Professional Documents

Culture Documents

Oee 2

Oee 2

Uploaded by

roysumit88880 ratings0% found this document useful (0 votes)

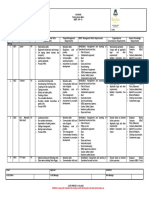

4 views1 pageThis document outlines the main elements of OEE engagement and focuses on reducing the 6 biggest losses: breakdowns, setup/changeover time, small stops, reduced speed, start-up rejects, and yield losses. It lists countermeasures like predictive maintenance, SMED, skills matrices, timing charts, and problem-solving tools that can be used to analyze and address failure categories contributing to each loss type. The overall goal is to improve availability, performance, speed, and quality through minimizing downtime, setup times, minor stops, production rate issues, initial product defects, and manufacturing rejects.

Original Description:

Original Title

OEE 2

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the main elements of OEE engagement and focuses on reducing the 6 biggest losses: breakdowns, setup/changeover time, small stops, reduced speed, start-up rejects, and yield losses. It lists countermeasures like predictive maintenance, SMED, skills matrices, timing charts, and problem-solving tools that can be used to analyze and address failure categories contributing to each loss type. The overall goal is to improve availability, performance, speed, and quality through minimizing downtime, setup times, minor stops, production rate issues, initial product defects, and manufacturing rejects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageOee 2

Oee 2

Uploaded by

roysumit8888This document outlines the main elements of OEE engagement and focuses on reducing the 6 biggest losses: breakdowns, setup/changeover time, small stops, reduced speed, start-up rejects, and yield losses. It lists countermeasures like predictive maintenance, SMED, skills matrices, timing charts, and problem-solving tools that can be used to analyze and address failure categories contributing to each loss type. The overall goal is to improve availability, performance, speed, and quality through minimizing downtime, setup times, minor stops, production rate issues, initial product defects, and manufacturing rejects.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 1

OEE Engagement – Main Focus

Main Elements 6 BIG LOSSES Countermeasures Failure Categories

Main Focus

• Tooling Failures

Breakdowns •

•

Unplanned Maintenance

PM Schedule Follow Predictive General Breakdowns

• Equipment Failures

Maintenance

• Setup/Changeover

Skills Matrix

Availability Setup and •

•

Material Shortages

Operator Shortages

Adjustments • Major Adjustments

SMED * BTM • Warm-up Time

Down time Loss • Obstructed Product Flow

Small Stops Skills Matrix • Component Jams

• Misfeeds

• Sensor Blocked

• Clearing/Checking

Chokotei Losses MTBA

Performance Reduced Speed Skills Matrix Cp-CPk Study

•

•

Rough Running

Under Nameplate Capacity

• Under Design Capacity

• Equipment Wear

• Operator Inefficiency

Timing Chart BTM

Speed Loss

• Scrap

Start-up * SWCS * ETM •

•

Rework

In-process Damage

Rejects • In-process Expiration

• Incorrect Assembly

Why-Why ISHIKAWA

Yield • Scrap

Manufacturing • Rework

Cp-Cpk Why-Why

Rejects / Holds •

•

In-process Damage

In-process Expiration

Quality Loss • Incorrect Assembly

8D PFMEA

* SWCS: Standard Work Combination Sheet

BTM: Best Tool Matching

ETM: Equipment Theoretical Matching

You might also like

- DISA Parts and Services Catalogue 2019Document141 pagesDISA Parts and Services Catalogue 2019Yanto Daryanto100% (2)

- Polaroid - Process and Quality Control Case Study: Preparation by Presentation byDocument6 pagesPolaroid - Process and Quality Control Case Study: Preparation by Presentation byVinit Vijay SankheNo ratings yet

- Sample Dipum Project SolutionsDocument49 pagesSample Dipum Project Solutionsapi-1958474450% (2)

- 53B Intro To TPM Six Big LossesDocument32 pages53B Intro To TPM Six Big Lossesechsan dwi nugrohoNo ratings yet

- Pronest 2017 LT: Cad/Cam Nesting SoftwareDocument2 pagesPronest 2017 LT: Cad/Cam Nesting SoftwareACT Machinery B.V.No ratings yet

