 10. STO (Inter Company Stock Transport Order): Details the inter-company stock transport order process with steps from supplying to receiving plant.

- 11. Integration: Covers the integration aspects of SAP MM with other modules such as SD, focusing on organizational structure and processes.

- 13. MM & FI Integration: Explores the integration between SAP MM and FI modules, detailing valuation and account assignments.

Shrini Damarla

SAP MM Chicago

SAP Material Management

Spl. Procurement & Integration

SAP Material Management Spl. Procurement

TABLE OF CONTENT

Special Procurements

1. Sub Contract Scenarios ………………………………………………………………

a. Sub contract Scenario: 1 (Lack of Manpower)

b. Sub contract Scenario: 2 (Lack of Premises/ Building)

2. Vendor Consignment ………………………………………………………………..

3. Pipe line scenario……………………………………………....................................

4. External Service Management…………....................………………….........................

5. RTP…………………....................................…………………....................................

6. Split Valuation……………....................................…………………..........................

7. Serial Numbering for materials…………………....................................………………

8. Batch Management …………………....................................………………………

9. STO without SD, without billing………………….........................................................

10. STO with SD, with billing…………………....................................................................

Integration

11. MM – SD Integration

a. Creation of SD Organizational Structure …………………....................................

b. Customer Master and Partner determination ………………….............................

c. Sales Order Settings …………………....................................……

d. Third Party Scenario…………………....................................……………

12. MM – PP Integration

a. CBP – Overview ……………………………

b. MRP through CBP reorder point…………………...........................…….

13. MM – WM Integration

a. Warehouse Management – Overview …………………....................

b. Warehouse Management - IMG settings…………………..................

14. MM – FI Integration

a. Define Valuation Control (OMWM)

b. Group Together Valuation Areas (OMWD)

c. Define Valuation Classes (OMSK)

d. Define Account Grouping for Movement Types (OMWN)

e. Configure Automatic Postings (OMWB)

Shrini Damarla - Chicago Page 1

SAP Material Management Spl. Procurement

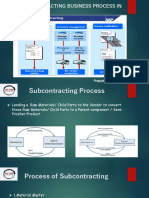

1. Sub-contract Scenario-1

Sub contract Scenario: 1 (Lack of Manpower)

Pre Requisites:

Create a material type XALB ( X Semi fin Product) by copying SAP std. Semi finished product

(HALB) and update the same for its valuation areas (i.e. plants- xpl1,xpl2)

o T code: OMS2 or SPRO Logistics - General Material Master Basic Settings

Material Types Define Attributes of Material Types)

Create a number range for the semi fin product XALB (Tcode MMNR) and assign number

range to the XALB

o SPRO Logistics - General Material Master Basic Settings Material Types

Define Number Ranges for Each Material Type or T code: MMNR

Steps in Sub-contract Scenario:

1. Create 3 materials (Tcode : MM01) with a mat type (ROH) – Raw material

Tyre, Tube, Rim

2. Create a material (MM01) with a material type (XALB) – Semi-finished

WHEEL by entering Val class: 7900, price in Std. price field.

3. Maintain Bill of Material (BOM) for WHEEL (Tcode is CS01) and specify the relation of

WHEEL with the Raw materials as under

In initial screen enter

Material No: wheel Number

Plant: XPL1

BOM usage: 1 (Production)

a. One WHELL = One Tyre, One Tube, One Rim

Note: Item category should be ―L‖ – Stock Item

4. Maintain Initial stock entries for the Raw Materials (Use Tcode MB1C and MVT = 561)

5. Now Check the Stock status of the Raw materials (MMBE/MB52)

6. Create a Sub contract Vendor (XK01) or make one of the vendor the existing vendors as

sub-contractor

7. Create a Purchasing Info Record (PIR) (ME11) for the WHEEL material and sub contract

Vendor.

Note: Select Info-category as ‖Sub-contract‖, enter the service or conversion charges in net

price field in PIR

8. Maintain source list for the WHEEL Material

Shrini Damarla - Chicago Page 2

SAP Material Management Spl. Procurement

9. Make a transfer Posting to issue the raw material (Tyre, Tube, Rim) to the sub contract

vendor with Tcode MB1B and MVT = 541

10. Check the Stock status (MB52) Raw mat qty. will be reduced.

11. Check the stock sent to sub contract vendor – Tcode = ME2o(not zero)

12. Create PO (ME21N) to sub-contract vendor for the WHEEL Material.

Note: Enter Item Category as ―L‖ – Sub-Contract

13. Make a Goods Receipt (MIGO) for WHEEL Material with respect to the above PO (MVT 101)

Note: ―BOM‖ will be exploded and 543 MVT will be triggered for all the Raw material

/components

14. Check the Material and Accounting documents

15. One material doc will be created and one A/c document also created with the following A/cs.

Material/Vendor GL A/c Description

Wheel 790000 Unfinished products +ve

893010 Cost of goods sold -ve

SC vendor 417001 Purchased services +ve

191100 Goods Rcvd/Invoice R -ve

Tyre 300000 Inventory - Raw Mate -ve

400020 Raw materials consumed +ve

Tube 300000 Inventory - Raw Mate -ve

400020 Raw materials consumed +ve

Rim 300000 Inventory - Raw Mate -ve

400020 Raw materials consumed +ve

16. Do the LIV (MIRO)

Shrini Damarla - Chicago Page 3

SAP Material Management Spl. Procurement

1. Sub-contract Scenario-2

Sub contract Scenario: 2 (Lack of Premises/ Building)

In this scenario:

Company does not have Building/premises to keep the raw materials

Company will order raw material to their vendors, however the delivery address is SC Vendor

So Raw materials will be supplied directly by our vendors to our SC vendor

Company will raise a PO for WHEEL item to SC vendor

SC vendor will supply WHEEL and company do MIGO

Payment via MIRO to all vendors including SC vendors

Pre-requisites

You should have

o Raw mat : Tyre, Tube, Rim

o Semi fin : Wheel

You should have Vendors

o Regular vendors for supplying Raw materials

o SC vendor for supplying Semi-finished product

Steps:

1. Create a PO to our regular vendor (say JK) for supplying of Tyre, Tube and Rim

However delivery address should be SC vendor

Use Tcode = ME21N

Select Doc type = RNB - RRPO

In Header data

Org data - TAB

Purchasing Organization RPO

Purchasing Group RPG

Company Code RMOT

Enter Vendor No : xxxxx

Press enter

In Item overview

Mat No Qty. del dt. Plant Str. loc. (opt)

xxx (Tyre) xxx xx/xx/xx RPL1 s11

xxx (tube) xxx xx/xx/xx RPL1 s11

xxx (rim) xxx xx/xx/xx RPL1 s11

Go to Item details

For 1st line item (say Tyre)

o In Delivery address – TAB

Enter Vendor No: SC vendor No

Check ‗check box‘ SC vendor

Once you do for one line item sys prompts to change the delivery

address for other line items. Click Yes

Click check button on application tool bar

Click save button

Sys create a PO

2. Do GR ( MIGO) for Tyre, tube and Rim for the above PO

Steps:

Use Tcode = MIGO

Enter PO No: xxx

Shrini Damarla - Chicago Page 4

SAP Material Management Spl. Procurement

Sys reflects the PO details in MIGO screen

[ You can observe that Str. Loc. and Plant are blocked]

It is a simple logical GR to indicate the SAP that this material received by SC

vendor

Check item ok ‗check box‘ for all line items

Click check button on application tool bar

Click save button to post

Observation:

One mart doc will be create

One a/c ing doc will be created and triggers the following a/cs

G/L Accounts Description

For Tyre 300000 Inventory - Raw Mate +ve

191100 Goods Rcvd/Invoice R -ve

For tube 300000 Inventory - Raw Mate +ve

191100 Goods Rcvd/Invoice R -ve

For rim 300000 Inventory - Raw Mate +ve

191100 Goods Rcvd/Invoice R -ve

Stock status:

Plant stock provided to vendor - Qty. increased

3. Create a PO to SC vendor for wheel

Enter item category: L - subcontract

3. Do MIGO for Wheel

How to deal the Scrap

1. Create cylinder with ROH material type

2. Scrap with HAWA Material Type

3. Create CONE with HALB Material type

4. Create BOM (CS01) for ‗CONE‘ Material

By relating

1 Cone = 1 cylinder - 1 Scrap

Shrini Damarla - Chicago Page 5

SAP Material Management Spl. Procurement

2. Vendor Consignment

Consignment is functionality in MM purchasing, when you purchase the material from vendor

on consignment basis.

