Professional Documents

Culture Documents

MI-102 Intro

Uploaded by

Ayush Kishore0 ratings0% found this document useful (0 votes)

11 views10 pagesOriginal Title

MI-102_Intro

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views10 pagesMI-102 Intro

Uploaded by

Ayush KishoreCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 10

MIN-102: Basic Manufacturing Processes

(L-T-P: 2-0-4; Credits 4)

Dr. Rahul S. MULIK

Relative Weightage of Marks

Class Work Sessional (CWS): 15%

Practical Sessional (PRS): 15%

Mid Term Examination (MTE): 30%

End Term Examination (ETE): 40%

Duration End Term Examination (ETE): 3 Hours

MI-102: Basic Manufacturing Processes I. I. T. ROORKEE

COURSE CONTENT

S. TOPIC ~ No of

No Lectures

1 INTRODUCTION: Engineering 2

materials, materials properties &

selection of manufacturing process

2 CASTING: Fundamentals of casting 8

process, pattern materials, pattern

types, allowances, gating system,

molding sand: composition and

properties, cores, casting defects and

their remedies

3 JOINING: Basic principle of welding, 6

types of weld joints, classification of

welding processes, gas welding,

manual metal arc welding, welding

defects and remedies, soldering and

brazing

COURSE CONTENT (Continued)

S. Particulars ~ No of

No Lectures

4 MACHINING: Basic principle of 6

machining, lathe, drilling, milling and

grinding machines and their

operations, cutting tools used

5 FORMING: Fundamentals of metal 6

forming, forging, rolling, extrusion,

wire drawing and tube drawing,

relevant defects and remedies

Total 28

Class Work Sessional (CWS) 15 Marks

Quiz 10 Marks

Attendance 05 Marks

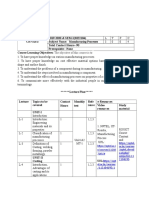

Suggested Books

S. Name of Book, Authors, Year of

No Publisher, ISBN Publication

1 Materials and Processes in 1997

Manufacturing, E.Paul DeGarmo, J.T.

Black, R. A. Kohser, Prentice Hall of India

Pvt. Limited- New Delhi

(ISBN 81-203-1243-0)

2 Manufacturing Engineering and 2000

Technology, S. Kalpakjian, S.R. Schmid,

Pearson Education, New Delhi,

(ISBN 81-7808-157-1)

3 Fundamentals of Modern 2002

Manufacturing, Mikell P. Groover, John

Wiley and Sons Inc.

(ISBN 0-471-40051-3)

MI-102: Manufacturing Techniques I. I. T. ROORKEE

Suggested Books (Continued)

4 Processes and Materials of 1990

Manufacture, R.A. Lindberg, Prentice Hall

India Limited,

(ISBN 81-203-0663-5)

5 Manufacturing Technology (Vol 1 and 2), 1998

P.N. Rao, Tata McGraw Hill New Delhi

(ISBN 0074631802)

6 Principles of Foundry Technology (4 th 2003

Edition), P. L. Jain, Tata McGraw Hill New

Delhi,

(ISBN 0-07-044-760-8)

MI-102: Manufacturing Techniques I. I. T. ROORKEE

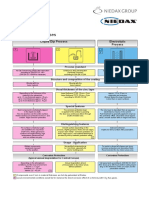

List of Practicals for MI-102: MANUFACTURING TECHNIQUES

Turn Shop Description

0 All Shops Visit to Different Shops of the Workshop for

Familiarization

(To be Completed in the Very FIRST TURN of a

Section)

C-1 CARPENTRY-1 Pattern Making of T-Joint

C-2 CARPENTRY-2 Pattern Making of Wooden Handle

F-1 FOUNDRY-1 Study of Different Foundry Tools and

Making a Green Sand Mould of Half Bearing Block

F-2 FOUNDRY-2 Making Green Sand Mold and Casting of Bearing

Block

W-1 WELDING-1 Arc Welding of Butt Joint

W-2 WELDING-2 Gas Welding of Butt Joint

MI-102: Manufacturing Techniques I. I. T. ROORKEE

List of Practicals for MI-102: MANUFACTURING TECHNIQUES (Contd.)

