Professional Documents

Culture Documents

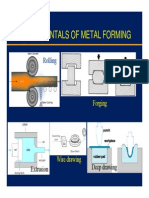

Fundamental of Metal Forming

Uploaded by

kuba Defaru0 ratings0% found this document useful (0 votes)

14 views38 pagesOver view

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOver view

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views38 pagesFundamental of Metal Forming

Uploaded by

kuba DefaruOver view

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 38

Overview of Metal Forming

Material Behavior in Metal Forming

Temperature in Metal Forming

Strain Rate Sensitivity

Friction and Lubrication in Metal Forming

Department of Mechanical Engineering

Large group of manufacturing processes in

which plastic deformation is used to change

the shape of metal workpieces

The tool, usually called a die, applies stresses

that exceed yield strength of metal

The metal takes a shape determined by the

geometry of the die

Department of Mechanical Engineering

Stresses to plastically deform the metal are

usually compressive

• Examples: rolling, forging, extrusion

However, some forming processes

• Stretch the metal (tensile stresses)

• Others bend the metal (tensile and compressive)

• Still others apply shear stresses

Department of Mechanical Engineering

Desirable material properties:

• Low yield strength and high ductility

These properties are affected by temperature:

• Ductility increases and yield strength decreases when

work temperature is raised

Other factors:

• Strain rate and friction

Department of Mechanical Engineering

Characterized by significant deformations and

massive shape changes

"Bulk" refers to workparts with relatively low

surface area‑to‑volume ratios

Starting work shapes include cylindrical billets

and rectangular bars

Department of Mechanical Engineering

Figure 18.2 – Basic bulk deformation processes: (a) rolling

Department of Mechanical Engineering

Figure 18.2 – Basic bulk deformation processes: (b) forging

Department of Mechanical Engineering

Figure 18.2 – Basic bulk deformation processes: (c) extrusion

Department of Mechanical Engineering

Figure 18.2 – Basic bulk deformation processes: (d) drawing

Department of Mechanical Engineering

• Forming and related operations performed on

metal sheets, strips, and coils

• High surface area‑to‑volume ratio of starting

metal, which distinguishes these from bulk

deformation

• Often called pressworking because presses

perform these operations

– Parts are called stampings

– Usual tooling: punch and die

Department of Mechanical Engineering

Figure 18.3 ‑ Basic sheet metalworking operations: (a) bending

Department of Mechanical Engineering

Figure 18.3 ‑ Basic sheet metalworking operations: (b) drawing

Department of Mechanical Engineering

Figure 18.3 ‑ Basic sheet metalworking operations: (c) shearing

Department of Mechanical Engineering

• Plastic region of stress-strain curve is primary interest

because material is plastically deformed

• In plastic region, metal's behavior is expressed by the

flow curve:

n

K

where K = strength coefficient; and n = strain

hardening exponent

• Stress and strain in flow curve are true stress and

true strain

Department of Mechanical Engineering

• For most metals at room temperature, strength

increases when deformed due to strain hardening

• Flow stress = instantaneous value of stress required

to continue deforming the material

Yf K n

where Yf = flow stress, that is, the yield strength as a

function of strain

Department of Mechanical Engineering

Determined by integrating the flow curve

equation between zero and the final strain

value defining the range of interest

_

K n

Yf

1 n

_

where Yf = average flow stress; and =

maximum strain during deformation process

Department of Mechanical Engineering

For any metal, K and n in the flow curve

depend on temperature

• Both strength and strain hardening are reduced at

higher temperatures

• In addition, ductility is increased at higher temperatures

Department of Mechanical Engineering

Any deformation operation can be

accomplished with lower forces and power at

elevated temperature

Three temperature ranges in metal forming:

• Cold working

• Warm working

• Hot working

Department of Mechanical Engineering

Performed at room temperature or slightly

above

Many cold forming processes are important

mass production operations

Minimum or no machining usually required

• These operations are near net shape or net shape

processes

Department of Mechanical Engineering

Better accuracy, closer tolerances

Better surface finish

Strain hardening increases strength and

hardness

Grain flow during deformation can cause

desirable directional properties in product

No heating of work required

Department of Mechanical Engineering

• Higher forces and power required

• Surfaces of starting workpiece must be free of

scale and dirt

• Ductility and strain hardening limit the amount

of forming that can be done

– In some operations, metal must be annealed to allow

further deformation

– In other cases, metal is simply not ductile enough to be

cold worked

Department of Mechanical Engineering

Performed at temperatures above room

temperature but below recrystallization

temperature

Dividing line between cold working and warm

working often expressed in terms of melting

point:

• 0.3Tm, where Tm = melting point (absolute temperature)

for metal

Department of Mechanical Engineering

Lower forces and power than in cold working

More intricate work geometries possible

Need for annealing may be reduced or

eliminated

Department of Mechanical Engineering

Deformation at temperatures above

recrystallization temperature

Recrystallization temperature = about one ‑half

of melting point on absolute scale

• In practice, hot working usually performed somewhat

above 0.5Tm

• Metal continues to soften as temperature increases

above 0.5Tm, enhancing advantage of hot working

above this level

Department of Mechanical Engineering

Capability for substantial plastic deformation of

the metal ‑ far more than possible with cold

working or warm working

Why?

• Strength coefficient is substantially less than at room

temperature

• Strain hardening exponent is zero (theoretically)

• Ductility is significantly increased

Department of Mechanical Engineering

• Workpart shape can be significantly altered

• Lower forces and power required

• Metals that usually fracture in cold working can

be hot formed

• Strength properties of product are generally

isotropic

• No strengthening of part occurs from work

hardening

– Advantageous in cases when part is to be subsequently

processed by cold forming

Department of Mechanical Engineering

Lower dimensional accuracy

Higher total energy required (due to the

thermal energy to heat the workpiece)

Work surface oxidation (scale), poorer surface

finish

Shorter tool life

Department of Mechanical Engineering

Theoretically, a metal in hot working behaves

like a perfectly plastic material, with strain

hardening exponent n = 0

• The metal should continue to flow at the same flow

stress, once that stress is reached

• However, an additional phenomenon occurs during

deformation, especially at elevated temperatures: Strain

rate sensitivity

Department of Mechanical Engineering

• Strain rate in forming is directly related to

speed of deformation v

• Deformation speed v = velocity of the ram or

other movement of the equipment

Strain rate is defined:

. v

h

.

where = true strain rate; and h = instantaneous height

of workpiece being deformed

Department of Mechanical Engineering

In most practical operations, valuation of strain

rate is complicated by

• Workpart geometry

• Variations in strain rate in different regions of the part

Strain rate can reach 1000 s-1 or more for some

metal forming operations

Department of Mechanical Engineering

Flow stress is a function of temperature

At hot working temperatures, flow stress also

depends on strain rate

• As strain rate increases, resistance to deformation

increases

• This effect is known as strain‑rate sensitivity

Department of Mechanical Engineering

Figure 18.5 ‑ (a) Effect of strain rate on flow stress at an

elevated work temperature. (b) Same relationship

plotted on log‑log coordinates

Department of Mechanical Engineering

Yf C m

where C = strength constant (similar but not

equal to strength coefficient in flow curve

equation), and m = strain‑rate sensitivity

exponent

Department of Mechanical Engineering

Figure 18.6 ‑ Effect of

temperature on flow stress

for a typical metal. The

constant C in Eq. (18.4),

indicated by the intersection

of each plot with the vertical

dashed line at strain rate =

1.0, decreases, and m

(slope of each plot)

increases with increasing

temperature

Department of Mechanical Engineering

Increasing temperature decreases C, increases

m

• At room temperature, effect of strain rate is almost

negligible

Flow curve is a good representation of material behavior

• As temperature increases, strain rate becomes

increasingly important in determining flow stress

Department of Mechanical Engineering

In most metal forming processes, friction is

undesirable:

• Metal flow is retarded

• Forces and power are increased

• Wears tooling faster

Friction and tool wear are more severe in hot

working

Department of Mechanical Engineering

Metalworking lubricants are applied to

tool‑work interface in many forming

operations to reduce harmful effects of friction

Benefits:

• Reduced sticking, forces, power, tool wear

• Better surface finish

• Removes heat from the tooling

Department of Mechanical Engineering

Type of forming process (rolling, forging,

sheet metal drawing, etc.)