We will provide the premises to vendor in our stores; however we are not responsible for the

stock.

The stock is legally owned by the vendor only

When the delivery comes, we will make a GR even then, stock still legally by the vendor. If

you look at our stock status, it shows as ‗Vendor Consignment‘ stock.

As and when we want the material, whatever the quantity it is we will simply transfer the

vendor consignment stock in to our company own stock.

Vendor need not send the invoice or bill for with drawl quantity. Company will settle his

consignment liabilities

IMG Settings: Vendor Consignment

1. Activate consignment prices via info records

SPRO Material Management General Settings for Material Management Activate

consignment prices via info records (OMEV)

Double click: Activate consignment prices via info records

Select Radio button as below

Click Save and come back

2. Maintain Message settings and communication method for your vendor

Conditions SPRO Logistic Invoice Verification Message Determination Maintain

Change Conditions Output Type: KONS and key combination is: company code and vendor.

Enter Company code: XMOT, then click ‗Execute‘ button

Then enter Vendor No: XXXXXX

Select Vendor line and Click ―Communication‘ button

Then enter Output device: LP01

Check Print Immediately, and then save it and go back.

Steps in Vendor Consignment `

1. Create or change the material master (MM01 or MM02)

2. Create Info Record (ME11), with info category as ‗consignment‘

Note: Maintain Tax Code in purchase data view

3. Maintain Source List for the above material and Vendor (ME01)

4. Create Purchase Order (ME21N) with item category as ‗K‘

5. Take the receipt of the material i.e. GR (MIGO)

Here as a proof of action one material document is created

However no Accounting document creates

6. Now the stock status (MMBE) shows that the material now as ‗Vendor Consignment‘

7. Transfer the stock to company own stock (MB1B – Mvt 411K)

Now as a proof of action one material document is created

Here Accounting document creates with the following a/cs

GL A/c Description

169900 A/c payable consignment sale -ve

300000 Inventory - Raw Mate a/c -ve

Shrini Damarla - Chicago Page 6

SAP Material Management Spl. Procurement

8. Consignment liabilities can be settled in MRKO

Enter the following:

o Company code:

o Vendor:

o Plant:

o Material

o Material Document:

o Check consignment select Display.

Note: First Select Display radio button and execute it. It is success full then selects the radio

button to settle and execute it again.

Shrini Damarla - Chicago Page 7

SAP Material Management Spl. Procurement

3 . Pipe line scenario

In this process company receives the material like gas, water and electricity continuously from

the vendor through pipe

Company will settle the consumed quantity on a periodic basis as per the agreement entered

between vendor and company

In this process: No PO and No GR will be done.

Only posting the consumptions periodically (on monthly or bi-weekly basis)

The rest of the process is same as consignment

Steps: in pipe line scenario

1. Create a material type XIPE from the standard Material type PIPE (Pipe line material) (OMS2)

and update qty. and value to the valuation areas (Plants)

[SPROIMGLogistics - General Material Master Basic Settings Material Types

Define Attributes of Material Types or Tcode = OMS2]

2. Create a number range and assign the same to the XIPE material type (MMNR)

3. Create a material master record (Water) with material type XIPE.

4. Identify the existing vendor as the supplier to this pipe line material

5. Create a Purchasing Info record (PIR) (ME11) for the above material and Vendor

6. Note: select the info Category as Pipe line and maintain tax code in purchasing data 1 screen

7. Goods Issue/with draw will be done by using the Tcode MB1A MVT 201P for the cost center

8. Check the stock status MMBE, no qty will appear in Order stock (because NO PO), No qty in

str. loc (because NO GR).

9. Check the material document and A/c document and note down the A/c details

o Mat doc will be created as a proof of goods issue

o A/c doc will be created with the following A/Cs

G/L Account Description

169900 Accounts Payable – c –ve

400000 Consumption, raw mat.1 +ve

10. Pipe line liabilities can be settled in MRKO

Shrini Damarla - Chicago Page 8

SAP Material Management Spl. Procurement

4. External Service Management (ESM)

This topic covers the procurement of Services

o Creation of Service Master

o Creation of Service PO

o Creation of Service Entry Sheet

o Entering of Invoice.

IMG Settings:

1. Define Mat/Service Group (OMSF)

SPRO Logistics - General Material Master Settings for Key Fields Define Material

Groups

o Click new entries

o Enter X_GARDEN as XX garden service group

o Click Save

Steps:

1. Create a Service Master Record (AC01)(it is equivalent to MM01)

o Click create button: or F5

Activity No: %_1......... (don‘t enter anything)

Description: XX Garden Services

Enter Service Category:

GRND - Basis Services (it is SAP std. Service category)

Enter Base Unit of Measure (BUM) = H (Hours)

o Click Basic Data Button:

Enter Service/Mat Group: X_Garden XX Garden Service

Enter Valuation class: 3200

Click Save.

o SAP creates a Service Master Record

Note: It creates a Activity No

2. Go to display mode of Service master Record. (AC03)

o Find X_Garden services by using the find button

o Note Down the Activity No

3. Consider any existing vendor for Garden maintenance or Create a new vendor for this

services (XK01)

4. Create a Service PO (ME21N) with

o In Item Over view :

Item category : - D (service)

A/c Assignment category - K (cost center)

enter relevant fields like; Delivery dates and delivery plants in Item over view

screen

o In Item Details Screen: enter

Activity No

Order Qty (in Hours)

Order Price (Per hour)

Shrini Damarla - Chicago Page 9

SAP Material Management Spl. Procurement

Cost center : GM_CC

Click Save and note down the PO no

5. Create a Service entry sheet (ML81N) (Equivalent to MIGO)

o Click 'Other Purchase orders' button

o Enter Your Service PO No.

o Click Create Button.

o System will provide a service entry sheet no

o Enter

Description as: Jan 2012 Services

Qty of Hours : 30 hours

Click 'Flag' button to Accept this services

Click Save

o System will create a acceptance document by accepting these entries with the service

entry sheet number.

6. Go to MIGO and enter the acceptance doc. no see that accounts hit by the system

G/L a/c Description

417000 Purchased services +ve

191100 Goods Rcvd/Invoice R –ve

7. Do MIRO for Invoice verification

Shrini Damarla - Chicago Page 10

SAP Material Management Spl. Procurement

5. RTP (Returnable Transport Packaging) Material

Packaging materials are two types

o Non-returnable to vendor

Mat will arrive - not necessary to send back to vendor

o Returnable to vendor

Mat will arrive with packing but it has to send back to vendor

SAP std. mat types of packing are

1. VERP - packing material ( non-returnable)

2. LEIH – RTP

Business Process for RTP

Vendor V1 is supplying Oxygen Gas to our company @ Rs. 120/- Per KG

Vendor will supply this gas in cylinder, which we have to return back

At the time GR we receive the Cylinder and Oxygen Gas

So in stock status

Cylinder Qty.

Gas qty.

should increase

However Value of Cylinder should not be increased

We have to return back the Empty Cylinder to vendor at an appropriate time

Pre requisites:

Go to OMS2

o Select LEIH - RTP material

o Click Qty. and value update folder

o Set check box to both qty. and value update for our valuation areas

Val area Qty value

GPL1

o Click save

Steps:

Create a Material CYLINDER - with a mat type LEIH (RTP)

Create a Material OXYGEN - with mat type ROH or GROH

Create a PO (ME21N)

Mat No Qty. Del date Plant Str. loc.

OXYGEN 15 xx/xx/xx XPL1 xxx

Make GR (MIGO)

o Option: Goods Receipt

o Sub option: Purchase order

o MVT : 101

o Enter PO No: xxxxx.

o Sys fill the PO info to MIGO Screen

o In Item Overview screen

Click + marked symbol button

Sys display the empty line items to add NON Order materials

Enter

Mat no Qty. Str. Loc. Plant Mvt Spl.

Shrini Damarla - Chicago Page 11

SAP Material Management Spl. Procurement

CYLINDER 01 xxx xxx 841 M

Change the movement type from 501 to 841 M ( gr w/o PO as RTP)

Spl. Vendor No

M xxxx

o Check Item OK

o Click Check button on application tool bar

o Sys validate your entries

o Click save to post the doc

Observations:

One mat doc will be created as a proof of this action of RTP

One Accounting doc will be created and trigger the following accounts

G/L account Description

300000 Inventory - Raw Mate +ve

191100 Goods Rcvd/Invoice R -ve

[Note: No a/c doc or value updating for CYLINDER is done]

Stock status:

U/R stock type Qty.