Turn Shop Description

M-1 MACHINE-1 Study of Lathe and Job Preparation on it

M-2 MACHINE-2 Study of Milling Machine and Job Preparation on it

(Keyway Cutting)

M-3 MACHINE-3 Study of Different Drilling, Boring, & Grinding

Machines

Ft-1 FITTING-1 Study of Various Fitting Hand Tools, Marking, &

Measuring Devices

S-1 SMITHY-1 Study of Different Forming Tools & Power Presses

S-2 SMITHY-2 Brazing, Soldering, and Mechanical Joint

Sequence of Rotation

⮚For Odd numbered Sections (A1, A3, A5, B1, B3, B5, E1, E3, E5, F1, F3, F5, H1, H3, H5):

0 🡪 F-1 🡪 F-2 🡪 C-1 🡪 C-2 🡪 W-1 🡪 W-2 🡪 S-1 🡪 S-2 🡪 M-1 🡪 M-2 🡪 M-3🡪Ft-1

⮚For Even numbered Sections (A2, A4 , A6, B2, B4, B6, E2, E4, E6, F2, F4, F6, H2, H4 and H6):

0🡪 C-1 🡪 C-2🡪 F-1 🡪 F-2 🡪 M-1 🡪 M-2 🡪 M-3 🡪 Ft-1 🡪 W-1 🡪 W-2 🡪 S-1 🡪 S-2

MI-102: Manufacturing Techniques I. I. T. ROORKEE

You might also like

- SRM University School of Mechanical Engineering Lesson Plan Course Code: Me0353Document2 pagesSRM University School of Mechanical Engineering Lesson Plan Course Code: Me0353PradeepvenugopalNo ratings yet

- MEF 112 Course HandoutDocument4 pagesMEF 112 Course HandoutAR7 StudioNo ratings yet

- Manufacturing Processes SyllabusDocument14 pagesManufacturing Processes SyllabusdeekamittalNo ratings yet

- MT (MEL - 3206) Course Handout Sem IVDocument3 pagesMT (MEL - 3206) Course Handout Sem IVVikasNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- Manufacturing TechDocument6 pagesManufacturing TechSachi MensiNo ratings yet

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- ME6402 MT II by WWW - Learnengineering.inDocument102 pagesME6402 MT II by WWW - Learnengineering.inVikram C KNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- 5 MPDocument3 pages5 MPASIST MechNo ratings yet

- MFT-2 .Two Marks With KeyDocument13 pagesMFT-2 .Two Marks With KeySujith KumarNo ratings yet

- Manufacturing EngineeringDocument3 pagesManufacturing EngineeringRavichandran GNo ratings yet

- MNNIT, Engineering GraphicsDocument1 pageMNNIT, Engineering GraphicsMo AlamNo ratings yet

- MEC207Document4 pagesMEC207Senthil Muthu Kumar TNo ratings yet

- Manufacturing Technology-IIDocument70 pagesManufacturing Technology-IISaideep GhimireNo ratings yet

- MP SyllabusDocument1 pageMP SyllabusRAMAKANT RANANo ratings yet

- Br20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesDocument2 pagesBr20 - B.Tech. - Mechanical Engineering Syllabus: Course ObjectivesBashu Dev SanjelNo ratings yet

- Manufacturing Technology - I Syllabus: Topic AnalysisDocument6 pagesManufacturing Technology - I Syllabus: Topic AnalysisjayctaNo ratings yet

- Metallurgical Engineering Department - HandbookDocument133 pagesMetallurgical Engineering Department - HandbookChandra Mouli BangaloreNo ratings yet

- Metallurgical Standards ProgrammeDocument131 pagesMetallurgical Standards ProgrammeKan Nan DNo ratings yet