- Pronest 2017 LT: Cad/Cam Nesting SoftwareDocument2 pagesPronest 2017 LT: Cad/Cam Nesting SoftwareACT Machinery B.V.No ratings yet

- Concept Diagram - STD TemplateDocument5 pagesConcept Diagram - STD TemplatePalani KumarNo ratings yet

- Cast Designer 2018 E Brochure GravityDocument14 pagesCast Designer 2018 E Brochure GravityVivek ShrivastavaNo ratings yet

- Gas Turbine Technology Update - April - 2005Document28 pagesGas Turbine Technology Update - April - 2005Riza Agung Nugraha100% (2)

- Lubrication SystemDocument62 pagesLubrication SystemLac LENo ratings yet

- Engineering Maintenance ConceptDocument7 pagesEngineering Maintenance ConceptArief supriyatnoNo ratings yet

- Motor Protection TechnologiesDocument2 pagesMotor Protection Technologiesapi-3826631100% (1)

- Presentation Filomeno MartinaDocument18 pagesPresentation Filomeno MartinaAníbal DI LUCHNo ratings yet

- The SAMI Asset Healthcare Triangle: Strategic Asset Management Intl. LLCDocument2 pagesThe SAMI Asset Healthcare Triangle: Strategic Asset Management Intl. LLCyadiNo ratings yet

- Hypersizer For Composite Bicycle AnalysisDocument29 pagesHypersizer For Composite Bicycle AnalysislawrenceNo ratings yet

- Pronest 2019: Cad/Cam Nesting SoftwareDocument4 pagesPronest 2019: Cad/Cam Nesting SoftwareMani BMK GNo ratings yet

- Headbox Condition Testing - FlyerDocument1 pageHeadbox Condition Testing - FlyerAmmar MalikNo ratings yet

- Materi Webinar Open Pit / Tambang TerbukaDocument32 pagesMateri Webinar Open Pit / Tambang TerbukaNanda Yuri HayuNo ratings yet

- Introduction To In-Circuit TestDocument30 pagesIntroduction To In-Circuit TestHoàng Thảo NguyễnNo ratings yet

- Nesting SoftwareDocument4 pagesNesting SoftwareMahmud MaherNo ratings yet

- Case Study RajeevDocument1 pageCase Study Rajeevyatin rajput100% (1)

- Infor EAM Overview: Dwayne Maxwell, EAM Business Solutions ConsultantDocument22 pagesInfor EAM Overview: Dwayne Maxwell, EAM Business Solutions ConsultantJacky MoraudNo ratings yet

- What Is Overall Equipment Effectiveness (OEE) ?Document12 pagesWhat Is Overall Equipment Effectiveness (OEE) ?timcolmanNo ratings yet

- Basic Vibration Analysis Training-1Document193 pagesBasic Vibration Analysis Training-1Sanjeevi Kumar SpNo ratings yet

- Project Case - Smart SewingDocument18 pagesProject Case - Smart SewingRksNo ratings yet

- Training Plan Ojt SampleDocument5 pagesTraining Plan Ojt SampleAlmira BanzonNo ratings yet

- New Rules For Old Software:: Tailoring Your CMMI Process For Maintenance ProjectsDocument34 pagesNew Rules For Old Software:: Tailoring Your CMMI Process For Maintenance ProjectsvoicemannNo ratings yet

- Steam TurbineDocument78 pagesSteam TurbineAbhishek Verma100% (1)

- Commissioning For BioProcessDocument33 pagesCommissioning For BioProcessZulfahmi FerdiansyahNo ratings yet

- Warehouse Management SystemsDocument5 pagesWarehouse Management SystemsRidho AnjikoNo ratings yet

- Abhinav C.VDocument1 pageAbhinav C.VAbhinav SinhaNo ratings yet

- Pricelist WSD Car Grp.0 20210409Document3 pagesPricelist WSD Car Grp.0 20210409mustapha ahamNo ratings yet

- BEMS-MP-05 Training Needs MatrixDocument84 pagesBEMS-MP-05 Training Needs MatrixrememberNo ratings yet

- SAMI Production Triangle & MatrixDocument2 pagesSAMI Production Triangle & MatrixJosé RodríguezNo ratings yet

