Professional Documents

Culture Documents

The Objective of This Course Is To: Manufacturing Processes

Uploaded by

KARAMTOTHU GANESH NAIK (N160423)Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Objective of This Course Is To: Manufacturing Processes

Uploaded by

KARAMTOTHU GANESH NAIK (N160423)Copyright:

Available Formats

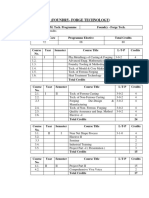

Course Coordinator 2019-2020 & SEM-I(ME2104) L T P C

CH VASU Subject Name: Manufacturing Processes 3 0 0 4

Total Contact Hours– 90

Prerequisite : None

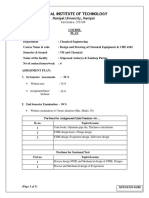

Course Learning Objectives: The objective of this course is to

1. To have proper knowledge on various manufacturing processes.

2. To have proper knowledge on cost effective material options based on the near net

shape and surface finish.

3. To understand the problems of a component during its manufacturing.

4. To understand the steps involved in manufacturing a component.

5. To understand the effect of manufacturing processes on properties of a component.

6. To communicate more effectively with the industrial people in manufacturing

terminology.

******Lecture Plan*****

Lecture Topics to be Contact Monthly Refe e-Resources

covered Hours test rence Video Study

resources material

UNIT-I

Introduction

L-1 Introduction: 1 1,2,3

Engineering

materials and its 1. NPTEL, IIT-

properties Roorke, RGUKT

L-2 Classification of 1 1,2,3 Manufacturing Course

manufacturing Content

Process

processes Unit1&2 and

MT-1 URL: https://nptel.

L-3 Definitions of 1 1,2,3

Casting, welding, https://nptel.ac.i ac.in/courses

forming ,powder n/courses/11210 /nptel_downl

metallurgy. 7145/# oad.php?

subjectid=11

UNIT-II

2104195

Casting URL:https://npt

L-4 Introduction, 1 1,2,3 el.ac.in/courses

Advantages of /112104195/1

casting and its

applications

L-5 Steps involved in 1 1,2,3

making a casting,

Patterns and Pattern

making:

L-6 Types of patterns, 1 1,2,3

Materials used for

patterns, Pattern

allowances,

L-7 Moulding sand: 1 1,2,3

Molding sand

composition, Testing RGUKT

sand properties, Course

Sand Content

preparation

L-8 Reclamation of 1 1,2,3

molding sand, Core:

Core sands, Types of

cores

L-9 Core prints, 1 1,2,3

Chaplets, Forces

acting on the

molding flasks

L-10 Gating, Gating ratio 2 1,2,3

and Design of

Gating systems,

Core, Core print.

Crucible melting and

cupola operation,

Steel making

processes, Charge

calculations

L-11 Solidification of 2 1,2,3

casting, Concept,

Solidification of pure

metal and alloys,

L-12 Risers, Types 1 1,2,3

function and design,

Casting design

considerations,

L-13 Centrifugal, Die, 1 1,2,3

Investment,

L-14 CO2 Molding. 1 1,2,3

Casting

defects, Causes and

remedies.

UNIT-III

Welding

L-15 Classification of 1 1,2,3

welding process, Arc

welding

L-16 Weld bead geometry, 2 1,2,3

V-I Characteristic

curves of power

source Unit 3

L-17 V-I Characteristic 1 MT-2 1,2,3

L-18 SMAW 1 1,2,3

L-19 SAW 1 1,2,3

L-20 GTAW,GMAW 2 1,2,3

L-21 CO2 welding, Gas 1 1,2,3

welding cutting

L-22 Resistance welding, 1 1,2,3

seam spot, projection

L-23 Upset and flash butt 1 1,2,3

welding

L-24 Heat affected zones 2 1,2,3

in welding, Methods

to minimize HAZ

L-25 Soldering & 1 1,2,3

Brazing: Types and

its applications

L-26 Thermit welding, 1 1,2,3

Friction welding,

Diffusion Bonding

L-27 Electron beam 2 1,2,3

welding, and Laser

beam welding.