- R PT Instruction PlanDocument6 pagesR PT Instruction PlanVipin KumarNo ratings yet

- Production Management Op KannaDocument18 pagesProduction Management Op Kannasam_swamynathanNo ratings yet

- IC141 Product Realization TechnologyDocument1 pageIC141 Product Realization Technologyparitoshjain01No ratings yet

- FINAL MCW-17ME35A - Notes PDFDocument108 pagesFINAL MCW-17ME35A - Notes PDFAMOGHNo ratings yet

- AE 2253 Production Technology Lesson Plan for Aeronautical Engineering Sem IVDocument2 pagesAE 2253 Production Technology Lesson Plan for Aeronautical Engineering Sem IVGiridharan SharmaNo ratings yet

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocument4 pagesMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNo ratings yet

- Manufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Document2 pagesManufacturing Technology-1: Course Code: 15ME1106 L T P C 3 0 0 3Madduri HemantNo ratings yet

- Course Plan: Marthandam College of Engineering and TechnologyDocument4 pagesCourse Plan: Marthandam College of Engineering and Technologyabilash_nivasNo ratings yet

- Manufacturing Process Lab IiiDocument5 pagesManufacturing Process Lab IiiMuhammad Bilal SahiNo ratings yet

- Automotive Manufacturing Processes and TechnologiesDocument3 pagesAutomotive Manufacturing Processes and Technologiesvikas raiNo ratings yet

- Manufacturing Tech-1Document6 pagesManufacturing Tech-1Vikram Rao0% (1)

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinNo ratings yet

- Mechanical Testing StandardsDocument132 pagesMechanical Testing StandardsAmit KumarNo ratings yet

- GTU Bachelor of Engineering Manufacturing Processes SyllabusDocument3 pagesGTU Bachelor of Engineering Manufacturing Processes Syllabuskk bhattNo ratings yet

- Jain Un Syllabus 4th SemDocument13 pagesJain Un Syllabus 4th SemAnshul LallNo ratings yet

- The Objective of This Course Is To: Manufacturing ProcessesDocument5 pagesThe Objective of This Course Is To: Manufacturing ProcessesKARAMTOTHU GANESH NAIK (N160423)No ratings yet

- Tool Die MakerDocument32 pagesTool Die MakerUmesh KsNo ratings yet

- List of StandardDocument126 pagesList of Standardarunas10810% (1)

- Lecture Plan Guru Tegh Bahadur Institute of Technology: Manufacturing Process (ETME - 107)Document4 pagesLecture Plan Guru Tegh Bahadur Institute of Technology: Manufacturing Process (ETME - 107)muthu vNo ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringDocument49 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringAbhi SharmaNo ratings yet

- SYLLABUSMPDocument1 pageSYLLABUSMPChirag AhujaNo ratings yet

- Manufacturing Process SyllabusDocument3 pagesManufacturing Process SyllabusRohit KumarNo ratings yet

- B.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsDocument11 pagesB.Tech. Mechanical Engineering, Third Year (6 Semester) : Sr. No. Course No. Subject L T P Hours CreditsAnkesh KapilNo ratings yet

- Teaching Plan For - Tool Engineering T E (Mechanical) Mechanical Engineering DepartmentDocument3 pagesTeaching Plan For - Tool Engineering T E (Mechanical) Mechanical Engineering DepartmentpatilsspNo ratings yet

- Production Technology Course OutDocument5 pagesProduction Technology Course Outmurjass85No ratings yet

- JigsDocument5 pagesJigsTamilSelvanSoundararajNo ratings yet

- Lesson Plan Model-1newDocument4 pagesLesson Plan Model-1newSatheesh KumarNo ratings yet

- Manufacturing Technology 2Document2 pagesManufacturing Technology 2Jeremaiah HaylingNo ratings yet

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 pagesBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayNo ratings yet

- Manufacturing Technology NotesDocument97 pagesManufacturing Technology Notesswap1983No ratings yet