- Backlog ManagementDocument28 pagesBacklog ManagementMaximo SupportNo ratings yet

- Mechanical Drives/Power Transmission: Course AgendaDocument2 pagesMechanical Drives/Power Transmission: Course Agendah2jfg4ihjbhjdbcqNo ratings yet

- 2007 12 ICC Incremental TrainingDocument129 pages2007 12 ICC Incremental Trainingvikas.vkp50% (4)

- Error, Failure and FaultDocument16 pagesError, Failure and FaultkamarulzamaniNo ratings yet

- Open Cast ExpertmodelDocument9 pagesOpen Cast ExpertmodelmotaNo ratings yet

- Zund Cut Center ZCC SoftwareDocument7 pagesZund Cut Center ZCC SoftwareClaudiu MinaNo ratings yet

- Panasonic InternshipDocument1 pagePanasonic InternshipAIZUDDIN ASMANNo ratings yet

- Brewery Asset Care Practices 45m SharedDocument45 pagesBrewery Asset Care Practices 45m SharedRiyuk YagamiNo ratings yet

- Complex Maintenance, Repair, and Overhaul OverviewDocument35 pagesComplex Maintenance, Repair, and Overhaul OverviewwwwramkumarNo ratings yet

- Tata Motors PE Division - Vision, Mission & Core ValuesDocument1 pageTata Motors PE Division - Vision, Mission & Core ValuesGODSPEED. AltNo ratings yet

- 118 LSS BBO3 - Process Capability PDFDocument65 pages118 LSS BBO3 - Process Capability PDFSteph JoseNo ratings yet

- Overall Equipment EffectivenessDocument1 pageOverall Equipment EffectivenessMario Alejandro Charlin SteinNo ratings yet

- Comparative Value Chain CSR Activities Analysis of Apex: Prepared ForDocument6 pagesComparative Value Chain CSR Activities Analysis of Apex: Prepared ForSouman GuhaNo ratings yet

- WP00142 A GBTraining KursprogrammonlineDocument1 pageWP00142 A GBTraining Kursprogrammonlinemkiani2No ratings yet

- Optimizing Your Product Support SolutionDocument27 pagesOptimizing Your Product Support SolutionSaeed KazemiNo ratings yet

- Group 2 - TPS FrameworkDocument5 pagesGroup 2 - TPS FrameworkJaishree Lakshmikanth ms23w015No ratings yet

- K012556370 PDFDocument8 pagesK012556370 PDFVan ToanNo ratings yet

- Maintenance Zero Base Sizing v0Document3 pagesMaintenance Zero Base Sizing v0AlexandreNo ratings yet

- SAMI Triangle & MatrixDocument2 pagesSAMI Triangle & MatrixJosé RodríguezNo ratings yet

- RE140 Section 2 - Maintenance Policies (NXPowerLite)Document39 pagesRE140 Section 2 - Maintenance Policies (NXPowerLite)Ahmed FaragNo ratings yet

- Lean Six Sigma Operations Black Belt Bridge - Week 1: Evaluate Measurement System OverviewDocument27 pagesLean Six Sigma Operations Black Belt Bridge - Week 1: Evaluate Measurement System OverviewSteph JoseNo ratings yet

- Applying Quality - August 2021 - Kenneth SullivanDocument32 pagesApplying Quality - August 2021 - Kenneth SullivanIdham Idham IdhamNo ratings yet

- Equipment Initial Production Control SystemDocument1 pageEquipment Initial Production Control Systemsrmohapatra5086No ratings yet

- Etapdemo Features and RestrictionsDocument2 pagesEtapdemo Features and RestrictionsvrallamcitoNo ratings yet

- Live Memory Forensics On Android With VolatilityDocument109 pagesLive Memory Forensics On Android With VolatilitykasmaNo ratings yet

- Mueller A-20806&a-20807 AdjustableVertical IndicatorPosts Form12111Document8 pagesMueller A-20806&a-20807 AdjustableVertical IndicatorPosts Form12111gbogboiweNo ratings yet

- Gamp StandardsDocument6 pagesGamp Standardszaman_rafiqNo ratings yet

- Power Diagnostics ServiceDocument20 pagesPower Diagnostics ServiceShahid KhanNo ratings yet