Cylinder Increased ( under RTP)

Oxygen Increased

Do MIRO for invoice verification

How to return the CYLINDER to Vendor

Use Tcode = MB1C

In initial screen

o Movement Type 842 M - GR RTP Reversal

o Plant GPL1

o Storage Location S11, Press enter

In Second screen, enter

o Vendor No 401805 (from whom you received)

Mat No Qty.

xxxxxx xx press enter

Sys validates your entries

Click save

Observations:

o One mat doc

No Accounting doc

Stock status: U/R stock type

o Cylinder Qty. Decreased

Shrini Damarla - Chicago Page 12

SAP Material Management Spl. Procurement

6. Split Valuation

What is Split Valuation?

Same material will have different prices

The material prices are valuated based on the origin of place or Quality/grade can be called

as "Split Valuation". For example

o Rice with different Grades

o Integrated Chips (ICs) from different places

IMG Settings: Split Valuation

1. Activate Split Valuation (OMW0)

SPRO Material management Valuation and A/c assignment Split Valuation Activate split

valuation.

Split material valuation active

Split material valuation in-active

2. Configure Split Valuation (OMWC)

SPRO Material management Valuation and A/c assignment Split Valuation Configure Split

Valuation

Global Categories: It is a set/Group of Valuation categories can be called as Global

categories

Valuation Category: The category/the way the material will be procured

Ex: Origin of place, Grade of the material

Steps:

1. Click ‗Global categories‘ button or F6

2. Click create button and enter

Valuation Category : P

Description : Procurement

3. Click ‗Create‘ button again System display that ‗Valuation Category P was/were created‘

4. Click Save

Global Type: A set of Valuation types can be called as Global types

Valuation type: The material procurement based on Val category

Steps:

1. Click ‗ Global types‘ button

2. Click Create button and enter

Valuation Type B_IC_Japan

Ext. Purchase Orders 2 – Ext. Pos allowed

Int. purchase orders 0 – Internal Pos not allowed

Acct. cat. Reference 0001

3. Click Create button again

4. Click save

5. Repeat the same for different valuation types called

B_IC_LOCAL

B_IC_GERMANY

B_IC_US

Shrini Damarla - Chicago Page 13

SAP Material Management Spl. Procurement

3. Assign Valuation type and Valuation Category

Again click Global Categories

Put the cursor on your valuation category

Click Types--> Category

Select your valuation type (i.e B_IC_JAPAN)

Click Active button

Repeat the same for all valuation types

Now you valuation types have been assigned to your valuation category

Click Save

4. Assign Val. Cat to Org units (plants)

Steps:

1. Click ‗Category OUs ‗button

2. Select your plant and click ‗activate‘ button

3. Now click save

Steps:

1. Create a material master record (MM01)

a. Assign val. category 'P' in A/c-1view

2. Create/Extend this material for different Valuation types (MM01)

3. Identify existing vendor for supplying the above material/ or Create a vendor (XK01)

4. Maintain source list for the above material (ME01)

5. Create a PO with the above material and different Valuation types, Different Quantities,

Delivery dates (ME21N)

6. Repeat the same by creating different valuation types

7. Make GR by using Tcode – MIGO

a. Enter PO no, and Mvt 101

Shrini Damarla - Chicago Page 14

SAP Material Management Spl. Procurement

7. Serial Number Management

Serial Numbering for materials

IMG settings:

1. Define Serial no profile (OIS2)

SPROPlant Maintenance and Customer Service Master Data in Plant Maintenance and

Customer Service Technical Objects Serial Number Management Define Serial

Number Profiles

SAP standard serial number profile is = 0001

Select 0001 and click copy as XSNP – X Serial No Profile

Now select XSNP and Click Serializing procedures

Now for Serialization procedure MMSL, set serial no usage as '03' - Obligatory

(mandatory/Required)

Steps: Serial number profile

1. Create a material (Engine/Chassis) with (MM01) with General Plant Data /Storage 2 view

In this view enter Serial no Profile

2. Make use of existing vendor as a supplier to this material (Engine /chassis)

3. Create PIR for the above material and Vendor

4. Maintain source list for the above material and vendor

5. Create a PO (ME21N) for the above material and vendor

6. Make a GR (MIGO) with MVT type 101

7. Note: You will observe a new tab 'Serial No ' Tab will be created

Enter Serial no‘s for the Qty you receive

Shrini Damarla - Chicago Page 15

SAP Material Management Spl. Procurement

8. Batch Management

IMG settings: Batch Management

1. Specify Batch Level and Activate Status Management (OMCT)

SPRO-->Logistics - General -->Batch Management -->Specify Batch Level and Activate

Status Management

Steps:

Click Batch level button

Set as 'Batch unique at material level'

Click Back button

click 'Batch status management' button

Set Batch status management as Active

Steps in Batch management

1. Create a material (MM01)/ make use of existing material (MM02)

In Purchasing view

o Check the Check box of Batch Management

2. Identify one vendor to supply the above material

3. Create a PO for the above material and vendor

4. Make a GR for the above material ( MIGO)

You can observe in Item details tab

o Batch - Tab will appear

Enter the Qty. you are receiving

click check button

system will state that creating a Batch XXXX no

click Batch Tab

o System will assign a batch no

Click save

5. Check the stock status of the material (MMBE)

System will show the material with batch number also

6. Receive one more time same material (MIGO)

System will show the material with another batch number

7. Now check the Stock status

System will show the material with Two batch numbers

8. How the batch will be handled during the stock transfer?

Tcode = MB1b

MVT = 311 (Str. loc - to - Str. Loc one step method)

Shrini Damarla - Chicago Page 16

SAP Material Management Spl. Procurement

9. Stock Transport Order (STO)

What is Stock Transfer?

Transferring of stock from one org. unit to other org. Unit can be called stock transfer

Stock Transfers types:

1. Intra company stock transfers (with in the Co_cd)

I. Str. Loc. - to - str. Loc.

II. Plant - to - Plant

2. Inter Company stock transfers ( Between Co_cd)

I. Co_cd - to - Co_cd

Inter Company Stock transfers can be done in 3 ways

I. w/o SD, w/o Billing

II. With SD , w/o billing

III. With SD and With billing

Inter Company Stock transfers: (Co_cd - to – Co_cd) -- W/o SD, w/o billing

Pre Requisites:

1. Material Master

I. Mat type: select HAWA/HALB/FERT and copy as your own Mat type

II. Create a No range and assign to mat type

III. Create a Material Master record with above mat type

IV. Extend this mat master record to other plant of other co_cd

2. Purchase Oder

I. Doc type: select doc type UB and copy as your own doc type

II. Create a No range and assign No range to Doc type

3. Finance department

I. Create Two G/L A/c for Common expenses in both Co_cds

II. Maintain co_cd clearing a/c between Co_cds

Steps:

In Mat master

a) IMG settings:

1. Create Material type ASWA by copying from the SAP std. material type for trading goods

- i.e HAWA and update Qty. and value check boxes for both sending and receiving plant

o Go to OMS2

Select HAWA

Click copy as ASWA - Ashoka Trading Goods

Select ASWA

Click Qty. and Value update check boxes for both ASP1,ASP2 and QPL1 and

QPL2

Click save

2. Create a No range (MMNR) assign to material type ASWA

3. Create a material (MM01) with a Material type ASWA (Ashoka Trading Goods) in a ASP1

o Select basic data1, Purchasing and A/cing 1 views

o Click org level button

Enter Plant = ASP1

o In basic data view

Mat description: Foot Mat

Base Unit of Measure EA

Material Group AS_RUBBER

Shrini Damarla - Chicago Page 17

SAP Material Management Spl. Procurement

o In purchasing view

Purchasing Group ASP

o In A/c ing view

Valuation Class 3100

Price 400

4. Extend the same into the other plant belongs to other co_cd (from ASP1 - to QPL2)

o Tcode = MM01

o In Initial screen

Material No: XXXX

Ind. Sect Mech. Engg.