- Kings: PR1204-Manufacturing Technology-IDocument4 pagesKings: PR1204-Manufacturing Technology-IJayavignesh ReddyNo ratings yet

- Diploma Work Shop TechnologyDocument10 pagesDiploma Work Shop TechnologyadarshNo ratings yet

- Semester Within The Dates Specified by GTUDocument6 pagesSemester Within The Dates Specified by GTUvishallchhayaNo ratings yet

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- ME F219 - Course Handout - 2022-23Document3 pagesME F219 - Course Handout - 2022-23YERRAMILLI SRIVATSAVNo ratings yet

- Me 2252 Manufacturing TechnologyDocument3 pagesMe 2252 Manufacturing TechnologyRamarajan YogeeswaranNo ratings yet

- Introduction, Press & MachiningDocument327 pagesIntroduction, Press & MachiningLucky DagaNo ratings yet

- Syllabus With ReportDocument44 pagesSyllabus With ReportrajeshNo ratings yet

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationFrom EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNo ratings yet

- New_Progress_Report[1] (1)Document64 pagesNew_Progress_Report[1] (1)Ayush KishoreNo ratings yet

- 5 Statistical Process control 1Document42 pages5 Statistical Process control 1Ayush KishoreNo ratings yet

- Tutorial 3 -ForecastingDocument4 pagesTutorial 3 -ForecastingAyush KishoreNo ratings yet

- Quality+Statistical ProcessDocument173 pagesQuality+Statistical ProcessAyush KishoreNo ratings yet

- Tutorial 2-Inventory Management QuestionsDocument14 pagesTutorial 2-Inventory Management QuestionsAyush KishoreNo ratings yet

- 5 Statistical Process control 1Document42 pages5 Statistical Process control 1Ayush KishoreNo ratings yet

- 7 Product DesignDocument82 pages7 Product DesignAyush KishoreNo ratings yet

- Open Book Quiz Spring 2020-21Document3 pagesOpen Book Quiz Spring 2020-21Ayush KishoreNo ratings yet

- 1.0 Introduction 2Document94 pages1.0 Introduction 2Ayush KishoreNo ratings yet

- CEN 665 Lecture 24 25 26 Pedestrian related collisions-compressedDocument104 pagesCEN 665 Lecture 24 25 26 Pedestrian related collisions-compressedAyush KishoreNo ratings yet

- 13 ForecastingDocument89 pages13 ForecastingAyush KishoreNo ratings yet

- 1.0 Introduction 2Document94 pages1.0 Introduction 2Ayush KishoreNo ratings yet

- 4 Quality Six SigmaDocument52 pages4 Quality Six SigmaAyush KishoreNo ratings yet

- MSW Segregation - Image - Robotic - ArmsDocument23 pagesMSW Segregation - Image - Robotic - ArmsAyush KishoreNo ratings yet

- CEN-204 Introductory LecturesDocument18 pagesCEN-204 Introductory LecturesAyush KishoreNo ratings yet

- Application of Satellite Data and AIDocument8 pagesApplication of Satellite Data and AIAyush KishoreNo ratings yet

- CEN 305 - IntroductionDocument46 pagesCEN 305 - IntroductionAyush Kishore100% (1)

- Calculate quadrant, semi-circle and circle measurementsDocument2 pagesCalculate quadrant, semi-circle and circle measurementsAyush KishoreNo ratings yet

- TRUMPF Technical Data Sheet TruLaser 3030 - 3040Document3 pagesTRUMPF Technical Data Sheet TruLaser 3030 - 3040Tani MakmurNo ratings yet

- Casting: Aim of The ExperimentDocument7 pagesCasting: Aim of The Experimentsanskar mittalNo ratings yet

- Prosedur Pengelasan Pipa HDPE-SHDS 160SDocument10 pagesProsedur Pengelasan Pipa HDPE-SHDS 160SIJEN GEOTHERMALNo ratings yet

