100% found this document useful (1 vote)

4K views28 pagesBagging Machine

The document provides instructions for calibrating and operating a bagging machine. It includes steps for zero calibration and span calibration of the machine's weighing indicator. It also lists quantitative discharge setting values that can be switched by inputting different codes to control the bagging process.

Uploaded by

Fredrick OtienoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

4K views28 pagesBagging Machine

The document provides instructions for calibrating and operating a bagging machine. It includes steps for zero calibration and span calibration of the machine's weighing indicator. It also lists quantitative discharge setting values that can be switched by inputting different codes to control the bagging process.

Uploaded by

Fredrick OtienoCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

- Bagging Machine: The document begins by introducing the topic of bagging machines with the title page.

- Bagging Machine Components: Details and images of the major components involved in a bagging machine, including feeding and logic operations.

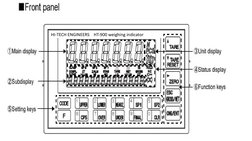

- Bagging Machine Controller: An overview of the controller unit mentioning its function in managing machine operations.

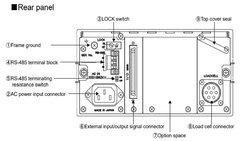

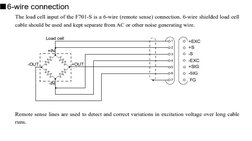

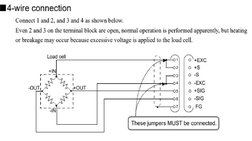

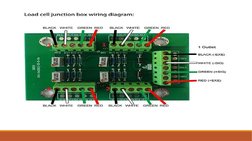

- Load Cell Connections: Technical explanation of load cell connection mechanisms, including diagrams for different pin assignments.

- Wiring Diagrams: Illustrations of wiring connections for load cells, specifying different configurations and cable types.

- Calibration Procedures: Step-by-step guide through the calibration procedures necessary for the bagging machine's accuracy.

- Actual Calibration Procedure: Details the complete process for performing a calibration on the machine.

- Weighing Settings and Operations: Sections cover the weighing methods, discharge controls, and sequence control settings used during operations.

- Sequence-Control-Related Settings: Explains configurations and scenarios influencing sequence control during bagging operations.