Mat type ASWA

o Click select views and Select

o Basic data 1, purchasing and Accounting 1

Click Org Objects

Plant MPL2

o In Purchasing view

Purchasing Group MPG

o In Accounting1 view

Valuation class = 3100

Price = 400

o Click save

In Purchase Order

1. Define Number range for PO (OMH6) ( for STO Purpose)

SPRO MM Purchasing Purchase order Define No range

2. Define document type (OMEC)

SPROMMPurchasingPurchase orderDefine No range Define Document Types

SAP std. doc type for STO (Stock transport Order) is = UB

Select UB and click copy as ASUB

Assign Number range (AT) to ASUB doc type

Click save

In Finance/ controlling

1. Create G/L Account (399991) in Both ASMT and QMOT

Use Tcode = FS00

Creation of G/L a/c in ASMT

Use Tcode = FS00

Set your ASMT co-cd before creation of G/L A/c

click change co_cd button

enter your co_cd = ASMT

Select Fixed A/c folder

Select G/L A/c - 399997 - inventory Taking AA

Click copy as G/L a/c no 399996

Press enter button

System will copy the details of G/L a/c 399997 into 399996

Check and enter the following

In Type and description - tab

Account Group - fixed A/cs

Check balance sheet A/c

Shrini Damarla - Chicago Page 18

SAP Material Management Spl. Procurement

Short Text : Inventory taking AAT

G/L Acct Long Text :Inventory taking (off set entry)- AA

Group account number: 135100 Raw Materials

In Control data - Tab

Account currency INR

Check only balances in local currency

Tax category * All tax types allowed

Check 'Posting w/o tax allowed'

Alternative account no. : Make it empty

Check line item display

Sort key : 001 Posting date

In create/Bank Interest - Tab

Field status group : G007 AA (w/o accumulated depreciation)

Interest calc. frequency 01

Click save

System will add a new G/l a/c 399996 in Fixed A/c folder

o Repeat the same by creating G/l a/c 399991 in QMOT also

Important Note:

Go to G/L A/c no 399997 of ASMT and click Lock button

Un-check 'Blocked for Posting'

Repeat the same for the G/L A/c no 399997 of MMOT

2. Maintain Co_cd clearing a/c between Co_cds

o Use Tcode = OBYA

o Enter

Company code 1 ASMT

Company code 2 QMOT

o Press enter

o In Co_cd 1

Posted in HMOT

Cleared against MMOT

Debit posting key 40 Credit posting key 50

Account debit 399997 Account credit 399996

o In Co_cd 2

Posted in MMOT

Cleared against HMOT

Debit posting key 40 Credit posting key 50

Account debit 399996 Account credit 399997

o Click Save

Steps in STO

1. Check the material List (MM60) for the material records are available in both plants

2. Maintain Initial stock entry in supplying Plant (QPL2)

o Tcode = MB1C Mvt = 561

3. Check the stock status MMBE for both QPL2 and ASP1

o System will show stock in QPL2 - s21

4. Create a Stock transport Order at ASMT Co_cd

o Use Tcode = ME21N

o Select doc type as 'ASUB- ASHOKA STO PO

o Enter org data in Org - tab

Shrini Damarla - Chicago Page 19

SAP Material Management Spl. Procurement

Purchase Org. ASPO

Purchase Group ASP

Company Code ASMT

o Enter supplying Plant as QPL2

o In Item over view, enter

Material No Qty Del. Dt. Del. Plant Str. Loc.

Foot mat 333 xxxx HPL2 s22

o Note: system chooses item category as U - Stock trnasfer

o Click check and Save

o System will create a STO-PO

5. Check the stock status MMBE again

6. Issue the material from MPL1- s11 by using MB1B - MVT 351

o In Initial screen

Movement Type 351RTYIJ

Plant MPL1

Storage Location S11

o Press enter

o System will ask for PO No and line item no

o Enter PO and line item

o Press enter and clcik adopt + details button

o Click save

7. Check for an a/c document

o Go to MIGO enter mat doc no

o Click FI doc button in doc info tab

o You can find 2 a/c docs will be created (1 for MMOT and 1 for HYMT)

o In MMOT

G/L A/c Description

310000 Trading Goods -ve

399995 Inventory taking AA +ve

o In HYMT

G/L A/c Description

310000 Trading Goods +ve

399995 Inventory taking AA -ve

8. Check the stock status MMBE

o Supplying plant stock will reduce

o Stock in transit qty increased

9. Do MIGO Mvt 101 w.r.t STO PO

o Material doc will be created as a proof of GR

o NO a/c doc will be created

10. Check the stock status MMBE

o The stock will be transferred from transit category to Receiving str loc

Shrini Damarla - Chicago Page 20

SAP Material Management Spl. Procurement

STO A) Inter Company Stock Transport Order (Between Companies)

Pre requisites:

Supplying Plant (SPL1) Receiving Plant (RPL2)

1. Create Receiving Plant (RPL1) as Customer 1. Create Supplying Plant (SPL1) as a Vendor

(XD01) with an account group ship-to-party (XK01) with an account group 0007

(0002) - In Purchasing data screen

- Menu barextrasEnter Plant = SPL1

2. Create a Material Master Record with mat 3. Extend the material to receiving plant with sales

type HALB/HAWA/FERT and select Sales views

views also

- Sales Org = Supply. Plnt Sales Org - Sales Org = Receiving. Plnt Sales Org

- Dist. Channel = Supp.plnt Dist Channel - Dist. Channel = Recv.plnt Dist Channel

- Division = X - Division = X

(A common division should be maintained both sides)

Note :

In OMS2 select your mat type and update the Qty. and value check boxes to both supplying and

receiving plants

There can be a price difference of the material in the both plants.

There will be a cross company billing.

IMG Settings:

1. Define Shipping Data for Plants 1. Define Shipping Data for Plants

SPRO MM Purchasing PO SPRO MM Purchasing PO

Setup STO Setup STO Define Setup STO Setup STO Define

Shipping Data for Plants Shipping Data for Plants

Customer No Plant -- Empty Customer No Plant – Sppl. Pl Cust No

Sales org -- Supply Plant S Org Sales org – Recv Plant S Org

Distr. channel- Supply Plant Dist Distr. channel- Recv Plant Dist Channel

Channel

Int comp.bill Div - X Int comp.bill Div - X

(A common division should maintained both sides)

be

2. Assign Doc type and Checking Rule 3. Assign Doc type and Checking Rule

SPRO MM Purchasing PO SPRO MM Purchasing PO

Setup STO Setup STO Assign Doc Setup STO Setup STO Assign Doc

type and Checking Rule type and Checking Rule

Doc Type Plant Deliv type Chek Doc Type Plant Deliv type Chek

rule rule

NB SPL1 NLCC 01

Shrini Damarla - Chicago Page 21

SAP Material Management Spl. Procurement

NB RPL1 NLCC 01

Doc Type and Movement types:

STO Purchasing Document Movement Type DeliveryType Billing

Type Category Supl plnt Recv plnt

w/o SD w/o Billing UB U 351 101 -- --No--

with SD w/o Billing UB U 641 101 NL --No--

with SD,with Billing NB -- 643 101 NLCC --Yes--

Steps:

Supplying Plant Side Receiving Plant Side

1. Create a PO

2. Create a Delivery (Shipping Notification)

3. Do Picking and Post Goods Issue (PGI)

4. Do MIGO

5. Create Invoice

6. Do MIRO

Supplying Plant Side Receiving Plant Side

1. Create a Stock Transport Order (ME21N)

with Doc type NB

In Item details you will Observe Shipping

Tab will be created and you can find

Customer No in it.

2. Make an outbound delivery with shipping

point/plant

- Enter PO No and Click ‗Execute‘

- Click Deliver button

- Delivery No will be generated

3. For Goods Issue, Use Tcode = VL02 4. PO history will get the delivery details

- Enter Delivery No, Click Pickup

button.

- Enter Picking qty and click PGI button

5. Make a GR (Use Tcode = MIGO)

6. Check the Stock status (MMBE)

7. Create an Invoice (Use Tcode =???) 8. Make a MIRO for Payment

Shrini Damarla - Chicago Page 22

SAP Material Management Spl. Procurement

Shrini Damarla - Chicago Page 23

SAP Material Management Spl. Procurement

INTEGRATION

Shrini Damarla - Chicago Page 24

SAP Material Management Spl. Procurement

1. MM – SD Integration

1. SD Organizational Structure

Creation of SD Organizational Structure

A. Define SD Org Units.

B. Assign SD Org Units.

A. Define SD Org Units.

1. Define Sales Organization (OVX5)

[It is a unit/entity which is looking after the sales activities of the company]

SPROEnterprise StructureDefinition Sales and Distribution Define, copy, delete,

check sales organization

Double .click 'Copy, delete, check sales organization'

Click 'Copy Org Object' or F6

Select

From Sales Organization = 0001 - SAP std. Sales Org.

To Sales Organization = XSO

Press enter

System copies the 0001 data into XSO

Go back

Click 'Define Sales Organization' (for editing)

Click Position and enter Sales Org = XSO

Select XSO and click Details button

o Change

The text description as : XXXX Sales Org.