Unit 4 Metal

Forming

Metal

L-28 Forming: Nature of 1 1,2,3

plastic deformation

L-29 Hot and cold 2 1,2,3

working, Strain Unit 4

hardening, Recovery, MT-3

Recrystallization and

grain growth

L-30 Rolling: Principle, 1 1,2,3

Types of rolling

mills

L-31 passes, Forces in 1 1,2,3

rolling and power

requirements

L-32 Extrusion: Basic 1 1,2,3

extrusion process

and its

characteristics

L-33 Hot extrusion 1 1,2,3

and cold extrusion,

L-34 Impact extrusion, 1 1,2,3

Hydrostatic

extrusion

L-35 Forging: Principles 2 1,2,3

of forging, Tools and

dies

L-36 Types: Smith 1 1,2,3

forging, Drop

Forging, Forging

hammers

L-37 Rotary forging, 1 1,2,3

forging defects

L-38 Wire Drawing. Sheet 1 1,2,3

metal forming

L-39 Spring back effect, 1 1,2,3

Stamping

L-40 Blanking, Bending, 2 1,2,3

Drawing, Piercing

L-41 Coining, Embossing, 1 1,2,3

Stretch forming

L-42 Hot and cold 1 1,2,3

spinning. Special

forming

L-43 Hydro forming, High 2 1,2,3

energy rate forming.

Unit 5 Powder

metallurgy

L-44 Powder metallurgy: 2 1,2,3

Introduction,

Production

L-45 characterization of 1 1,2,3

powders,

Compaction

L-46 Die compaction, and 1 1,2,3

Hot Isostatic

pressing

L-46 Sintering of powder 1 1,2,3

compacts

L-47 Post sintering 2 1,2,3

operations

L-48 Applications. 1 1,2,3

Learning resources

Text book:

1. M. Groover, Fundamentals of Modern Manufacturing: Materials, Processes, and

Systems, 6th Edition, John Wiley & Sons 2016

References:

1. Savitha Sharma, Manufacturing processes, international publications 4th edition, 2011.

2. P.C. Sharma, “A text book of production technology”, S. Chand and Company, 4 th edition,

2003.

3. Rajendra Singh, Introduction to basic manufacturing processes: new age publications: 2 nd

edition, 2014.

Web resources:

1. Web resources:NPTEL, December 31, 2009, “Manufacturing Processes”

URL: https://nptel.ac.in/courses/112107145/

2. NPTEL, IIT- Kanpur, Introduction to Manufacturing Processes

URL: https://nptel.ac.in/courses/112104195/1

3. RGUKT Course Content

Course outcomes: At the end of the course, the student will be able to

CO 1 Explain various manufacturing processes.

Select the type of casting process one has to adopt for manufacturing a designed

CO 2 component.

CO 3 Choose the types of joining process required for joining of metals

CO 4 Demonstrate the deformation behavior of a material during processing.

CO 5 Define the advantages and applications of powder metallurgy

CO 6 Illustrate the operations of metal forming and forging.

For Theory courses only:

Course Nature Theory

Assessment Method

Assessment Weekly tests Monthly tests End Semester Test Total

Tool

Weightage (%) 10% 30% 60% 100%

You might also like

- Engineering Materials PDFDocument24 pagesEngineering Materials PDFPradeepkumarKatgiNo ratings yet

- Supply Chain ManagementDocument19 pagesSupply Chain ManagementsumiNo ratings yet

- Materials Joining TechnologyDocument4 pagesMaterials Joining Technologykanna nrNo ratings yet

- MFT I SyllabusDocument3 pagesMFT I SyllabusVamsi RockzzNo ratings yet

- M.Tech (Foundry-Forge Technology)Document8 pagesM.Tech (Foundry-Forge Technology)JagdishNo ratings yet

- Manufacturing Technology 2Document2 pagesManufacturing Technology 2Jeremaiah HaylingNo ratings yet

- 7th Sem SyllabusDocument6 pages7th Sem SyllabusAshwit KumarNo ratings yet

- MT (MEL - 3206) Course Handout Sem IVDocument3 pagesMT (MEL - 3206) Course Handout Sem IVVikasNo ratings yet

- Course ObjectivesDocument4 pagesCourse ObjectivesHOD TD GITNo ratings yet

- Course Handout (BMP)Document4 pagesCourse Handout (BMP)058-Somyajit RayNo ratings yet

- Dissertation Format Lingayas VidyapeethDocument14 pagesDissertation Format Lingayas Vidyapeethumair saifullahNo ratings yet

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- R PT Instruction PlanDocument6 pagesR PT Instruction PlanVipin KumarNo ratings yet

- Production Technology Course OutDocument5 pagesProduction Technology Course Outmurjass85No ratings yet

- Metal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveDocument3 pagesMetal Forming Process 2 2 0 3 Prerequisite: - Course ObjectiveB. selvababuNo ratings yet

- BMP - Electric Arc WeldingDocument91 pagesBMP - Electric Arc Weldingsujay nayakNo ratings yet

- GateDaywise PlanningDocument18 pagesGateDaywise Planningn.g.kalyaniNo ratings yet

- MET 204 Manufacturing ProcessDocument8 pagesMET 204 Manufacturing Processrejeesh_rajendranNo ratings yet