Hot working or cold working

Work material

Chemical reactivity with tool and work metals

Ease of application

Cost

Department of Mechanical Engineering

You might also like

- Fundamentals of Metal FormingDocument38 pagesFundamentals of Metal FormingAd Man GeTigNo ratings yet

- Pertemuan 2 Material Behavior in Metal FormingDocument37 pagesPertemuan 2 Material Behavior in Metal FormingMayonkFound ationNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Chapter 18-Fundamentals Metal FormingDocument33 pagesChapter 18-Fundamentals Metal Formingdrbasit93No ratings yet

- 1 Fundamentals of Metal FormingDocument43 pages1 Fundamentals of Metal Formingdawitdafe4No ratings yet

- Metal Forming ProcessDocument5 pagesMetal Forming ProcesstadeleNo ratings yet

- Lec 7Document38 pagesLec 7Romany AdelNo ratings yet

- Metal Forming - FundamentalDocument35 pagesMetal Forming - FundamentalR ChannelNo ratings yet

- Fundamental of Metal FormingDocument31 pagesFundamental of Metal FormingHusain AliNo ratings yet

- Proses Manufaktur - Fundamental of Metal FormingDocument35 pagesProses Manufaktur - Fundamental of Metal FormingAnatolium IrgrandeNo ratings yet

- ManufProc 4 BulkFormingDocument96 pagesManufProc 4 BulkFormingHannan yusuf KhanNo ratings yet

- Chapter 18-Fundamentals Metal FormingDocument32 pagesChapter 18-Fundamentals Metal FormingZaka UllahNo ratings yet

- Lec1 - Fundamentals of Metal FormingDocument40 pagesLec1 - Fundamentals of Metal Formingthisidisforfun03No ratings yet

- Tutorial 3Document18 pagesTutorial 3omar salahNo ratings yet

- Class 12Document31 pagesClass 12Ayush BhadauriaNo ratings yet

- Chapter 18-Fundamentals of Metal FormingDocument33 pagesChapter 18-Fundamentals of Metal FormingMuhammad Qasim QureshiNo ratings yet

- Metal FormingDocument80 pagesMetal FormingIbrahim Mehkri100% (1)

- Metal FormingDocument80 pagesMetal Formingashok PradhanNo ratings yet

- Metals FormingDocument34 pagesMetals FormingBilisuma SeyoumNo ratings yet

- Fundamentals of Metal Forming: RollingDocument26 pagesFundamentals of Metal Forming: RollingamitNo ratings yet

- Fundamentals of Metal Forming: RollingDocument26 pagesFundamentals of Metal Forming: RollingAyush BhadauriaNo ratings yet

- Plastic Deformation Tool Die Yield STR Ength Geometry of The Die. Stresses Applied Co Mpressive Stretch Bend Shear StressesDocument102 pagesPlastic Deformation Tool Die Yield STR Ength Geometry of The Die. Stresses Applied Co Mpressive Stretch Bend Shear StressesEbrahim AliNo ratings yet

- Plastic Deformation and Metal Forming FundamentalsDocument83 pagesPlastic Deformation and Metal Forming FundamentalsNawaz KhanNo ratings yet

- Chapter 4Document113 pagesChapter 4girma workuNo ratings yet

- Amr Shehata FayedDocument29 pagesAmr Shehata FayeddpksobsNo ratings yet

- Chapter 3 MFG IIDocument145 pagesChapter 3 MFG IITiliksew Wudie Assabe100% (1)

- Fundamentals of Metal FormingDocument38 pagesFundamentals of Metal FormingriyannnNo ratings yet