Statistic Currency: INR

Note: Sales org. Calendar field should be filled (with 01)

Click Address button or Shift + F5

Edit the address information

Click Save

2. Define Distribution channel (OVXI)

[Distribution channel: The channel through which saleable materials or services reach

customers]

SPROSPROEnterprise StructureDefinition Sales and Distribution Define, copy,

delete, check distribution channel

Click 'Copy, delete, check distribution channel'

Click 'Copy Org Object' or F6 and Select

o From Distr. Channel 01 - SAP std Distribution channel

o To Distr. Channel XD

o Press enter

Shrini Damarla - Chicago Page 25

SAP Material Management Spl. Procurement

o System copies the 01 data into XD

o Go back

o Click 'Define distribution channel' for Editing

o Click Position and enter Distribution channel = XD

o Select XD and change

o The text description as: XXXX Distribution channel. And Click Save

3. Define Division (OVX8)

SPRO-->Enterprise Structure -->Definition -->Logistics - General -->Define, copy, delete,

check division

Click 'Copy, delete, check division'

Click 'Copy Org Object' or F6

Select

o From Division 00 - SAP std. division

o To Division XD

Click enter

System copies the 00 data into XD

Go back

Click 'Define Division' for editing

Click Position and enter Division = XD

Select XD and change

o The text description as : XXXX Division.

Click Save

4. Maintain sales office (OVX1)

SPRO-->Enterprise Structure -->Definition -->Sales and Distribution -->Maintain sales office

[Sales office: It is an org unit from where sales activities will be carried out]

Click 'New entries' and enter

Sales office Description

XSOF XXXX sales Office

and enter the address

5. Maintain sales group (OVX4)

[A Group of people or an individual who is taking care of sales activities from Sales Office]

SPRO-->Enterprise Structure -->Definition -->Sales and Distribution -->Maintain sales group

Click 'New entries' and enter

Sales Group Description

XSG XXXX Sales Group

Click Save

Shrini Damarla - Chicago Page 26

SAP Material Management Spl. Procurement

B) Assign SD Org Units.

1. Assign sales organization to company code (OVX3)

SPRO Enterprise Structure Assignment Sales and Distribution Assign sales

organization to company code

XSO XMOT

2. Assign distribution channel to sales organization (OVXK)

SPRO Enterprise Structure Assignment Sales and Distribution Assign

distribution channel to sales organization

XSO XD (XXXX division)

Note: This entry already exists

3. Assign division to sales organization (OVXA) (MM-SD)

SPRO Enterprise Structure Assignment Sales and Distribution Assign division

to sales organization

o Click new entries

XSO XXX sales org XD XXXX division

4. Set up sales area (OVXG)

[Sales area is a combination of a Sales organization, Distribution channel, Division]

SPRO Enterprise Structure Assignment Sales and Distribution Set up sales

area

o Click new entries

XSO XD XD.

5. Assign sales office to sales area (OVXM)

SPRO Enterprise Structure Assignment Sales and Distribution Assign sales

office to sales area

o Click new entries

XSO XD XD XSOF

6. Assign sales group to sales office (OVXJ)

SPRO Enterprise Structure Assignment Sales and Distribution Assign sales

group to sales office

o Click new entries

XSOF XSG (XXXX sales Group)

7. Assign sales organization - distribution channel - plant (OVX6)

[MM and SD Integration Point]

SPRO Enterprise Structure Assignment Sales and Distribution Assign sales

organization - distribution channel - plant

o Click new entries

XSO XD XPL1, XSO XD XPL2

Shrini Damarla - Chicago Page 27

SAP Material Management Spl. Procurement

2. Customer Master Record

Customer is a person or a company who buy our product on either credit basis or on cash

basis.

In Finance terminology, they can also be called as 'debtors'

What is customer master Record?

A Complete information regarding the customer will be entered in this master file

Types of customers:

Regular Customers

Fixed Customers

One time Customers

IMG settings in Customer Master:

1. Creation of Customer A/c Group (OBD2)

SPROFinancial Accounting Accounts Receivable and Accounts Payable Customer Accounts

Master Data Preparations for Creating Customer Master Data Define Account Groups with

Screen Layout

Select SAP std. customer A/c group (i.e Sold -to- party = 0001)

Click copy as XCAG - xxx Customer A/c Group then save it.

2. Create Number Ranges for Customer Accounts (XDN1)

SPROFinancial AccountingAccounts Receivable and Accounts Payable Customer Accounts

Master Data Preparations for Creating Customer Master Data Create Number Ranges for

Customer Accounts

3. Assign Number Ranges to Customer Account Groups (OBAR)

SPROFinancial Accounting Accounts Receivable and Accounts PayableCustomer Accounts

Master Data Preparations for Creating Customer Master Data Assign Number Ranges to

Customer Account Groups

Vendor A/c Group No Range

XCAG XBC (XXX No. range)

Tcodes for Creation Change Display List of Customers

Customer Master XD01 XD02 XD03 VCUST

Shrini Damarla - Chicago Page 28

SAP Material Management Spl. Procurement

3. Partner Determination

IMG settings: Customer Partner Determination

1. Set up Partner Determination

Path: SPROSales and DistributionBasic FunctionsPartner DeterminationSet Up

Partner Determination

Click Set Up Partner Determination for Customer Master

1. Double click 'Partner functions' folder and check for SAP std partner functions i.e

Sold-to-party - SP

Ship-to-party - SH

Bill-to-party - BP

Payer - PY are available or not?

2. Double click 'Account Groups - Function Assignment' folder

Click 'New entries'

Sold-to-party - SP - VCAG - Volvo cust. a/c grp.

Ship-to-party - SH - VCAG - Volvo cust. a/c grp

Bill-to-party - BP - VCAG - Volvo cust. a/c grp

Payer - PY - VCAG - Volvo cust. a/c grp

3. Double click 'Partner Determination Procedures'

Click 'New entries' and define a partner determination procedure

VPDP - Volvo Part Det. Procedure

4. Select 'SPDP' and double click 'Partner Functions in Procedure'

Click 'New entries'

Partner det. Proc. Partner functions

VPDP SP

VPDP SH

VPDP BP

VPDP PY

Check Mandatory check box for all partner .functions

5. Now double click 'Partner Determination Procedure Assignment'

Click Position and enter our A/c group: VCAG

Group Part det proc.

VCAG SPDP

Shrini Damarla - Chicago Page 29

SAP Material Management Spl. Procurement

2. Define Common Distribution Channels (VOR1)

SPROSales and Distribution Master Data Define Common Distribution Channels

Sales Org Dist Channel Ref dis. ch for cond Ref dist ch. for cust.

VSO VD VD VD

3. Define Common Divisions (VOR2)

SPROSales and Distribution Master Data Define Common Divisions

Sales org Div. Ref. Div for Cond Ref Div. for cust

VSO VD VD VD

4. Define Transportation Zones (OVR1)

SPROSales and Distribution Basic Functions Routes Route Determination Define

Transportation Zones

Click 'New entries'

Country Transport. Zone Description

IN XXXX VTZ Volvo Transportation Zone

Click save

Shrini Damarla - Chicago Page 30

SAP Material Management Spl. Procurement

4. Sales Order

What is Sales Order?

Sales order is an Internal Document

It will be initiated by sales group belongs to a sales office

It may reach the Production people via Sales In charge

It is like a PR (Purchase Requisition) in MM

It is a transactional data

It consists of Customer details, Product or Material, Qty required, Price etc.

IMG settings - Sales Order

1. Define Number Ranges For Sales Documents (VN01)

SPRO Sales and DistributionSalesSales DocumentsSales Document

HeaderDefine Number Ranges for Sales Documents

2. Define Sales Document Types (VOV8)

SPROSales and DistributionSales Sales DocumentsSales Document

HeaderDefine Sales Document Types

SAP std. doc type for sales order is = OR

Select OR and click copy as

VOR - Volvo Sales order then

assign number range VS to VOR document type

3. Assign Sales Area To Sales Document Types (OVAZ)

SPROSales and DistributionSalesSales DocumentsSales Document

HeaderAssign Sales Area to Sales Document Types

3.1 Combine Sales organizations

Sales Org Ref. sales org

VSO VSO

3.2 Combine distribution channels

Sales org Dist channel Ref dist channel

VSO VD VD

3.3 Combine divisions

Sales org Division Ref division

VSO VD VD

3.4 Assign sales order types permitted for sales areas

Click new entries

Ref Sales org. Ref Dist Ch Ref Division Sales ord type

VSO VD VD VOR

4. Determine pricing Procedure (Tcode = OVKK)

SPROSales and Distribution Basic Functions Pricing Pricing Control Define and

Assign Pricing Procedures

Double click 'Define Pricing Procedure Determination'

click new entries

Sales org Dist Ch Div DoPr CuPP Pric Proc Cond

type

VSO VD VD A 1 RVAA01 PR00

Shrini Damarla - Chicago Page 31

SAP Material Management Spl. Procurement

5. Define Rules By Sales Area (OVF2)

SPROEnterprise Structure Assignment Sales and Distribution Business Area

Account Assignment Define Rules by Sales Area

Click position

Enter

Sorg Dist channel Div Rule

VSO VD VD 001(Business are determination from plt/div)

6. Assign Business Area To Plant And Division ( MM-SD integration)(OVF0)

SPROEnterprise Structure Assignment Sales and Distribution Business Area

Account Assignment Assign Business Area to Plant and Division

Click new entries

Plant Div Business Area

VPL1 VD 0001

VPL2 VD 0001

Shrini Damarla - Chicago Page 32

SAP Material Management Spl. Procurement

5. Third Party Scenario

What is Third Party?