- BMP - Powder MetallurgyDocument71 pagesBMP - Powder Metallurgymantra2010No ratings yet

- MEC207Document4 pagesMEC207Senthil Muthu Kumar TNo ratings yet

- DMM Ii-CdsDocument5 pagesDMM Ii-CdsKrishna MurthyNo ratings yet

- Course Plan: Marthandam College of Engineering and TechnologyDocument4 pagesCourse Plan: Marthandam College of Engineering and Technologyabilash_nivasNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- 2-2 R20-Die DesignDocument18 pages2-2 R20-Die DesignSirisha AsadiNo ratings yet

- SyllabusDocument2 pagesSyllabusPrabhakara Rao Peeka100% (1)

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- BMP PDFDocument17 pagesBMP PDFmantra2010No ratings yet

- BMP - Metal WorkingDocument17 pagesBMP - Metal Workingmantra2010No ratings yet

- BMP - CastingDocument217 pagesBMP - Castingmantra2010No ratings yet

- First Year Syllabus - 2022-23Document25 pagesFirst Year Syllabus - 2022-23Art SplashNo ratings yet

- 20ME403 Engineering Materials and Metallurgy Unit - IV Digital MaterialDocument55 pages20ME403 Engineering Materials and Metallurgy Unit - IV Digital MaterialDark ranger YtNo ratings yet

- VLSI Design Assignment-1Document1 pageVLSI Design Assignment-1educational9hubNo ratings yet

- Auto Shop A D Garage Practice: Code Ma 301 L T PDocument26 pagesAuto Shop A D Garage Practice: Code Ma 301 L T PAkashNo ratings yet

- BMP - ExtrusionDocument24 pagesBMP - Extrusionmantra2010No ratings yet

- BMP - DrawingDocument22 pagesBMP - Drawingmantra2010No ratings yet

- Course ObjectivesDocument5 pagesCourse Objectives75Ujwal TDNo ratings yet

- BMP - RollingDocument46 pagesBMP - Rollingmantra2010No ratings yet

- ME2201 Manufacturing Technology-IDocument9 pagesME2201 Manufacturing Technology-IHiru Purushothaman HirudayanathanNo ratings yet

- RPS MECH 2304 ManufacturingDocument5 pagesRPS MECH 2304 ManufacturingJemica DamarNo ratings yet

- Advanced ManufacturingDocument9 pagesAdvanced ManufacturingBen JoeNo ratings yet

- Sri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6Document6 pagesSri Venkateswara College of Engineering Course Delivery Plan - Theory Page 1 of 6Ʀoʛeʀ Ɩeo ƖɩbɩŋNo ratings yet

- Production and Industrial Engineering ReviewedDocument36 pagesProduction and Industrial Engineering ReviewedabhijitsainiNo ratings yet

- TIU Diploma 2nd SEMDocument13 pagesTIU Diploma 2nd SEMTechno India UniversityNo ratings yet

- 18ME653 - Syllabus - CO - PODocument4 pages18ME653 - Syllabus - CO - PORameshkumarNo ratings yet

- 20ME403 Engineering Materials and Metallurgy Unit - 1 Digital MaterialDocument55 pages20ME403 Engineering Materials and Metallurgy Unit - 1 Digital MaterialDark ranger YtNo ratings yet

- AMT SyllabusDocument5 pagesAMT SyllabuschupchapNo ratings yet

- 15UME302 Manufacturing Technology - I L T P C 3 0 0 3Document4 pages15UME302 Manufacturing Technology - I L T P C 3 0 0 3Kumareshg GctkumareshNo ratings yet

- MI-102 IntroDocument10 pagesMI-102 IntroAyush KishoreNo ratings yet

- Design and Drawing COURSE PLAN 2017 FinalDocument5 pagesDesign and Drawing COURSE PLAN 2017 FinalqeftfgNo ratings yet

- MT-1 (English) - N SchemeDocument288 pagesMT-1 (English) - N SchemeKumar Subramanian100% (1)

- BMP - Other Welding ProcessesDocument76 pagesBMP - Other Welding Processessujay nayakNo ratings yet

- Ucm Course - Plan (2017)Document8 pagesUcm Course - Plan (2017)kumareshNo ratings yet

- Automobile ComponentsDocument6 pagesAutomobile Componentsshincy ARNo ratings yet

- P23. Mapping of Course Outcome With Program OutcomesDocument31 pagesP23. Mapping of Course Outcome With Program OutcomesBhaskar MondalNo ratings yet