- 2.1 Overview of Metal FormingDocument8 pages2.1 Overview of Metal FormingWillykateKairuNo ratings yet

- Fundamentals of Metal Forming Processes: Amr Shehata FayedDocument29 pagesFundamentals of Metal Forming Processes: Amr Shehata FayedErick Maza MartinezNo ratings yet

- Handout-8a-Metal Forming BasicDocument23 pagesHandout-8a-Metal Forming BasicAmardhianaNo ratings yet

- Rolling, Forging, Extrusion & DrawingDocument13 pagesRolling, Forging, Extrusion & DrawingMuhammad Ali AbroNo ratings yet

- Defects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarDocument22 pagesDefects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarKarun PeriyasamyNo ratings yet

- Defects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarDocument22 pagesDefects in Metal Forming Processes: Prepared By:-Amitkumar R. ShelarCepi Sindang KamulanNo ratings yet

- Casting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingDocument44 pagesCasting Forming Sheet Metal Processing Powder-And Ceramics Processing Plastics ProcessingRaj PatelNo ratings yet

- Metal FormingDocument13 pagesMetal Formingabdsu75No ratings yet

- UntitledDocument7 pagesUntitledKondwani NguletiNo ratings yet

- Resistance WeldingDocument24 pagesResistance WeldingSenthil Kumar K LNo ratings yet

- Resistance WeldingDocument24 pagesResistance WeldingSenthil Kumar K LNo ratings yet

- Manufacturing Processes FormabilityDocument6 pagesManufacturing Processes FormabilityG. Dancer GhNo ratings yet

- Forging Processes MEE 3024 2014Document36 pagesForging Processes MEE 3024 2014krunal07786No ratings yet

- Lecture 32 - Introduction To Metal FormingDocument23 pagesLecture 32 - Introduction To Metal Formingkunal gargNo ratings yet

- Source of HeatDocument9 pagesSource of HeatSreekumar RajendrababuNo ratings yet

- MPP - SRS Class 6 Bulk Deforfmation Process - FinalDocument44 pagesMPP - SRS Class 6 Bulk Deforfmation Process - FinalSuk bahadur GurungNo ratings yet

- Unit - Iii: Metal Forming ProcessesDocument63 pagesUnit - Iii: Metal Forming ProcessesRohith RoNo ratings yet

- MFG II 3182 Chapter 1Document58 pagesMFG II 3182 Chapter 1Naol EmanaNo ratings yet

- ForgingDocument37 pagesForgingchris mushunjeNo ratings yet

- COLD WELDING AND PRESSURE GAS WELDINGDocument46 pagesCOLD WELDING AND PRESSURE GAS WELDINGFajar SiradzNo ratings yet

- 18 Fundamentals of Metal Forming Review Questions and Multiple Choice QuizDocument2 pages18 Fundamentals of Metal Forming Review Questions and Multiple Choice Quizhzeem50% (2)

- RJ - METAL FORMING PROCESS - NotesDocument16 pagesRJ - METAL FORMING PROCESS - NotesAnshul YadavNo ratings yet

- Extrusion and Wire Drawing 2020 PDFDocument64 pagesExtrusion and Wire Drawing 2020 PDFChand PatelNo ratings yet

- Flow Stress or True StressDocument7 pagesFlow Stress or True StressRajshekar NagarajNo ratings yet

- Fundamentals of Metal FormingDocument22 pagesFundamentals of Metal Formingelmar waruwuNo ratings yet

- "Influence of Die Angle in Cold Extrusion": A Case Study OnDocument17 pages"Influence of Die Angle in Cold Extrusion": A Case Study OnKarthik B KamathNo ratings yet

- Solid-State Welding ProcessesDocument17 pagesSolid-State Welding ProcessescfcshakerNo ratings yet

- Metal Forming Processes Unit-IDocument9 pagesMetal Forming Processes Unit-IDimas Mahendra P BozerNo ratings yet