Our vendor will supply certain materials to our customer based on our purchase order can be

called Third party

Third party Scenario:

Customer want of certain material and approach our sales person request him to arrange the

same and ready to pay the necessary charges of those materials

Our Sales person initiates a sales order for these materials.

Production people will create a PR for same and send it to Purchase department to supply

that material directly to customer (Delivery address of the customer will be provided in PR)

Then Purchase department will create a PO to a vendor who supplies this material to us and

request him to supply this as a special case to customer directly (Customer address will be

entered in Po at delivery address place

Customer will deliver the material and submit the bill for payment

Purchase department will verify his bill (through MIRO) and recommend for payment

Finance department will pay the vendor amount after cross checking the customer payment

has been made to our company or not.

Highlights in Third party configuration in SAP

In this scenario as a mm consultant we configure the steps in such a way that everything is almost

automatic

o Sales person will create a Sales order

o System will create an automatic PR

o Purchase department will execute automatic PO transaction

o System will create a PO automatically to a vendor with a delivery address as customer

address

o System will not allow to make GR w.r.t to this PO since its delivery address is customer

o Even though the vendor has been set as GR based inv. Verification check box (CREDIT

basis vendor), system will allow to make a MIRO

Steps in Third party scenario

1. Create a material type: XAWA (XXX Trading goods) by copying existing sap std. material type

for trading goods = HAWA (OMS2) and make Qty and value updates for your plants XPL1

and XPL2

2. Create a number range (MMNR) and assign to BAWA material type

3. Create a material (TV Stand) with a material type XAWA (X trading goods) with the

following views:

Basic data1, Purchasing, A/c ing 1, Sales org data 1, 2, Sales General/Plant,

MRP1, MRP2, Gen plant/str. 2 views

In Sales org data 1 view

o Enter Division and tax codes – 0 – no tax

In Sales Org data 2 view

o Enter Item Cat. = 'BANS' – third party

In Sales General/Plant view

o Transportation group = 0001

Shrini Damarla - Chicago Page 33

SAP Material Management Spl. Procurement

o Loading group = 0001

o Availability check: 01

In purchasing view

o Check Automatic PO

In MRP 1 view

o Enter MRP type: ND – No planning

In MRP 2 view

o Ext proc = 'F'

o Planned Delivery time = (say) 1 day

In General/plant data str. 2 view

o Check Negative stock allowed

In accounting view

o Valuation class: 3100

4. Create a customer (XD01) with A/c group sold to party

In Initial screen:

o A/c Group : Volvo customer Group (VCAG)

o Customer No : empty

o Company code VMOT

o Sales Organization VSO

o Distribution Channel VD

o Division VD

In General data Screen:

In Address Tab:

o Title : Mr.

o Name : Chiranjeevi

o Address: street and city, country details.

o Transportation Zone: VTZ- Volvo transportation zone

In Unloading point –TAB

o Unloading point : Hyderabad

o Calendar: 01 – German calendar

IN Contact Person – TAB

o Click ‗company code data‘ button

In A/c management – TAB

o Reconciliation A/c : 140000 – trade receivable domestic

o Cash mgmt group A1

Click ‗Pay terms transaction‘ TAB

o Terms of payment 0001

o Check payment history record

Click ‗Sales Area data‘ button

In Sales TAB

o Sales Office VSOF

o Sales Group VSG

o Cust.pric.proc. 1 – standard

Click Shipping tab

o Delivery Priority 01 – high priority

o Shipping Conditions 01 – As soon as possible

o Delivering Plant VPL1

Click ‗Billing document‘ tab

o Inco terms FOB Free on Board

Shrini Damarla - Chicago Page 34

SAP Material Management Spl. Procurement

o Tax classification 1 – liable for tax

Click partner functions

o See that SP, SH, BP and PY are appearing in the table?

5. Create a Vendor (XK01)/Make use of the existing vendor (XK02)

In purchasing view

o Check the Automatic PO check box

6. Maintain PIR (ME11) for the above material (TV stand) and Vendor

7. Maintain Source list (ME01) for the above material and vendor

8. Create a Customer info record - Condition record for customer (VK11)

Enter Condition type: PR00

Click Key combination and

o Select customer/Material with release Press enter

Enter

o Sales Organization VSO

o Distribution Channel VD

o Customer No : XXXX

o Enter Mat no xxx

o Price xxx

Click save

9. Create a Sales order (VA01) for the above Customer and Material

In initial screen enter the following:

o Order Type VOR

o Sales Organization VSO

o Distribution Channel VD

o Division VD

o Sales Office VSOF

o Sales Group VSG

Press enter

In Overview Screen

o Enter Sold to party: XXXXX (customer no)

In Sales Tab

o Pay terms: 0001

o Inco terms: FOB free on board

o Material No XXXXX and

o Item category 'TAS' - third party

Click Save

10. Go to display mode of Sales order (VA03) and Double click line item of the material (TV

stand) then go to 'Schedule Lines' tab and check whether PR has been generated or not?

Note down the PR Number.

11. Go to display mode of PR (ME53N) and check

Item category = S

A/c Assign. Category = '1' or 'X' (X means Auxiliary A/c

In item details

o Source of supply tab will have Vendor Address

o Delivery address Tab will have customer address

12. Execute ME59N and enter relevant Org details.

Run on test mode first if it is successful

Then execute it directly.

13. Go to display mode of PO (ME23N) and check

Shrini Damarla - Chicago Page 35

SAP Material Management Spl. Procurement

Item category = S and A/c Assign. category = '1' or 'X' (X means Auxiliary A/c)

In item details

o Delivery address Tab will have customer address

14. Send the PO to vendor, vendor will supply the material directly to customer

15. Vendor will submit an invoice (Bill) to the company.

16. MIRO will be done from the Purchasing Organization

17. Vendor payment will be made only after company receives the payment from customer

While you are doing the Third party you may get the following errors:

Error 1: Account 893010 has been set as not Error 2: Pricing error: Mandatory condition

relevant for tax MWST is missing

Steps: Steps:

o Use Tcode = FS00 o Use Tcode = V/08

o Change the co_cd as your co_cd o Click position

o Click find button and enter o Enter Pricing Procedure =

o a/c no = 893010 RVAA01

o Double click a/c no o Select RVAA01

o Click Control data tab o Click Control Data

o Click change button o Click position and Enter step

o Enter no 915 or select ‗MWST‘ and

Tax category V1 uncheck required column

o click save

Shrini Damarla - Chicago Page 36

SAP Material Management Spl. Procurement

MRP

MRP through (CBP-Reorder point)

IMG settings: MRP through (CBP-Reorder point)

1. Carry Out Overall Maintenance of Plant Parameters (OMI8)

SPROMaterials Management Consumption-Based Planning Plant Parameters Carry

Out Overall Maintenance of Plant Parameters

Click copy button and enter

From Plant 1000

To Plant hpl1

Click copy

System messages as "Parameters from plant 1000 were copied to plant HPL1'

Click maintain

Enter plant = HPL1

Click maintain button again

Click MRP controller button

Click 'New entries' button

Plant HPL1

MRP Controller HMC Honda MRP controller

Click save

2. Carry Out Overall Maintenance of MRP Groups (OPPZ)

SPRO Materials Management Consumption-Based Planning MRP Groups Carry Out

Overall Maintenance of MRP Groups

Enter plant = HPL1

Click Copy

From Plant

Plant 1000

MRP group 0040 (Planning grp with final assembly)

To plant

Plant HPL1

MRP group 0040

Click copy

Click maintain

Plant HPL1

MRP group 0040

Click maintain

Click Sch/doc type button

HPL1 0040 Planning with final assembly HNB

Click creation indicator enter the following

Plant HPL1 Honda Plant 1

MRP group 0040 Planning with final assembly

Create Purchase Req. 2 Purchase requisitions in opening period

Create MRP list 1 MRP list

Schedule lines 3 Schedule lines

Click save

Shrini Damarla - Chicago Page 37

SAP Material Management Spl. Procurement

3. Activate MRP and Set Up Planning File (OMDU)

SPRO Production Material Requirements Planning Planning File Entries Activate

MRP and Set Up Planning File

Click 'MRP' button

Click position and enter plant gpl2

Plant activate requirements planning

GPL2 Check box and Click save

MRP Steps:

Step - 1 –Create a Material Master (MM01), Select MRP 1 View, MRP 2 view also

MRP type = V1 - Manual reorder Point with ext. req.[Defines when the rule used to

determine WHEN the PR or Planned Order will be be created. ]

Reorder point = 100 nos. [Make sure that your ROP is higher than your current stock on

hand, otherwise MRP will not create any documents.]