- Syllabus of DCS-IDocument2 pagesSyllabus of DCS-IManik GoyalNo ratings yet

- Syllabus of Foundation Compulsory Courses: CO CO1 CO2 CO3 CO4 CO5Document2 pagesSyllabus of Foundation Compulsory Courses: CO CO1 CO2 CO3 CO4 CO5TALHA PARVEZNo ratings yet

- EWS Me 1,2,3 CO PO MappingDocument4 pagesEWS Me 1,2,3 CO PO MappingYogesh ChaudhariNo ratings yet

- Finite Element Method: Catalog DescriptionDocument3 pagesFinite Element Method: Catalog DescriptionO.p. BrarNo ratings yet

- Eme SyllabusDocument6 pagesEme SyllabusAnurag YadavNo ratings yet

- Thixoforming: Semi-solid Metal ProcessingFrom EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- TCS Express & Logistics (PVT.) LTDDocument26 pagesTCS Express & Logistics (PVT.) LTDSyed Shafqat ShahNo ratings yet

- Chapter 6Document9 pagesChapter 6harleycrispino.eduNo ratings yet

- Cse329 Management-Information-systems SyllabusDocument2 pagesCse329 Management-Information-systems SyllabusaNo ratings yet

- HELE 6 - Buyers and Sellers of Fruits or SeedlingsDocument46 pagesHELE 6 - Buyers and Sellers of Fruits or SeedlingsJohnzen Carl B. Dela IslaNo ratings yet

- ThermoformingDocument21 pagesThermoformingLoisroi ValdezNo ratings yet

- 200120-NSH AMC CONTRACT ConceptDocument22 pages200120-NSH AMC CONTRACT ConceptSaurabh YadavNo ratings yet

- Zara Apparel Manufacturing and Retail-17032020-091841amDocument1 pageZara Apparel Manufacturing and Retail-17032020-091841amUsman MalikNo ratings yet

- Product Offer For TelecommunicationsDocument84 pagesProduct Offer For TelecommunicationsisfaroNo ratings yet

- Sap Warehouse Management Transaction CodesDocument12 pagesSap Warehouse Management Transaction CodesArief SetiawanNo ratings yet

- Product Differentiation and ExamplesDocument8 pagesProduct Differentiation and ExamplesApplopediaNo ratings yet

- Chapter 4 - E-StartupsDocument15 pagesChapter 4 - E-StartupsGagana PNo ratings yet

- SAP Question BankDocument33 pagesSAP Question Bankpunithan81No ratings yet

- Manila Cavite Laguna Cebu Cagayan de Oro DavaoDocument7 pagesManila Cavite Laguna Cebu Cagayan de Oro DavaoMonica GarciaNo ratings yet

- Resume GopalakrishnanDocument2 pagesResume GopalakrishnansymongkryshNo ratings yet

- Marketing Research TemplateDocument24 pagesMarketing Research TemplateJanina ResurreccionNo ratings yet

- Big Data - GCP IM Point of ViewDocument38 pagesBig Data - GCP IM Point of Viewkarthik_integerNo ratings yet

- Burden PreparationDocument14 pagesBurden PreparationAkarshit NandeshwarNo ratings yet

- Data Karyawan Aktiv September 2017Document24 pagesData Karyawan Aktiv September 2017Yayat SupriatnaNo ratings yet

- PSM Internal 1 - Vibhanshu KhareDocument3 pagesPSM Internal 1 - Vibhanshu KharePriya SinghNo ratings yet

- The Taste of India: - by Tanish SaradaDocument14 pagesThe Taste of India: - by Tanish SaradaJayveer Singh RathoreNo ratings yet

- Sap AfsDocument105 pagesSap Afstucu23456100% (2)

- Infosys BPM Limited Annual Report 2021-22Document160 pagesInfosys BPM Limited Annual Report 2021-22Siddharth BhargavaNo ratings yet

- Strategic Brand ManagementDocument4 pagesStrategic Brand Managementivan rickyNo ratings yet

- Tactical Marketing Plan (Part of Business Plan)Document5 pagesTactical Marketing Plan (Part of Business Plan)Jevgeni FjodorovNo ratings yet

- On Mechanical Workshop Ne Railways GorakhpurDocument20 pagesOn Mechanical Workshop Ne Railways Gorakhpurersmt78640% (10)

- New ProjectDocument195 pagesNew ProjectVarun NeelagarNo ratings yet

- Logistic & Distribution Management: Lotus Thread Company LTDDocument6 pagesLogistic & Distribution Management: Lotus Thread Company LTDSanchit GuptaNo ratings yet

- Packaging Data SheetDocument29 pagesPackaging Data SheetAlineMeirelesNo ratings yet

- 2.SALES AND MARKE-WPS OfficeDocument36 pages2.SALES AND MARKE-WPS OfficeIts JohnNo ratings yet