Professional Documents

Culture Documents

INTRODUCTION

Uploaded by

Rakha Dhaniwijaya0 ratings0% found this document useful (0 votes)

3 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views10 pagesINTRODUCTION

Uploaded by

Rakha DhaniwijayaCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 10

PRODUCTION PROCESS

DEFINITION

transforming a range of inputs into outputs that are

required by the market.

INPUTS TRANSFORMATION

PROCESS OUTPUTS

• Labour

•Land/building •Finished goods

•Machinery •Services

•Materials

Objective: to create goods and services that meet

the needs and wants of customers

Business must produce the correct number of

products, in the shortest possible time, to the

best quality and at a competitive price.

ADDED VALUE

• Any production process involves a series of links

in a production chain.

• At each stage value is added in the course of

production.

• Adding value involves making a product more

desirable to a consumer so that they will pay

more for it. Adding value therefore is not just

about manufacturing, but relates to all processes

that make the final product more desirable.

PROCESSING TYPES

Job or 'make complete' production is the

creation of single items by either one operative

or a team of operative's.

Batch production The term batch refers to a

specific group of components, which go through

a production process together. As one batch

finishes, the next one starts.

Flow production is a continuous process of parts

and sub-assemblies passing on from one stage

to another until completion.

JOB PRODUCTION

• Job production is unique in the fact that the

project is considered to be a single operation,

which requires the complete attention of the

operative before he or she passes on to the next

job

JOB PRODUCTION BENEFIT

1. The job is a unique product, which exactly matches the

requirements of the customer, often from as early as

the design stage. It will therefore tend to be specific to

a customer's order and not in anticipation of a sale

2. As the work is concentrated on a specific unit,

supervision and inspection of work are relatively

simple.

3. Specifications for the job can change during the course

of production depending upon the customer's

inspection to meet his or her changing needs.

4. Working on a single unit job, coping with a variety of

tasks and being part of a small team working towards

the same aim would provide employees with a greater

level of satisfaction

BATCH PRODUCTION

Batches are continually processed through each

machine before moving on to the next operation.

This method is sometimes referred to as

'intermittent' production as different job types are

held as work-in progress between the various

stages of production.

BATCH PRODUCTION BENEFIT

1. It is particularly suitable for a wide range of almost similar goods,

which can use the same machinery on different settings.

2. It economises upon the range of machinery needed and reduces

the need for a flexible workforce.

3. Units can respond quickly to customer orders by moving buffer

stocks of work-in-progress or partly completed products through the

final production stages.

4. It makes possible economies of scale in techniques of production,

bulk purchasing and areas of organisation.

5. It makes costing easy and provides a better information service for

management.

FLOW PRODUCTION

Units are worked upon in each operation and then passed

straight on to the next work stage without waiting for the

batch to be completed.

For flow production to be successful there needs to be a

continuity of demand. If demand varied, this could lead

to a constant overstocking of finished goods.

Achieving a smooth flow of production requires

considerable pre-production planning to make sure that

raw materials are purchased and delivered just-in-time,

that sufficient labour is employed and that there is

continuous attention to quality throughout the production

process.

FLOW PRODUCTION BENEFIT

Ease of using just-in-time techniques to eliminate waste and

minimise costs

Labour and other production costs will be reduced through detailed

planning and the use of robotics and automation

Deviation in the line can be quickly spotted through ongoing quality

control techniques

As there is no rest between operations, work-in-progress levels can

be kept low

The need for storage space is minimal

The physical handling of items is minimal

Investment in raw materials and parts are quickly converted into

sales

Control is easy.

You might also like

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Apply Quality StandardsDocument27 pagesApply Quality StandardsChristian BehilNo ratings yet

- PM-Solved Paper 2006Document27 pagesPM-Solved Paper 2006anuragmamgainNo ratings yet

- Pom - Unit 1Document16 pagesPom - Unit 1Mohak SinghNo ratings yet

- Operation ManagementDocument18 pagesOperation Managementayman jodehNo ratings yet

- Production & Productivity (Sheet-4)Document31 pagesProduction & Productivity (Sheet-4)2223401015No ratings yet

- Types of Production Processes ExplainedDocument13 pagesTypes of Production Processes Explainedshivam tripathiNo ratings yet

- Production: Industrial Plant & SafetyDocument12 pagesProduction: Industrial Plant & SafetyHussein TarhiniNo ratings yet

- Production Capacity 62584Document16 pagesProduction Capacity 62584temesgen bimrawNo ratings yet

- Production Management - AFFANDocument82 pagesProduction Management - AFFANaffanNo ratings yet

- CH 20Document5 pagesCH 20meelas123No ratings yet

- Production Productivity Sheet 1Document32 pagesProduction Productivity Sheet 1shohag.rcdNo ratings yet

- Continuous Flow Process ExampleDocument4 pagesContinuous Flow Process ExampleSheena Mae PalaspasNo ratings yet

- Unit II PMGTDocument15 pagesUnit II PMGTAshish UikeyNo ratings yet

- OM Unit1&2Document25 pagesOM Unit1&2Arvind KumarNo ratings yet

- Product Development PrinciplesDocument3 pagesProduct Development PrinciplesCollins OtienoNo ratings yet