- Process Hazard Analysis TrainingDocument20 pagesProcess Hazard Analysis TrainingAdenike AdebolaNo ratings yet

- Load Tests For Jet Grouting at MacauDocument8 pagesLoad Tests For Jet Grouting at MacauMatteoTrigliaReatoNo ratings yet

- Cross Reference For Off-Line Converters Sanken ElectricDocument18 pagesCross Reference For Off-Line Converters Sanken Electricfxt22555No ratings yet

- Differential Pressure Level InstrumentsDocument36 pagesDifferential Pressure Level InstrumentsDuong NguyenNo ratings yet

- Pw5001c - en FR SPDocument28 pagesPw5001c - en FR SPrich_n2No ratings yet

- 1 - Relays & Contactors PDFDocument14 pages1 - Relays & Contactors PDFSallak IdrisNo ratings yet

- J02222PH - Wilcon San Fernando - Co 02 - 19.10.2022Document7 pagesJ02222PH - Wilcon San Fernando - Co 02 - 19.10.2022Minh HoangNo ratings yet

- Melbourne Cricket Club CRM Case StudyDocument4 pagesMelbourne Cricket Club CRM Case StudySid KharbandaNo ratings yet

- 9709 s13 QP 42Document4 pages9709 s13 QP 42Irtiza HussainNo ratings yet

- Module: From Ideas To Implementation Chapter 10: Cathode Rays and The Development of Television (Questions, Pages 185-186)Document4 pagesModule: From Ideas To Implementation Chapter 10: Cathode Rays and The Development of Television (Questions, Pages 185-186)bananananananaaaNo ratings yet

- Candy ctdf1006-16s PDFDocument27 pagesCandy ctdf1006-16s PDFgolg1de1994100% (1)

- A. B. Chattopadhyay - Machining and Machine Tools-Wiley India Pvt. Ltd. (2017)Document847 pagesA. B. Chattopadhyay - Machining and Machine Tools-Wiley India Pvt. Ltd. (2017)Never Give Up Fight for dreamNo ratings yet

- ASTM D2172-11 Quantitative ExtractionDocument13 pagesASTM D2172-11 Quantitative ExtractionAbbasi Hussain100% (1)

- Automatic Fire Detector SpacingDocument14 pagesAutomatic Fire Detector SpacinghidayatmaNo ratings yet

- Theraml Power Plant (UPRVUNL)Document21 pagesTheraml Power Plant (UPRVUNL)Ankur SinghNo ratings yet

- Installation Instructions: 30GA900161 (60 HZ - 115-v Control) 30GA900171 (50 or 60 HZ - 230-v Control)Document16 pagesInstallation Instructions: 30GA900161 (60 HZ - 115-v Control) 30GA900171 (50 or 60 HZ - 230-v Control)Don CauilaneNo ratings yet

- Technical DescriptionDocument3 pagesTechnical DescriptionSamant KhannaNo ratings yet

- HIRA AssessmentDocument25 pagesHIRA AssessmentPanchdev KumarNo ratings yet

- 2013 Catalogue V2Document54 pages2013 Catalogue V2otringalNo ratings yet

- MBR2200 Datasheet PDFDocument2 pagesMBR2200 Datasheet PDFMuneer JaafarNo ratings yet

- Cis81 E1 4 TransportLayerDocument77 pagesCis81 E1 4 TransportLayersvitakNo ratings yet

- Ipfocus Aug2012 EzineDocument44 pagesIpfocus Aug2012 EzineavtechpanamaNo ratings yet

- Load Calc - Pipe SupportsDocument3 pagesLoad Calc - Pipe SupportssridharNo ratings yet

- Engineering Drawing: By: Engr. Farhan HanifDocument59 pagesEngineering Drawing: By: Engr. Farhan Hanifhania dogarNo ratings yet

- Zirconium Information Center Zirconium Information Center Properties, Applications and Research Properties, Applications and ResearchDocument6 pagesZirconium Information Center Zirconium Information Center Properties, Applications and Research Properties, Applications and ResearchLai Wei KhangNo ratings yet