- Fire StopDocument55 pagesFire StopHESuarezNo ratings yet

- PipeworkDocument5 pagesPipeworkTAPIZ ACMVNo ratings yet

- Electrodes For GMAWDocument1 pageElectrodes For GMAWkapsarcNo ratings yet

- PE 4210 Lab #1 Wellbore SchematicsDocument5 pagesPE 4210 Lab #1 Wellbore SchematicsRichard OwusuNo ratings yet

- FQP For Flue Gas Duct PipingDocument5 pagesFQP For Flue Gas Duct PipingAshwani DograNo ratings yet

- Cast Iron Welding - Procedures and Free GuideDocument8 pagesCast Iron Welding - Procedures and Free GuideKhin Aung ShweNo ratings yet

- Dokumen - Tips Inspection Checklist Distillation ColumnDocument5 pagesDokumen - Tips Inspection Checklist Distillation ColumnSaidFerdjallah100% (1)

- NHB 700 - The Practice of Heat TreatmentDocument75 pagesNHB 700 - The Practice of Heat TreatmentConrad Hendrik De KockNo ratings yet

- White Paper - Mitigating Corrosion and Erosion in Waste To Energy and Biomass BoilersDocument20 pagesWhite Paper - Mitigating Corrosion and Erosion in Waste To Energy and Biomass BoilersmostafaNo ratings yet

- Unit 3 - Week 2: Assignment 2Document4 pagesUnit 3 - Week 2: Assignment 2Jayaganesh KhandigeNo ratings yet

- Ceilcote 680 Primer AKZO PDFDocument4 pagesCeilcote 680 Primer AKZO PDFamitzalteNo ratings yet

- Cement Test Report - RamcoDocument1 pageCement Test Report - RamcoKrishna GouravNo ratings yet

- CSWIP 3.1 (SET-3) : Exam - 3Document11 pagesCSWIP 3.1 (SET-3) : Exam - 3JAGADEESH NAIK100% (2)

- AL-340D Lathe Operation Manual and Parts ListDocument57 pagesAL-340D Lathe Operation Manual and Parts Listrao_saintNo ratings yet

- Pinhole Repair ProcedureDocument6 pagesPinhole Repair ProcedurediinarghNo ratings yet

- Six Month Industrial Training Presentation on Detergent ManufacturingDocument19 pagesSix Month Industrial Training Presentation on Detergent ManufacturingAgbara RichardNo ratings yet

- Iit LectureDocument38 pagesIit LectureNIshantNo ratings yet

- Galvanizing Processes ComparisonDocument3 pagesGalvanizing Processes ComparisonAlin MoicaNo ratings yet

- Cochran BoilerDocument7 pagesCochran BoilersridharbhsNo ratings yet

- Tabla Uw-12Document1 pageTabla Uw-12Christian Lopez Mendez100% (1)

- Diamond Coring Tool DD 160Document1 pageDiamond Coring Tool DD 160AntoNo ratings yet

- Product Details of ACRATEX Paint 16L White LatexDocument1 pageProduct Details of ACRATEX Paint 16L White LatexNancy April CalingasanNo ratings yet

- Poster VVVVDocument1 pagePoster VVVVManishi GoelNo ratings yet

- H2S ScavengerDocument7 pagesH2S ScavengerRizwan FaridNo ratings yet

- TDS Tam 355 Multipurpose Epoxy RedDocument2 pagesTDS Tam 355 Multipurpose Epoxy RedYudhi NapitupuluNo ratings yet

- Star-Drain A4x16 EngDocument16 pagesStar-Drain A4x16 EngVLADONo ratings yet

- Double Cut Tee Plan Brace Connection On Beam WebDocument1 pageDouble Cut Tee Plan Brace Connection On Beam WebRajveer SinghNo ratings yet

![New_Progress_Report[1] (1)](https://imgv2-2-f.scribdassets.com/img/document/725734117/149x198/0f6d3fb5f9/1713848146?v=1)