- Metal Forming FundamentalsDocument6 pagesMetal Forming FundamentalsRupak KumarNo ratings yet

- Chapter2 Lecture OkDocument39 pagesChapter2 Lecture OkAlaaNo ratings yet

- 6 PDFDocument14 pages6 PDFkuba DefaruNo ratings yet

- Asignment II FinalDocument2 pagesAsignment II Finalkuba DefaruNo ratings yet

- Metal FormingDocument13 pagesMetal Formingkuba DefaruNo ratings yet

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDocument8 pagesAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed Machiningkuba DefaruNo ratings yet

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDocument8 pagesAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed Machiningkuba DefaruNo ratings yet

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDocument8 pagesAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed Machiningkuba DefaruNo ratings yet

- 6 PDFDocument14 pages6 PDFkuba DefaruNo ratings yet

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDocument8 pagesAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed Machiningkuba DefaruNo ratings yet

- Cutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning OperationsDocument6 pagesCutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning Operationskuba DefaruNo ratings yet

- An Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed MachiningDocument8 pagesAn Experimental Technique For The Measurement of Temperature Fields For The Orthogonal Cutting in High Speed Machiningkuba DefaruNo ratings yet

- Experimental Investigation and Surface Roughness Analysis On Hard Turning of AISI D2 Steel Using Coated Carbide InsertDocument6 pagesExperimental Investigation and Surface Roughness Analysis On Hard Turning of AISI D2 Steel Using Coated Carbide Insertkuba DefaruNo ratings yet

- Experimental Investigation and Surface Roughness Analysis On Hard Turning of AISI D2 Steel Using Coated Carbide InsertDocument6 pagesExperimental Investigation and Surface Roughness Analysis On Hard Turning of AISI D2 Steel Using Coated Carbide Insertkuba DefaruNo ratings yet

- Cutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning OperationsDocument6 pagesCutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning Operationskuba DefaruNo ratings yet

- Cutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning OperationsDocument6 pagesCutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning Operationskuba DefaruNo ratings yet

- Cutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning OperationsDocument6 pagesCutting-Parameter Selection For Maximizing Production Rate or Minimizing Production Cost in Multistage Turning Operationskuba DefaruNo ratings yet

- Temperature Measurement When High Speed Machining Hardened Mould/die SteelDocument9 pagesTemperature Measurement When High Speed Machining Hardened Mould/die Steelkuba DefaruNo ratings yet

- CV Examples: How to Highlight Skills & AchievementsDocument8 pagesCV Examples: How to Highlight Skills & AchievementsCrye BiggieNo ratings yet

- Measurement: Ravindra Nath YadavDocument8 pagesMeasurement: Ravindra Nath Yadavkuba DefaruNo ratings yet

- Parallel Turning Process Parameter Optimization Based On A Novel Heuristic ApproachDocument12 pagesParallel Turning Process Parameter Optimization Based On A Novel Heuristic Approachkuba DefaruNo ratings yet

- CIRP Annals - Manufacturing Technology: E. Budak (1), E. OzturkDocument4 pagesCIRP Annals - Manufacturing Technology: E. Budak (1), E. Ozturkkuba DefaruNo ratings yet

- ToT On Curriculum Review For Program Accreditation Pptslides4traineesDocument127 pagesToT On Curriculum Review For Program Accreditation Pptslides4traineeskuba DefaruNo ratings yet

- Iloc and Loc Uses PDFDocument16 pagesIloc and Loc Uses PDFsaurabhNo ratings yet

- SABS Standards and Their Relevance to Conveyor SpecificationsDocument17 pagesSABS Standards and Their Relevance to Conveyor SpecificationsRobert Nicodemus Pelupessy0% (1)

- UCT APM M2 U1 - TP Leadership QuestionnaireDocument4 pagesUCT APM M2 U1 - TP Leadership QuestionnaireLincolyn MoyoNo ratings yet

- Abaqus 6.12: Abaqus Example Problems ManualDocument606 pagesAbaqus 6.12: Abaqus Example Problems ManualThiago GomesNo ratings yet