- Production Management FunctionsDocument13 pagesProduction Management FunctionsMaryjane AdebayoNo ratings yet

- Om2 TPSDocument21 pagesOm2 TPSharischarmNo ratings yet

- Production and operations management: Mass, batch, continuous production planningDocument8 pagesProduction and operations management: Mass, batch, continuous production planningPadmmaja VanamaNo ratings yet

- Operations Management OverviewDocument38 pagesOperations Management OverviewTesfaye ejetaNo ratings yet

- Product Design ProcessDocument7 pagesProduct Design ProcessMau BautistaNo ratings yet

- Project - OmDocument30 pagesProject - OmSesha Sai KumarNo ratings yet

- Introducti O N: Types of Production SystemsDocument38 pagesIntroducti O N: Types of Production SystemsPrasad DhanikondaNo ratings yet

- Part One Ppc-IDocument34 pagesPart One Ppc-ITMIMITWJ2030No ratings yet

- Mastering Production ManagementDocument25 pagesMastering Production Managementromalyn purificacionNo ratings yet

- Production-Process 1. Job ProductionDocument2 pagesProduction-Process 1. Job ProductionMuahid RasiyidinNo ratings yet

- CH I - Introduction To Opeartion ManagementDocument38 pagesCH I - Introduction To Opeartion ManagementSanjay ThakurNo ratings yet

- Production SystemDocument100 pagesProduction Systembroshan100% (1)

- Unit 3 - POM NewDocument26 pagesUnit 3 - POM NewYogitha GowdaNo ratings yet

- Business Section 4.1 NewDocument10 pagesBusiness Section 4.1 NewJuné MaraisNo ratings yet

- Production and Operation CombinedDocument86 pagesProduction and Operation CombinedScott The BloggerNo ratings yet

- Om Unit IDocument20 pagesOm Unit IMiyonNo ratings yet

- Production Methods and EfficiencyDocument8 pagesProduction Methods and EfficiencyHelenaNo ratings yet

- Production Management New Unit 1Document47 pagesProduction Management New Unit 1Saif Ali KhanNo ratings yet

- What Is Production SystemDocument5 pagesWhat Is Production SystemJorge Arellano HinojosaNo ratings yet

- Managing Production and Service OperationsDocument22 pagesManaging Production and Service OperationsJam LarsonNo ratings yet

- OpmtqmDocument4 pagesOpmtqmJayson ZonsaNo ratings yet

- Production and Operations Management ActivitiesDocument4 pagesProduction and Operations Management ActivitiesManuel PlandañoNo ratings yet

- Logistic Supply ChainDocument9 pagesLogistic Supply ChainOlveda, RochelleNo ratings yet

- Production & Operation ManagementDocument55 pagesProduction & Operation ManagementrishabhNo ratings yet

- Managing Operations GloballyDocument22 pagesManaging Operations GloballyJona BustamanteNo ratings yet

- Module 4Document13 pagesModule 4isabel payupayNo ratings yet

- Chapter 2Document7 pagesChapter 2Gamme AbdataaNo ratings yet

- Chapter 17 - ProductionDocument43 pagesChapter 17 - ProductionBasma FadlyNo ratings yet

- Types of Production Systems: BY: Nitesh KR - Pal DFT Semester 6Document18 pagesTypes of Production Systems: BY: Nitesh KR - Pal DFT Semester 6Nitesh Kumar PalNo ratings yet

- Production of Goods andDocument17 pagesProduction of Goods andHelenaNo ratings yet

- 4.1 Production of Goods and ServiceDocument6 pages4.1 Production of Goods and ServiceannabellNo ratings yet

- 4.1 - Production of Goods and Services - 2Document9 pages4.1 - Production of Goods and Services - 2Haris ParkerNo ratings yet

- Module 1Document113 pagesModule 1Anirudh SNo ratings yet

- Concept of ProductionDocument5 pagesConcept of ProductionLucky GargNo ratings yet

- Process Design: Learning OutcomesDocument12 pagesProcess Design: Learning OutcomesMejidana, Rica Mae N.No ratings yet

- Process Design and TypesDocument13 pagesProcess Design and TypessaskiaNo ratings yet

- Unit 4 - Entrepreneurship - Management - WWW - Rgpvnotes.inDocument22 pagesUnit 4 - Entrepreneurship - Management - WWW - Rgpvnotes.inRhode MarshallNo ratings yet

- Wa0003.Document39 pagesWa0003.0102192528No ratings yet

- Process Design Analysis BreakdownDocument2 pagesProcess Design Analysis Breakdownanushka goelNo ratings yet

- Production Methods: It Is The Processes and Techniques That Are UsedDocument6 pagesProduction Methods: It Is The Processes and Techniques That Are UsedNischalGautamNo ratings yet

- 8 Types of Production Systems ExplainedDocument6 pages8 Types of Production Systems ExplainedJyoti NawlaniNo ratings yet

- Scope of Production and Operations ManagementDocument9 pagesScope of Production and Operations ManagementPrakash ReddyNo ratings yet