MRP controller = HMC - Honda MRP controller [A Group or individual person responsible

for easy planning]

Lot size = HB - Replenish to maximum stock level [Lot size - Determine calculation to be

used to determine the QUANTITY in the PR or Planned Order ]

Maximum Stock level = 1000

In MRP 2 View

o Enter planned delivery time = 2 days

Step 2 -- View current stock on hand. (Tcode = MD04)

[Make sure that your ROP is higher than your current stock on hand, otherwise MRP willl not create

any documents. In this case Stock on hand (20) < ROP (100), so MRP will suggest you purchase

stock. ]

Step 3 --- Run MRP for the material

[Use transaction MD02 (Single Item, Multi-Level MRP run). The Single Item means for one material

only. Multi-Level refer to all levels of Bill of Material (BOM).]

Use Tcode = MD02

In Initial screen:

o Material No = xxxxx

o MRP area = xxxxx

o Plant = XPL1

o Processing Key = NETCH (Net change for total Horizon)

o Create PR = PR in Open period

o Delivery Sch = 3 - Schedule lines

o Create MRP List = 1 MRP List

o Planning Mode = 1 or 3

o Scheduling =1

Step 4 -- Evaluate results of MRP run

Use Stock Requirement List again (transaction MD04)

You should now have a Purchase Requisition or Planned Order for a quantity to take stock up

to maximum level (as was specified in material master).

Shrini Damarla - Chicago Page 38

SAP Material Management Spl. Procurement

Warehouse Management

IMG settings: Warehouse Management

1. Define warehouse number (EC09)

SPROIMGEnterprise Structure Definition Logistics Execution Define, copy, delete,

check warehouse number

Steps:

Click 'Copy/delete/check warehouse number'

Click 'Org Object' or F6

SAP std. warehouse no = 001

Enter

From Warehouse No. 001

To Warehouse No. YWN

Press enter

Go back or F3

Click 'Define warehouse number' (for editing)

Click position

Enter Warehouse No = YWN

Warehouse No Description

YWN Hyundai Warehouse Number

Click save

2. Assign warehouse number to plant/storage location (OML2) [Integration point of MM-

WM]

SPROMGEnterprise Structure Assignment Logistics Execution Assign warehouse

number to plant/storage location

Steps:

Click New entries

Plant Str loc W. No Description

HYP1 S11 YWN Hyundai Warehouse Number

HYP1 S12 YWN Hyundai Warehouse Number

Click save

3. Define Storage Type (OML4)

SPRO IMG Logistics Execution Warehouse ManagementMaster Data Define

Storage Type

SAP Warehouse Storage types are

001 High-rack storage

002 Shelf Storage

003 Open storage

004 Block storage

005 Fixed bin storage

006 Hazardous Materials

007 Pallet storage

Select SAP std Storage type 001 - High-rack storage

Click copy as YHS by entering the following

Warehouse number YWN

Storage type YHS

Shrini Damarla - Chicago Page 39

SAP Material Management Spl. Procurement

Press enter

Click save

4. Define Storage Sections (OML6)

SPRO-->IMG-->Logistics Execution-->Warehouse Management -->Master Data -->Define

Storage Sections

Steps:

SAP std Storage Section = 001 - Total section

Select 001

Click copy as YSS - Hyundai Storage section

WH No St. type St. sec Description

YWN YHS YTS Hyundai Total section

Click save

5. Define Picking Areas

SPRO IMG Logistics ExecutionWarehouse ManagementMaster Data Define

Picking Areas

Steps:

Click New entries

WH No St. type Picking area Description

YWN YHS YPA Hyundai picking area

Click save

6. BIN creation

6.1 Define Storage Bin Types (OML7)

SPRO IMG Logistics Execution Warehouse Management Master Data

Storage Bins Define Storage Bin Types (OML7)

Steps:

o Click New entries

WHno Str Bin type Description

YWN LB Hyundai Small Bin

o Click save

6.2 Define Blocking Reasons (OML9)

SPRO IMG Logistics Execution Warehouse Management Master Data

Storage Bins Define Blocking Reasons

Steps:

o Click New entries

WHNo Block reason Description

YWN E Expired items

o Click save

6.3 Define Storage Bin Structure

SPRO IMG Logistics Execution Warehouse ManagementMaster Data

Define Field Usage Storage Bins Define Storage Bin Structure

Steps:

o Click New entries

o System will display a template for BIN

Shrini Damarla - Chicago Page 40

SAP Material Management Spl. Procurement

o Enter the following information

Warehouse No. YWN Hyundai Warehouse Number

Storage Type YHS Hyundai High-rack storage

Sequence number 001

Template CCCNNCCCCC

Structure AA

Start value HYB01

End value HYB09

Increment 1

Storage Section YTS Hyundai Total section

Picking Area YPA Hyundai Picking area

Stor.. bin type LB Hyundai Small Bin

Maximum Weight KG

o Press enter

o On menu bar -->Environment-->Create bins

o System display the BINs with the numbers as per the structure designed

o On Application tool bar Click 'Create online' button

o System displays the message Do you want to create bins?

o Click Yes

Create a material master record with warehouse views

Steps:

Use Tcode = MM01

Select Views Basic data1, Purchasing, A/cing 1 and also warehouse mgmt 1, 2 views

In warehouse mgmt view-2

Enter

o Storage Bin HYB01

o Picking Area YPA

7. IMG settings: TO (Transfer Order) and TR (Transfer Requirement)

7.1. Define Number Ranges (OMLW)

SPROIMGLogistics Execution Warehouse ManagementMaster Data Define

Number Ranges

Steps:

Click ' for Transfer Requirement' button

Enter Warehouse No........ ywn

Create a no range

Repeat the same for TO also

Assign these No ranges to respective docs

Click Number ranges button

System will display the different doc type entries

Click Position

Enter Warehouse No. awn

W.house No NR for TO NR for TR

o AWN TO TR

Click save

Tcodes in WM

Shrini Damarla - Chicago Page 41

SAP Material Management Spl. Procurement

Creation of Transfer Order = LT01

Creation of Transfer Requirement = LB01

Total WM stock = LS26

To view the BIN stock = LS24

Printing of Transfer Order (TO) = LT31

Shrini Damarla - Chicago Page 42

SAP Material Management Spl. Procurement

13. MM & FI Integration

MM & FI Integration

It can also be called as

o Automatic Account Assignment (AAA)

o Valuation and A/c Assignment (VAA)

Valuation and Account Assignment:

This is fully integrated with FI.

Material Valuation: Stock value = Stock Qty. X Price

Material valuation will updates the G/L accounts in Financial Accounting.

Material Valuation features:

1. It allows you to re-evaluate the materials

2. You can evaluate the materials differently based on sub stocks.

3. It allows you to evaluate the balance sheet.

Define Valuation Control (OMWM)

• Choosing the valuation level is one of the first steps we will perform while customizing the

system.

• If using the PP Production module, the valuation area must be set at the plant level.

• For account determination, you can group together valuation areas by activating the valuation

grouping code. This makes the configuration of automatic postings much easier.

Group Together Valuation Areas

• Valuation areas are grouped together with the objective of simplifying management of the

standard accounts table by minimizing the number of entries.

• Along with other factors, the valuation grouping code determines the G/L Accounts, to which a

goods movement is posted (Automatic Account Determination).

• The valuation grouping code makes it easier to set the automatic account determination.

• Within the chart of accounts, we assigned the same valuation grouping code to the valuation

areas.

• Since we want to assign to the same G/L account, we assigned the same valuation grouping

code to the valuation areas.