- Group Case Study: Premier Automotive Services LimitedDocument2 pagesGroup Case Study: Premier Automotive Services LimitedKryzel Jean Tumbaga ValdezNo ratings yet

- Speed Control Methods of 3-Phase Induction MotorsDocument3 pagesSpeed Control Methods of 3-Phase Induction MotorsBenzene diazonium saltNo ratings yet

- Welder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingDocument4 pagesWelder Training in SMAW, GTAW & GMAW Welding Engineering & NDT Consultancy Welding Engineering Related TrainingKavin PrakashNo ratings yet

- Call Log ReportDocument44 pagesCall Log ReportHun JhayNo ratings yet

- June 28th Altran Capital Market Day Presentation DeckDocument52 pagesJune 28th Altran Capital Market Day Presentation Deckvenkata.krishnan100% (1)

- COT English 3rd PrepositionDocument14 pagesCOT English 3rd PrepositionGanie Mae Talde Casuncad100% (1)

- Vidya Mandir Public School Class 11 Computer Science String Assignment SolutionsDocument5 pagesVidya Mandir Public School Class 11 Computer Science String Assignment SolutionsArun SharmaNo ratings yet

- Elm-490-Clinical Practice Evaluation 2 - Single Placement EncryptedDocument17 pagesElm-490-Clinical Practice Evaluation 2 - Single Placement Encryptedapi-439334022No ratings yet

- Abdul Jabbar (Mechanical Engineer) AGROFEED KSADocument4 pagesAbdul Jabbar (Mechanical Engineer) AGROFEED KSAftimum1No ratings yet

- A4931 DatasheetDocument12 pagesA4931 DatasheetDiego HernandezNo ratings yet

- Economics Not An Evolutionary ScienceDocument17 pagesEconomics Not An Evolutionary SciencemariorossiNo ratings yet

- Experiences in The OperationDocument7 pagesExperiences in The OperationUsama Bin SabirNo ratings yet

- BOYSEN® Marmorino™ Italian Marble Finish: Liters UseDocument1 pageBOYSEN® Marmorino™ Italian Marble Finish: Liters UseJohn Ray Esmama CalasicasNo ratings yet

- Ac and DC MeasurementsDocument29 pagesAc and DC MeasurementsRudra ChauhanNo ratings yet

- Prelims Module On Forensic 1Document17 pagesPrelims Module On Forensic 1Vanessa CorpuzNo ratings yet

- Electrical Tools, Eq, Sup and MatDocument14 pagesElectrical Tools, Eq, Sup and MatXylene Lariosa-Labayan100% (2)

- The Practice of Medicinal Chemistry, 4th EditionDocument2 pagesThe Practice of Medicinal Chemistry, 4th Editionlibrary25400% (1)

- Gerunds vs InfinitivesDocument87 pagesGerunds vs InfinitivesDeby NavarroNo ratings yet

- Products For Enhanced Oil RecoveryDocument4 pagesProducts For Enhanced Oil RecoverypmarteeneNo ratings yet

- Partlist Sym Vf3i 185Document83 pagesPartlist Sym Vf3i 185Jack Wilder100% (1)

- SreejithDocument23 pagesSreejithAkn SNo ratings yet

- RV RVR en 0714 Edit PDFDocument6 pagesRV RVR en 0714 Edit PDFJacques FerreiraNo ratings yet

- BudgetingForecastingCoursePresentation 1547839506611Document91 pagesBudgetingForecastingCoursePresentation 1547839506611ikakkos100% (2)

- E-Ship Assignment 2 Utkarsh Surjey MBA-FT-EDocument3 pagesE-Ship Assignment 2 Utkarsh Surjey MBA-FT-Eutkarsh surjeyNo ratings yet

- Brochure PILA Lamps and LuminairesDocument42 pagesBrochure PILA Lamps and Luminairesaldtol21No ratings yet

- Enlightened DespotismDocument19 pagesEnlightened Despotismmeghna mNo ratings yet