- u1Document9 pagesu1Rohit GoyalNo ratings yet

- Kritika (21421096)Document9 pagesKritika (21421096)Mohit sharmaNo ratings yet

- Donald J. Trump SOFDocument13 pagesDonald J. Trump SOFCBS News Politics90% (20)

- Partnership MCQ'SDocument6 pagesPartnership MCQ'SAngelo MilloraNo ratings yet

- Deloitte NL Risk Sdgs From A Business PerspectiveDocument51 pagesDeloitte NL Risk Sdgs From A Business PerspectiveAshraf ChowdhuryNo ratings yet

- Hair Oil PresentationDocument12 pagesHair Oil Presentationmohan_ved02550% (2)

- How to Write an Order LetterDocument14 pagesHow to Write an Order LettermidhunNo ratings yet

- Engro-Polymer-Chemicals 2021 ReportDocument197 pagesEngro-Polymer-Chemicals 2021 ReportUmer FarooqNo ratings yet

- IBS301 International Business Work Plan 2023Document19 pagesIBS301 International Business Work Plan 2023sha ve3No ratings yet

- Multiple Choice Problems ChapterDocument1 pageMultiple Choice Problems ChapterJohn Carlos Doringo100% (1)

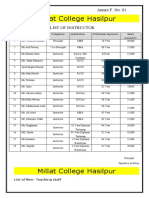

- Millat College Hasilpur: Annex F. No. 01Document3 pagesMillat College Hasilpur: Annex F. No. 01Hashim IjazNo ratings yet

- The Isis Engineering Company Operates A Job Order Costing System WhichDocument2 pagesThe Isis Engineering Company Operates A Job Order Costing System WhichAmit PandeyNo ratings yet

- RuPay TrainingDocument4 pagesRuPay TrainingSeldon Pradhan DoraeholicNo ratings yet

- GSM - Lec 1b PDF GlobalisationDocument61 pagesGSM - Lec 1b PDF GlobalisationĐình Hiệp ĐỗNo ratings yet

- MPR Project Report Sample FormatDocument24 pagesMPR Project Report Sample FormatArya khattarNo ratings yet

- Unit II: Absorption, Variable, and Throughput Costing: Multiple Choice QuestionsDocument43 pagesUnit II: Absorption, Variable, and Throughput Costing: Multiple Choice QuestionsJosh EspirituNo ratings yet

- Holy Angel University School of Business and Accountancy Bachelor of Science in Management AccountingDocument5 pagesHoly Angel University School of Business and Accountancy Bachelor of Science in Management AccountingJoanna GarciaNo ratings yet

- CH 03Document34 pagesCH 03rajat318No ratings yet

- How Much Growth Can A Firm Afford?: Robert C. HigginsDocument11 pagesHow Much Growth Can A Firm Afford?: Robert C. HigginsFrancisco López-HerreraNo ratings yet

- E-Commerce in Afghanistan: Department of Management SciencesDocument12 pagesE-Commerce in Afghanistan: Department of Management SciencesEnamNo ratings yet

- IT in Disaster RecoveryDocument20 pagesIT in Disaster RecoverykirarakiNo ratings yet

- IPN Mexico School Marketing Strategy SWOT AnalysisDocument5 pagesIPN Mexico School Marketing Strategy SWOT AnalysisPedro ArroyoNo ratings yet

- Business Finance Lesson 2Document20 pagesBusiness Finance Lesson 2Iekzkad RealvillaNo ratings yet

- Bank Of Punjab Internship ReportDocument49 pagesBank Of Punjab Internship ReportHussain HadiNo ratings yet

- Why China's Economic Growth Has Been Slow Despite SuccessDocument2 pagesWhy China's Economic Growth Has Been Slow Despite SuccessBraeden GervaisNo ratings yet

- The Millionaire Real Estate InvestorDocument434 pagesThe Millionaire Real Estate InvestorKhafre Gold50% (2)

- Sap MM QuestionsDocument12 pagesSap MM QuestionsBhaskar NagNo ratings yet

- HISTORICAL ORIGINS AND FORMS OF UNDERDEVELOPMENT AND DEPENDENCE IN AFRICADocument21 pagesHISTORICAL ORIGINS AND FORMS OF UNDERDEVELOPMENT AND DEPENDENCE IN AFRICAJuma DutNo ratings yet

- There Are No Permanent Changes Because Change Itself Is Permanent. It Behooves The Industrialist To Research and The Investor To Be VigilantDocument10 pagesThere Are No Permanent Changes Because Change Itself Is Permanent. It Behooves The Industrialist To Research and The Investor To Be Vigilantagrvinit123No ratings yet

- REAL ESTATE and COVIDDocument6 pagesREAL ESTATE and COVIDAcademic WarriorNo ratings yet

- GENERALLY ACCEPTED ACCOUNTING PRINCIPLES Chapter - 3Document3 pagesGENERALLY ACCEPTED ACCOUNTING PRINCIPLES Chapter - 3RitaNo ratings yet

- b2 1 AndoDocument60 pagesb2 1 AndoSudhagarNo ratings yet