• Valuation Area Company Code Chart Of Accounts Valuation Group Code

TPL1 TMOT INT 0001

Grouping of Valuation Areas

Company Code Valuation Area

Valuation

Grouping Code/

Valuation

Modification

Plant Valuation Area

Define Valuation Classes

• The Valuation class is a group of material with the same G/L account.

• When you create a material master record, you must assign the material to a valuation class.

The valuation class is assigned to a material at plant level. However, if using split valuation,

the valuation class will be assigned at the valuation type level.

Shrini Damarla - Chicago Page 43

SAP Material Management Spl. Procurement

• The choices for valuation class are dependent on the material type. In general, several

valuation classes can be allowed for one material type. Also, the same valuation class could

be allowed for different material types.

• The link between the valuation class and the material type is the account category reference.

The account category reference is assigned to a material type.

• The G/L account determined for a material is carried out according to the settings for its

valuation class.

Step1:

• Account Category Reference

Account Category Reference (4 Char): Group of valuation classes that‘s the system uses to

check whether the valuation class you have entered is allowed when you maintain accounting

data in a material master record.

Step2:

• Valuation Class

Here The Valuation Class is defined and a Account Category Reference is attached to a

Valuation Class.

Example: 3000 (Raw Materials) -> 0001 (Reference for Raw Materials)

Step3:

• Material Type / Account Category Reference

Here the Material Type can be assigned to a Account Category Reference.

Example: ROH (Raw Materials) -> 0001 (Reference For Raw Materials)

Material Type

Account Category

Reference

Valuation Class

Define Account Grouping for Movement Types

• Movement type

• Special stock indicator

• Value updating

• Quantity updating

• Movement Indicator

• Consumption posting

• Posting string for values

• Counter

• Transaction/event key

• Account modification

• Check

Shrini Damarla - Chicago Page 44

SAP Material Management Spl. Procurement

Transaction key

Movement type FR1

Value String Transaction key Dr Stock

WA01 BSX

Transaction Key Cr GR/IR

WRX

The following diagram shows the relation between Chart of account, Transaction, account

modifiers, accounts posting keys.

Account Determination Procedure Overview

Shrini Damarla - Chicago Page 45

SAP Material Management Spl. Procurement

Material Plant

Master

Type of

Transaction

Material

Type Company

Movement type Qty Code

String

Account

Categ.

Reference

Value

string

Val. Grouping

Account Code

Valuation

modification Chart of

Class

Account

Processing

Key

G/L

Account

TRANSACTION / EVENT KEYS IN SAP (WITH NOTES ON APPLICABILITY)

AUM Stock transfers are there between plants and from one movement type to another with split

valuation. The difference between the price at the delivering plant and the receiving point is

booked at the later.

Account to be opened:

Loss – Stock Transfer

Gain – Stock Transfer A/c

BO1 Check-up Subsequent settlement of Provisions (e.g.: volume based rebate)

BO2 -- Check-up.

Subsequent settlement of revenues -conditions in inv. Verification

BO3 Check-up Provision Differences

BSV The Company sends materials for subcontract work, this transaction is considered. Accounts

to be opened

Materials Consumed/Trading Goods w/o cost element -- for ROH

Inventory Change – Cost of Goods sold w/o Cost element --for FERTs

BSX All stock postings to Stock Accounts due to Goods receipts & goods issues in Inventory

Management. B/s Inventory A/c s 11101 to 11111

DIF Small Differences that may arise during invoice verification in the invoice amount not

exceeding tolerance.

Accounts to be opened:

Loss—Inventory Differences A/c

Gain---Inventory Differences A/c

FRX These are used for posting delivery costs when goods and invoices are received for purchase

orders

FR1 Freight Clearing 69002 Separate A/c s is required

FR2 Provisions for freight Charges 69002

FR3 Customs Clearing 69002

FR4 Provisions for Customs Clearing

FRL Services are performed for the company externally.

Account to be opened:

Purchased Services A/c

Shrini Damarla - Chicago Page 46

SAP Material Management Spl. Procurement

FRN Services are performed for the company externally and hence delivery costs

Account to be opened:

External Procurement Costs A/c

GBB Offsetting Entries for Inventory Postings

AUA For Order settlement

68005 (Factory output for Production)

AUF For GRs for orders (w/o account assignment) 68005

BSA For initial entry of stock balances 11199

INV Expenditure/Income from Inventory differences

68004 – Raw Material Consumption A/c

VAX For goods issues for sales orders with no assignment object

The account will not be cost element

68002 –Raw Material Indigenous

72001 – Stores & Spares

VAY For goods issues for sales orders with assignment object

The account is a cost element

VBO Consumption from stock provided to vendor

68002 –Raw Material Indigenous

VBR For internal goods issues (e.g.: to a cost center)

68005—Factory output for Production

72001 – Stores & Spares

VKA For consumption in Sales Order without SD (Mvt. Type 231)

68005—Factory output for Production

VNG For Scrapping & destruction

68004 – Raw Material Consumption – Others

VQY For sampling with account assignment

ZOB For goods issues with no Purchase order reference (Mvt 501)

ZOF For goods issues with no production order reference (Mvt 521)

KBS Account - assigned Purchase Order i.e. Account assignment taken from PO

Account need not be assigned in OBYC

KDR Exchange rate rounding differences in case of foreign currency invoices

80029 -- Exchange Rate Difference - Valuation 1

KDM Exchange rate rounding differences for open items (invoice posting with a

Different exch. rate than the GR/due to Std price difference/insufficient stock coverage)

80028 --Exchange Rate Difference - foreign currency to local

KDV Material ledger from low levels E/R diff.

KON Consignment payables

KTR Offsetting entry for price differences in cost object hierarchies

68005—Factory output for Production

LKW Accruals and deference. Acct. (material ledger)

PRD Price Differences

Loss/Gain Inventory Differences (Two A/cs to be opened & assigned)

68004 – Raw Material Consumption – Others A/c is assigned

PRK Price Differences in cost object hierarchies

Loss/Gain Inventory Differences (Two A/cs to be opened & assigned)

RKA Inv. reductions from logistic invoice verification

UMB Gain/loss from revaluation Check-up- 68004 is found attached (Raw Material Consumption –

Others A/c )

UPF Unplanned delivery costs

VST Input Tax

WGI Goods issue inflation revaluation

WGR Goods receipt inflation revaluation

WRX GR/IR clearing account

40051 – GR/IR Clearing A/c

WRY GR/IR clearing acct (mat. ledger) (old)

Shrini Damarla - Chicago Page 47

SAP Material Management Spl. Procurement

IMG settings: Valuation and A/c Assignment (VAA)

1. Define Valuation Control (OMWM)

Path: SPROIMGMaterials Management Valuation and Account Assignment Account

Determination Account Determination without Wizard Define Valuation Control

[Note: Valuation grouping code is the one parameter which is the link between MM and FI]

Steps:

Set Valuation grouping to active

Click save

2. Group Together Valuation Areas (OMWD)

Path: SPROIMGMaterials Management Valuation and Account Assignment Account

Determination Account Determination without Wizard Group Together Valuation Areas

Note: Valuation area means: You‘re Plant. Grouping together valuation areas means: Group all your

Plants.

How we will group together our plants? : Through Valuation grouping code.

Valuation grouping code (for Chart of A/c = INT ) = 0001 (INT means: International Chart

of A/c)

Valuation grouping code (for Chart of A/c = CAUS ) = US01 (CAUS means: Chart of A/c

US)

Valuation grouping code (for Chart of A/c = CAFR ) = FR01 (CAFR means : Chart of A/c

France)

Steps:

System displays Valuation Area and Valuation grouping code entries in a table

Click Position

enter Val Area = ASP1

Val area Co_cd Chart of A/c Valuation grp code

VPL1 VMOT INT 0001

VPL2 VMOT INT 0001

Click save

3. Define Valuation Classes (OMSK)

Path: SPROIMGMaterials Management Valuation and Account Assignment Account

Determination Account Determination without Wizard Define Valuation Classes

4. Define Account Grouping for Movement Types (OMWN)

Path: SPROIMGMaterials Management Valuation and Account Assignment Account

Determination Account Determination without Wizard Define Account Grouping for Movement

Types

5. Configure Automatic Postings (OMWB)

Path: SPROIMGMaterials Management Valuation and Account Assignment Account

Determination Account Determination without Wizard Configure Automatic Postings

Shrini Damarla - Chicago Page 48

You might also like

- Scheduling Agreement to Invoice Cycle GuideNo ratings yetScheduling Agreement to Invoice Cycle Guide135 pages